EN 15774:2010

(Main)Food processing machinery - Machines for processing fresh and filled pasta (tagliatelle, cannelloni, ravioli, tortellini, orecchiette and gnocchi) - Safety and hygiene requirements

Food processing machinery - Machines for processing fresh and filled pasta (tagliatelle, cannelloni, ravioli, tortellini, orecchiette and gnocchi) - Safety and hygiene requirements

This European Standard applies to machines for the processing of fresh and filled pasta, by mixing, kneading, dough sheet forming, pasta forming and pasteurizing, as described in Clause 3.

It applies to stationary and movable machines (not intended to be moved during operation), with a nominal capacity of not less than 25 kg/h.

This European Standard deals with all significant hazards, hazardous situations, and events when the machines falling within the scope of this standard are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). It deals with the hazards during the following phases of themachines' lifetime: transport, assembly and installation, commissioning, setting and adjusting, operation, cleaning, fault finding, maintenance, de-commissioning, dismantling, disabling and scrapping.

This European Standard applies to the following groups of machines:

- discontinuous manually loaded kneading machines with or without lifting and tilting devices;

- continuous kneading machine

- combination of dough kneading and dough sheet forming machine;

- forming machine processing one single dough sheet;

- forming machine processing two dough sheets;

- dough sheet forming machine;

- sizing roller machine;

- dough transport shuttle machine;

- steam pasteurizer machine;

- cooler machine;

- dough sheet cutting machine;

- gnocchi machine;

- typical shapes pasta machine.

This European Standard is not applicable to the following machines:

- household machines;

- auxiliary equipment (not changing the characteristics of product): conveying systems not part of the machinery, weighting and bagging equipment, lifting and tilting machinery (dealt with in EN 13288).

This European Standard is not applicable to pasta processing machines, which are manufactured before the date of its publication as EN.

Nahrungsmittelmaschinen - Maschinen zur Herstellung von frischen und gefüllten Teigwaren (Tagliatelle, Cannelloni, Ravioli, Tortellini, Orecchiette und Gnocchi) - Sicherheits- und Hygieneanforderungen

Diese Europäische Norm behandelt Maschinen zur Herstellung von frischen und gefüllten Teigwaren durch

Mischen, Kneten, Laminieren, Nudelformung und Pasteurisierung, wie in Abschnitt 3 definiert.

Diese Norm ist auf stationäre und ortsveränderliche Maschinen (ein Verschieben ist während der Benutzung

ist nicht vorgesehen) mit einem Nenndurchsatz von nicht weniger als 25 kg/h anwendbar.

Diese Europäische Norm behandelt alle signifikanten Gefährdungen, Gefahrensituationen und Ereignisse, die

auf Maschinen im Anwendungsbereich dieser Norm zutreffen, wenn sie bestimmungsgemäß und unter

Bedingungen, die vom Hersteller als Fehlanwendung vernünftigerweise vorhersehbar sind, verwendet werden

(siehe Abschnitt 4). Sie behandelt die Gefährdungen, die während der folgenden Phasen der Lebensdauer

dieser Maschine auftreten: Transport, Montage und Installation, Inbetriebnahme, Einrichten und Einstellen,

Betrieb, Reinigung, Fehlersuche, Wartung, Abbau, Zerlegung, Außerbetriebsetzen und Verschrottung.

Dieses Dokument ist für folgende Maschinengruppen anwendbar:

⎯ diskontinuierliche mit Hand beladene Knetmaschinen mit oder ohne Hebe- und Kippeinrichtungen;

⎯ kontinuierliche Knetmaschine

⎯ Kombination von Teigknetmaschine und Teigbahnformmaschine;

⎯ Formmaschine für die Verarbeitung einer Teigbahn;

⎯ Formmaschine für die Verarbeitung von zwei Teigbahnen;

⎯ Teigbahnformmaschine (Laminator);

⎯ Kalibrierwalzenmaschine;

⎯ Teigbehältertransporteur;

⎯ Dampfpasteurisierer;

⎯ Kühleinrichtung;

⎯ Teigbahnschneideeinrichtung;

⎯ Gnocchi-Maschine;

⎯ Formmaschine für typische Nudeln.

