EN 13384-2:2003+A1:2009

(Main)Chimneys - Thermal and fluid dynamic calculation methods - Part 2: Chimneys serving more than one heating appliance

Chimneys - Thermal and fluid dynamic calculation methods - Part 2: Chimneys serving more than one heating appliance

This part of EN 13384 specifies methods for calculation of the thermal and fluid dynamic characteristics of chimneys serving more than one heating appliance.

This part of EN 13384 covers both the cases, either

(1) where the chimney is connected with more than one connecting flue pipe from individual or several appliances in a multi-inlet arrangement or

(2) where the chimney is connected with an individual connecting flue pipe connecting more than one appliance in a cascade arrangement.

The case of multiple inlet cascade arrangement is covered by the case (1).

This part of EN 13384 deals with chimneys operating under negative pressure conditions (there can be positive pressure condition in the connecting flue pipe) and with chimneys operating under positive pressure conditions and is valid for chimneys serving heating appliances for liquid, gaseous and solid fuels.

This part of EN 13384 does not apply to:

- chimneys with different thermal resistance or different cross-section in the various chimney segments. This part does not apply to calculate energy gain.

- chimneys with open fire places, e.g. open fire chimneys or chimney inlets which are normally intended to operate open to the room

- chimneys which serve a mixture of fan assisted or forced draught burners or natural draught appliances. Fan assisted appliances with draught diverter between the fan and the chimney are considered as natural draught appliances.

- chimneys with multiple inlets from more than 5 storeys. (This does not apply to balanced flue chimney.)

- chimneys serving heating appliances with open air supply through ventilation openings or air ducts, which are not installed in the same air supply pressure region (e.g. same side of building).

For positive pressure chimneys this part only applies if any heating appliance which is out of action can be positively isolated to prevent flue gas back flow.

Abgasanlagen - Wärme- und strömungstechnische Berechnungsverfahren - Teil 2: Abgasanlagen mit mehreren Feuerstätten

Dieser Teil der Normreihe 13384 legt Berechnungsmethoden für die wärme- und strömungstechnischen

Eigenschaften von mehrfach belegten Abgasanlagen fest.

Dieser Teil der EN 13384 umfasst zwei Fälle:

1) Abgasanlagen in die mehrere Verbindungsstücke von einzelnen oder mehreren Feuerstätten in Mehrfachanordnung

münden;

2) Abgasanlagen in die ein bestimmtes Verbindungsstück münden, das mehrere Wärmerzeuger in

Kaskadenschaltung verbindet.

Der Fall von Mehrfachanschlüssen von Kaskadenschaltungen ist durch Fall 1) abgedeckt.

!Dieser Teil von EN 13384 befasst sich mit Unterdruck-Abgasanlagen (im Verbindungsstück können Überdruckbedingungen

herrschen) sowie mit Überdruck-Abgasanlagen und gilt für Abgasanlagen mit Feuerstätten

für flüssige, gasförmige und feste Brennstoffe."

Dieser Teil der Normreihe EN 13384 gilt nicht für:

- Abgasanlagen mit unterschiedlichen Wärmedurchlasswiderständen oder unterschiedlichen Querschnitten

in den verschiedenen Abschnitten der Abgasanlage. Energiegewinne werden durch diesen Teil der

Normreihe nicht berücksichtigt;

- Abgasanlagen für offene Feuerstätten, z. B. offene Kamine oder Abgaseinleitungen in die Abgasanlage,

die bestimmungsgemäß offen im Raum betrieben werden;

- Abgasanlagen für ein Gemisch aus Abgasen von Ventilator unterstützten- oder Überdruckbrennern oder

Naturzugkesseln;

- Abgasanlagen mit Mehrfachanschlüssen aus mehr als 5 Geschossen (dies gilt nicht für Luft-Abgasanlagen);

- Abgasanlagen an die Wärmerzeuger angeschlossen werden, denen die Zuluft über Zuluftöffnungen oder

Zuluftkanäle zugeführt wird, die sich nicht druckmäßig im gleichen Luftverbund befinden (z. B. auf der

gleichen Seite des Gebäudes).

