prEN 3-7

(Main)Portable fire extinguishers - Part 7: Characteristics, performance requirements and test methods

Portable fire extinguishers - Part 7: Characteristics, performance requirements and test methods

This document specifies the characteristics, performance requirements and test methods for portable fire extinguishers.

Reference to the suitability of an extinguisher for use on gaseous fires (Class C fires) are at the manufacturer’s discretion but are applied only to powder type extinguishers which have gained a Class B or Class A and Class B rating.

Suitability of extinguishers for use on Class D fires (fires involving flammable metals) is outside the scope of this document in respect of test fires. However, extinguishers claiming Class D suitability are covered in all other respects by the requirements in this document for powder extinguishers.

It is considered hazardous for powder and carbon dioxide fire extinguishers to be used on Class F fires. For this reason, powder and carbon dioxide fire extinguishers are excluded for conformance with regard to Class F in this document.

NOTE The extinction of a metal fire presents a situation so specific (in terms of the metal itself, its form, the configuration of the fire etc.) that it is not possible to define a representative standard fire for the purposes of testing. The efficiency of extinguishers on Class D fires is established on a case by case basis.

Tragbare Feuerlöscher - Teil 7: Eigenschaften, Leistungsanforderungen und Prüfungen

Dieses Dokument legt die Eigenschaften, Leistungsanforderungen und Prüfverfahren für tragbare Feuerlöscher fest.

Eine Angabe zur Eignung eines Feuerlöschers für den Einsatz bei Gasbränden (Brandklasse C) liegt im Ermessen des Herstellers und gilt nur für Pulver-Feuerlöscher, die die Mindestanforderungen an das Löschvermögen für die Brandklasse B oder Brandklasse A und B erreicht haben.

Die Eignung von Feuerlöschern für die Brandklasse D (Brände von Metallen) liegt nur im Hinblick auf die Prüfobjekte außerhalb des Anwendungsbereiches dieses Dokuments. Alle anderen Anforderungen dieses Dokuments an Pulver-Feuerlöscher gelten auch für Feuerlöscher, die die Eignung für die Brandklasse D beanspruchen.

Der Einsatz von Pulver- und Kohlendioxid-Feuerlöschern bei Bränden der Brandklasse F wird als gefährlich erachtet. Aus diesem Grund sind Pulver- und Kohlendioxid-Feuerlöscher von der Übereinstimmung hinsichtlich der Brandklasse F in diesem Dokument ausgenommen.

ANMERKUNG Das Ablöschen eines Metallbrandes stellt eine derartige Besonderheit dar (in Bezug auf das Metall selbst, seine Form, die Brandentwicklung usw.), dass es nicht möglich ist, ein repräsentatives Prüfobjekt festzulegen. Das Löschvermögen für ein Prüfobjekt der Brandklasse D ist Gegenstand von besonderen Falluntersuchungen.

Extincteurs d'incendie portatifs - Partie 7: Caractéristiques, performances et méthodes d'essai

Le présent document spécifie les caractéristiques, exigences de performances et les méthodes d’essai pour les extincteurs d’incendie portatifs.

La mention de l’utilisation possible d’un extincteur pour des foyers gazeux (feux de classe C) est laissée à la discrétion du fabricant, mais n’est possible que pour des extincteurs à poudre qui ont obtenu des foyers-types sur feux de classe B ou sur feux de classes A et B.

L’aptitude des extincteurs à être utilisés sur les feux de classe D (feux impliquant des métaux inflammables) ne fait pas partie du domaine d’application du présent document en ce qui concerne les foyers-types. En revanche, tous les autres aspects des extincteurs déclarés utilisables sur les feux de classe D sont couverts par les exigences du présent document pour les extincteurs à poudre.

Il est considéré comme dangereux d’utiliser des extincteurs à poudre ou au dioxyde de carbone sur les feux de classe F. Pour cette raison, le présent document exclut de procéder à l’évaluation de la conformité des extincteurs à poudre ou au dioxyde de carbone par rapport à la classe F.

NOTE L’extinction d’un feu de métaux présente une situation spécifique (en termes du métal lui-même, de sa forme, de la configuration du feu, etc.) au point qu’il n’est pas possible de définir un feu type représentatif pour les besoins de l’essai. L’efficacité des extincteurs sur les feux de la classe D doit être évaluée au cas par cas.

Prenosni gasilniki - 7. del: Lastnosti, zahteve za delovanje in preskusne metode

General Information

- Status

- Not Published

- Publication Date

- 28-Apr-2027

- Technical Committee

- CEN/TC 70 - Manual means of fire fighting equipment

- Drafting Committee

- CEN/TC 70/WG 5 - Revision of EN 3

- Current Stage

- 4060 - Closure of enquiry - Enquiry

- Start Date

- 24-Jul-2025

- Due Date

- 05-Mar-2026

- Completion Date

- 24-Jul-2025

Relations

- Effective Date

- 30-Mar-2022

Overview

The prEN 3-7:2025 standard, titled Portable Fire Extinguishers - Part 7: Characteristics, Performance Requirements and Test Methods, is developed by the European Committee for Standardization (CEN). This technical document specifies the essential characteristics, performance criteria, and rigorous test methods applicable to portable fire extinguishers. prEN 3-7:2025 serves as a fundamental requirement for manufacturers, testing laboratories, and regulatory bodies ensuring the quality and safety of portable fire extinguishers.