Diese Europäische Norm ist für die folgenden Maschinen nicht anwendbar:

⎯ Haushaltsgeräte;

⎯ Zusatzgeräte (die die Charakteristik des Produkts nicht ändern): Fördereinrichtungen, die nicht Teil der

Maschine sind, Wiege- und Verpackungseinrichtungen, Hebe- und Kippeinrichtungen (werden in

EN 13288 behandelt).

Diese Europäische Norm ist nicht für Nudelverarbeitungsmaschinen anwendbar, die vor dem CENAusgabedatum

dieser Europäischen Norm hergestellt werden.

Machines pour les produits alimentaires - Machines pour pâtes alimentaires (tagliatelle, cannelloni, ravioli, tortellini, orecchiette et gnocchi) - Prescriptions relatives à la sécurité et à l'hygiène

La présente Norme européenne s’applique aux machines de transformation des pâtes fraîches et farcies, utilisées pour le mélange, le pétrissage, le laminage de feuillets de pâte, le formage des pâtes et la pasteurisation, comme décrit à l’Article 3.

Elle s’applique aux machines fixes et mobiles (non destinées à être déplacées pendant le fonctionnement), d'une capacité nominale d’au moins 25 kg/h.

La présente Norme européenne traite tous les phénomènes dangereux significatifs, situations dangereuses, événements dangereux lorsque les machines répondant au domaine d’application de la présente norme, sont utilisées comme prévu et dans des conditions de mauvais usage raisonnablement prévisible par le fabricant (voir Article 4). Elle traite des phénomènes dangereux pendant les phases suivantes de al durée de vie des machines : transport, assemblage et installation, mise en service, paramétrage et réglage, fonctionnement, nettoyage, détection de défaut, entretien, mise hors service, démontage, mise hors fonction et mise à la ferraille.

La présente Norme européenne s'applique aux groupes suivants de machines :

- machines de pétrissage discontinu à chargement manuel avec ou sans dispositifs élévateur/basculeur ;

- machine de pétrissage continu ;

- machine combinée de pétrissage et de façonnage de pâte feuilletée ;

- machine de laminage pour un seul feuillet de pâte ;

- machine de laminage pour deux feuillets de pâte ;

- machine de laminage de feuillet de pâte ;

- machine à calibrer ;

- chariot de transport de pâte ;

- pasteurisateur à vapeur ;

- machine à refroidir ;

- machine à découper les feuillets de pâte ;

- machine à gnocchi ;

- machine à façonner les pâtes.

La présente Norme européenne n'est pas applicable aux machines suivantes :

- machines domestiques ;

- équipement auxiliaire (ne changeant pas les caractéristiques du produit) : systèmes de transport ne faisant pas partie de la machine, équipements de pesage et d’ensachage, les élévateurs/basculeur

Stroji za predelavo hrane - Stroji za obdelavo svežih in polnjenih testenin (široki rezanci, kaneloni, ravioli, tortelini, ušesca in školjke) - Varnostne in higienske zahteve

Ta evropski standard velja za stroje za predelavo svežih in polnjenih testenin z mešanjem, gnetenjem, oblikovanjem testa v plasti, oblikovanjem testenin in pasterizacijo, kot je opisano v Klavzuli 3. Velja za stacionarne in premične stroje (ki se jih med delovanjem ne sme premikati) z najmanjšo nazivno kapaciteto 25 kg/uro. Ta evropski standard obravnava vse velike nevarnosti, nevarne situacije in dogodke, kadar se stroji znotraj področja uporabe tega standarda uporabljajo kot predvideno in pod pogoji napačne uporabe, ki jih razumno predvidi proizvajalec (glej klavzulo 4). Obravnava nevarnosti med naslednjimi fazami življenjske dobe strojev: prevoz, montaža in namestitev, usposobitev, nastavljanje in prilagajanje, delovanje, čiščenje, iskanje napak, vzdrževanje, izločitev iz uporabe, razstavljanje, izklapljanje in uničenje. Ta evropski standard velja za naslednje skupine strojev: - nezvezni, ročno polnjeni stroji za gnetenje z ali brez naprav za dvigovanje in nagibanje; - zvezni stroji za gnetenje; stroj, ki kombinira gnetenja testa in oblikovanje testa v plasti; stroj za oblikovanje, ki obdeluje eno plast testa; - stroj za oblikovanje, ki obdeluje dve plasti testa; stroj za oblikovanje plasti; - stroj za merjenje z valji; stroj za lokalni prevoz testa; stroj za pasteriziranje s paro; hladilni stroj; stroj za rezanje plasti testa; stroj za školjke; stroj za testenine tipičnih oblik..