!Bei Überdruck-Abgasanlagen gilt dieser Teil nur dann, wenn alle nicht in Betrieb befindlichen Feuerstätten

sicher abgesperrt werden können, um einen Abgasrückfluss zu verhindern."

Conduit de fumée - Méthode de calcul thermo-aéraulique - Partie 2 : Conduits de fumée desservant plus d'un appareil de chauffage

La présente partie de la norme EN 13384 définit des méthodes de calcul des caractéristiques thermo aérauliques de conduits de fumée desservant plusieurs générateurs de chaleur.

Cette partie de la norme EN 13384 traite des deux cas suivants :

(1) cas où le conduit de fumée est relié à plusieurs conduits de raccordement partant d'un ou de plusieurs générateurs de chaleur dans un système multientrées ou

(2) cas où le conduit de fumée est relié à un seul conduit de raccordement reliant plusieurs générateurs de chaleur dans un système en cascade.

Le cas du système multientrées en cascade est couvert par le cas (1).

!La présente partie de l'EN 13384 traite des conduits de fumée fonctionnant dans des conditions de pression négative (il peut y avoir une pression positive dans le conduit de raccordement) et des conduits de fumée fonctionnant dans des conditions de pression positive : elle s'applique à des conduits desservant des générateurs de chaleur pour combustibles liquides, gazeux et solides."

Cette partie de la norme EN 13384 ne s'applique pas aux conduits de fumée suivants :

- conduits de fumée présentant une résistance thermique différente ou une section différente dans les différents segments du conduit de fumée. Cette partie ne s’applique pas pour le calcul du gain énergétique.

- conduits avec foyer ouvert, par exemple conduits de cheminées d'appartements ou entrées de conduits de fumée normalement conçues pour fonctionner ouvertes sur la pièce ;

- conduits desservant une combinaison d'appareils de chauffage ventilés, d'appareils à tirage forcé ou d'appareils à tirage naturel. Les appareils ventilés possédant un régulateur de tirage entre le ventilateur et le conduit de fumée sont considérés comme des appareils à tirage naturel ;

- conduits multi-entrées desservant plus de 5 étages. (Ceci ne s'applique pas au conduit de fumée collectif «équilibré» pour appareils étanches) ;

- conduits desservant des générateurs de chaleur alimentés à l'air libre par l'intermédiaire d'ouvertures de ventilation ou de conduits aérauliques qui ne sont pas installés dans la même zone de pression d'amenée d'air frais (par exemple du même côté du bâtiment).

!Pour les conduits de fumée à pression positive, cette partie ne s’applique que si chaque générateur de chaleur qui est arrêté peut être isolé pour éviter un refoulement des fumées."

Dimniki - Računske metode termodinamike in dinamike fluidov - 2. del: Dimniki za več kot eno ogrevalno napravo

General Information

- Status

- Withdrawn

- Publication Date

- 13-Jan-2009

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 166 - Chimneys

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 01-Apr-2015

- Completion Date

- 11-Feb-2026

Not Harmonized89/106/EEC - Construction products

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 08-Apr-2015

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13384-2:2003+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chimneys - Thermal and fluid dynamic calculation methods - Part 2: Chimneys serving more than one heating appliance". This standard covers: This part of EN 13384 specifies methods for calculation of the thermal and fluid dynamic characteristics of chimneys serving more than one heating appliance. This part of EN 13384 covers both the cases, either (1) where the chimney is connected with more than one connecting flue pipe from individual or several appliances in a multi-inlet arrangement or (2) where the chimney is connected with an individual connecting flue pipe connecting more than one appliance in a cascade arrangement. The case of multiple inlet cascade arrangement is covered by the case (1). This part of EN 13384 deals with chimneys operating under negative pressure conditions (there can be positive pressure condition in the connecting flue pipe) and with chimneys operating under positive pressure conditions and is valid for chimneys serving heating appliances for liquid, gaseous and solid fuels. This part of EN 13384 does not apply to: - chimneys with different thermal resistance or different cross-section in the various chimney segments. This part does not apply to calculate energy gain. - chimneys with open fire places, e.g. open fire chimneys or chimney inlets which are normally intended to operate open to the room - chimneys which serve a mixture of fan assisted or forced draught burners or natural draught appliances. Fan assisted appliances with draught diverter between the fan and the chimney are considered as natural draught appliances. - chimneys with multiple inlets from more than 5 storeys. (This does not apply to balanced flue chimney.) - chimneys serving heating appliances with open air supply through ventilation openings or air ducts, which are not installed in the same air supply pressure region (e.g. same side of building). For positive pressure chimneys this part only applies if any heating appliance which is out of action can be positively isolated to prevent flue gas back flow.

