EN 12975-2:2001

(Main)Thermal solar systems and components - Solar collectors - Part 2: Test methods

Thermal solar systems and components - Solar collectors - Part 2: Test methods

This European Standard specifies test methods for validating the durability, reliability and safety requirements for liquid heating collectors as specified in EN 12975-1. This standard also includes three test methods for the thermal performance characterisation for liquid heating collectors.

It is not applicable to those collectors in which the thermal storage unit is an integral part of the collector to such an extent that the collection process cannot be separated from the storage process for the purpose of making measurements of these two processes.

It is not basically not applicable to tracking concentrating collectors, however thermal performance testing as given in clause 6.3 (quasi dynamic testing) is also applicable to most concentrating collector designs, from stationary non-imaging concentrators as CPCs to high concentrating tracking designs. Parts of the solar radiation measurement have to be adjusted in case of a tracking collector and in case a pyrheliometer is used to measure beam radiation.

Collectors that are custom built (built in; e.g. roof integrated collectors that do not compose of factory made modules and are assembled directly on the place of installation) cannot be tested in their actual form for durability, reliability and thermal performance according to this standard. Instead, a module with the same structure as the ready collector may be tested. The module gross area shall be at least 2m2.

Thermische Solaranlagen und ihre Bauteile - Kollektoren - Teil 2: Prüfverfahren (einschließlich Corrigendum EN 12975-2:2001/AC:2002)

Diese Europäische Norm legt Prüfverfahren für den Nachweis der Erfüllung der Anforderungen an Dauerhaftigkeit, Zuverlässigkeit und Sicherheit für Flüssigkeitskollektoren nach EN 12975-1 fest. Diese Norm enthält auch drei Prüfverfahren für die Charakterisierung der Wärmeleistung von Flüssigkeitskollektoren.

Die Norm ist nicht auf Kollektoren anwendbar, bei denen der Wärmespeicher ein integraler Bestandteil des Kollektors ist, so dass bei der Durchführung von Messungen der Prozess im Kollektor vom Prozess der Wärme-speicherung nicht getrennt werden kann.

Die Norm ist grundsätzlich auf nachgeführte konzentrierende Kollektoren nicht anwendbar; die Prüfung der Wär-meleistung nach Abschnitt 6.3 (quasi-dynamische Prüfung) ist jedoch auf die meisten Konstruktionen konzentrie-render Kollektoren anwendbar, vom stationären nichtabbildenden Konzentrator als CPC bis zu hoch konzentrie-renden nachgeführten Konstruktionen. Teile der solaren Strahlungsmessung müssen im Falle nachgeführter Kollektoren abgestimmt werden. Das Gleiche gilt für den Fall, dass zur Messung direkter Strahlung ein Pyrhelio-meter verwendet wurde.

Kundenspezifische Kollektoren (z. B. in der Dacheindeckung integrierte Kollektoren, die keine industriell herge-stellten Module enthalten und direkt am Einsatzort zusammengebaut werden), können in ihrer ursprünglichen Form in Bezug auf Dauerhaftigkeit, Zuverlässigkeit und Wärmeleistung nicht nach dieser Norm geprüft werden. An ihrer Stelle darf ein Modul geprüft werden, das die gleiche Bauweise aufweist wie der fertig eingebaute Kollektor. Die Bruttofläche des Moduls muss mindestens 2 m2 betragen.

Installations solaires thermiques et leurs composants - Capteurs - Partie 2: Méthodes d'essais

La présente norme européenne fixe des méthodes d'essai permettant de valider les precsriptions de durabilité et de fiabilité pour des capteurs pour le chauffage de liquide, tels que spécifiés dans le prEN XXX-1. La présente norme comprend également trois méthodes d'essai pour la caractérisation des performances thermiques des capteurs pour le chauffage de liquide. Elle ne s'applique pas aux capteurs dans lesquels le dispositif de stockage thermique fait partie intégrante du capteur dans la mesure où les opérations de captage et de stockage de l'énergie ne peuvent pas être séparées etc.

Toplotni sončni sistemi in sestavni deli - Sprejemniki sončne energije - 2. del: Preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 05-Jun-2001

- Withdrawal Date

- 28-Mar-2006

- Technical Committee

- CEN/TC 312 - Thermal solar systems and components

- Drafting Committee

- CEN/TC 312 - Thermal solar systems and components

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 29-Mar-2006

- Completion Date

- 29-Mar-2006

Relations

- Replaced By

EN 12975-2:2006 - Thermal solar systems and components - Solar collectors - Part 2: Test methods - Effective Date

- 22-Dec-2008

- Corrected By

EN 12975-2:2001/AC:2002 - Thermal solar systems and components - Solar collectors - Part 2: Test methods - Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 12975-2:2001 is a standard published by the European Committee for Standardization (CEN). Its full title is "Thermal solar systems and components - Solar collectors - Part 2: Test methods". This standard covers: This European Standard specifies test methods for validating the durability, reliability and safety requirements for liquid heating collectors as specified in EN 12975-1. This standard also includes three test methods for the thermal performance characterisation for liquid heating collectors. It is not applicable to those collectors in which the thermal storage unit is an integral part of the collector to such an extent that the collection process cannot be separated from the storage process for the purpose of making measurements of these two processes. It is not basically not applicable to tracking concentrating collectors, however thermal performance testing as given in clause 6.3 (quasi dynamic testing) is also applicable to most concentrating collector designs, from stationary non-imaging concentrators as CPCs to high concentrating tracking designs. Parts of the solar radiation measurement have to be adjusted in case of a tracking collector and in case a pyrheliometer is used to measure beam radiation. Collectors that are custom built (built in; e.g. roof integrated collectors that do not compose of factory made modules and are assembled directly on the place of installation) cannot be tested in their actual form for durability, reliability and thermal performance according to this standard. Instead, a module with the same structure as the ready collector may be tested. The module gross area shall be at least 2m2.