This standard supersedes the previous version EN 3-7:2004+A1:2007 and forms part of a broader series (EN 3) that addresses aspects such as construction, pressure resistance, mechanical testing, and conformity evaluations.

Key Topics

Scope and Classification

- Defines performance requirements for portable fire extinguishers.

- Reference to suitability for extinguishing Class C (gaseous) fires is limited to powder extinguishers with Class A or Class B ratings.

- Class D fires (flammable metals) are outside the scope in terms of fire testing due to the complexity of metal fires; however, powder extinguishers claiming Class D suitability must meet other requirements.

- Powder and CO2 extinguishers are considered hazardous for Class F fires (cooking oils and fats) and are excluded for those ratings.

Technical Characteristics and Testing

- Detailed specifications for internal pressure, discharge control, operating temperature range, and maximum mass.

- Test methods cover fire performance across Class A, B, and F fires, duration of operation, residual charge, and discharge control reliability.

- Evaluation of hose assemblies, control valves, safety devices, and pressure indicators to ensure functional integrity.

Corrosion Resistance and Material Compatibility

- Requirements for resistance against external corrosion and interaction with extinguishing media.

- Use of standard test methods such as ISO 9227 salt spray tests.

Marking and Identification

- Guidelines for extinguisher coloring and clear marking to ensure easy identification and compliance with safety protocols.

Applications

Manufacturers and Designers

- Use prEN 3-7:2025 as a guide to design and produce portable fire extinguishers that meet stringent European performance and safety requirements.

- Ensures that products can reliably extinguish specified fire classes, maximizing safety.

Testing Laboratories and Certification Bodies

- Apply defined test methods and performance criteria to verify extinguisher compliance before market release.

- Facilitate conformity assessments aligning with European regulatory frameworks.

End-Users and Safety Managers

- Select appropriate fire extinguishers tailored for specific fire risks like Class A, B, or F fires with confidence in tested performance.

- Understand limitations regarding use on Class C and Class D fires for safety considerations.

Regulatory Authorities

- Adopt EN 3-7 as part of national standardization to harmonize firefighting equipment safety across member states.

- Ensure product certification and usage comply with regulations to enhance fire safety.

Related Standards

EN 3-8: Requirements for Construction and Mechanical Testing

- Complements prEN 3-7 by specifying construction, pressure resistance, and mechanical testing for extinguishers with maximum pressure ≤ 30 bar.

EN 3-9: Additional Pressure Resistance Requirements for CO2 Extinguishers

- Specifies pressure-related additional criteria for carbon dioxide extinguishers to enhance safety.

EN 3-10: Conformity Assessment Procedures

- Details provisions for evaluating conformity of portable fire extinguishers against performance standards such as prEN 3-7.

ISO 9227: Corrosion Tests in Artificial Atmospheres

- Provides standardized salt spray test methods referenced for corrosion resistance evaluation in portable extinguishers.

EN 615: Specifications for Powder Extinguishing Media

- Defines powder quality requirements ensuring compatibility and effectiveness in powder-type extinguishers covered by prEN 3-7.

Keywords: portable fire extinguishers, fire extinguisher standards, prEN 3-7, performance requirements, test methods, Class A fire, Class B fire, Class C fire, Class D fire, Class F fire, fire safety equipment, European fire extinguishing standards, CEN standards, extinguisher testing, fire extinguisher performance, corrosion resistance, fire extinguisher certification.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

prEN 3-7 is a draft published by the European Committee for Standardization (CEN). Its full title is "Portable fire extinguishers - Part 7: Characteristics, performance requirements and test methods". This standard covers: This document specifies the characteristics, performance requirements and test methods for portable fire extinguishers. Reference to the suitability of an extinguisher for use on gaseous fires (Class C fires) are at the manufacturer’s discretion but are applied only to powder type extinguishers which have gained a Class B or Class A and Class B rating. Suitability of extinguishers for use on Class D fires (fires involving flammable metals) is outside the scope of this document in respect of test fires. However, extinguishers claiming Class D suitability are covered in all other respects by the requirements in this document for powder extinguishers. It is considered hazardous for powder and carbon dioxide fire extinguishers to be used on Class F fires. For this reason, powder and carbon dioxide fire extinguishers are excluded for conformance with regard to Class F in this document. NOTE The extinction of a metal fire presents a situation so specific (in terms of the metal itself, its form, the configuration of the fire etc.) that it is not possible to define a representative standard fire for the purposes of testing. The efficiency of extinguishers on Class D fires is established on a case by case basis.

This document specifies the characteristics, performance requirements and test methods for portable fire extinguishers. Reference to the suitability of an extinguisher for use on gaseous fires (Class C fires) are at the manufacturer’s discretion but are applied only to powder type extinguishers which have gained a Class B or Class A and Class B rating. Suitability of extinguishers for use on Class D fires (fires involving flammable metals) is outside the scope of this document in respect of test fires. However, extinguishers claiming Class D suitability are covered in all other respects by the requirements in this document for powder extinguishers. It is considered hazardous for powder and carbon dioxide fire extinguishers to be used on Class F fires. For this reason, powder and carbon dioxide fire extinguishers are excluded for conformance with regard to Class F in this document. NOTE The extinction of a metal fire presents a situation so specific (in terms of the metal itself, its form, the configuration of the fire etc.) that it is not possible to define a representative standard fire for the purposes of testing. The efficiency of extinguishers on Class D fires is established on a case by case basis.