This part of EN 13384 specifies methods for calculation of the thermal and fluid dynamic characteristics of chimneys serving more than one heating appliance. This part of EN 13384 covers both the cases, either (1) where the chimney is connected with more than one connecting flue pipe from individual or several appliances in a multi-inlet arrangement or (2) where the chimney is connected with an individual connecting flue pipe connecting more than one appliance in a cascade arrangement. The case of multiple inlet cascade arrangement is covered by the case (1). This part of EN 13384 deals with chimneys operating under negative pressure conditions (there can be positive pressure condition in the connecting flue pipe) and with chimneys operating under positive pressure conditions and is valid for chimneys serving heating appliances for liquid, gaseous and solid fuels. This part of EN 13384 does not apply to: - chimneys with different thermal resistance or different cross-section in the various chimney segments. This part does not apply to calculate energy gain. - chimneys with open fire places, e.g. open fire chimneys or chimney inlets which are normally intended to operate open to the room - chimneys which serve a mixture of fan assisted or forced draught burners or natural draught appliances. Fan assisted appliances with draught diverter between the fan and the chimney are considered as natural draught appliances. - chimneys with multiple inlets from more than 5 storeys. (This does not apply to balanced flue chimney.) - chimneys serving heating appliances with open air supply through ventilation openings or air ducts, which are not installed in the same air supply pressure region (e.g. same side of building). For positive pressure chimneys this part only applies if any heating appliance which is out of action can be positively isolated to prevent flue gas back flow.

EN 13384-2:2003+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13384-2:2003+A1:2009 has the following relationships with other standards: It is inter standard links to EN 13384-2:2003, EN 13384-2:2015, EN 1443:2003, EN 15287-2:2008, EN 15287-1:2007, EN 13384-1:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13384-2:2003+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13384-2:2003+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Abgasanlagen - Wärme- und strömungstechnische Berechnungsverfahren - Teil 2: Abgasanlagen mit mehreren FeuerstättenConduit de fumée - Méthode de calcul thermo-aéraulique - Partie 2 : Conduits de fumée desservant plus d'un appareil de chauffageChimneys - Thermal and fluid dynamic calculation methods - Part 2: Chimneys serving more than one heating appliance91.060.40Dimniki, jaški, kanaliChimneys, shafts, ductsICS:Ta slovenski standard je istoveten z:EN 13384-2:2003+A1:2009SIST EN 13384-2:2003+A1:2009en,fr,de01-julij-2009SIST EN 13384-2:2003+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13384-2:2003+A1

January 2009 ICS 91.060.40 Supersedes EN 13384-2:2003 English Version

Chimneys - Thermal and fluid dynamic calculation methods - Part 2: Chimneys serving more than one heating appliance

Conduit de cheminée - Méthode de calcul thermo-aéraulique - Partie 2 : Conduits de fumée desservant plus d'un appareil de chauffage

Abgasanlagen - Wärme- und strömungstechnische Berechnungsverfahren - Teil 2: Abgasanlagen mit mehreren Feuerstätten This European Standard was approved by CEN on 11 March 2003 and includes Amendment 1 approved by CEN on 23 November 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13384-2:2003+A1:2009: ESIST EN 13384-2:2003+A1:2009

