prEN 15496

(Main)Cycles - Requirements and test methods for cycle locks

Cycles - Requirements and test methods for cycle locks

This document specifies performance requirements and describes test methods for strength, security, function and corrosion resistance of locks for cycles. It also covers certain aspects regarding the safety of the rider of the cycle on which the lock is mounted. This document covers permanently-mounted cycle locks and removable locks.

Fahrräder - Anforderungen und Prüfverfahren für Fahrradschlösser

Dieses Dokument legt Anforderungen an die Leistungsfähigkeit fest und beschreibt die Prüfverfahren hinsichtlich der Festigkeit, Sicherheit, Funktion und Korrosionsbeständigkeit von Fahrradschlössern. Es behandelt auch bestimmte Aspekte im Hinblick auf die Sicherheit des Fahrers, an dessen Fahrrad das Schloss angebracht ist. Dieses Dokument behandelt dauerhaft befestigte und abnehmbare Fahrradschlösser.

Cycles - Exigences et méthodes d'essai pour les antivols pour cycles

Le présent document prescrit les exigences de performance et décrit les méthodes requises pour les essais de résistance, de sécurité, de fonctionnalité et de résistance à la corrosion appliqués aux antivols destinés aux cycles. Le présent document concerne les antivols installés définitivement et les antivols amovibles.

Kolesa - Zahteve in preskusne metode za ključavnice

General Information

- Status

- Not Published

- Publication Date

- 01-May-2024

- Technical Committee

- CEN/TC 333 - Cycles

- Drafting Committee

- CEN/TC 333 - Cycles

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 22-Nov-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

Overview

The European standard prEN 15496:2022 specifies essential requirements and test methods for cycle locks, targeting strength, security, functionality, and corrosion resistance. Developed by the Technical Committee CEN/TC 333 "Cycles," this standard addresses both permanently-mounted and removable locks used to secure bicycles. The document aims to enhance the security level of unattended bicycles while ensuring rider safety and lock durability under practical conditions. Replacing the older EN 15496:2008, this updated standard integrates the latest testing procedures to address evolving lock-picking techniques and mechanical attacks.

Key Topics

Performance Requirements

The standard defines strict criteria for the mechanical and functional performance of cycle locks, focusing on operational unlocking torque, key strength, locking mechanism resistance, and corrosion endurance.Test Methods

Procedures cover a broad range of tests including:- Tensile, torsional, and impact strength tests for lock housings, shackles, and chain components

- Cutting and pulling resistance tests against common attack methods

- Drill resistance testing for locking mechanisms

- Picking resistance evaluations utilizing simulated lock-picking tools

- Corrosion resistance testing through accelerated salt spray exposure

Lock Types Defined

- Permanently-mounted cycle locks (e.g., frame locks) that become integral to the bike

- Removable locks such as padlocks, chain locks, cable locks, and U-shackle locks which can be detached without tools other than a key

Safety Considerations

The standard includes safety requirements to minimize hazards to riders caused by lock design or mounting.Marking and Durability

Requirements for clear, durable markings on locks and keys for identification and traceability purposes, along with durability testing of markings.

Applications

Manufacturers

Designers and producers of cycle locks use this standard to ensure their products meet recognized European security and durability benchmarks, enhancing market acceptance and consumer confidence.Quality Control

Testing laboratories and certification bodies apply the prescribed test methods to evaluate lock models and verify compliance, facilitating standard conformity and performance claims.Retail and Consumers

Retailers benefit from offering locks that adhere to prEN 15496, as the standard helps customers make informed decisions based on proven security levels. Cyclists gain assurance of lock robustness and resistance against common theft tactics.Urban Mobility and Bike-Sharing

Entities managing public bike-sharing schemes or urban cycling infrastructure employ locks complying with this standard to reduce theft rates and maintenance costs.