This European Standard specifies test methods for validating the durability, reliability and safety requirements for liquid heating collectors as specified in EN 12975-1. This standard also includes three test methods for the thermal performance characterisation for liquid heating collectors. It is not applicable to those collectors in which the thermal storage unit is an integral part of the collector to such an extent that the collection process cannot be separated from the storage process for the purpose of making measurements of these two processes. It is not basically not applicable to tracking concentrating collectors, however thermal performance testing as given in clause 6.3 (quasi dynamic testing) is also applicable to most concentrating collector designs, from stationary non-imaging concentrators as CPCs to high concentrating tracking designs. Parts of the solar radiation measurement have to be adjusted in case of a tracking collector and in case a pyrheliometer is used to measure beam radiation. Collectors that are custom built (built in; e.g. roof integrated collectors that do not compose of factory made modules and are assembled directly on the place of installation) cannot be tested in their actual form for durability, reliability and thermal performance according to this standard. Instead, a module with the same structure as the ready collector may be tested. The module gross area shall be at least 2m2.

EN 12975-2:2001 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12975-2:2001 has the following relationships with other standards: It is inter standard links to EN 12975-2:2006, EN 12975-2:2001/AC:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12975-2:2001 is associated with the following European legislation: Standardization Mandates: M/077. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12975-2:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Thermische Solaranlagen und ihre Bauteile - Kollektoren - Teil 2: Prüfverfahren (einschließlich Corrigendum EN 12975-2:2001/AC:2002)Installations solaires thermiques et leurs composants - Capteurs - Partie 2: Méthodes d'essaisThermal solar systems and components - Solar collectors - Part 2: Test methods27.160Solar energy engineeringICS:Ta slovenski standard je istoveten z:EN 12975-2:2001SIST EN 12975-2:2002en01-november-2002SIST EN 12975-2:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12975-2June 2001ICS 27.160English versionThermal solar systems and components - Solar collectors - Part2: Test methodsInstallations solaires thermiques et leurs composants -Capteurs - Partie 2: Méthodes d'essaisThermische Solaranlagen und ihre Bauteile - Kollektoren -Teil 2: PrüfverfahrenThis European Standard was approved by CEN on 19 January 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.Although this (draft) European Standard has been developed in one language only in accordance with Resolution BT 74/1997 related to theone language experiment, it exists in accordance with the CEN/CENELEC Internal Regulations in the three official versions (English,French, German).CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2001 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12975-2:2001 ESIST EN 12975-2:2002

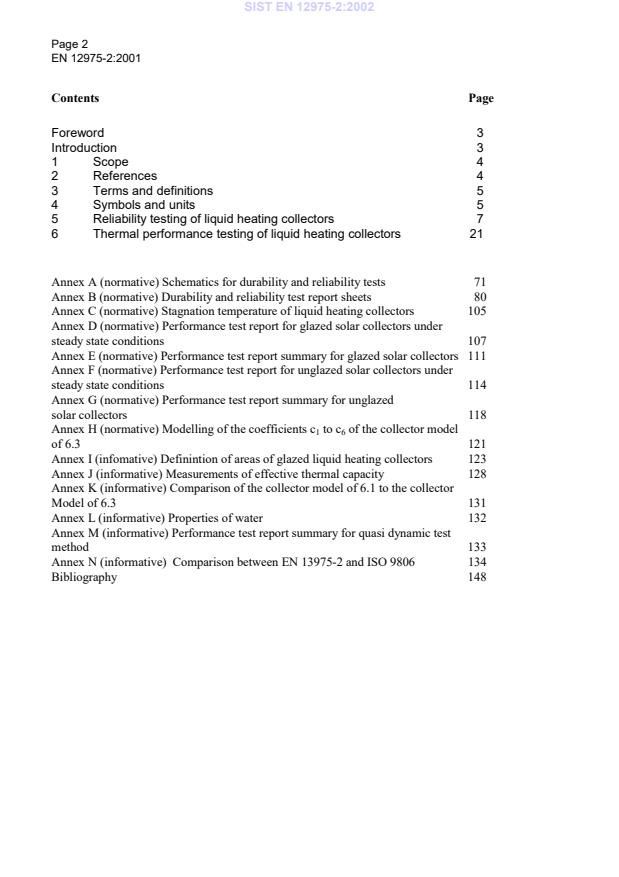

Page 2EN 12975-2:2001Contents

PageForeword3Introduction31Scope42References43Terms and definitions54Symbols and units55Reliability testing of liquid heating collectors76Thermal performance testing of liquid heating collectors21Annex A (normative) Schematics for durability and reliability tests71Annex B (normative) Durability and reliability test report sheets80Annex C (normative) Stagnation temperature of liquid heating collectors105Annex D (normative) Performance test report for glazed solar collectors understeady state conditions107Annex E (normative) Performance test report summary for glazed solar collectors111Annex F (normative) Performance test report for unglazed solar collectors understeady state conditions114Annex G (normative) Performance test report summary for unglazedsolar collectors118Annex H (normative) Modelling of the coefficients c1 to c6 of the collector modelof 6.3121Annex I (infomative) Definintion of areas of glazed liquid heating collectors123Annex J (informative) Measurements of effective thermal capacity128Annex K (informative) Comparison of the collector model of 6.1 to the collectorModel of 6.3131Annex L (informative) Properties of water132Annex M (informative) Performance test report summary for quasi dynamic testmethod133Annex N (informative)

