EN 13445-8:2006

(Main)Unfired pressure vessels - Part 8: Additional requirements for pressure vessels of aluminium and aluminium alloys

Unfired pressure vessels - Part 8: Additional requirements for pressure vessels of aluminium and aluminium alloys

This Part 8 of this European Standard specifies requirements for unfired pressure vessels and their parts made of aluminium and aluminium alloys in addition to the general requirements for unfired pressure ves-sels under EN 13445:2002 Parts 1 to 5. This European Standard specifies unfired pressure vessels for loads up to 500 full cycles.

NOTE Cast materials are not included in this version. Details regarding cast materials will be subject to an amendment to or a revision of this European Standard.

Unbefeuerte Druckbehälter - Teil 8: Zusätzliche Anforderungen an Druckbehälter aus Aluminium und Aluminiumlegierungen

Dieser Teil 8 der Europäischen Norm legt zusätzlich zu den allgemeinen Anforderungen an unbefeuerte

Druckbehälter nach EN 13445:2002, Teile 1 bis 5, Anforderungen an aus Aluminium und Aluminiumlegie-rungen

hergestellte unbefeuerte Druckbehälter und deren Bauteile fest. Diese Europäische Norm gilt für unbe-feuerte

Druckbehälter für Druckbelastungen bis zu 500 vollen Lastzyklen.

ANMERKUNG Gusswerkstoffe sind in der vorliegenden Fassung nicht enthalten. Angaben zu Gusswerkstoffen werden

in einer Ergänzung bzw. Überarbeitung dieser Europäischer Norm aufgenommen.

Récipients sous pression non soumis à la flamme - Partie 8 : Exigences complémentaires pour les récipients sous pression en aluminium et alliages d'aluminium

La présente partie 8 de cette norme européenne spécifie les exigences relatives aux récipients sous pression non

soumis à la flamme et à leurs composants en aluminium et alliages d’aluminium, en complément des exigences

générales énoncées dans les parties 1 à 5 de l’EN 13445 :2002. La présente norme européenne concerne les

récipients sous pression non soumis à la flamme pouvant aller jusqu’à 500 cycles complets de chargement.

NOTE Les matériaux moulés ne sont pas inclus pour l’instant. Des détails relatifs aux matériaux moulés feront l’objet d’un

amendement ou à une révision de la présente norme européenne.

Neogrevane tlačne posode – 8. del: Dodatne zahteve za tlačne posode iz aluminija in aluminijevih zlitin

General Information

- Status

- Withdrawn

- Publication Date

- 10-Oct-2006

- Withdrawal Date

- 21-Jul-2009

- Technical Committee

- CEN/TC 54 - Unfired pressure vessels

- Drafting Committee

- CEN/TC 54/WG 54 - D - Manufacture

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 22-Jul-2009

- Completion Date

- 22-Jul-2009

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 25-Jul-2009

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 13445-8:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Unfired pressure vessels - Part 8: Additional requirements for pressure vessels of aluminium and aluminium alloys". This standard covers: This Part 8 of this European Standard specifies requirements for unfired pressure vessels and their parts made of aluminium and aluminium alloys in addition to the general requirements for unfired pressure ves-sels under EN 13445:2002 Parts 1 to 5. This European Standard specifies unfired pressure vessels for loads up to 500 full cycles. NOTE Cast materials are not included in this version. Details regarding cast materials will be subject to an amendment to or a revision of this European Standard.

This Part 8 of this European Standard specifies requirements for unfired pressure vessels and their parts made of aluminium and aluminium alloys in addition to the general requirements for unfired pressure ves-sels under EN 13445:2002 Parts 1 to 5. This European Standard specifies unfired pressure vessels for loads up to 500 full cycles. NOTE Cast materials are not included in this version. Details regarding cast materials will be subject to an amendment to or a revision of this European Standard.