prEN 3-7 is classified under the following ICS (International Classification for Standards) categories: 13.220.10 - Fire-fighting. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 3-7 has the following relationships with other standards: It is inter standard links to EN 3-7:2004+A1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 3-7 is associated with the following European legislation: EU Directives/Regulations: 2008/68/EC; Standardization Mandates: M/TDG. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 3-7 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2025

Nadomešča:

SIST EN 3-7:2004+A1:2008

Prenosni gasilniki - 7. del: Lastnosti, zahteve za delovanje in preskusne metode

Portable fire extinguishers - Part 7: Characteristics, performance requirements and test

methods

Tragbare Feuerlöscher - Teil 7: Eigenschaften, Leistungsanforderungen und Prüfungen

Extincteurs d'incendie portatifs - Partie 7: Caractéristiques, performances et méthodes

d'essai

Ta slovenski standard je istoveten z: prEN 3-7

ICS:

13.220.10 Gašenje požara Fire-fighting

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

May 2025

ICS 13.220.10 Will supersede EN 3-7:2004+A1:2007

English Version

Portable fire extinguishers - Part 7: Characteristics,

performance requirements and test methods

Extincteurs d'incendie portatifs - Partie 7: Tragbare Feuerlöscher - Teil 7: Eigenschaften,

Caractéristiques, performances et méthodes d'essai Leistungsanforderungen und Prüfungen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 70.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 3-7:2025 E

worldwide for CEN national Members.