Comparison between EN 13975-2 and ISO 9806134Bibliography148SIST EN 12975-2:2002

Page 3EN 12975-2:2001ForewordThis European Standard has been prepared by Technical Committee CEN/TC 312 "Thermal solarsystems and components", the secretariat of which is held by ELOT.This European Standard shall be given the status of a national standard, either by publication of anidentical text or by endorsement, at the latest by December 2001, and conflicting national standardsshall be withdrawn at the latest by December 2001.The annexes A, B, C, D, E, F, G and H are normative. The annexes I, J, K, L, M, N and O areinformative.According to the CEN/CENELEC Internal Regulations, the national standards organizations of thefollowing countries are bound to implement this European Standard: Austria, Belgium, CzechRepublic, Denmark, Finland, France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg,Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and the United Kingdom.IntroductionThis standard specifies test methods for determining the ability of a liquid heating solar collector toresist the influence of degrading agents. It defines procedures for testing collectors under well-definedand repeatable conditions.This standard also provides test methods and calculation procedures for determining the steady-stateand quasi-steady-state thermal performance of glazed liquid heating solar collectors. It containsmethods for conducting tests outdoors under natural solar irradiance and natural and simulated windand for conducting tests indoors under simulated solar irradiance and wind.This standard also provides methods for determining the thermal performance of unglazed liquidheating solar collectors. Unglazed collectors are in most cases used for heating swimming pools orother low temperature consumers. In general the collectors are put together on-site, connectingabsorber strips with manifolds. Real absorber areas are mostly between ten to one hundred squaremeters. For unglazed absorbers, readily fabricated modules with a specific size are seldom used.Therefore, during the test, it is to check, that a realistic flow pattern and flow velocity is used.This standard also provides test methods and calculation procedures for determining the steady-state aswell as the all-day thermal performance parameters for liquid heating solar collectors, under changingweather conditions. It contains methods for conducting tests outdoors during whole days and understationary inlet temperature conditions and natural solar irradiance and natural and/or simulated windconditions. Important effects for the all-day performance of the collector, as the dependence onincident angle, wind speed, diffuse fraction of solar irradiance, thermal sky radiation and thermalcapacity are taken into account. Dependence on flow rate is not included in this standard.Some of the advantages of the proposed extension of the present steady-state test methods of all-daytesting are: A shorter and less expensive outdoor test, suitable for European climate conditions. A much wider range of collectors can be tested with the same method. At the same time, a much more complete characterisation of the collector is achieved. The collector model is still directly compatible with that of the present basic test standards, andonly correction terms are applied in this extended approach. All additions are based on long agreed collector theory. At any time, full backwards comparability to steady-state can be established by evaluating onlyperiods of the test days that correspond to steady-state test requirements. The same test equipment can be used as for stationary testing with only minor changes, which alsowill improve the accuracy of steady-state testing.SIST EN 12975-2:2002

Page 4EN 12975-2:2001 Commonly available standard PC software can be used for the parameter identification, such asspreadsheets or more advanced statistical packages that has Multiple Linear Regression (MLR) asan option.An accurate long term prediction of the collector performance (not included in this standard) can be anintegral part of this test method, as the same collector model and parameters can be used for bothtesting and prediction.1ScopeThis European Standard specifies test methods for validating the durability, reliability and safetyrequirements for liquid heating collectors as specified in EN 12975-1. This standard also includes threetest methods for the thermal performance characterisation for liquid heating collectors.It is not applicable to those collectors in which the thermal storage unit is an integral part of thecollector to such an extent that the collection process cannot be separated from the storage process forthe purpose of making measurements of these two processes.It is not basically not applicable to tracking concentrating collectors, however thermal performancetesting as given in clause 6.3 (quasi dynamic testing) is also applicable to most concentrating collectordesigns, from stationary non-imaging concentrators as CPCs to high concentrating tracking designs.Parts of the solar radiation measurement have to be adjusted in case of a tracking collector and in casea pyrheliometer is used to measure beam radiation.Collectors that are custom built (built in; e.g. roof integrated collectors that do not compose of factorymade modules and are assembled directly on the place of installation) cannot be tested in their actualform for durability, reliability and thermal performance according to this standard. Instead, a modulewith the same structure as the ready collector may be tested. The module gross area shall be at least2m2.2ReferencesThis European Standard incorporates, by dated or undated reference, provisions from otherpublications. The normative references are cited at the appropriate places in the text and thepublications are listed hereafter. For dated references, subsequent amendments to or revisions of any ofthese publications apply to this European Standard only when incorporated in it by amendment orrevision. For undated references the latest edition of the publication referred to applies.ISO 9060Solar energy - Specification and classification of instruments formeasuring hemispherical solar and direct solar radiation.ISO 9806-1Test methods for solar collectors – Part 1: Thermal performanceof glazed liquid heating collectors including pressure drop.ISO 9806-2Test methods for solar collectors – Part 2: Qualification testprocedures.ISO 9806-3: 1995Test methods for solar collectors - Part 3: Thermal performance ofunglazed liquid heating collectors (sensible heat transfer only)including pressure drop.ISO 9846Solar energy - Calibration of a pyranometer using a pyrheliometer.ISO 9847Solar energy - Calibration of field pyranometers by comparison toa reference pyranometer.ISO/TR 9901EN ISO 9488Solar energy - Field pyranometers - Recommended practice foruse.Solar Energy - Vocabulary