EN 13445-8:2006 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13445-8:2006 has the following relationships with other standards: It is inter standard links to EN 13445-8:2009, EN ISO 13710:2004, EN 378-2:2008+A2:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13445-8:2006 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13445-8:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Unfired pressure vessels - Part 8: Additional requirements for pressure vessels of aluminium and aluminium alloysRécipients sous pression non soumis a la flamme - Partie 8 : Exigences complémentaires pour les récipients sous pression en aluminium et alliages d'aluminiumUnbefeuerte Druckbehälter - Teil 8: Zusätzliche Anforderungen an Druckbehälter aus Aluminium und AluminiumlegierungenTa slovenski standard je istoveten z:EN 13445-8:2006SIST EN 13445-8:2007en23.020.30MHNOHQNHPressure vessels, gas cylindersICS:SLOVENSKI

STANDARDSIST EN 13445-8:200701-marec-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13445-8October 2006ICS 23.020.30 English VersionUnfired pressure vessels - Part 8: Additional requirements forpressure vessels of aluminium and aluminium alloysRécipients sous pression non soumis à la flamme - Partie 8: Exigences complémentaires pour les récipients souspression en aluminium et alliages d'aluminiumUnbefeuerte Druckbehälter - Teil 8: ZusätzlicheAnforderungen an Druckbehälter aus Aluminium undAluminiumlegierungenThis European Standard was approved by CEN on 14 July 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13445-8:2006: E

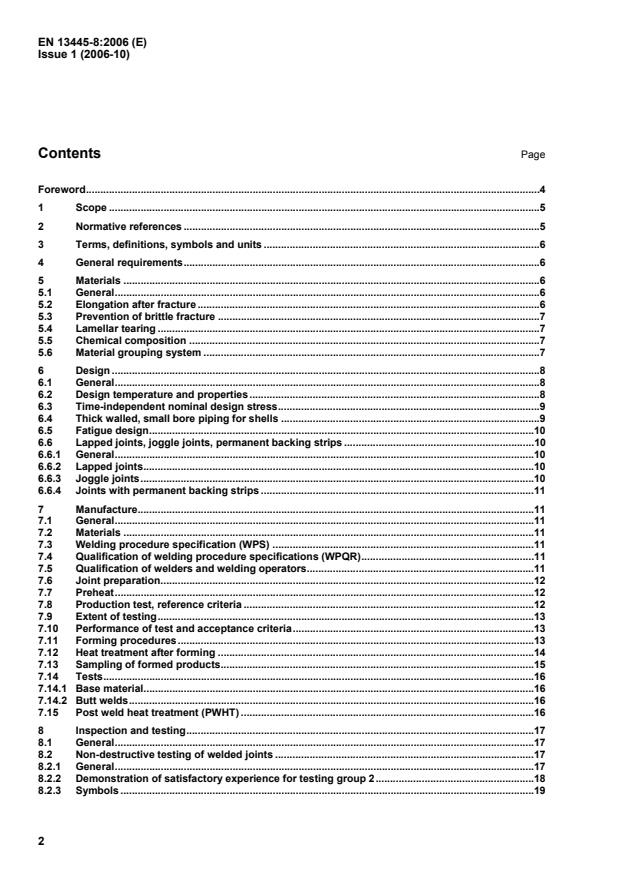

Relationship between this European Standard and the Essential

Requirements of EU Directive 97/23/EC.26 Bibliography.27

Cast materials are not included in this version. Details regarding cast materials will be subject to an amendment to or a revision of this European Standard. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 571-1, Non-destructive testing — Penetrant testing — Part 1: General principles EN 573-3, Aluminium and aluminium alloys — Chemical composition and form of wrought products — Part 3: Chemical composition EN 583-4, Non-destructive testing — Ultrasonic examination — Part 4: Examination for discontinuities perpendicular to the surface EN 970, Non-destructive examination of fusion welds — Visual examination EN 1289:1998, Non-destructive examination of welds — Penetrant testing of welds — Acceptance levels EN 1435:1997, Non-destructive examination of welds — Radiographic examination of welded joints EN 1712, Non-destructive examination of welds — Ultrasonic examination of welded joints — Acceptance levels

EN 1714, Non-destructive examination of welds — Ultrasonic examination of welded joints EN 12062:1997, Non-destructive examination of welds — General rules for metallic materials EN 12392:2000, Aluminium and aluminium alloys — Wrought products — Special requirements for products intended for the production of pressure equipment EN 13445-1:2002, Unfired pressure vessels — Part 1: General EN 13445-2:2002, Unfired pressure vessels — Part 2: Materials EN 13445-3:2002, Unfired pressure vessels — Part 3: Design EN 13445-4:2002, Unfired pressure vessels — Part 4: Fabrication EN 13445-5:2002, Unfired pressure vessels — Part 5: Inspection and testing