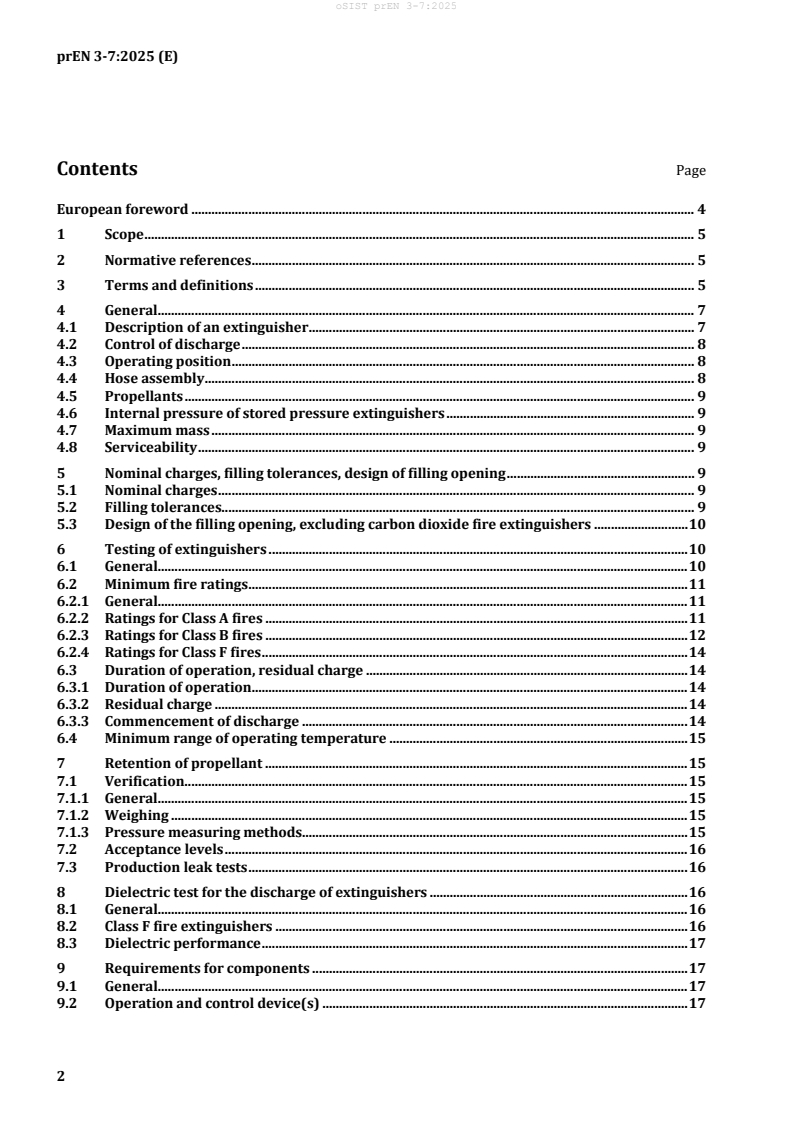

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 General. 7

4.1 Description of an extinguisher . 7

4.2 Control of discharge . 8

4.3 Operating position . 8

4.4 Hose assembly . 8

4.5 Propellants . 9

4.6 Internal pressure of stored pressure extinguishers . 9

4.7 Maximum mass . 9

4.8 Serviceability . 9

5 Nominal charges, filling tolerances, design of filling opening . 9

5.1 Nominal charges . 9

5.2 Filling tolerances. 9

5.3 Design of the filling opening, excluding carbon dioxide fire extinguishers . 10

6 Testing of extinguishers . 10

6.1 General. 10

6.2 Minimum fire ratings . 11

6.2.1 General. 11

6.2.2 Ratings for Class A fires . 11

6.2.3 Ratings for Class B fires . 12

6.2.4 Ratings for Class F fires . 14

6.3 Duration of operation, residual charge . 14

6.3.1 Duration of operation. 14

6.3.2 Residual charge . 14

6.3.3 Commencement of discharge . 14

6.4 Minimum range of operating temperature . 15

7 Retention of propellant . 15

7.1 Verification . 15

7.1.1 General. 15

7.1.2 Weighing . 15

7.1.3 Pressure measuring methods. 15

7.2 Acceptance levels . 16

7.3 Production leak tests . 16

8 Dielectric test for the discharge of extinguishers . 16

8.1 General. 16

8.2 Class F fire extinguishers . 16

8.3 Dielectric performance . 17

9 Requirements for components . 17

9.1 General. 17

9.2 Operation and control device(s) . 17

9.3 Safety devices . 17

9.4 Hose, hose connectors and nozzle . 18

9.4.1 General . 18

9.4.2 Hose resistance test . 18

9.5 Control valve . 18

10 Means of pressure indication . 19

10.1 Pressure gauge . 19

10.2 Pressure indicator . 20

11 Horns for carbon dioxide extinguishers . 20

12 Extinguisher wall bracket . 21

13 Resistance to corrosion . 21

13.1 Resistance to external corrosion/deterioration . 21

13.2 Resistance to extinguishing medium of extinguishers using water based and gaseous

extinguishing media . 22

13.3 Material compatibility . 22

14 Fire performance . 22

14.1 General . 22

14.2 Class A fire rating . 22

14.3 Class B fire rating . 22

14.4 Class F fire rating . 22

15 Extinguisher identification . 23

15.1 Colour . 23

15.2 Marking . 23

16 Maintenance . 27

17 Documentation . 27

Annex A (normative) Duration of operation, residual charge tests . 28

Annex B (normative) Range of operating temperature . 29

Annex C (normative) Dielectric test . 30

Annex D (normative) Operation and emission control mechanisms/devices . 32

Annex E (normative) Test for performance of the hose . 33

Annex F (normative) Control valve test . 34

Annex G (normative) Test on the horn . 35

Annex H (normative) Resistance to corrosion . 36

Annex I (normative) Fire tests . 37

Annex J (normative) Measurement of moisture content of wood . 49

Annex K (normative) Compaction/shock procedure . 50

Annex L (normative) . 52

Bibliography . 53

European foreword

This document (prEN 3-7:2025) has been prepared by Technical Committee CEN/TC 70 “Manual means

of firefighting equipment”, the secretariat of which is held by AFNOR.

This document will supersede EN 3-7:2004+A1:2007.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

EN 3 consists of the following parts, under the general title "Portable fire extinguishers":

— Part 7: Characteristics, performance requirements and test methods

— Part 8: Requirements for the construction, pressure resistance and mechanical tests for extinguishers

with a maximum allowable pressure equal to or lower than 30 bar, which comply with the

requirements of EN 3-7

— Part 9: Additional requirements to EN 3-7 for pressure resistance of CO extinguishers

— Part 10: Provisions for evaluating the conformity of a portable fire extinguisher to EN 3-7

1 Scope

This document specifies the characteristics, performance requirements and test methods for portable

fire extinguishers.

Reference to the suitability of an extinguisher for use on gaseous fires (Class C fires) are at the

manufacturer’s discretion but are applied only to powder type extinguishers which have gained a

Class B or Class A and Class B rating.

Suitability of extinguishers for use on Class D fires (fires involving flammable metals) is outside the

scope of this document in respect of test fires. However, extinguishers claiming Class D suitability are

covered in all other respects by the requirements in this document for powder extinguishers.

It is considered hazardous for powder and carbon dioxide fire extinguishers to be used on Class F fires.

For this reason, powder and carbon dioxide fire extinguishers are excluded for conformance with

regard to Class F in this document.

NOTE The extinction of a metal fire presents a situation so specific (in terms of the metal itself, its form, the

configuration of the fire etc.) that it is not possible to define a representative standard fire for the purposes of

testing. The efficiency of extinguishers on Class D fires is established on a case by case basis.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 9227, Corrosion tests in artificial atmospheres — Salt spray tests

ISO 657-1, Hot-rolled steel sections — Part 1: Equal-leg angles — Dimensions

ISO 4470, Sawn timber — Determination of the average moisture content of a lot

EN 615, Fire protection — Fire extinguishing media — Specifications for powders (other than class D

powders)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

fire extinguisher

appliance containing an extinguishing medium which can be expelled by the action of internal pressure

and be directed on to a fire in a controlled manner

Note 1 to entry: This pressure can be stored pressure or pressure produced by the release of an auxiliary gas

from a cartridge.

Note 2 to entry: Pay attention consistency with EN 1866-1.

3.2

portable fire extinguisher

fire extinguisher which is designed to be carried and operated by hand and which is in working order

having a mass of not more than 20 kg

Note 1 to entry: Throughout this document it is referred to as an “extinguisher”.

3.3

gaseous extinguishing medium

volatile gaseous fire extinguishing medium that does not leave a residue upon evaporation

3.4

body

part of the extinguisher that contains a pressurised extinguishing media immediately prior to discharge

including all pressure retaining materials and permanent joints, but excluding any detachable

accessories, such as hoses, valves and closures

3.5

extinguishing medium

substance contained in the extinguisher intended to extinguish a fire

3.6

charge

mass or volume of the extinguishing medium contained in the extinguisher, expressed as a volume (in

litres) for water-based extinguishers and as a mass (in kilograms) for other extinguishers

Note 1 to entry: Propellants are not considered to be part of the charge.

