EN 14165:2004

(Main)Space engineering standards - Fracture control

Space engineering standards - Fracture control

This standard specifies the fracture control requirements to be imposed on space systems.

The requirements contained in this standard, when implemented, also satisfy the requirements applicable to the NASA STS and ISS as defined in the NASA document NSTS 1700.7 (incl. the ISS Addendum). Since this standard and the NASA document NSTS 1700.7 (incl. the ISS Addendum) are subject to different independent approval authorities, and recognizing that possible changes to documents may occur in the future, the user of this standard is advised to confirm the current status.

NOTE The definitions used in this standard are based on ECSS nomenclature and are given in clause 3. The NASA nomenclature differs in some cases from that used by ECSS. When STS-specific requirements and nomenclature are included, they are identified as such.

Raumfahrttechnik - Überwachung des Rissfortschritts

Ingénierie Spatiale - Maîtrise de la rupture

Standardi v vesoljski tehniki – Kontrola razpok

General Information

- Status

- Withdrawn

- Publication Date

- 27-Apr-2004

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/SS T02 - Aerospace

- Drafting Committee

- CEN/SS T02 - Aerospace

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Aug-2014

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 20-Aug-2014

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 14165:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Space engineering standards - Fracture control". This standard covers: This standard specifies the fracture control requirements to be imposed on space systems. The requirements contained in this standard, when implemented, also satisfy the requirements applicable to the NASA STS and ISS as defined in the NASA document NSTS 1700.7 (incl. the ISS Addendum). Since this standard and the NASA document NSTS 1700.7 (incl. the ISS Addendum) are subject to different independent approval authorities, and recognizing that possible changes to documents may occur in the future, the user of this standard is advised to confirm the current status. NOTE The definitions used in this standard are based on ECSS nomenclature and are given in clause 3. The NASA nomenclature differs in some cases from that used by ECSS. When STS-specific requirements and nomenclature are included, they are identified as such.

This standard specifies the fracture control requirements to be imposed on space systems. The requirements contained in this standard, when implemented, also satisfy the requirements applicable to the NASA STS and ISS as defined in the NASA document NSTS 1700.7 (incl. the ISS Addendum). Since this standard and the NASA document NSTS 1700.7 (incl. the ISS Addendum) are subject to different independent approval authorities, and recognizing that possible changes to documents may occur in the future, the user of this standard is advised to confirm the current status. NOTE The definitions used in this standard are based on ECSS nomenclature and are given in clause 3. The NASA nomenclature differs in some cases from that used by ECSS. When STS-specific requirements and nomenclature are included, they are identified as such.

EN 14165:2004 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14165:2004 has the following relationships with other standards: It is inter standard links to EN 16603-32-01:2014, EN 13291-2:2003, EN 14101:2001, EN 13291-3:2003, EN 16602-40:2018, EN 16602-10-09:2020, EN 13701:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14165:2004 is associated with the following European legislation: Standardization Mandates: M/237. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14165:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Standardi v vesoljski tehniki – Kontrola razpokRaumfahrttechnik - Überwachung des RissfortschrittsIngénierie Spatiale - Maîtrise de la ruptureSpace engineering standards - Fracture control49.140Vesoljski sistemi in operacijeSpace systems and operationsICS:Ta slovenski standard je istoveten z:EN 14165:2004SIST EN 14165:2004en01-september-2004SIST EN 14165:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14165April 2004ICS 49.140English versionSpace engineering standards - Fracture controlIngénierie Spatiale - Maîtrise de la ruptureRaumfahrttechnik - Überwachung des RissfortschrittsThis European Standard was approved by CEN on 27 February 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14165:2004: ESIST EN 14165:2004

1) ECSS-E-30-01A.SIST EN 14165:2004

The definitions used in this standard are based on ECSS nomenclature and are given in clause 3.The NASA nomenclature differs in some cases from that used by ECSS. When STS-specific requirementsand nomenclature are included, they are identified as such.2Normative referencesThis European Standard incorporates by dated or undated reference, provisions from other publications.These normative references are cited at the appropriate places in the text and the publications are listedhereafter. For dated references, subsequent amendments to or revisions of any of these apply to thisEuropean Standard only when incorporated in it by amendment or revision. For undated references thelatest edition of the publication referred to applies (including amendments).EN 13291-2:2003, Space product assurance — General requirements — Part 2: Quality assurance.EN 13291-3:2003, Space product assurance — General requirements — Part 3: Materials, mechanicalparts and processes.EN 13701:2001, Space systems — Glossary of terms.EN 14097, Space product assurance — Nonconformance control system.EN 14101:2001, Space product assurance — Material selection for controlling stresscorrosion cracking.EN ISO 14620-1, Space systems - Safety requirements - Part 1: System safety (ISO 14620-1:2002).NAS410, Certification and qualification of non-destructive test personnel.MIL-STD-1522A, Standard general requirements for safe design and operation of pressurized missileand space systems.MIL-I-6870, Inspection program requirements, nondestructive, for aircraft and missile materials andparts.MSFC-STD-1249, Standard NDE guidelines and requirements for fracture control programs.NSTS/ISS 13830, Implementation Procedure for NSTS Payload System Safety Requirements.NSTS 1700.7, Safety Policy and Requirements For Payloads Using the Space Transportation System(STS).SIST EN 14165:2004