!!!!(PZeC,j,l, PZeOC,j,l)"""" . 4314.8Inner wall temperature (TiobC,j,l) . 4515Balanced flue chimney . 4515.1Principle of the calculation method . 4515.2Pressure equilibrium condition. 4515.3Mass flow requirement . 4615.4Pressure requirements . 46!!!!15.4.1Negative pressure chimneys"""" . 4615.4.2Positive pressure chimneys . 4715.5Temperature requirements . 4815.6Calculation procedure for balanced flue chimneys . 4915.7Mass flow of the supply air. 5015.8Determination of the temperatures in balanced flue chimneys . 5115.8.1Separate ducts . 5115.8.2Concentric ducts . 5115.8.3Concentric connection pipes . 5815.9!!!!Pressures of the air supply ducts"""" . 6415.9.1!!!!Draught due to chimney effect of the air supply duct of chimney segment j"""" . 6415.9.2Draught due to chimney effect !!!!deleted text"""" of the air supply duct of connection pipes . 6415.9.3Pressure resistance of the air supply duct of the chimney segment j (PRB,j) . 6515.10Density and velocity of the supply air . 6815.10.1Density and velocity of the supply air in the air supply duct averaged over the length of the chimney segment . 6815.10.2Density and velocity of the supply air averaged over the length of the connection pipes . 69Annex A (informative)

Recommendations . 70A.1 Recommendations for the chimney and heating appliances: . 70A.2 Recommendations for connecting flue pipes: . 70Annex B (informative)

Characteristics for the heating appliance . 71SIST EN 13384-2:2003+A1:2009

(1) where the chimney is connected with more than one connecting flue pipe from individual or several appliances in a multi-inlet arrangement or

(2) where the chimney is connected with an individual connecting flue pipe connecting more than one appliance in a cascade arrangement.

The case of multiple inlet cascade arrangement is covered by the case (1). !This part of EN 13384 deals with chimneys operating under negative pressure conditions (there can be positive pressure condition in the connecting flue pipe) and with chimneys operating under positive pressure conditions and is valid for chimneys serving heating appliances for liquid, gaseous and solid fuels." This part of EN 13384 does not apply to: − chimneys with different thermal resistance or different cross-section in the various chimney segments. This part does not apply to calculate energy gain. − chimneys with open fire places, e.g. open fire chimneys or chimney inlets which are normally intended to operate open to the room − chimneys which serve a mixture of fan assisted or forced draught burners or natural draught appliances. Fan assisted appliances with draught diverter between the fan and the chimney are considered as natural draught appliances. − chimneys with multiple inlets from more than 5 storeys. (This does not apply to balanced flue chimney.) − chimneys serving heating appliances with open air supply through ventilation openings or air ducts, which are not installed in the same air supply pressure region (e.g. same side of building). !For positive pressure chimneys this part only applies if any heating appliance which is out of action can be positively isolated to prevent flue gas back flow." 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. !EN 1443:2003" Chimneys – General requirements !deleted text" SIST EN 13384-2:2003+A1:2009

3 Terms and definitions !For the purposes of this document, the terms and definitions given in EN 1443:2003, EN 13384-1:2002,

EN 15287-1:2007, EN 15287-2:2008 and the following apply." 3.1

chimney segment part of a chimney between two consecutive flue gas connections or between the last flue gas connection and the chimney outlet 3.2

collector segment part of a connecting flue pipe between two consecutive flue gas connections or between the last flue gas connection and the chimney inlet 3.3

air-flue gas system system of concentric or non concentric ducts or parallel ducts for transport of combustion air from the open air to the heating appliances and products of combustion from the heating appliances to the open air 3.4

flue gas mass flow (m&) mass of the flue gas leaving the heating appliance through the connecting flue pipe per unit of time. In case of a chimney serving more than one heating appliance, the air being transported through an appliance which is out of action is also given the term flue gas mass flow. 3.4.1

declared flue gas mass flow (jW,m&) flue gas mass flow given by the manufacturer of the heating appliance j with respect to the heat output used in the calculation 3.4.2

calculated flue gas mass flow (jWc,m&) flue gas mass flow calculated with respect to calculated draught and the working conditions of the heating appliance j 3.5

calculated flue gas temperature (jWc,T) flue gas temperature at the outlet of the heating appliance j depending on the calculated flue gas mass flow 3.6

calculated draught of the flue gas of the heating appliance (PWc,j) draught at the flue gas outlet of the heating appliance j depending on the calculated flue gas mass flow 3.7

flue damper device to close or partially close the flue SIST EN 13384-2:2003+A1:2009

balanced flue chimney chimney where the point of air entry to the combustion air duct is adjacent to the point of discharge of combustion products from the flue, the inlet and outlet being so positioned that wind effects are substantially balanced 3.9

cascade arrangement arrangement where two or more appliances situated in the same space are connected by a common connecting flue pipe to the chimney 3.10