3.7

water-based extinguisher

extinguisher containing either water, water with additive(s)

Note 1 to entry: This also includes foam and wet chemical.

3.8

powder extinguisher

extinguisher containing fire extinguishing powder

3.9

carbon dioxide extinguisher

extinguisher containing carbon dioxide

3.10

gaseous media extinguisher

extinguisher containing a gaseous extinguishing medium excluding CO (may be referred to as clean

agents)

3.11

duration of operation

time during which the extinguishing medium is discharged with the valve fully open without

interruption not including discharge of residual gas

Note 1 to entry: Pay attention consistency with EN 1866-1.

3.12

residual charge

quantity of medium remaining after continuous complete discharge including all propellant gas

3.13

pressure at maximum operating temperature

P (T ) pressure experimentally measured

max

pressure measured in the extinguisher after stabilisation during at least 24 h at maximum operating

temperature and for cartridge operated extinguishers, the maximum pressure is the maximum pressure

recorded for 0,5 s during a period of three minutes, excluding the first second after release of the

propellant gas

Note 1 to entry: Pay attention consistency with EN 1866-1.

3.14

pressure at minimum operating temperature P(T )

min

pressure measured in the extinguisher after stabilisation during at least 24 h at minimum operating

temperature

Note 1 to entry: This pressure is only measured on stored pressure extinguishers.

3.15

maximum operating temperature

T

max

maximum operating temperature declared by the manufacturer

3.16

minimum operating temperature

T

min

minimum operating temperature declared by the manufacturer

3.17

body cover

a non-pressure bearing cover that covers all or part of the body not including the foot ring/footstand

3.18

clean agent

agent that evaporates after use (excluding water and CO )

Note 1 to entry: Clean is not dealing with environmental or toxicological purposes, regulated by laws.

4 General

4.1 Description of an extinguisher

4.1.1 An extinguisher is categorized by the type of extinguishing medium it contains. At present, there

are:

— water based;

— powder extinguishers;

— carbon dioxide extinguishers;

— gaseous extinguishing media extinguishers included clean agent.

NOTE Examples of such media are given in the EN 15004 series.

Water based extinguishers, containing different proportions of low freeze depressant shall be treated as

separate and distinct models.

4.1.2 An extinguisher consists of the following main components:

a) body with all accessories (see 3.4);

b) body fittings, such as:

— control device(s) with all accessories (see 4.2, 4.3 and 9.1);

— hose assembly (see 4.4 and 9.4) and/or horns and/or nozzles;

— head assembly with all accessories. This also constitutes the main closure (see 5.3);

— operating device with all accessories (see 4.3).

NOTE The head assembly, operating device and control device(s) can be separate or can be incorporated in a

single unit.

c) media (see 4.1.1). For powder extinguisher the media shall be according to EN 615 excluding

powder for Class D extinguishers;

d) propellant or propellant cartridge (see 4.5);

e) mounting bracket (optional);

f) marking and instructions.

4.2 Control of discharge

Extinguishers shall be fitted with a self-closing control valve to enable the discharge to be interrupted

temporarily (see 9.5). A normally open control valve is not allowed.

4.3 Operating position

Extinguishers shall operate without being turned over to an inverted position. The operating device of

an extinguisher shall be located on the top of the extinguisher. A control device at the end of the hose is

permitted. Hand wheel controls of the valve on external propellant cartridges shall be located on the

top 60 % of the extinguisher body.

4.4 Hose assembly

Extinguishers having a mass of extinguishing medium greater than 3 kg, or a volume of extinguishing

medium greater than 3 l shall be provided with a discharge hose.

The discharge hose assembly shall have a flexible section of minimum overall length of 400 mm.

When an extinguisher having a mass of extinguishing medium less than or equal to 3 kg, or a volume of

extinguishing medium less than or equal to 3 l is fitted with a discharge hose, the discharge hose

assembly shall have a flexible section of minimum overall length of 250 mm.

4.5 Propellants

Only propellants listed in Table 1 or mixtures thereof, shall be used. The maximum water content shall

be as specified in Table 1, except when used in stored pressure water-based extinguishers. Tracers may

be added to the propellant to facilitate leakage detection, but the tracer need not be indicated in the

marking.

Table 1 — Permitted propellants

Maximum water content

Propellant

mass fraction, %

Air 0,006

Argon 0,006

Carbon dioxide 0,015

Helium 0,006

Nitrogen 0,006

4.6 Internal pressure of stored pressure extinguishers

Stored pressure extinguishers, except carbon dioxide, shall have a means of continuously indicating the

internal pressure visually. (see 7.1.3.2 and Clause 10).

4.7 Maximum mass

The mass of a fully charged extinguisher shall not exceed 20 kg.

4.8 Serviceability

It shall be possible to open the extinguisher in order to:

— externally and internally inspect the pressure retaining body;

— service and recharge the extinguisher.

5 Nominal charges, filling tolerances, design of filling opening

5.1 Nominal charges

Nominal charges of extinguishers shall be equal to one of the values given in Tables 3 to 8 according to

the nature of the extinguishing medium.

5.2 Filling tolerances

The actual charge of the extinguisher shall be equal to the nominal charge within the tolerances given in

Table 2.