(ISO 9488:1999)SIST EN 12975-2:2002

Page 5EN 12975-2:2001EN 12975-1:2000Thermal solar systems and components - Solar collectors - Part 1:General requirements3Terms and definitionsFor the purpose of this standard, the Terms and definitions given in EN ISO 9488 apply.4Symbols and unitsa1algebraic constant, reference to T*mWm-2K-1a2algebraic constant, reference to T*mWm-2K-2AAabsorber area of collectorm2Aaaperture area of collectorm2AGgross area of collectorm2AMoptical air massbucollector efficiency coefficient (wind dependence)m-1 sb1collector efficiency coefficientWm-2K-1b2collector efficiency coefficientWsm-3K-1c1heat loss coefficient at (Tm - Ta)=0Wm-2K-1c2temperature dependence of the heat loss coefficientWm-2K-2c3wind speed dependence of the heat loss coefficientJm-3K-1c4sky temperature dependence of the heat loss coefficientWm-2K-1c5effective thermal capacityJ m-2K-1c6wind dependence in the zero loss efficiencysm-1cfspecific heat capacity of heat transfer fluidJkg-1K-1Ceffective thermal capacity of collectorJK-1DdateYYMMDDELlongwave irradiance ( >3m)Wm-2Elongwave irradiance on an inclined surface outdoorsWm-2Eslongwave irradianceWm-2Fradiation view factorF´collector efficiency factorGhemispherical solar irradianceWm-2G*hemispherical solar irradianceWm-2G''net irradianceWm-2Gbdirect solar irradiance (beam irradiance)Wm-2Gddiffuse solar irradianceWm-2LTlocal timehKincidence angle modifierKbincidence angle modifier for direct radiationKdincidence angle modifier for diffuse radiationmthermally active mass of the collectorkg.mmass flowrate of heat transfer fluidkgs-1Q.useful power extracted from collectorWQ.Lpower loss of collector Wttimestaambient or surrounding air temperature°Ctdpatmospheric dew point temperature°CSIST EN 12975-2:2002

Page 6EN 12975-2:2001tecollector outlet (exit) temperature°Ctincollector inlet temperature°Ctmmean temperature of heat transfer fluid°Ctsatmospheric or sky temperature°Ctstgstagnation temperature°CTabsolute temperatureKTaambient or surrounding air temperatureKT*mreduced temperature difference ( = (tm – ta)/G*)m2KW-1Tsatmospheric or equivalent sky radiation temperatureKUmeasured overall heat loss coefficient of collector,with reference to T*mWm-2K-1ULoverall heat loss coefficient of a collector with uni-form absorber temperature tmWm-2K-1usurrounding air speedms-1Vf fluid capacity of the collectorm3ppressure difference between fluid inlet and outletPattime intervalsTtemperature difference between fluid outlet and inlet(te - tin)Ksolar absorptancetilt angle of a plane with respect to horizontaldegreesazimuth angledegreeshemispherical emittancesolar hour angledegreesangle of incidencedegreeslatitudedegreeswavelengthµmcollector efficiency, with reference to T*mo zero-loss collector efficiency ( at T*m = 0), reference to T*mStefan-Boltzmann constantWm-2K-4density of heat transfer fluidkgm-3ccollector time constantstransmittance()eeffective transmittance-absorptance product()edeffective transmittance-absorptance product fordiffuse solar irradiance()eneffective transmittance-absorptance product fordirect solar radiation at normal incidence()eeffective transmittance-absorptance product fordirect solar radiation at angle of incidence NOTE 1

In the field of solar energy the symbol G is used to denote solar irradiance, rather thanthe generic symbol E for irradiance.NOTE 2

C is often denoted (mC)e in basic literature (see also Annex H)NOTE 3

For more information about thermal performance coefficients (parameters) c1 to c6,see Annex H.SIST EN 12975-2:2002

Page 7EN 12975-2:20015Reliability testing of liquid heating collectors5.1 GeneralThe tests shall be carried out in the sequence shown in table 1. Changes in the test sequence, uponagreement of all parties involved or at discretion of the test laboratory, shall be reported with the testresults and the reasons for deviation shall be given.For some qualification tests, a part of the collector may have to be tampered with in some way, forexample a hole may have to be drilled in the back of the collector to attach a temperature sensor to theabsorber. In these cases care should be taken to ensure that any damage caused does not affect theresults of subsequent qualification tests, for example by allowing water to enter into a previouslyraintight collector.NOTE

This sequence has been determined with a view to minimise test costs while ensuringthat the possible effects of each degrading influence are likely to be evaluated in a later test.(For example, rain penetration may result if a collector is distorted by exposure to hightemperatures).Table 1 - Test sequenceSequenceSubclauseTest15.2Internal pressure25.3High-temperature resistance 1)35.4Exposure45.5External thermal shock 2)55.6Internal thermal shock 2)65.7Rain penetration 3)75.8Freeze resistance 4)85.2Internal pressure (retest)95.9Mechanical load106.1-6.2-6.3Thermal performance115.10Impact resistance125.11Final inspection1)For organic absorbers, the high-temperature resistance test shall beperformed first in order to determine the collector stagnation temperatureneeded for the internal pressure test.2)The two external and internal thermal shock tests may be combined with theexposure test or the high-temperature resistance test.3)The rain penetration test shall be carried out only for glazed collectors.4)

The freeze resistance test shall be carried out only for collectors claimed tobe freeze resistant.SIST EN 12975-2:2002

Page 8EN 12975-2:20015.2 Internal pressure tests for absorbers5.2.1 Metallic absorbers5.2.1.1 ObjectiveThe absorber shall be pressure-tested to assess the extent to which it can withstand the pressures whichit might meet in service.5.2.1.2 Apparatus and procedureThe apparatus, shown in figure A.1, consists of a hydraulic pressure source (electrical pump or handpump), a safety valve, an air-bleed valve and a pressure gauge with an accuracy better than 5%. Theair-bleed valve shall be used to empty the absorber of air before pressurisation. The metallic absorbershall be filled with water at room temperature and pressurised to the test pressure for the test period(see 5.2.1.3.2). This pressure shall be maintained while the absorber is inspected for swelling,distortion or ruptures.5.2.1.3 Test conditions5.2.1.3.1 TemperatureMetallic absorbers shall be pressure-tested (see 5.2.1.3.2) at ambient temperature within the range 5°Cto 30°C.5.2.1.3.2 PressureThe test pressure shall be 1,5 times the maximum collector operating pressure specified by themanufacturer.The test pressure shall be maintained for 15 min.5.2.1.4 ResultsThe collector shall be inspected for leakage, swelling and distortion. The results of this inspection shallbe reported together with the values of pressure and temperature used and the duration of the test.5.2.2 Absorbers made of organic materials (plastics or elastomers)5.2.2.1 ObjectiveThe absorber shall be pressure-tested (see 5.2.1.3.2) to assess the extent to which it can withstand thepressures, which it might meet in service while operating at elevated temperature. The tests shall becarried out at elevated temperatures, because the pressure resistance of an organic absorber may beadversely affected as its temperature is increased.SIST EN 12975-2:2002