General Information

- Status

- Published

- Publication Date

- 09-Nov-2010

- Withdrawal Date

- 30-May-2011

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 7 - Pasta processing plant

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Dec-2021

- Completion Date

- 02-Dec-2021

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 1672-2:2005+A1:2009 - Food processing machinery - Basic concepts - Part 2: Hygiene requirements - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15774:2010 is a CEN European Standard specifying safety and hygiene requirements for machines used in the processing of fresh and filled pasta (tagliatelle, cannelloni, ravioli, tortellini, orecchiette and gnocchi). It applies to stationary and movable industrial machines with a nominal capacity of ≥ 25 kg/h and covers all significant hazards during the machine life‑cycle (transport, installation, commissioning, operation, cleaning, maintenance, de‑commissioning and scrapping). The standard is intended for pasta processing machinery used as intended and for reasonably foreseeable misuse.

Key topics and technical requirements

EN 15774:2010 addresses both safety and hygienic design. Main technical topics include:

- Scope of machines covered: discontinuous and continuous kneaders, dough sheet forming and sizing machines, forming machines (single and double sheet), dough transport shuttles, steam pasteurizers, coolers, cutting machines, gnocchi and typical shapes pasta machines.

- Excluded equipment: household machines and certain auxiliary equipment (e.g., external conveying systems, weighing/bagging, and lifting/tilting machinery addressed by EN 13288).

- Hazard identification: mechanical, electrical, thermal, noise, inhalation of mists/dusts, slip/trip/fall, ergonomic and hygienic hazards, and stability/overturning risks.

- Protective measures: design elimination of crushing/pinch points, guarding of moving parts, electrical safety (including earth faults and emergency stop), hold‑to‑run controls, interlocks, start warnings, and degrees of protection (see EN 60529/IP codes).

- Hygienic design and cleanability: materials, surface finish, joints, fasteners, ventilation openings and ease of cleaning (normative Annex B).

- Noise test code: measurement and declaration of noise emissions (normative Annex A).

- Verification & documentation: tests and validation of safety/hygiene measures, operator instructions, training, marking, signals and warnings.

- Regulatory linkage: relationship to Machinery Directive 2006/42/EC (Annex ZA).

Applications and who uses this standard

EN 15774:2010 is essential for:

- Machine manufacturers and designers - to design safe, hygienic pasta processing equipment and prepare CE documentation.

- Food industry plant engineers & QA/HACCP teams - for procurement specifications, hygienic validation and maintenance planning.

- Safety engineers and compliance officers - for risk assessment, conformity assessment and regulatory compliance.

- Integrators, maintenance staff and test labs - to verify noise, electrical safety and cleanability requirements.

Practical uses include specification drafting, machine commissioning, hygiene audits, operator training and documenting conformity for CE marking.

Related standards

- EN 13288 - lifting and tilting machinery (auxiliary equipment)

- EN 60529 - degrees of protection (IP codes)

- EU Machinery Directive 2006/42/EC - essential requirements referenced by EN 15774:2010