!!!!multi"""" inlet arrangement arrangement where two or more appliances situated in different spaces are connected to the chimney by individual connecting flue pipes 3.11

air duct independent duct in a building or a structural part of a flue terminal conveying combustion air to a room-sealed appliance 3.12

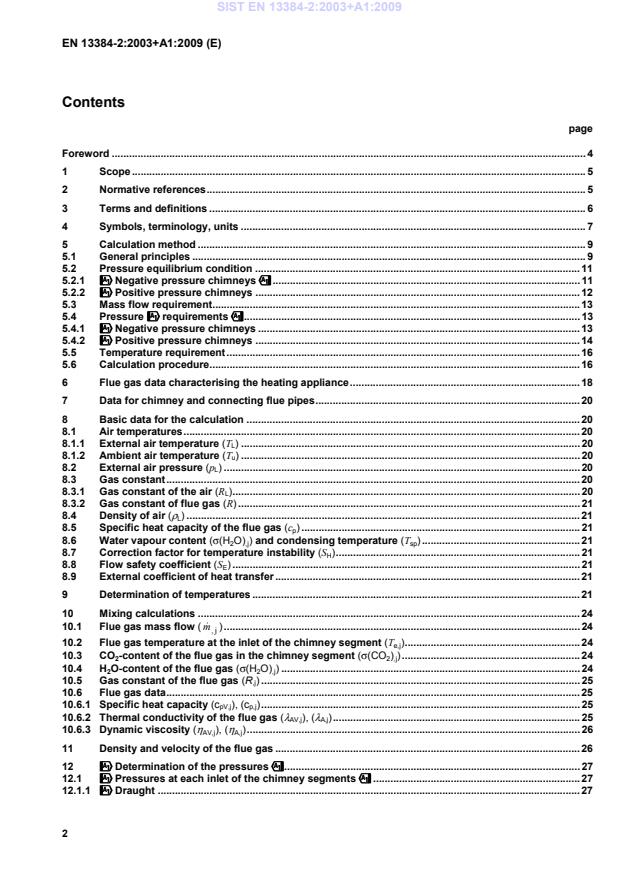

pressure equalising opening opening or duct that directly connects the air duct with the flue at its base 4 Symbols, terminology, units Symbols, terminology and units are given to make the text of this standard understandable, although a part of them is already listed in part 1 of this standard series. Indices added to symbols for purposes of the calculation method for chimneys serving more than one heating appliance relate to one chimney segment and/or connection flue pipe section. An example of an indices numbering scheme is given in Figures 1 and 2. Indices numbering shall begin at the lowest, farthest appliance connection. For more than one cascade system/connection, the indices numbering scheme for the calculation formula should be adopted in a similar manner to that for a single cascade scheme. Symbols assigned to a specific section will be indicated by the number of the section after the comma (e. g. H,1 is the effective height of a section of a chimney segment between the outlet of the connecting flue pipe of the heating appliance in the lowest position and the outlet of the connecting flue pipe of the next heating appliance).

Table 1 - Symbols, terminology, units Symbols Terminology Units A cross sectional area of the chimney m2 cp specific heat capacity of flue gas J/(kg·K) D diameter m Dh hydraulic diameter

m g acceleration due to gravity = 9,81 m/s2 H,j effective height of the chimney segment j m HV,j effective height of the connecting flue pipe j m K,j coefficient of cooling of the chimney segment j - kj coefficient of heat transmission of the chimney segment j W/(m2·K) SIST EN 13384-2:2003+A1:2009