Page 9EN 12975-2:20015.2.2.2 Apparatus and procedure5.2.2.2.1 GeneralThe apparatus consists of either a hydraulic or a pneumatic pressure source, and a means of heating theabsorber to the required test temperature.The characteristics of a solar irradiance simulator shall be the same as those of the simulator used forefficiency testing of liquid heating solar collectors.A temperature sensor shall be attached to the absorber to monitor its temperature during the test. Thesensor shall be positioned at two-thirds of the absorber height and half the absorber width. It shall befixed firmly in a position to ensure good thermal contact with the absorber. The sensor shall beshielded from solar radiation.The test conditions specified in 5.2.2.3 shall be maintained for at least 30 min prior to test and for thefull duration of the test.The pressure in the absorber shall be raised in stages as specified in 5.2.2.3, and the absorber shall beinspected for swelling, distortion or rupture after each increase in pressure. The pressure shall bemaintained while the absorber is being inspected.For safety reasons, the collector shall be encased in a transparent box to protect personnel in the eventof explosive failure during this test.5.2.2.2.2 Organic absorbers for use in unglazed collectors (test temperature < 90°C)Where the maximum test temperature is below 90°C, absorbers may be submerged in a heated waterbath and pressure-tested. The pressurised fluid supply to the absorber shall be fitted with a safety valve,air-bleed valve (if required) and pressure gauge having an accuracy better than 5%. The apparatus isshown in figure A.2.5.2.2.2.3 Organic absorbers for use with oil-based fluids (test temperature > 90°C)When the test temperature exceeds 90 °C, the absorber may be connected to a hot oil circuit. Theabsorber and hot oil circuit are then pressurised. The hot oil circuit shall be fitted with a safety valve,air-bleed valve and pressure gauge having an accuracy better than 5%.The absorber may be heated by any of the following methods:a) connecting a heater in the oil circuit (see figure A.3);b) heating the whole collector in a solar irradiance simulator (see figure A.4);c) heating the whole collector outdoors under natural solar irradiance (see figure A.4).Safety measures should be taken to protect personnel from hot oil in the event of explosive failureduring this test.5.2.2.2.4 Organic absorbers - high temperature pneumatic pressure testThe absorber may be pressure-tested using compressed air, when heated by either of the followingmethods:a) heating the whole collector in a solar irradiance simulator (see figure A.5);b) heating the whole collector outdoors under natural solar irradiance (see figure A.5).The compressed air supply to the absorber shall be fitted with a safety valve and a pressure gaugehaving an accuracy better than 5%.SIST EN 12975-2:2002

Page 10EN 12975-2:20015.2.2.3 Test conditions5.2.2.3.1 TemperatureFor absorbers made of organic materials, the test temperature shall be the maximum temperature whichthe absorber will reach under stagnation conditions.The reference conditions given in table 2 shall be used.The calculations employed to determine the test temperature are included in Annex C and shall either:- use measured collector performance characteristics, or- extrapolate from average values, measured in the high-temperature resistance test (see 5.3.3), of theglobal solar irradiance (natural or simulated) on the collector plane, the surrounding air temperatureand the absorber temperature.Table 2 - Climate reference conditions to determine test temperatures for internal pressure testof organic absorbersClimate parameterValue for all climate classesGlobal solar irradiance on collector plane, G in W/m21000Surrounding air temperature, ta in °C305.2.2.3.2 PressureThe test pressure shall be 1,5 times the maximum collector operating pressure specified by themanufacturer.For absorbers made of organic materials, the pressure shall be raised to the test pressure in equal stagesof 20 kPa (approximately) and maintained at each intermediate pressure for 5 min. The test pressureshall then be maintained for a least 1 h.5.2.2.4 ResultsThe collector shall be inspected for leakage, swelling and distortion. The results of the inspection shallbe reported.Full details of the test procedure used, including the temperature, intermediate pressures and testperiods used, shall be reported with the test results.5.3 High-temperature resistance test5.3.1 ObjectiveThis test is intended to assess rapidly whether a collector can withstand high irradiance levels withoutfailures such as glass breakage, collapse of plastic cover, melting of plastic absorber, or significantdeposits on the collector cover from outgassing of collector material.SIST EN 12975-2:2002

Page 11EN 12975-2:20015.3.2 Apparatus and procedureThe collector shall be tested outdoors, or in a solar irradiance simulator. A schema for testing is shownin figure A.6.The characteristics of the solar irradiance simulator to be used for the high-temperature resistance testshall be those of the solar irradiance simulator used for efficiency testing of liquid heating solarcollectors.The collector shall be mounted outdoors or in a solar simulator, and shall not be filled with fluid. Oneof its fluid pipes shall be sealed to prevent cooling by natural circulation of air, but the other shall beleft open to permit free expansion of air in the absorber.A temperature sensor shall be attached to the absorber to monitor its temperature during the test. Thesensor shall be positioned at two-thirds of the absorber height and half the absorber width. It shall befixed firmly in a position to ensure good thermal contact with the absorber. The sensor shall beshielded from solar radiation.NOTE 1

When testing collectors, such as evacuated tubular collectors, for which it is notappropriate to measure the stagnation temperature at the absorber, the temperature sensorshould be placed at a suitable location in the collector, and this location should be clearlydescribed with the test results.NOTE 2