Table 2 — Filling tolerances

Extinguishing medium Relative tolerance

%

Powder

1 kg ± 5

2 kg ± 3

≥ 3 kg ± 2

All other media 0

- 5

5.3 Design of the filling opening, excluding carbon dioxide fire extinguishers

5.3.1 The filling opening shall have a minimum diameter of:

— 20 mm for extinguishers with a charge of less than or equal to 3 kg or 3 l;

— 25 mm for extinguishers with a charge of more than 3 kg or 3 l.

5.3.2 The main closure of the filling opening, intended to be removed during service or maintenance,

shall be provided with an automatic means of venting any residual pressure from the extinguisher. The

initial venting of any residual pressure shall occur when the means of securing the closure, or pressure

retaining part, is disengaged by not more than one third of full engagement.

5.3.3 If the connection between the head and the cylinder is made with thread assembly, the

minimum number of threads to be in full engagement when the extinguisher is fully operational is

three.

6 Testing of extinguishers

6.1 General

Extinguishers for testing shall be stored for at least 24 h at a temperature of (20 ± 5) °C before the tests

are carried out and shall be maintained within this temperature range until tested. Tests shall be

carried out within 5 min of its removal from storage.

Powder extinguishers shall be subjected to the compaction/shock procedure given in Annex K before

the storage period, preceding the duration of operation test, the control valve test, and before the fire

performance test.

All other extinguishers excluded CO shall be subjected to the compaction/shock procedure according

to Annex K only before the storage period preceding the duration of operation test.

NOTE If the compaction process is located in a place following the temperature requirement of the storage

(20 ± 5) °C, the compaction can be performed at any time during the control temperature storage time.

Class D extinguishers are not subject to the requirement of 6.2.

6.2 Minimum fire ratings

6.2.1 General

Fire classes are defined in EN 2.

The minimum fire ratings are specified in Tables 3 to 10, according to the type of extinguishing medium

and the charge.

Fire performance shall be tested in accordance with Clause 14, and the extinguisher shall attain a

Class A rating, a Class B rating, a Class F rating or any combination of these classes of fire, specified in

the relevant table, in accordance with the rating claimed by the manufacturer.

Powder and carbon dioxide fire extinguishers should not be used on Class F fires as their use on this

type of fire is considered hazardous. For this reason, powder and carbon dioxide fire extinguishers shall

neither be tested for Class F capability according to this document nor marked with the “F” use code

symbol.

6.2.2 Ratings for Class A fires

Permitted fire ratings of extinguishers for Class A fires are given in Tables 3, 4 and 5.

NOTE The numbers in the first column of each table refer to the size of the test fire (see Annex I).

Table 3 — Fire ratings, minimum duration of operation and nominal charges

for powder extinguishers

Fire rating Minimum Nominal permitted charges

duration of

operation

s kg

5A 6 1

8A 6 1, 2

13A 9 1, 2, 3, 4

21A 9 2, 3, 4, 6

27A 9 3, 4, 6, 9

34A 12 4, 6, 9

43A 15 6, 9, 12

55A 15 6, 9, 12

Table 4 — Fire ratings, minimum duration of operation and nominal charges for water

based extinguishers

Fire rating Minimum Nominal permitted charges

duration of

operation

s l

5A 6 1, 2, 3

8A 9 1, 2, 3, 6

13A 9 1, 2, 3, 6, 9

21A 9 2, 3, 6, 9

27A 12 3, 6, 9

34A 15 3, 6, 9

43A 15 6, 9

55A 15 6, 9

Table 5 —Fire ratings, minimum duration of operation and nominal charges for gaseous and

clean agent extinguishing mediums extinguishers

Fire rating Minimum Nominal permitted charges

duration of

operation

s l

5A 6 1, 2, 3,4

8A 9 1, 2, 3, 4, 6

13A 9 2, 3, 4, 6, 9

21A 9 3, 4, 6, 9, 12

27A 12 3, 4, 6, 9, 12

34A 15 4, 6, 9, 12

43A 15 6, 9, 12

55A 15 6, 9, 12

6.2.3 Ratings for Class B fires

Permitted fire ratings of extinguishers for Class B fires are given in Tables 6, 7, 8 and 9.

Water based fire extinguishers claiming suitability for use on polar solvent shall additionally pass the

tests specified in Annex I and shall be marked accordingly.

NOTE The numbers in the first column of each table refer to the size of the test fire (see Annex I).

Table 6 —Fire ratings, minimum duration of operation and nominal charges

for powder extinguishers

Fire rating Minimum Nominal permitted charges

duration of

operation

s kg

21B 6 1

34B 6 1, 2

55B 9 1, 2, 3

70B 9 2, 3, 4

89B 9 2, 3, 4

113B 12 2, 3, 4, 6

144B 15 3, 4, 6, 9

183B 15 4, 6, 9, 12

233B 15 4, 6, 9, 12

Table 7 — Fire ratings, minimum duration of operation and nominal charges for water based

extinguishers

Fire rating Minimum Nominal permitted charges

duration of

operation

s l

21B 6 1

34B 6 1, 2

55B 9 1, 2, 3

70B 9 1, 2, 3

89B 9 2, 3

113B 12 2, 3, 6

144B 15 3, 6, 9

183B 15 6, 9

233B 15 6, 9

Table 8 — Fire ratings, minimum duration of operation and nominal charges for CO2

extinguishers

Fire rating Minimum Nominal permitted charges

duration of

operation

s kg

21B 6 2

34B 6 2

55B 9 2, 5

70B 9 5

89B 9 5

113B 12 5

Table 9 — Fire ratings, minimum duration of operation and nominal charges for gaseous and

clean agent extinguishing mediums extinguishers

Fire rating Minimum Nominal permitted charges

duration of

operation

s kg

21B 6 1, 2

34B 6 1, 2,3

55B 9 1, 2, 3, 4

70B 9 1, 2, 3, 4, 6

89B 9 2, 3, 4, 6, 9

113B 12 3, 4, 6, 9, 12

144B 15 3, 4, 6, 9, 12

183B 15 4, 6, 9, 12

233B 15 4, 6, 9, 12

6.2.4 Ratings for Class F fires

Permitted fire ratings of extinguishers for Class F fires are given in Table 10.