Keywords: EN 15774:2010, food processing machinery, fresh and filled pasta, safety and hygiene, cleanability, noise emission, pasta processing machines, hygienic design.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 15774:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Machines for processing fresh and filled pasta (tagliatelle, cannelloni, ravioli, tortellini, orecchiette and gnocchi) - Safety and hygiene requirements". This standard covers: This European Standard applies to machines for the processing of fresh and filled pasta, by mixing, kneading, dough sheet forming, pasta forming and pasteurizing, as described in Clause 3. It applies to stationary and movable machines (not intended to be moved during operation), with a nominal capacity of not less than 25 kg/h. This European Standard deals with all significant hazards, hazardous situations, and events when the machines falling within the scope of this standard are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). It deals with the hazards during the following phases of themachines' lifetime: transport, assembly and installation, commissioning, setting and adjusting, operation, cleaning, fault finding, maintenance, de-commissioning, dismantling, disabling and scrapping. This European Standard applies to the following groups of machines: - discontinuous manually loaded kneading machines with or without lifting and tilting devices; - continuous kneading machine - combination of dough kneading and dough sheet forming machine; - forming machine processing one single dough sheet; - forming machine processing two dough sheets; - dough sheet forming machine; - sizing roller machine; - dough transport shuttle machine; - steam pasteurizer machine; - cooler machine; - dough sheet cutting machine; - gnocchi machine; - typical shapes pasta machine. This European Standard is not applicable to the following machines: - household machines; - auxiliary equipment (not changing the characteristics of product): conveying systems not part of the machinery, weighting and bagging equipment, lifting and tilting machinery (dealt with in EN 13288). This European Standard is not applicable to pasta processing machines, which are manufactured before the date of its publication as EN.

This European Standard applies to machines for the processing of fresh and filled pasta, by mixing, kneading, dough sheet forming, pasta forming and pasteurizing, as described in Clause 3. It applies to stationary and movable machines (not intended to be moved during operation), with a nominal capacity of not less than 25 kg/h. This European Standard deals with all significant hazards, hazardous situations, and events when the machines falling within the scope of this standard are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). It deals with the hazards during the following phases of themachines' lifetime: transport, assembly and installation, commissioning, setting and adjusting, operation, cleaning, fault finding, maintenance, de-commissioning, dismantling, disabling and scrapping. This European Standard applies to the following groups of machines: - discontinuous manually loaded kneading machines with or without lifting and tilting devices; - continuous kneading machine - combination of dough kneading and dough sheet forming machine; - forming machine processing one single dough sheet; - forming machine processing two dough sheets; - dough sheet forming machine; - sizing roller machine; - dough transport shuttle machine; - steam pasteurizer machine; - cooler machine; - dough sheet cutting machine; - gnocchi machine; - typical shapes pasta machine. This European Standard is not applicable to the following machines: - household machines; - auxiliary equipment (not changing the characteristics of product): conveying systems not part of the machinery, weighting and bagging equipment, lifting and tilting machinery (dealt with in EN 13288). This European Standard is not applicable to pasta processing machines, which are manufactured before the date of its publication as EN.

EN 15774:2010 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15774:2010 has the following relationships with other standards: It is inter standard links to EN 60529:1991, EN 61310-1:2008, EN 1672-2:2005+A1:2009, EN ISO 14122-3:2001, EN 1088:1995+A2:2008, EN ISO 3744:2009, EN ISO 13732-1:2008, EN ISO 13732-3:2008, EN ISO 14122-2:2001, EN ISO 14122-1:2001, EN 626-1:1994+A1:2008, EN ISO 12100-2:2003, EN 614-1:2006+A1:2009, EN ISO 11688-1:2009, EN ISO 4871:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15774:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15774:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za predelavo hrane - Stroji za obdelavo svežih in polnjenih testenin (široki rezanci, kaneloni, ravioli, tortelini, ušesca in školjke) - Varnostne in higienske zahteveNahrungsmittelmaschinen - Maschinen zur Herstellung von frischen und gefüllten Teigwaren (Tagliatelle, Cannelloni, Ravioli, Tortellini, Orecchiette und Gnocci) - Sicherheits- und HygieneanforderungenMachines pour les produits alimentaires - Machines pour pâtes alimentaires (tagliatelle, cannelloni, ravioli, tortellini et gnocchi) - Exigences relatives à la sécurité et à l'hygièneFood processing machinery - Machines for processing fresh and filled pasta (tagliatelle, cannelloni, ravioli, tortellini, orecchiette and gnocchi) - Safety and hygiene requirements67.260Tovarne in oprema za živilsko industrijoPlants and equipment for the food industryICS:Ta slovenski standard je istoveten z:EN 15774:2010SIST EN 15774:2011en01-januar-2011SIST EN 15774:2011SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15774