EN ISO 6520-1, Welding and allied processes — Classification of geometric imperfections in metallic materials — Part 1: Fusion welding (ISO 6520-1:1998) EN ISO 9606-2, Qualification test of welders — Fusion welding — Part 2: Aluminium and aluminium alloys (ISO 9606-2:2004) EN ISO 10042:2005, Welding — Arc-welded joints in aluminium and its alloys — Quality levels for imperfections (ISO 10042:2005) EN ISO 15614-2, Specification and qualification of welding procedures for metallic materials — Welding procedure test — Part 2: Arc welding of aluminium and its alloys (ISO 15614-2:2005) CEN ISO/TR 15608, Welding — Guidelines for a metallic materials grouping system (ISO/TR 15608:2005) 3 Terms, definitions, symbols and units For the purposes of this document, the terms, definitions, symbols and units given in EN 13445:2002 Parts 1 to 5 apply. NOTE Further symbols are listed in 8.2.3. 4 General requirements The general requirements of EN 13445-1 shall apply. 5 Materials 5.1 General The requirements of EN 13445-2 shall apply with the following additions/exclusions. 5.2 Elongation after fracture NOTE Also see 4.1.4 of EN 13445-2:2002. Aluminium and aluminium alloys used for welded parts of pressure vessels that are subjected to cold forming (e.g. rolled shells and heads) shall have a specified minimum elongation after fracture measured on a gauge length ooSL65,5= (5.2-1) that is ≥ 14 % in the longitudinal or transverse direction as defined by the material specification. Aluminium and aluminium alloys used for parts of pressure vessels that are not subjected to cold forming (e.g. straight flanges and nozzles) shall have a specified minimum elongation after fracture measured on a gauge length ooSL65,5= (5.2-2) that is ≥ 10 % in the longitudinal or transverse direction as defined by the material specification.

Table 5.6-1 below.

aluminium alloys EN AW number Chemical symbol Temper 21

Pure aluminium with ≤ 1 % impurities or alloy content EN AW — 1050A EN AW — 1070A EN AW — 1080A

EN AW-Al 99,5 EN AW-Al 99,7 EN AW-Al 99,8(A) O, H111, H112 O, H111, H112 O, H111, H112 Non heat treatable alloys 22.1 Aluminium-manganese alloys EN AW — 3003

EN AW — 3103 EN AW — 3105 EN AW-Al Mn1Cu EN AW-Al Mn1 EN AW-Al Mn0,5Mg0,5 O, H111, H112 O, H111, H112 O, H111

22.2 Aluminium-magnesium alloys with Mg ≤ 1,5 % EN AW — 5005 EN AW — 5005A EN AW — 5050 EN AW-Al Mg1(B) EN AW-Al Mg1(C) EN AW-Al Mg1,5(C) O, H111, H112 O, H111, H112 O, H111 22.3 Aluminium-magnesium alloys with 1,5 % < Mg ≤ 3,5 % EN AW — 5049 EN AW — 5052 EN AW — 5154A EN AW — 5251 EN AW — 5454 EN AW — 5754 EN AW-Al Mg2Mn0,8 EN AW-Al Mg2,5 EN AW-Al Mg3,5(A) EN AW-Al Mg2 EN AW-Al Mg3Mn(A) EN AW-Al Mg3 O, H111, H112 O, H111, H112 O, H111, H112 O, H111, H112 O, H111, H112 O, H111, H112 22 22.4 Aluminium-magnesium alloys with Mg > 3,5 % EN AW — 5083 EN AW — 5086 EN AW-Al Mg4,5Mn0,7 EN AW-Al Mg4 O, H111, H112 O, H111