NOTE The numbers in the first column of each table refer to the size of the test fire (see Annex I).

Table 10— Fire ratings, minimum duration of operation and nominal charges for F Class

extinguishers

Fire Minimum Nominal

rating duration of permitted

operations charges

s I

5F 6 1, 2

15F 6 1, 2

25F 9 1, 2, 3, 6

40F 12 2, 3, 6, 9

75F 15 2, 3, 6, 9

6.3 Duration of operation, residual charge

6.3.1 Duration of operation

6.3.1.1 Minimum duration

The duration of operation shall be greater than or equal to the appropriate value given in Tables 3 to 10

when the extinguisher is tested according to Annex A after being subjected to the compaction/shock

procedure in accordance with Annex K (see Clause 6).

6.3.1.2 Spread of measurements

When three extinguishers are tested in accordance with Annex A, after being subjected to the

compaction/shock procedure in accordance with Annex K (see Clause 6), the duration of operation of

each extinguisher shall be within 15 % of the average value.

6.3.2 Residual charge

The residual charge (see 3.12) of extinguishing medium shall not be more than 10 % of the nominal

charge when the extinguisher is tested in accordance with Annex A after being subjected to the

compaction/shock procedure in accordance with Annex K (see Clause 6).

6.3.3 Commencement of discharge

When tested in accordance with Annex A, after being subjected to the compaction/shock procedure in

accordance with Annex K, all extinguishers shall operate within 4 s of the control valve being opened.

When testing extinguishers pressurized by a separate action, the control valve shall be operated within

6 s after activation.

6.4 Minimum range of operating temperature

6.3.1 T and T claimed by the manufacturer shall be used for the tests in 6.4.2, 6.4.3 and Annex B.

max min

6.3.2 Extinguishers shall be able to operate between T and T :

max min

— T for all extinguishers shall be 60 °C or higher;

max

— T excluding water-based extinguisher, shall be – 20 °C, - 30 °C or lower;

min

— T for water-based extinguishers shall be + 5 °C, 0 °C, - 5 °C, - 10 °C, - 15 °C, - 20 °C, - 25 °C,

min

- 30 °C or lower. For water extinguishers without any additive T shall be + 5 °C.

min

When tested at T and T temperature limits, in accordance with Annex B, extinguishers shall

max min

conform to the following requirements:

— the discharge shall commence within 10 s of the opening of the control valve;

— except for CO extinguishers, the duration of operation shall be not more than twice the value

established at a temperature of 20 °C. CO extinguishers shall conform to 6.4.3;

— the duration of operation shall be not less than 6s;

— the residual charge shall be not more than 15 % of the nominal charge for extinguishers containing

BC type powder, and not more than 10 % of the nominal charge for extinguishers containing other

media.

6.3.3 The duration of operation of CO extinguishers shall be as follows.

At T the duration of operation shall be not more than the value established at a temperature of 20 °C.

max

At the minimum operating temperature, T , the duration of operation shall be not more than 2,5 times

min

the value established at 20 °C.

7 Retention of propellant

7.1 Verification

7.1.1 General

All extinguishers and propellant cartridges shall be designed in such a way as to permit their retention

of propellant to be checked at regular intervals.

7.1.2 Weighing

The following shall be capable of being checked by weight:

— propellant cartridges;

— CO extinguishers;

— gaseous or clean agent extinguishers.

7.1.3 Pressure measuring methods

7.1.3.1 It shall be possible to check the retention of pressure of a stored pressure extinguisher, with

the exception of carbon dioxide extinguishers, as specified in 7.1.3.1.1. or 7.1.3.1.2.

7.1.3.2. The extinguisher shall be fitted with a pressure gauge conforming to 10.1.

7.1.3.3 The extinguishers shall be fitted with a pressure indicator conforming to 10.2, plus a

connection to enable the internal pressure to be checked directly by an independent apparatus.

Such a connection shall be fitted with a pressure retaining cap and shall communicate directly to the

contents under pressure. Such a pressure retaining cap can be a separate cap or the pressure gauge.

7.2 Acceptance levels

Leakage from an extinguisher, or propellant cartridge, shall not exceed the following:

a) for stored pressure extinguishers a rate less than or equal to 6 % (v/v) of the expanded gas at 20 °C

per year;

NOTE The volume of the expanded gas is the free volume of the gas at 20 °C.

b) for extinguishers and propellant cartridges tested by weighing, a rate of 5 % of the nominal charge

per year;

c) for extinguishers, pressurised only at the moment of operation, after pressurisation a leak

exceeding 5 cm of gas per minute, per kilogram or litre of charge of the extinguisher.