Related Standards

- EN 1670:2007 – Building hardware corrosion resistance requirements and test methods

- EN 10277:2018 – Technical delivery conditions for bright steel products used in lock components

- EN ISO 9227:2017 – Salt spray tests for evaluating corrosion resistance in artificial atmospheres

- EN ISO 9994:2019 – Safety specifications for lighters, referenced for safety aspects of locking mechanisms

These complementary standards support the robustness, reliability, and safety requirements set out in prEN 15496, addressing material quality, environmental resistance, and operational safety.

By adhering to prEN 15496:2022, stakeholders can ensure cycle locks provide practical and effective security solutions while maintaining longevity and rider safety, fostering confidence in cycle security products throughout Europe and beyond.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

prEN 15496 is a draft published by the European Committee for Standardization (CEN). Its full title is "Cycles - Requirements and test methods for cycle locks". This standard covers: This document specifies performance requirements and describes test methods for strength, security, function and corrosion resistance of locks for cycles. It also covers certain aspects regarding the safety of the rider of the cycle on which the lock is mounted. This document covers permanently-mounted cycle locks and removable locks.

This document specifies performance requirements and describes test methods for strength, security, function and corrosion resistance of locks for cycles. It also covers certain aspects regarding the safety of the rider of the cycle on which the lock is mounted. This document covers permanently-mounted cycle locks and removable locks.

prEN 15496 is classified under the following ICS (International Classification for Standards) categories: 43.150 - Cycles. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 15496 has the following relationships with other standards: It is inter standard links to EN 15496:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 15496 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2022

Kolesa - Zahteve in preskusne metode za ključavnice

Cycles - Requirements and test methods for cycle locks

Fahrräder - Anforderungen und Prüfverfahren für Fahrradschlösser

Cycles - Exigences et méthodes d'essai pour les antivols pour cycles

Ta slovenski standard je istoveten z: prEN 15496

ICS:

43.150 Kolesa Cycles

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

July 2022

ICS 43.150 Will supersede EN 15496:2008

English Version

Cycles - Requirements and test methods for cycle locks

Cycles - Exigences et méthodes d'essai pour les antivols Fahrräder - Anforderungen und Prüfverfahren für

pour cycles Fahrradschlösser

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 333.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 15496:2022 E

worldwide for CEN national Members.