Pa PZOe,j maximum differential pressure at the flue gas inlet into the chimney segment j Pa PZOemin,j minimum differential pressure at the flue gas inlet into the chimney segment j Pa" R gas constant of the flue gas J/(kg·K) r mean value of roughness value of the inner wall m SIST EN 13384-2:2003+A1:2009

m2·K/W λA coefficient of thermal conductivity of flue gas W/(m·K) ρm,j density of flue gas averaged over the length and over the cross section of the chimney segment j kg/m3 ψ coefficient of flow resistance due to friction of the flue - ζ coefficient of flow resistance due to a directional and/or cross sectional and/or mass flow change in the flue - 5 Calculation method 5.1 General principles The calculation is based upon determining the mass flow distribution in the chimney which fulfils the pressure equilibrium condition (formula 1) at each flue gas inlet to the chimney (see Figure 1). After such a distribution has been found !four" requirements shall be verified: ! (1) the mass flow requirement (Equations 4 and 5) (2) the pressure requirement for minimum draught or maximum positive pressure (Equations 6 or 6b and 6c) (3) the pressure requirement for maximum draught or minimum positive pressure (Equation 6a or 6d) (4) the temperature requirement (Equation 7)"

In order to verify the criteria two sets of external conditions are used: the calculation of the minimum draught and maximum positive pressure (draught) is made with conditions for which the capacity of the chimney is minimal (i.e. high outside temperature); and also

the calculation of the maximum draught and minimum positive pressure and of the inner wall temperature with conditions for which the inside temperature of the chimney is minimal (i.e. low outside temperature)." The validation of the mass flow requirement and pressure requirement shall be done at following working conditions, using the external and ambient air temperatures specified in EN 13384-1. − All heating appliances are simultaneously operating at nominal heat output. − All heating appliances are simultaneously operating at minimum heat output − A single heating appliance operating at nominal heat output and all other appliances out of action (all possible cases) − A single heating appliance operating at minimum heat output and all other appliances out of action (all possible cases) If the control of the installation guarantees that not all appliances will be in operation simultaneously, the validation of the mass flow requirement and pressure requirement may be done with the maximum number of appliances which will be in operation under the most adverse condition. The validation for the mass flow requirement and pressure requirement for working conditions with heating appliances at minimum heat output is not required in the following cases: − the heating appliances do not have any heat output range − the heating appliances have a heat output which is limited to a fixed value as specified on a label on the appliance. In this case the nominal heat output is the given heat output on the label.

− heating appliances heated with solid fuels without fan and appliances with regulated air supply. The validation of the mass flow requirement for working conditions with appliances at nominal heat output is not required in the following case: − the heating appliances have a flue gas mass flow at minimum heat output higher than or equal to the flue gas mass flow at nominal heat output.

The temperature requirement shall be validated for the following relevant working condition, using the ambient and external air temperatures as specified in EN 13384-1: − heating appliances for solid fuels without fan and heating appliances with regulated air supply are in operation at nominal heat output,

− heating appliances with a draught diverter which provide domestic hot water only are out of action. These heating appliances operate with a considerable secondary air (These operate only a short time and therefore it can be assumed that condensation will not cause damage or a lack in safety); − heating appliances with a fixed output range are in operation at this (nominal) heat output; − all other heating appliances are in operation at minimum heat output. When chimneys suitable for operating under wet conditions are located inside a building the check of the temperature requirement is necessary only for the top of the chimney.

The validation of the temperature requirement is not necessary when the chimney serves only domestic gas fired water heaters with instantaneous production and domestic gas fired storage water heaters. If the chimney system includes a draught regulator, the system is handled as a cascade system. SIST EN 13384-2:2003+A1:2009

kR,kH,LZ,∑=−+−=NjkjPPPP in Pa (2) jBc,jV,jWc,jZe,PPPP++= in Pa (3) Where: PZ,j draught at the flue gas inlet to the chimney segment j

in Pa PH,k theoretical draught due to chimney effect in chimney segment k in Pa PR,k pressure resistance of the chimney segment k in Pa PWc,j calculated draught of the heating appliance

in Pa PV,j calculated pressure resistance of the connecting flue pipe of

chimney segment j

in Pa PBc,j calculated pressure resistance of the air supply for the

heating appliance j in Pa PZe,j required draught at the flue gas inlet to the chimney segment j !in Pa" PL wind velocity pressure