For payloads of the NASA STS or ISS, the applicable definition is: "A potential risk situation that canresult in personnel injury, loss of the NASA orbiter, ground facilities, or STS equipment (see NSTS 1700.7,paragraph 302)".3.1.7containmenttechnique that, if a part fails, prevents the propagation of failure effects beyond the container boundaries3.1.8crack or crack-like defectdefect that behaves like a crack that is initiated, for example, during material production, fabrication ortesting or developped during the service life of a componentNOTE

The term "crack" in this definition includes flaws, inclusions, pores and other similar defects.3.1.9crack aspect ratiofor a part-through crack, the ratio of crack depth (a) to half crack length (c), i.e. a/c3.1.10crack growth rate (da/dN, dc/dN, da/dt or dc/dt)rate of change of depth a or length c with respect to the number of load cycles N or time tSIST EN 14165:2004

This value is also called the fracture toughness. The parameter KIC is the fracture toughness forplane strain and is an inherent property of the material. For stress conditions other than plane strain, thefracture toughness is denoted KC. In fracture mechanics analyses, failure is assumed to be imminent whenthe applied stress-intensity factor is equal to or exceeds its critical value, i.e. the fracture toughness. See3.1.41.3.1.14cyclic loadingfluctuating load (or pressure) characterized by relative degrees of loading and unloading of a structureNOTE

Examples are loads due to transient responses, vibro-acoustic excitation, flutter and oscillating orreciprocating mechanical equipment.3.1.15damage-tolerantattribute of a structure if the amount of general degradation or the size and distribution of local defectsexpected during operation do not lead to structural degradation below limit-specified performance3.1.16fail safe (structure)damage-tolerance acceptability category in which the structure is designed with sufficient redundancy toensure that the failure of one structural element does not cause general failure of the entire structure3.1.17failure (structural)rupture, collapse, seizure, excessive wear or any other phenomenon resulting in an inability to sustainlimit loads, pressures and environments3.1.18fastenerany item that joins other structural items and transfers loads from one to the other across a joint(see 3.1.23)3.1.19fatiguecumulative irreversible damage in materials and structures incurred by cyclic application of loads ingiven environmentsNOTE

Fatigue can initiate and extend cracks, which degrade the strength of materials and structures.SIST EN 14165:2004

Factors of safety apply to MDP.SIST EN 14165:2004

Payload includes items such as free-flying automated spacecraft, individual experiments andinstruments.3.1.33proof testtest of a flight structure at a proof load or pressure that gives evidence of satisfactory workmanship andmaterial quality or establishes the initial crack sizes in the structure3.1.34Rratio of the minimum stress to maximum stress3.1.35residual stressstress that remains in the structure, owing to processing, fabrication or prior loading3.1.36rotating machineryany rotating mechanical assembly that has a kinetic energy of 19 300 J or moreNOTE

The amount being based on 0,5 Iw2 where I is the moment of inertia (kg/m2) and w is the angularvelocity (rad/s).3.1.37safe lifea fracture-control acceptability category which requires that the largest undetected crack that can exist inthe part does not grow to failure when subjected to the cyclic and sustained loads and environmentsencountered in the service life3.1.38service lifeinterval beginning with an item’s inspection after manufacture and ending with completion of its specifiedlife3.1.39static load (stress)load (stress) of constant magnitude and direction with respect to the structure3.1.40stress corrosion cracking (SCC)initiation or propagation of cracks, owing to the combined action of applied sustained stresses, materialproperties and aggressive environmental effects3.1.41stress intensity factor (K)calculated quantity that is used in fracture mechanics analyses as a measure of the stress-field intensitynear the tip of an idealized crack, calculated for a specific crack size, applied stress level and partgeometry (see 3.1.13)3.1.42thermal load (stress)structural load (or stress) arising from temperature gradients and differential thermal expansion betweenstructural elements, assemblies, subassemblies or itemsSIST EN 14165:2004