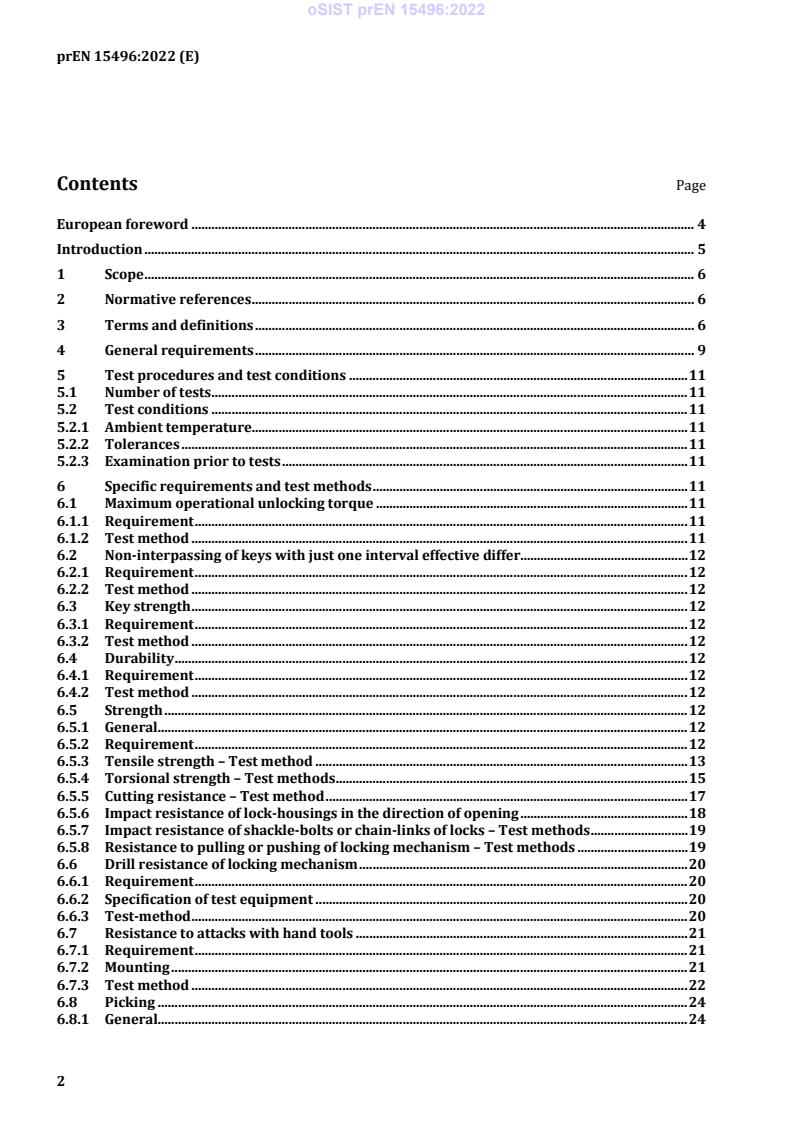

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General requirements . 9

5 Test procedures and test conditions . 11

5.1 Number of tests . 11

5.2 Test conditions . 11

5.2.1 Ambient temperature. 11

5.2.2 Tolerances . 11

5.2.3 Examination prior to tests . 11

6 Specific requirements and test methods . 11

6.1 Maximum operational unlocking torque . 11

6.1.1 Requirement . 11

6.1.2 Test method . 11

6.2 Non-interpassing of keys with just one interval effective differ . 12

6.2.1 Requirement . 12

6.2.2 Test method . 12

6.3 Key strength . 12

6.3.1 Requirement . 12

6.3.2 Test method . 12

6.4 Durability . 12

6.4.1 Requirement . 12

6.4.2 Test method . 12

6.5 Strength . 12

6.5.1 General. 12

6.5.2 Requirement . 12

6.5.3 Tensile strength – Test method . 13

6.5.4 Torsional strength – Test methods . 15

6.5.5 Cutting resistance – Test method . 17

6.5.6 Impact resistance of lock-housings in the direction of opening . 18

6.5.7 Impact resistance of shackle-bolts or chain-links of locks – Test methods . 19

6.5.8 Resistance to pulling or pushing of locking mechanism – Test methods . 19

6.6 Drill resistance of locking mechanism . 20

6.6.1 Requirement . 20

6.6.2 Specification of test equipment . 20

6.6.3 Test-method . 20

6.7 Resistance to attacks with hand tools . 21

6.7.1 Requirement . 21

6.7.2 Mounting . 21

6.7.3 Test method . 22

6.8 Picking . 24

6.8.1 General. 24

6.8.2 Requirement . 25

6.8.3 Test specimens . 25

6.8.4 Test equipment. 25

6.8.5 Test procedure . 25

6.8.6 Evaluation of test results . 26

6.8.7 Additional testing . 26

6.9 Corrosion resistance . 26

6.9.1 Requirement . 26

6.9.2 Test method . 26

7 Marking . 27

7.1 Requirement . 27

7.1.1 Cycle lock . 27

7.1.2 Keys . 27

7.2 Durability test . 27

7.2.1 Requirement . 27

7.2.2 Test method . 27

Annex A (informative) Calculation of m* . 28

Annex B (normative) Dimensions of test stand . 29

Annex C (informative) Photographs of tools specified in Table 2 and Table 3 . 30

Annex D (informative) Photographs of picking tools . 33

European foreword

This document (prEN 15496:2022) has been prepared by Technical Committee CEN/TC 333 “Cycles”,

the secretariat of which is held by UNI.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 15496:2008.

In comparison with the previous edition, the following technical modifications have been made:

— Normative references in Clause 2 have been updated.

Introduction

This document has been developed in response to demand throughout Europe aimed to ensure that

locking systems manufactured in compliance with this standard will offer unattended bicycles a high,

practical level of security. The tests have been designed and evaluated in practical tests by experts in

the lock industry and consideration has been given to the latest techniques employed by professional

cycle-thieves whose methods are constantly changing.