November 2010 ICS 67.260 English Version

Food processing machinery -Machines for processing fresh and filled pasta (tagliatelle, cannelloni, ravioli, tortellini, orecchiette and gnocchi) - Safety and hygiene requirements

Machines pour les produits alimentaires - Machines pour pâtes alimentaires (tagliatelle, cannelloni, ravioli, tortellini, orecchiette et gnocchi) - Prescriptions relatives à la sécuritéet à l'hygiène

Nahrungsmittelmaschinen - Maschinen zur Herstellung von frischen und gefüllten Teigwaren (Tagliatelle, Cannelloni, Ravioli, Tortellini, Orecchiette und Gnocci) - Sicherheits- und Hygieneanforderungen This European Standard was approved by CEN on 2 October 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15774:2010: ESIST EN 15774:2011

Noise test code for machines for processing fresh and filled pasta (tagliatelle, cannelloni, ravioli, tortellini, orecchiette and gnocchi)

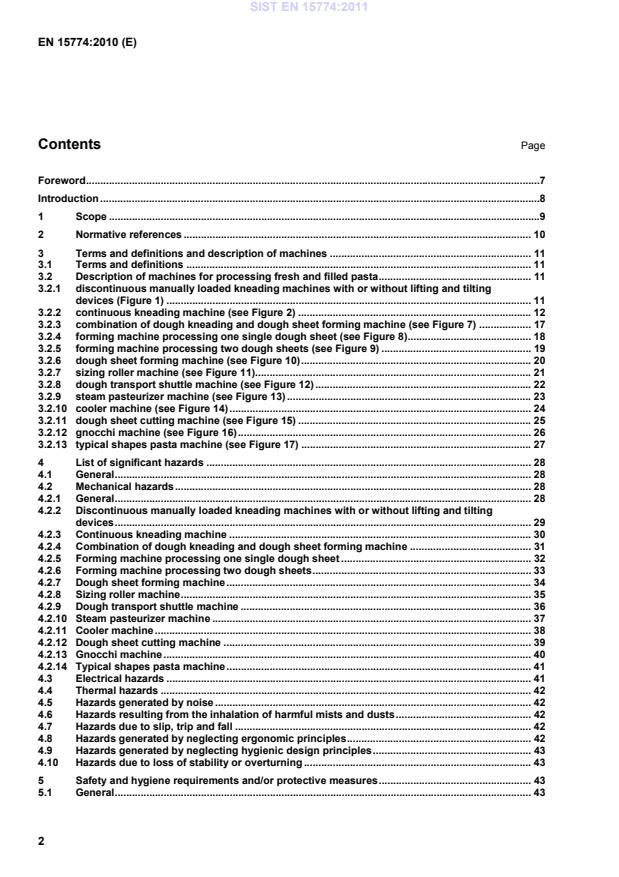

(Grade 2) . 59A.1 Definitions . 59A.2 Installation and mounting conditions . 59A.3 Operating conditions . 59A.4 Emission sound pressure level determination . 59A.5 Emission sound power level determination . 60A.6 Measurement uncertainties . 60A.7 Information to be recorded . 60A.8 Information to be reported. 60A.9 Declaration and verification of noise emission values . 60Annex B (normative)

Principles of design to ensure the cleanability of machinery . 62B.1 Definitions . 62B.2 Material of construction . 62B.2.1 Type of materials . 62B.2.2 Surface conditions . 62B.3 Design . 63B.3.1 Connections of internal surfaces . 63B.3.2 Surface assemblies and overlaps . 65B.3.3 Fasteners . 67B.3.4 Machines on the floor . 68B.3.5 Ventilation opening . 70B.3.6 Hinges . 71B.3.7 Control panel . 71SIST EN 15774:2011