7.3 Production leak tests

All extinguishers and propellant cartridges shall be tested for conformity to 7.2 a) and 7.2 b).

A rate of leakage greater than the limit specified in 7.2 a) or 7.2 b) shall result in the rejection of the

extinguisher or cartridge.

To test for conformity to 7.2 c), samples shall be tested to an appropriate sampling plan.

A rate of leakage greater than the limit specified in 7.2 c) shall result in the rejection of the batch of

extinguishers.

8 Dielectric test for the discharge of extinguishers

8.1 General

The dielectric test, where claimed by the manufacturer, is intended to test water based and clean agent

extinguishers for discharge on live electrical equipment by measurement of the electrical conductivity

of the discharge stream (see Annex C).

Carbon dioxide extinguishers do not need to be subjected to this test.

Where the manufacturer of a powder or a gaseous extinguishing medium declares that it is non-

conductive then it is not required to be submitted to this test.

NOTE 1 Passing the dielectric test is not intended to recommend the use on live electrical equipment but to

limit the risk to the operator in case of such use.

NOTE 2 For the marking requirement see 15.2.

8.2 Class F fire extinguishers

All extinguishers marked as suitable for use on Class F fires shall conform to the requirements of the

dielectric test. See 8.3.

8.3 Dielectric performance

When the extinguisher is in operation and the metallic plate is live, the current between the handle and

earth, and between the nozzle and earth, shall be not more than 0,5 mA at any time during the complete

discharge of the extinguisher.

The test shall be carried out in accordance with Annex C.

9 Requirements for components

9.1 General

With the exception of the safety device specified in 9.3 and the possible release of the hose if fitted, no

component of the fire extinguisher shall require to be mounted, removed or modified before or during

use.

Any action in order to take the extinguisher out of its location (e.g. bracket or cabinet) shall not be taken

into consideration.

9.2 Operation and control device(s)

The activation of the extinguisher shall not depend upon the repetition of a given action on the same

device.

The force or the energy required to activate the operating device(s) shall be no greater than those given

in Table 11 within the whole range of temperature.

Activation means the totality of actions required for pressurization (if the extinguisher is not

permanently under pressure) and the initial release of the extinguishing agent. If a single device can

activate the unit without repetition of movement, it is permissible for the same device to be re-used in

order to control the output. See Annex D.

Table 11 — Force or energy required to activate the operating device(s)

Type of device Maximum force or energy

Force Energy

N J

Finger trigger 100 —

Squeeze grip lever 200 —

a b

Screw down hand wheel 100 —

Strike knob — 2

a

The force shall be measured at the outside edge of the wheel.

b

The maximum rotation of wheel to be 360° to achieve fully opening position.

9.3 Safety devices

Every extinguisher shall be fitted with a safety device.

The safety device shall prevent inadvertent operation. The release of the safety device shall involve an

operation distinct from that of the operating mechanism and shall require a force between the limits of

5 N and 100 N when operated throughout the working temperature range of the extinguisher. Tests for

conformity to these forces shall be carried out at T , 20°C and T .

min max

The safety device shall be so constructed that any unaided manual attempt, using a force or impact

equal to twice the relevant value given in Table 11 to initiate discharge, without first operating this

device, does not deform or break any part of the mechanism in such a way as to prevent the subsequent

discharge of the extinguisher.

The safety device shall also be provided with means to show whether the extinguisher may have been

operated (safety element). This may be in the form of a wire and seal or a mechanism which prevents

re-insertion of the safety element. It shall be possible to see if the safety element has been removed.

9.4 Hose, hose connectors and nozzle

9.4.1 General

The hose, connectors and nozzle shall function throughout the operating temperature range and

coupling systems shall be designed and fitted in such a way that they cannot damage the hose.

The test specified in 9.4.2 shall be carried out on all components of the hose, connectors and nozzle

systems shall be tested up to and including the final discharge orifice. Where a metal threaded nozzle is

used a suitable blanking fitting may be used to fulfil the test requirements. Where a non-metallic nozzle

is present any blanking fitting shall not reinforce and/or aid pressure resistance of the nozzle

9.4.2 Hose resistance test

When tested in accordance with Annex E, the performance of the hose shall conform to a) or b) as

appropriate.

a) For all types except CO extinguishers:

— three times P(T ), the test being carried out at (20 ± 5) °C;

max

— twice P(T ), the test being carried out at (T ± 2) °C and at (T ± 2) °C;

max max min

b) for CO extinguishers:

— 1,5 times P(T ), the test being carried out at (20 ± 5) °C;

max

— 1,25 times P(T ), the test being carried out at (T ± 2) °C and at (T ± 2) °C.

max max min

9.5 Control valve

9.5.1 Extinguishers shall be fitted with a self-closing control valve allowing the discharge of the

extinguishing media to be discontinued. The valve shall be resistant to leakage following the cessation

of the emission as specified in 9.5.2, 9.5.3 or 9.5.4, as applicable.

Testing shall be carried out in accordance with Annex F.

9.5.2 For extinguishers other than 1 kg and 2 kg powder extinguishers and all CO extinguishers the

second value of pressure shall be either, not less than 80 % of the first measured value or not less than

50 % of the pressure measured before opening the control valve.

9.5.3 For 1 kg and 2 kg powder extinguishers the second pressure value shall be not less than 80 % of

the first measured value.

9.5.4 For CO extinguishers the s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...