The scope has been limited to security and durability requirements and, to some extent, the safety of

the rider.

1 Scope

This document specifies performance requirements and describes test methods for strength, security,

function and corrosion resistance of locks for cycles. It also covers certain aspects regarding the safety

of the rider of the cycle on which the lock is mounted. This document covers permanently-mounted

cycle locks and removable locks.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1670:2007, Building hardware — Corrosion resistance — Requirements and test methods

EN 10277:2018, Bright steel products — Technical delivery conditions

EN ISO 9227:2017, Corrosion tests in artificial atmospheres — Salt spray tests (ISO 9227:2017)

EN ISO 9994:2019, Lighters — Safety specification (ISO 9994:2018)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

cable lock

cable made of steel wire, in a single or spiral loop, with one end permanently attached to the lock

housing

3.2

chain and lock combination

chain with a detachable lock

3.3

chain lock

chain combined with a padlock or U-shackle lock

3.4

combination lock

lock that can be operated without a key and unlocked by moving parts of the lock in a certain pattern

(combination of movements)

3.5

cycle

any vehicle that has at least two wheels and is propelled solely or mainly by the muscular energy of the

person on that vehicle, in particular by means of pedals

3.6

cycle lock

device which, when locked, is intended to mechanically prevent the use of a bicycle

3.7

depth of incision

depth of transverse notches on the length of a key

3.8

detainer

part of the key mechanism of a locking mechanism which should first be moved by the key into a pre-

determined position before the key can be used for unlocking or locking

3.9

diamond-type frame

traditional type of cycle-frame consisting of a head-tube, a top-tube, a seat-tube, and a down-tube

3.10

key

device, supplied by the manufacturer, for locking and unlocking a lock and that is capable of being used

only through direct physical contact with the lock

3.11

key-operated lock

lock that is operated with a key

3.12

keyway

aperture extending along the whole or part of the length of the plug into which the key is inserted

3.13

key mechanism

part of the mechanism that recognises a correct key

Note 1 to entry: A key mechanism is also used as a synonym to “identification number” (regarding electronic

locks) and “combination code” (for combination locks).

3.14

lock housing

part of the lock containing the key mechanism and blocking mechanism

3.15

locking mechanism

part of the mechanism that is operated by the key mechanism to lock/unlock the lock

3.16

padlock

independent locking device comprising a housing, a key mechanism, a locking mechanism, and a

shackle

3.17

plug

part of the key-mechanism that can be moved when the proper key is used

3.18

permanently-mounted cycle lock

cycle lock that forms one unit (excluding accessories and keys), which is mounted on a cycle and that

can be considered as a permanent part of that cycle

Note 1 to entry: A permanently-mounted lock can also be equipped with accessories such as chains or cables

which can be locked with the same locking unit as that of the permanently-mounted lock.

Note 2 to entry: One of the most common types of lock of this type is the so-called frame lock.

3.19

practical effective differ

difference between key mechanisms of similar design, achieved only by the movable detainers, which

allow each key mechanism to be operated only by its own key

Note 1 to entry: The number of practical effective differs is equal to the number of theoretical differs after

deduction of the differs suppressed by the manufacturer due to technical constraints and deduction of the differs

suppressed by requirements in this document (see Clause 4).

3.20

removable cycle lock

cycle lock that consists of one or more than one unit and that can be used for locking a cycle but that

cannot be considered as a permanent part of that cycle since it is detachable without the use of any

tools other than a key

Note 1 to entry: Removable locks are often used for the connection of a cycle to other cycles or to fixed objects

such as a ground-anchor.

3.21

shackle

part of the lock which passes through and secures the lock fitting

3.22

u-shackle lock

lock housing with a partially or totally detachable shackle in which the legs of the shackle may or may

not be parallel to each other

4 General requirements

NOTE In Table 1, a summary of the requirements and test parameters, specified in this document, is

presented.