In some cases, such as evacuated collectors, it may be difficult to attach athermocouple to the absorber. In such cases, instead of attaching a thermocouple to theabsorber, the testing laboratory may partially fill the absorber with a special fluid, seal theabsorber and measure the pressure in the absorber. The relationship between the internalpressure in the absorber and its temperature should be known from the standard vapourpressure/temperature relationship for the fluid.The test shall be performed for a minimum of 1 h after steady-state conditions have been established,and the collector shall be subsequently inspected for signs of damage as specified in 5.3.4.5.3.3 Test conditionsThe set of reference conditions given in table 3 shall be used for all climate classes.Table 3 - Climate reference conditions for high-temperature resistance testClimate parameterValue for all climate classesGlobal solar irradiance on collector plane, G in W/m2>1000Surrounding air temperature, ta in °C20 - 40Surrounding air speed in m/s 15.3.4 ResultsThe collector shall be inspected for degradation, shrinkage, outgassing and distortion.The results of the inspection shall be recorded together with the average values of solar irradiance(natural or simulated) on the collector plane, surrounding air temperature and speed, and absorbertemperature (and the pressure of the special fluid in the absorber, if that method is used) recordedduring the test.SIST EN 12975-2:2002

Page 12EN 12975-2:20015.4 Exposure test5.4.1 ObjectiveThe exposure test provides a low-cost reliability test sequence, indicating (or simulating) operatingconditions which are likely to occur during real service and which also allows the collector to "settle",such that subsequent qualification tests are more likely to give repeatable results.5.4.2 Apparatus and procedureThe collector shall be mounted outdoors (see figure A.7), but not filled with fluid. One of the fluidpipes shall be sealed to prevent cooling by natural circulation of air, while the other shall be left opento permit free expansion of air in the absorber.The air temperature shall be recorded to an uncertainty of 1 K and the global irradiance on the plane ofthe collector recorded using a pyranometer of class I in accordance with ISO 9060. Irradiation andmean air temperature values shall be recorded every 30 min and rainfall shall be recorded daily. Thecollector shall be exposed until the test conditions have been met.At the end of the exposure, a visual inspection shall be made for signs of damage as specified in 5.4.4.5.4.3 Test conditionsThe set of reference conditions given in table 4 shall be used.The collector shall be exposed until at least 30 days (which need not be consecutive) have passed withthe minimum irradiation H shown in table 4. The irradiation is determined by recording irradiancemeasurements using a pyranometer.The collector shall also be exposed for at least 30 h to the minimum irradiance level G given in table 4,as recorded by a pyranometer, when the surrounding air temperature is greater than the value shown intable 4. These hours shall be made up of periods of at least 30 min.NOTE

In regions where these conditions cannot be met during certain periods of the year,the 30-h exposure to high irradiance levels (table 4) can be conducted in a solar irradiancesimulator having characteristics identical to those of a simulator used for efficiency testing ofliquid heating solar collectors. The 30-h exposure test should be conducted after the collectorhas completed at least 10 days, but no more than 15 days, of the exposure to the minimumirradiation level (table 4).If the external and internal thermal shock tests are combined with the exposure test, the first externaland internal shocks shall be caused during the first 10 of the 30 h defined above, and the second duringthe last 10 of the 30 h.Table 4 - Climate reference conditions for exposure test as well as for external and internalthermal shock testsClimate parameterValue for all climate classesGlobal solar irradiance on collector plane, G in W/m2850Global daily irradiation on collector plane, H in MJ/m214Surrounding air temperature, ta in °C10NOTE

Values given are minimum values for testing.SIST EN 12975-2:2002

Page 13EN 12975-2:20015.4.4 ResultsThe collector shall be inspected for damage or degradation. The results of the inspection shall bereported together with a record of the climatic conditions during the test, including daily irradiation,surrounding air temperature and rain.5.5 External thermal shock test5.5.1 ObjectiveCollectors may from time to time be exposed to sudden rainstorms on hot sunny days, causing a severeexternal thermal shock. This test is intended to assess the capability of a collector to withstand suchthermal shocks without a failure.5.5.2 Apparatus and procedureThe collector shall be mounted either outdoors or in a solar irradiance simulator, but shall not be filledwith fluid. One of its fluid pipes shall be sealed to prevent cooling by natural circulation of air, whilethe other shall be left open to permit free expansion of air in the absorber (see figure A.8).A temperature sensor may be optionally attached to the absorber to monitor its temperature during thetest. The sensor shall be positioned at two-thirds of the absorber height and half the absorber width. Itshall be fixed firmly in a position to ensure good thermal contact with the absorber. The sensor shall beshielded from solar radiation.NOTE 1

When testing collectors, such as evacuated tubular collectors, for which it is notappropriate to measure the stagnation temperature at the absorber, the temperature sensorshould be placed at a suitable location in the collector, and this location should be clearlydescribed with the test results.NOTE 2

In some cases, such as evacuated collectors, it may be difficult to attach athermocouple to the absorber. In such cases, instead of attaching a thermocouple to theabsorber, the testing laboratory may partially fill the absorber with a special fluid, seal theabsorber and measure the pressure in the absorber. The relationship between the internalpressure in the absorber and its temperature should be known from the standard vapourpressure/temperature relationship for the fluid.An array of water jets shall be arranged to provide a uniform spray of water over the collector.The collector shall be maintained under a high level of solar irradiance for a period of 1 h before thewater spray is turned on. It is then cooled by the water spray for 15 min before being inspected.The collector shall be subjected to two external thermal shocks.5.5.3 Test conditionsThe set of reference conditions given in table 4 shall be used.The specified operating conditions shall be:- solar (or simulated solar) irradiance G greater than the value shown in table 4.- surrounding air temperature ta greater than the value shown in table 4.SIST EN 12975-2:2002