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 72Bibliography . 73 Figures Figure 1a — Discontinuous manually loaded kneading machines without lifting and tilting system . 12Figure 1b — Discontinuous manually loaded kneading machines with lifting and tilting system . 12Figure 2 — Continuous kneading machine. 13Figure 3a — Kneading bowl singles shaft . 14Figure 3b — Kneading bowl double shaft . 14Figure 4 — Premixing device . 15Figure 5 — Dosing device for flour, semolina or other milled product . 16Figure 6a — Device for dough stabilization vertical . 17Figure 6b — Device for dough stabilization by belt . 17Figure 7 — Combination of dough kneading and dough sheet forming machine . 18Figure 8 — Forming machine processing one single dough sheet . 19Figure 9 — Forming machine processing two dough sheets . 20Figure 10 — Dough sheet forming machine . 21Figure 11 — Sizing roller machine . 22Figure 12 — Dough transport shuttle machine . 23Figure 13 — Steam pasteurizer machine . 24Figure 14 — Cooler machine . 25Figure 15 — Dough sheet cutting machine . 26Figure 16 — Gnocchi machine . 27Figure 17 — Typical shapes pasta machine . 28Figure 18 — Danger zones of discontinuous manually loaded kneading machine with or without lifting and tilting devices . 29Figure 19 — Danger zones of continuous kneading machine . 30Figure 20 — Danger zones of combination of dough kneading and dough sheet forming machine. 31Figure 21 — Danger zones of forming machine processing one single dough sheet . 32Figure 22 — Danger zones of forming machine processing two dough sheets . 33SIST EN 15774:2011

combination of dough kneading and dough sheet forming machine; forming machine processing one single dough sheet; forming machine processing two dough sheets; dough sheet forming machine; sizing roller machine; dough transport shuttle machine; steam pasteurizer machine; cooler machine; dough sheet cutting machine; gnocchi machine; typical shapes pasta machine. This European Standard is not applicable to the following machines: household machines; auxiliary equipment (not changing the characteristics of product): conveying systems not part of the machinery, weighting and bagging equipment, lifting and tilting machinery (dealt with in EN 13288). This European Standard is not applicable to pasta processing machines, which are manufactured before the date of its publication as EN. SIST EN 15774:2011

Optional assemblies: lifting and tilting system SIST EN 15774:2011

Key 1 bowl lid 2 bowl 3 kneading tool 4 tip device 5 lifting system

6 discharge dough 7 bowl locking device 8 tilting system 9 ingredient supply Figure 1a — Discontinuous manually loaded kneading machines without lifting and tilting system Figure 1b — Discontinuous manually loaded kneading machines with lifting and tilting system 3.2.2 continuous kneading machine (see Figure 2) 3.2.2.1 General Machine with automatically loading with the quantity of flour, semolina or other milled product, water, and any other ingredient (i.e. eggs, spinach, tomatoes, etc.) necessary to prepare the dough by kneading and automatically continuously dough discharge.

The principal components are: kneading bowl with single or double shaft; premixing device; flour

dosing device; liquid

dosing device; dough stabilization systems. Optional assemblies: premixing device, dough stabilization system. For the description of the principal components and optional assemblies see 3.2.2.1 to 3.2.2.5 and Figures 3 to 6 SIST EN 15774:2011

Key 1 dosing device for flour, semolina or other milled product 2 premixing device 3 bowl lid 4 bowl 5 shaft with blades

6 dough exit gate 7 hopper 8 eggs feeding 9 liquid

feeding 10 feeding for dough rework Figure 2 — Continuous kneading machine 3.2.2.2 kneading bowl (see Figure 3) Part of the continuous kneading machine where the dough is produced by kneading. Kneading is performed either by a single shaft with kneading blades or by two shafts with kneading blades driven in counterrotation. The discharge of dough at the end of the bowl is carried out by the last kneading blades. The principal components are: bowl with bowl lid (one or more); single shaft with kneading blades or two shafts with kneading blades driven in counterrotation; dough exit gate. SIST EN 15774:2011

Key 1 bowl lid 2 shaft with blade 3 dough exit gate Figure 3a — Kneading bowl singles shaft Figure 3b — Kneading bowl double shaft 3.2.2.3 premixing device (see Figure 4) Device that carries out the initial mixing stage of milled products and liquid ingredients i.e. water and eggs by rotation of a mixing tool in a tube (line blender). The principal components are: tube with connection pieces for inlet of milled product and liquid and premix outlet, mixing tool (e.g. shaft with blades). SIST EN 15774:2011