!in Pa" N number of heating appliances SIST EN 13384-2:2003+A1:2009

Key

1 Chimney

2 Connecting flue pipe j

3 Heating appliance j

4 Connecting flue pipe 2

5 Heating appliance 2

6 Connecting flue pipe 1

7 Heating appliance 1

8 Chimney segment 1

9 Chimney segment j Figure 1 - Example of multiple inlet arrangement and numbering pressure values and temperature values of a chimney serving more than one heating appliance 5.2.2 !!!!Positive pressure chimneys The following equations shall be fulfilled for each chimney segment j at all relevant working conditions: 1,0ZO,ZOe,≤−jjPP in Pa (3a) ()

kH,kR,LZO,∑=−+=NjkjPPPP in Pa (3b) SIST EN 13384-2:2003+A1:2009

in Pa PH,k theoretical draught due to chimney effect in chimney segment k in Pa PR,k pressure resistance of the chimney segment k in Pa PWOc,j calculated positive differential pressure of the heating appliance j in Pa PV,j calculated pressure resistance of the connecting flue pipe of chimney segment j

in Pa PBc,j calculated pressure resistance of the air supply for the heating appliance j in Pa PZOe,j maximum differential pressure at the flue gas inlet to the chimney segment j in Pa PL wind velocity pressure

in Pa N number of heating appliances" 5.3 Mass flow requirement !Equations 4 and/or. 5" shall be verified for all relevant working conditions (see 5.6).

For each heating appliance in operation at nominal or minimum heat output : jW,jWc,mm&&≥ in kg/s (4) and for each heating appliance out of action: 0jWc,≥m& in kg/s (5) Where: jWc,m& calculated mass flow of the heating appliance in kg/s jW,m& declared mass flow of the heating appliance in kg/s Where a damper is applied, flow resistance shall be taken as 0 unless additional data are available.

5.4 Pressure !!!!requirements""""

5.4.1 !!!!Negative pressure chimneys For negative pressure chimneys it has to be additionally checked that the negative pressure (minimum draught) in the chimney (PZ,j) is more than or equal to the negative pressure in the room where the heating appliance is placed at calculated draught conditions for air supply. The check on this pressure requirement shall be done using the same conditions as specified for the check on the mass flow requirement (see 5.3 and 5.6). The following relations shall be verified: jBc,jZ,PP≥ in Pa (6) where SIST EN 13384-2:2003+A1:2009

in Pa PBc,j calculated pressure resistance of the air supply for the heating appliance j in Pa If required it has to be additionally checked that the negative pressure (draught) in the chimney (PZmax,j) is less than or equal to the maximum allowed draught (PZemax,j) caused by the heating appliance. The relation (6a) shall be verified for all relevant working conditions (see 5.6). The check of this pressure requirement shall be done with a separate calculation using the newly calculated flue mass flows that fulfil the pressure equilibrium conditions at an external air temperature of TL = 258,15 K (tL = -15 °C, see EN 13384-1). ()jZemax,jBc,jV,jWmax,kR,kH,Zmax,

PPPPPPPNjkj=++≤−=∑= in Pa (6a) where PZmax,j maximum draught at the flue gas inlet into the chimney segment j

in Pa PZemax,j maximum allowed draught at the flue gas inlet into the chimney segment j

in Pa PH,k theoretical draught due to chimney effect in chimney segment k

in Pa PR,k pressure resistance of the chimney segment k

in Pa PWmax,j maximum draught for the heating appliance j in Pa PV,j calculated pressure resistance of the connecting flue pipe of chimney segment j in Pa

PBc,j calculated pressure resistance of the air supply for the heating appliance j in Pa

NOTE The values of PH,k and PR,k in Equations (2) and (6a) are normally different because the conditions are different." 5.4.2 !!!!Positive pressure chimneys For positive pressure chimneys it has to be additionally checked that the maximum positive pressure in the connecting flue pipe (PZO,j + PV,j) and in the chimney (PZO,j) is not higher than the excess pressure for which both are designated (PZV excess and PZ excess). The check on the pressure requirement shall be done using the same conditions as specified for the check on the mass flow requirement (see 5.3 and 5.6). The following relations shall be verified: PZO,j ≤ PZ excess in Pa (6b) PZO,j + PV,j ≤ PZV excess in Pa (6c) where PZO,j positive pressure at the flue gas inlet to the chimney segment j

in Pa PV,j calculated pressure resistance of the connecting flue pipe of chimney segment j in Pa PZexcess is the maximum allowed pressure from the designation of the chimney in Pa PZVexcess is the maximum allowed pressure from the designation of the connecting flue pipe in Pa SIST EN 13384-2:2003+A1:2009