In NASA NSTS 1700.7 (Safety Policy and Requirements For Payloads Using the SpaceTransportation System [STS]), the payload structural design is based on fracture control procedures whenthe failure of a STS payload structural item can result in a NASA STS payload catastrophic event.For the implementation of this standard the SI-units and associated symbols system shall be used.The assumptions and prerequisites which are the basis of the requirements contained in this standardare the following:a.All real structural elements contain crack-like defects located in the most critical area of thecomponent in the most unfavourable orientation. The inability of non-destructive inspection (NDI)techniques to detect such defects does not negate this assumption, but merely establishes anupper bound on the initial size of the cracks which result from these defects. For conservatism, thiscrack size then becomes the smallest allowable size to be used in any analysis or assessment.b.After undergoing a sufficient number of cycles at a sufficiently high stress amplitude, materialsexhibit a tendency to initiate fatigue cracks, even in non-aggressive environments.c.Whether, under cyclic or sustained tensile stress, a pre-existing (or load-induced) crack does ordoes not propagate depends on:·fracture toughness of the material;·initial size and geometry of the crack;·presence of an aggressive environment;·geometry of the item;·magnitude and number of loading cycles;·temperature of the material.d.The engineering discipline of linear elastic fracture mechanics provides analytical tools for theprediction of crack propagation and critical crack size.SIST EN 14165:2004

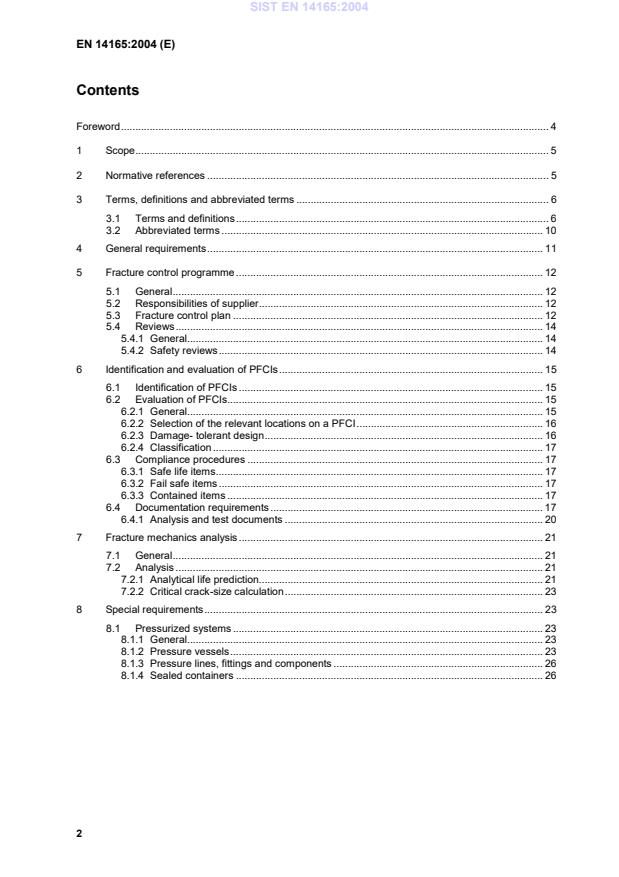

PFCIL(PotentialFracture criticalItem List)Damage-tolerantdesign principle- safe life- fail safeLocationsDesignapproachEvaluationanalysisClassificationDocumentationPressureCompositesRotatingmachineryWeldings,castingsOther structuralitemsFCILFLLILMaintenancemanualItem notfracture

criticalFracture criticalitemFracturelimited-life itemSIST EN 14165:2004

The above three lists may be reported in one document.SIST EN 14165:2004

The software package ESACRACK can be obtained from ESA, Thermal and Structures Division,P.O. Box 299, 2200 AG Noordwijk, The Netherlands.NOTE 2

The flight load spectra distributed with ESACRACK have been derived for payloads of the NSTS,and cannot be used for other structures without adequate verification.b.In cases where it is not planned to use ESACRACK, alternative analysis procedures may be used ifthey are shown to give comparable results. Alternative analysis procedures shall be submitted tothe customer for approval prior to their use.c.A fracture mechanics analysis shall include the following two items:1.crack-growth calculation;2.critical crack-size calculations.7.2.1Analytical life predictionAnalytical life prediction shall be performed on the basis of crack-growth analysis, which includes:a.Identification of all load events experienced by the item in question.The service-life profile shall be clearly defined, in order to identify all cyclic and sustained loadevents. The following events shall be considered:1.manufacturing or assembly;2.testing;3.handling, e.g. by a dolly or a hoist;4.transportation by land, sea and air;5.ascent;6.stay in orbit, including thermally induced loads;7.descent;SIST EN 14165:2004

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...