Table 1 — Summary of requirements and test parameters

Test parameter Requirement Test Requirement Unit

clause clause value

General requirements 4 -

Maximum operational unlocking torque 6.1.1 6.1.2 1 Nm

Non-interpassing of keys with just one interval 6.2.1 6.2.2 1,5 Nm

effective differ

Key strength 6.3.1 6.3.2 2 Nm

Durability 6.4.1 6.4.2 5000 n

Strength 6.5.2

Tensile strength

U-shackle locks: Tensile strength in the direction of 6.5.2 6.5.3.2.1 30 kN

opening

U-shackle locks: Tensile strength transverse or 6.5.2 6.5.3.2.2 10 kN

inclined to the direction of opening

Other locks 6.5.2 6.5.3.3 10 kN

Torsional strength

U-shackle locks 6.5.2 6.5.4.2 500 Nm

Chains for chain locks 6.5.2 6.5.4.3 500 Nm

Chain and lock combinations 6.5.2 6.5.4.4 500 Nm

Other locks 6.5.2 6.5.4.5 500 Nm

Cutting resistance 6.5.2 6.5.5.2 55 kN

Impact resistance of lock-housings in the 6.5.2 6.5.6 3050 g 5 strokes

direction of opening 1,0 m

–20 °C

Impact resistance of shackle-bolts or chain-links 6.5.2 6.5.7 3050 g 5 strokes

of locks – Test methods 1,0 m

–20 °C

Resistance to pulling or pushing of locking 6.5.2 6.5.8 5 kN

mechanism

Drill resistance of locking mechanism 6.6.1 6.6.3 2 min

Resistance to attacks with hand tools 6.7.1 6.7.3 180 seconds

Picking 6.8.2 6.8.5 228 m*

Corrosion resistance 6.9.1 6.9.2

Marking 7.1 7.2

4.1 A cycle lock shall be so designed that when it is mounted according to the manufacturer’s

instructions and locked, it shall fulfil all of the following requirements:

a) cycle cannot be either ridden or pushed along in a normal way and the rotation of at least one

wheel is prevented, and

b) it is not possible to remove the lock by detaching a part of the cycle that is easy to detach and attach

(e.g. a wheel or a seat-post), and

c) it is not possible to remove or unlock it by deforming a part of the cycle (e.g. the front fork or the

seat-stays) unless such deformation prevents the future normal use of the cycle.

4.2 For safety reasons, it shall not be possible for a permanently-mounted cycle lock or for a

removable cycle lock, when mounted according to the manufacturer’s instructions, to interfere with the

normal and safe use of the cycle.

4.3 For the requirements in subclauses 4.3.1 to 4.3.5 deviations from the requirements are permitted

if the same level of security can be achieved with other solutions. The assessment of any other such

solutions shall be presented in the test report.

4.3.1 The key mechanism shall have at least five active detainers.

4.3.2 The key shall be provided with at least three different depths of incision.

4.3.3 Only 60 % of the number of blocking elements shall be permitted to have the same incision.

When the 60 % value does not result in a whole number, the immediately lower whole number shall

apply

4.3.4 Not more than two equal, adjacent blocking elements shall be permitted.

4.3.5 The lock shall have a minimum number of practical effective differs (n), thus:

a) for key- operated locks: 2 500 with a minimum of 1 000 per keyway

b) for combination locks: 9 000

c) for key-operated electronic locks: 50 000

d) for electronic locks operated by a remote device: 100 000. After each operation, the receiver shall

require a new code, generated in a random pattern, in order to operate again.

4.4 Combination locks and electronic locks shall be so designed that it is not possible to determine

the correct code by visually inspecting external scratches or marks after 500 times of opening and

closing the lock.

4.5 Cycle locks shall be so designed that it is not possible to determine the correct code by visual

inspection through the key-hole or other openings.

4.6 All locks except combination locks shall be delivered with at least two, but not more than four,

keys or remote devices.