Page 14EN 12975-2:2001The water spray shall have a temperature of less than 25 °C and a flowrate in the range 0,03 kg/s to0,05 kg/s per square metre of collector aperture.If the temperature of the water which first cools the collector is likely to be greater than 25 °C (forexample if the water has been sitting in a pipe in the sun for some time), then the water shall bediverted until it has reached a temperature of less than 25 °C before being directed over the collector.5.5.4 ResultsThe collector shall be inspected for any cracking, distortion, condensation, water penetration or loss ofvacuum. The results of the inspection shall be reported. The measured values of solar irradiance,surrounding air temperature, absorber temperature (if measured), water temperature and water flowrateshall also be reported.5.6 Internal thermal shock test5.6.1 ObjectiveCollectors may from time to time be exposed to a sudden intake of cold heat transfer fluid on hot sunnydays, causing a severe internal thermal shock, for example, after a period of shutdown, when theinstallation is brought back into operation while the collector is at its stagnation temperature. This testis intended to assess the capability of a collector to withstand such thermal shocks without failure.5.6.2 Apparatus and procedureThe collector shall be mounted either outdoors or in a solar irradiance simulator (see figure A.9), butshall not be filled with fluid. One of its fluid pipes shall be connected via a shutoff valve to the heattransfer fluid source and the other (diagonally across the collector) shall be left open initially to permitthe free expansion of air in the absorber and also to permit the heat transfer fluid to leave the absorber(and be collected).A temperature sensor may be optionally attached to the absorber to monitor its temperature during thetest. The sensor shall be positioned at two-thirds of the absorber height and half the absorber width. Itshall be fixed firmly in a position to ensure good thermal contact with the absorber. The sensor shall beshielded from solar radiation.NOTE 1 When testing collectors, such as evacuated tubular collectors, for which it is notappropriate to measure the stagnation temperature at the absorber, the temperature sensorshould be placed at a suitable location in the collector, and this location should be clearlydescribed with the test results.NOTE 2 In some cases, such as evacuated collectors, it may be difficult to attach athermocouple to the absorber. In such cases, instead of attaching a thermocouple to theabsorber, the testing laboratory may partially fill the absorber with a special fluid, seal theabsorber and measure the pressure in the absorber. The relationship between the internalpressure in the absorber and its temperature should be known from the standard vapourpressure/temperature relationship for the fluid.The collector shall be maintained under a high level of solar irradiance for a period of 1 h before it iscooled by supplying it with heat transfer fluid for at least 5 min.The collector shall be subjected to two internal thermal shocks.SIST EN 12975-2:2002

Page 15EN 12975-2:20015.6.3 Test conditionsThe set of reference conditions given in table 4 shall be used.The specified operating conditions shall be:- solar (or simulated solar) irradiance G greater than the value shown in table 4;- surrounding air temperature ta greater than the value shown in table 4.The heat transfer fluid shall have a temperature of less than 25 °C. The recommended fluid flowrate isat least 0,02 kg/s per square metre of collector aperture (unless otherwise specified by themanufacturer).5.6.4 ResultsThe collector shall be inspected for any cracking, distortion, deformation, water penetration or loss ofvacuum. The results of the inspection shall be reported. The measured values of solar irradiance,surrounding air temperature, absorber temperature (if measured), heat transfer fluid temperature andheat transfer fluid flowrate shall also be reported.5.7 Rain penetration test5.7.1 ObjectiveThis test is applicable only for glazed collectors and is intended to assess the extent to which glazedcollectors are substantially resistant to rain penetration. They shall normally not permit the entry ofeither free-falling rain or driving rain. Collectors may have ventilation holes and drain holes, but theseshall not permit the entry of drifting rain.5.7.2 Apparatus and procedure5.7.2.1 GeneralThe collector shall have its fluid inlet and outlet pipes sealed (unless hot water is circulated through theabsorber, see 5.7.2.2), as shown in figure A.10, and be placed in a test rig at the shallowest angle to thehorizontal recommended by the manufacturer. If this angle is not specified, then the collector shall beplaced at a tilt of 30° to the horizontal or less. Collectors designed to be integrated into a roof structureshall be mounted in a simulated roof and have their underside protected. Other collectors shall bemounted in a conventional manner on an open frame or a simulated roof.The collector shall be sprayed on all sides from above perpendicular to the horizontal, using spraynozzles or showers.5.7.2.2 Detection of ingress of waterThe collector shall be mounted and sprayed as explained above while the absorber in the collector iskept warm (minimum 50 °C). This can be done either by circulating hot water at about 50 °C throughthe absorber or by exposing the collector to solar radiation. The penetration of water into the collectorshall be determined by inspection (looking for water droplets, condensation on the cover glass or othervisible signs) and by one of the following methods:a) by weighing the collector (minimum accuracy of scale ±1 gr); orb) by means of humidity measurement; orc) by means of measuring the condensation level.SIST EN 12975-2:2002

Page 16EN 12975-2:2001The heating up of the collector should be started before the spraying of the water in order to ensure thatthe collector box is dry before testing.5.7.3 Test conditionsThe collector shall be sprayed with water at a temperature lower than 30 °C with a flowrate of morethan 0,05 kg/s per square metre of sprayed area. The duration of the test shall be 4 h. If the weighingmethod is chosen, the collector shall be put on the scale before the start of the test on three consecutiveoccasions.