TL = 258,15 K (tL = -15 °C, see EN 13384-1). ()jmin,ZOejV,jBc,jmin,WOkH,kR,jZOmin,

PPPPPPPNjk=−−≥−=∑= in Pa (6d) where PZOmin,j minimum positive pressure at the flue gas inlet into the chimney segment j in Pa PZOemin,j minimum differential pressure at the flue gas inlet into the chimney segment j in Pa PH,k theoretical draught due to chimney effect in chimney segment k in Pa PR,k pressure resistance of the chimney segment k in Pa PWOmin,j minimum differential pressure of the heating appliance j in Pa PBc,j calculated pressure resistance of the air supply for the heating appliance j in Pa PV,j calculated pressure resistance of the connecting flue pipe of chimney segment j in Pa

NOTE The values of PH,k and PR,k in Equations (3b) and (6d) are normally different because the conditions are different." SIST EN 13384-2:2003+A1:2009

5.5 Temperature requirement The relations (7) shall be verified for all relevant working conditions (see 5.6).

The check of the temperature requirement shall be done with a separate calculation using the newly calculated flue mass flows that fulfil the pressure equilibrium conditions at an external air temperature of Tuo,j

(see EN 13384-1) Tiob,j ≥ Tg,j in K (7) Where: Tiob,j temperature of the inner wall of the chimney segment j at the end in K Tg,j temperature limit for chimney segment j in K

The temperature limit Tg,j for chimneys suitable for operating under dry conditions is equal to the condensing temperature Tsp,j of the flue gas (see 8.6). Tg,j = Tsp,j The temperature limit Tg,j for chimneys suitable for operating under wet conditions is equal to the freezing point of water: Tg,j = 273,15 K. NOTE The following cases can be exempted from meeting the temperature requirement provided that it is accepted that in case the requirement for temperature should be not fulfilled no guarantee can be given that no moisture appears. In this cases insulation is recommended.

− heating appliances which are substituted to a usual chimney which is already in operation and

− the heat output of the heating appliances which are connected and/or substituted does not exceed 30 kW for each and − the flue gas losses are not more or equal than 8 % and − an effective air conditioning of the chimney during standstill periods is given by draught diverters or dampers and − sufficient standstill periods are given (e. g. the minimum steady state heat output of the heating appliance is not less than 20 % as the required heat).

5.6 Calculation procedure For the calculation of the pressure and temperature values in a chimney serving more than one heating appliance an iterative procedure is necessary. This calculation procedure is based on the application of mass and energy conservation formulae under quasi steady state conditions. In each point of connection between various ducts (at the end of connecting flue pipes, the !beginning" and the end of the chimney segments), all called nodes (see Figure 2), the following procedure shall be used: SIST EN 13384-2:2003+A1:2009

Figure 2 - Designation of flow numbering for each node j (see formulae 8 and 9) - The mass flow and the temperature shall be calculated with formulae 8 and 9. j,jV,1-j,mmm&&&=+ in kg/s (8) je,jp,j,joV,jpV,jV,1-jo,1-jp,1-j,TcmTcmTcm⋅⋅=⋅⋅+⋅⋅&&& in J/s (9) where: 1-j,m& flue gas mass flow in chimney segment j-1 in kg/s jV,m& flue gas mass flow in connecting flue pipe

in kg/s j,m& flue gas mass flow in chimney segment j in kg/s cp,j-1 specific heat capacity of flue gas in chimney segment j-1 in J/(kg⋅K) cpV,j specific heat capacity of flue gas in connecting flue pipe j in J/(kg⋅K) cp,j specific heat capacity of flue gas in chimney segment j in J/(kg⋅K) To,j-1 temperature of the flue gas at the end of chimney segment j-1 in K ToV,j temperature of the flue gas at the end of connecting flue pip

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...