Heat treatable alloys 23 23.1 Aluminium-magnesium-silicon alloys EN AW — 6060 EN AW — 6061 EN AW-Al MgSi EN AW-Al Mg1SiCu T4 a T4 b, T6 c a for profiles only b for seamless pipes and flanges only c for flanges only 6 Design 6.1 General The requirements of EN 13445-3 shall apply with the following additions/exclusions. 6.2 Design temperature and properties NOTE Also see 4.2.2 of EN 13445-2:2002. The 2nd paragraph of 4.2.2.1 of EN 13445-2:2002 is not applicable for aluminium and its alloys. The maximum design temperature shall not exceed that defined in Table 1 of EN 12392:2000 as the maximum working temperature. The mechanical properties used for design shall be taken from the tabulated values in EN 12392 at room temperature for Rm/20 and at the highest design temperature for Re/t.

temper (T4 or T6). For aluminium and aluminium alloys values of 0,2 % proof strength (or 1 % proof strength for material

group 21-1000 series aluminium) for temperatures above 20 °C shall be established by linear interpolation between two adjacent values in EN 12392 except that for alloys 5083 and 5086 the respective value at 50 °C may be used for 65 °C. 6.3 Time-independent nominal design stress The design stress for aluminium and aluminium alloy materials shall be in accordance with the Table 6.3-1. Table 6.3-1 — Design Stresses for aluminium and aluminium alloy material Group according to Table 5.6-1 Design stresses at design condition Design stresses at test condition 21 f = [Rp1,0,t

/ 1,5] ftest = [Rp1,0,20

/ 1,05] 22 f = min ( [Rp0,2,t

/ 1,5]; [Rm,20 / 2,4] ) ftest = [Rp0,2, 20

/ 1,05] 23 f = min ( [Rp0,2,t

/ 1,5]; [Rm,20 / 3]

ftest = [Rp0,2, 20

/ 1,05]

Table 6.3-2 — Allowable Design Stress values for 6000 series Aluminium alloys in the welded condition (see 6.2) Value of f for design temperature (°C) not exceeding Material designation to EN 12392 50 75 100 125 150 175 200

EN AW 6060 40 40 40 38 36 22 14

EN AW 6061 55 55 55 54 51 43 32

6.4 Thick walled, small bore piping for shells Equation 6.4-1 and 6.4-2 may be used as an alternative to Annex B and C in EN 13445-3:2002 for thick-walled piping of aluminium and aluminium alloy materials, i.e. for piping with e/De > 0,16 and DN ≤ 50. The maximum allowable pressure shall be used for design. Limit Load Procedure pd < PS (6.4-1) This maximum allowable pressure can be determined as follows: /1,5ln32iOp0,2⋅⋅=DDRPS (6.4-2) NOTE The method proposed is the standard design method for vaporisers upstream a cryogenic pressure tank. These vaporisers are small bore piping (DN ≤ 50) with comparable thick wall thickness (e/De typically ranges from 0,23 to 0,33 or De/Di from 2,7 to 1,8).

NOTE This will be subject to a future revision of or an amendment to this Part 8. 6.6 Lapped joints, joggle joints, permanent backing strips 6.6.1 General The requirements of 5.7.4 in EN 13445-3:2002 are not applicable for pressure vessels of aluminium and aluminium alloys, and 5.7.4.1, 5.7.4.2, and 5.7.4.3.1 shall be replaced with the following 6.6.2, 6.6.3, and 6.6.4, respectively. 6.6.2 Lapped joints Lapped joints with fillet welds shall be used only when all of the following conditions are fulfilled: a) only testing group 4 is permitted; b) the materials are limited to material groups 21, 22.1, 22.2, 22.3, 22.4; c) for circumferential joints of shell to head only; d) the nominal wall thickness of the thickest pressure part does not exceed 8 mm; e) the overlap shall be minimum 4e, where e represents the nominal thickness of the thickest pressure part; f) both sides of the lap are welded; g) the maximum vessel diameter does not exceed 1 600 mm; h) non-corrosive conditions only are permitted. 6.6.3 Joggle joints Joggle joints shall be used only when all of the following conditions are fulfilled: a) the materials are limited to material groups 21, 22.1, 22.2, 22.3, and 22.4 (except 5454); b) for circumferential joints of shell to head only; c) the nominal wall thickness of the thickest pressure part does not exceed 12 mm; d) the inside of the vessel is not subject to corrosion; e) the intersections between longitudinal and circumferential joints shall be radiographed and found to be free of unacceptable imperfections; f) the maximum vessel diameter does not exceed 1 600 mm.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...