The weights recorded shall not vary by more than ±1 gr.5.7.4 ResultsThe collector shall be inspected for water penetration. The results of the inspection, i.e. the extensionof water penetration and the places where water penetrated shall be reported.5.8 Freeze resistance test5.8.1 ObjectiveThis test is intended to assess the extent to which water heating collectors which are claimed to befreeze resistant can withstand freezing, and freeze/thaw cycling. This test is not intended for use withcollectors for which it is clearly stated in the installation manual that they may only be used with anantifreeze fluid.Two test procedures are recommended:- one for collectors which are claimed to be freeze-resistant when filled with water, and- one for collectors which are claimed to resist freezing after being drained.5.8.2 Apparatus and procedure5.8.2.1 Freeze-resistant collectorsFor collectors which are claimed to be able to withstand freezing, the collector shall be mounted in acold chamber (see figure A.11). The collector shall be fitted correctly, shut completely and inclined atthe shallowest angle to the horizontal recommended by the manufacturer. If no angle is specified by themanufacturer, then the collector shall be inclined at an angle of 30° to the horizontal. Unglazedcollectors shall be tested in a horizontal position unless this is excluded by the manufacturer. Next, thecollector shall be filled with water at the operating pressure.The cold-chamber temperature shall be cycled, and at the end of each cycle the collector shall berefilled with water at operating pressure.The temperature of the water shall be monitored throughout the test.5.8.2.2 Collectors with drain-down protectionFor collectors which employ a drain-down system to protect them from freezing damage, the collectorshall be mounted in a cold chamber (see figure A.11). The collector shall be then inclined at theshallowest angle to the horizontal recommended by the manufacturer. If no angle is specified by themanufacturer, then the collector shall be inclined at an angle of 30° to the horizontal. Unglazedcollectors shall be tested in a horizontal position unless this is excluded by the manufacturer. Thecollector shall be next filled with water, kept at operating pressure for 10 min and then drained usingthe device installed by the manufacturer.SIST EN 12975-2:2002

Page 17EN 12975-2:2001If, 5 min after the start of the drain process, the amount of drained water from the collector correspondsto approximately 95 % of the total water which filled that collector, then in that case, no test in coldchamber is required.The cold-chamber temperature shall be cycled.The temperature shall be measured inside the absorber close to the inlet.After the last cycle the collector shall be refilled with water at operating pressure.5.8.3 Test conditionsThe contents of the absorber shall be maintained at (-20 ± 2) °C for at least 30 min during the freezingpart of the cycle, and are raised to above 10 °C during the thawing part of the cycle. The duration of thethawing part of the cycle shall be at least 30 min.The collector shall be subjected to three freeze-thaw cycles.5.8.4 ResultsThe number of cycles carried out shall be reported. The collector shall be inspected for leakage,breakage, distortion and deformation. These shall be reported together with the absorber temperaturesreached during the cycles and the times spent by the collector at the test temperatures. The tilt angleused for the test shall also be reported.5.9 Mechanical load test5.9.1 Positive pressure test of the collector cover5.9.1.1 ObjectiveThis test is intended to assess the extent to which the transparent cover of the collector is able to resistthe positive pressure load due to the effect of wind and snow.5.9.1.2 Apparatus and procedureThe collector shall be placed horizontally on an even ground. On the collector a foil shall be laid andon the collector frame a wooden or metallic frame shall be placed, high enough to contain the requiredamount of gravel or similar material (see figure A.12).The gravel, preferably type 2-32 mm, shall be weighed in portions and distributed in the frame so thateverywhere the same load is created (pay attention to the bending of the glass), until the wanted heightis reached.The test can also be carried out installing the collector in accordance with 5.9.2.2 and loading the coverusing suction cups, gravel or other suitable means (e.g. water).As a further alternative, the necessary load may be created by applying an air pressure on the collectorcover.5.9.1.3 Test conditionsThe test pressure shall be increased in steps of 100 Pa to the recommended maximum test pressure,which shall be at least 1000 Pa or optional load test above 1000 Pa up to the value as specified bymanufacturer.SIST EN 12975-2:2002

Page 18EN 12975-2:20015.9.1.4 ResultsThe pressure at which any failure of the collector cover occurs shall be reported together with details ofthe failure. If no failure occurs, then the maximum pressure which the collector sustained shall bereported.5.9.2 Negative pressure test of fixings between the cover and the collector box5.9.2.1 ObjectiveThis test is intended to assess the extent to which the fixings between the collector cover and collectorbox are able to resist uplift forces caused by the wind.5.9.2.2 Apparatus and procedureThe collector shall be installed horizontally on a stiff frame by means of its mounting fixtures. Theframe which secures the cover to the collector box shall not be restricted in any way.A lifting force which is equivalent to the specified negative pressure load, shall be applied evenly overthe cover. The load shall be increased in steps up to the final test pressure. If the cover has not beenloosened at the final pressure, then the pressure may be stepped up until failure occurs. The timebetween each pressure step shall be the time needed for the pressure to stabilise.Either of two alternative methods may be used to apply pressure to the cover:-Method (a): The load may be applied to the collector cover by means of a uniformly distributed setof suction cups (see figure A.13).-Method (b): For collectors which have an almost airtight collector box, the following procedure maybe used to create a negative pressure on the cover (see figure A.14). Two holes are made through thecollector box into the airgap between the collector cover and absorber, and an air source andpressure gauge are connected to the collector airgap through these holes. A negative pressure on thecover is created by pressurising the collector box. For safety reasons the collector shall be encasedin a transparent box to protect personnel in the event of failure during this test.During the test, the collector shall be visually inspected and any deformations of the cover and itsfixings reported. The collector shall be examined at the end of the test to see if there are any permanentdeformations.Test method (a) is not designed to check the strength of the collector mounting fixtures. If a glass coverfails before the fixings which hold the cover to the collector box, then the pressure at which the failureoccurred shall be noted. If the cover fails again then it shall be concluded that the collector isinadequately designed and the test need not be continued.5.9.2.3 Test conditionsThe test pressure shall be increased in steps of 100 Pa to the recommended maximum test pressure.The maximum test pressure may be specified to suit particular climatic conditions, otherwise a value of1000 Pa shall be used.5.9.2.4 ResultsAny deformations observed during the inspection shall be reported together with the pressure at whichany failure of the cover or cover fixings was observed. Details of the failures shall also be reported. Ifno failure occurs, then the maximum pressure which the collector sustained shall be reported.SIST EN 12975-2:2002

Page 19EN 12975-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...