Key 1 shaft with blades 2 milled products entry 3 liquid entry 4 product exit Figure 4 — Premixing device 3.2.2.4 dosing device for flour, semolina or other milled product (see Figure 5) Device that measures the flour as a percentage. The flour falls into the hopper where the shaker, driven by an electric motor, mixes it continuously to ensure a uniform flow of product towards the dosing screw. The screw, driven by the second motor, measures the product volumetrically and forwards it to the centrifugal kneading machine (premixing device). SIST EN 15774:2011

Key 1 hopper 2 shaker 3 dosing screw Figure 5 — Dosing device for flour, semolina or other milled product 3.2.2.5 device for dough stabilization (see Figure 6) Device where the needed floor time is provided that is necessary for achieving the required stability of dough. In systems with vertical dough flow the dough is filled overhand in a dough box and the

required residence time is achieved by the velocity of the rotary discharge valve. In systems with horizontal dough flow the dough is filled in a dough box at the inlet side. The needed floor time is achieved by the velocity of the horizontal conveyor belt that transports the dough to the discharge. The principal components are: Vertical systems: dough box, rotary discharge valve. Horizontal systems: dough box, conveyor belt, SIST EN 15774:2011

Key 1 dough 2 dough box 3 rotary discharge valve/discharge 4 conveyor belt Figure 6a — Device for dough stabilization vertical Figure 6b — Device for dough stabilization by belt 3.2.3 combination of dough kneading and dough sheet forming machine (see Figure 7) Kneading machine combined with a dough sheet forming machine where the final product is a dough sheet for further processing in pasta machines. After kneading the dough sheet is formed in an arrangement composed of three rollers with lobes for the breaking and of two smooth rollers for the sheet finishing. The principal components are: kneading bowl with bowl lid; shaft with kneading blades; dough sheet forming unit consisting of three rollers with lobes for the breaking and of two smooth rollers; for the sheet finishing; conveying belt for taking off the dough sheet. Optional assemblies: flour dosing device, premixing device. SIST EN 15774:2011

Key 1 flour

dosing device 2 premixing device 3 bowl lid 4 bowl 5 shaft with blades

6 rollers 7 belt 8 eggs supply 9 liquid

dosing pump Figure 7 — Combination of dough kneading and dough sheet forming machine

3.2.4 forming machine processing one single dough sheet (see Figure 8) Machine that can produce ravioli or cappelletti by filling, folding and closing one single cut fresh piece of dough sheet. The principal components are: one or two roller units for gross

and fine calibration of the dough sheet; feeding device for dough sheet supply to the die block (mould) with intermittent movement; supply and dosing unit for the filling; die block (mould) consisting of simultaneously working devices for shearing, forming, filling and closing the dough sheet and rolling the pasta afterwards. Optional assemblies: a station for rolling and sizing ravioli, devices for cutting and collecting scrap (dough residues) for recycling. SIST EN 15774:2011

Key 1 dough sheet supply 2 roller unit for gross calibration 3 roller unit for fine calibration 4 dough sheet feeding belt 5 mould 6 mould guard

7 product collection chute 8 scraps cutter 9

scraps collection 10 filling supply 11 product discharge chute 12

scraps discharge chute Figure 8 — Forming machine processing one single dough sheet 3.2.5 forming machine processing two dough sheets (see Figure 9) Machine used for the industrial production of ravioli by filling and closing two overlapping dough sheets. The principal components are: roller unit for calibration of each dough sheet; supply and dosing unit for the filling; die block (mould) consisting of simultaneously working devices for forming, filling and closing the dough sheets. Optional assemblies: devices for cutting and collecting scrap (dough residues) for recycling. SIST EN 15774:2011

Key 1 sheet supply 2 front sizing roller unit 3 rear sizing roller unit 4 filling supply

5 scrap collection belt 6 scrap cutter 7 product collection belt 8 mould Figure 9 — Forming machine processing two dough sheets 3.2.6 dough sheet forming machine (see Figure 10) Machine that forms a rough dough sheet right to the final customer's requirements, using an arrangement composed of three rollers with lobes for the breaking and of two smooth rollers for the sheet finishing. Dough is supplied through a hopper.

The principal components are: hopper with mixing device (shaft with blades); kneading rolls inside a special formed housing; calibrating rolls; optional assemblies: dough sheet conveyor be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...