4.7 A permanently-mounted key-operated cycle lock shall be so designed that the locking is positive,

i.e. the key shall not be removable from the lock until the blocking element of the shackle is in the

blocked and locked position.

4.8 Electronic locks shall have a function that makes the lock capable of preventing opening by

random or systematic generation and transmission of codes. An example of such a function is a time-

delay function that blocks reception of further codes for a certain time after each reception of an

incorrect code.

5 Test procedures and test conditions

5.1 Number of tests

Each test specified in 6.1 to 6.6, 6.7.3 and 6.9.2 shall be carried out on a new lock unless otherwise

specified or unless it is without doubt that one test has no influence on the next test.

5.2 Test conditions

5.2.1 Ambient temperature

All tests shall be carried out at an ambient temperature of +20 °C ± 5 °C.

5.2.2 Tolerances

Unless otherwise stated, the following tolerances apply:

Force ±2 %

Torque ±2 %

Mass/weight ±2 %

Dimension ±2 %

Time ±5 s

Temperature ±3 °C

5.2.3 Examination prior to tests

Prior to all tests the test personnel shall have the opportunity to examine the design of an assembled

lock, an unassembled lock, technical drawings and specifications.

6 Specific requirements and test methods

6.1 Maximum operational unlocking torque

6.1.1 Requirement

When tested by the method described in 6.1.2 the lock shall be unlocked at a torque not exceeding

1 Nm ± 0,1 Nm.

6.1.2 Test method

Insert the correct key fully in the lock when it is in the locked position and gradually apply a torque to

the key, turning it in the direction of unlocking. Record the maximum torque value needed in order to

unlock the lock.

6.2 Non-interpassing of keys with just one interval effective differ

6.2.1 Requirement

When tested by the method described in 6.2.2 it shall not be possible to operate the lock with the two

keys differing from the correct key by one interval in the first detainer (the detainer closest to the head

of the key).

6.2.2 Test method

Insert the next closest key fully in the lock when it is in the locked position and gradually apply a torque

to the key, turning it in the direction of unlocking. Increase the torque until a torque of 1,5 Nm ± 0,1 Nm

is applied.

6.3 Key strength

6.3.1 Requirement

When tested in accordance with 6.3.2, the key shall not break under the applied maximum torque of

2 Nm. After the test, the key shall be able to be removed from the lock and re-used to operate the same

lock.

6.3.2 Test method

Insert the correct key fully in the lock, blocked from rotation, and apply a torque of at least 2 Nm.

6.4 Durability

6.4.1 Requirement

When tested by the method described in 6.4.2 the lock shall retain its normal function.

6.4.2 Test method

Open and close the lock 5 000 times with the correct key or combination. Withdraw and insert any key

after each locking.

6.5 Strength

6.5.1 General

If a lock is of a type that should be subjected to a certain type of test, but is designed in such a way that it

is impossible to apply the particular test, the lock shall be exempted from that test. Such an exemption

shall be stated in the test report.

Strength tests shall, unless otherwise stated, be performed only with directions and positions of forces

that can be used in practice during the theft of a cycle. Of these directions and positions, those which the

test engineer considers most likely to open the lock shall be used.

6.5.2 Requirement

When tested by the methods described in 6.5.3, 6.5.4, 6.5.5, 6.5.6, and 6.5.7 the lock shall not break.

When tested by the method described in 6.5.8, the essential part of the locking mechanism shall not

completely detach from the lock.

6.5.3 Tensile strength – Test method

6.5.3.1 General

Permanently mounted cycle locks with a maximum inner dimension less than 150 mm shall not be

subjected to the tests in 6.5.3.2.

6.5.3.2 U-shackle locks

6.5.3.2.1 Tensile strength in the direction of opening

Secure the body of the lock in a mounting device and ensure that the mounting device does not affect

the test result.

Gradually apply a force F, as shown in Figure 1, to the lock in the opening direction until the lock breaks

or until a force of 30 kN is achieved and retained for 1 min, whichever occurs first.

For application of the force, use devices, as shown in Figure 1, with a diame

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...