EN 14101:2001

(Main)Space product assurance - Material selection for controlling stress-corrosion cracking

Space product assurance - Material selection for controlling stress-corrosion cracking

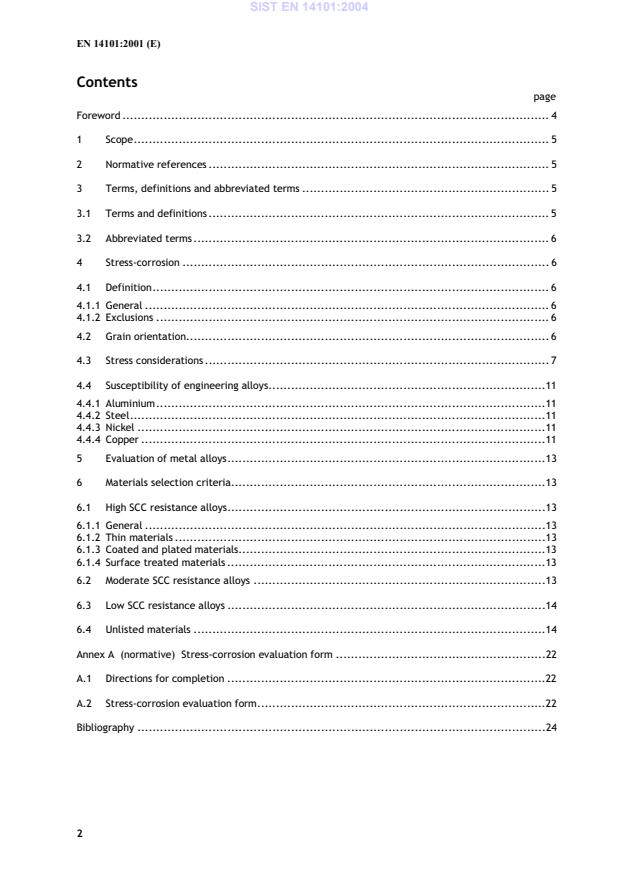

This European Standard sets forth the criteria to be used in the selection of materials for spacecraft and associated equipment and facilities so that failure resulting from stress-corrosion is prevented.

Three categories of materials are listed in Tables 1, 2 and 3 of this Standard. They represent metal alloys with a high, moderate and low resistance to stress-corrosion cracking.

The stress-corrosion susceptibility of alloys included in this Standard was determined at ambient temperature

- by means of laboratory tests in which specimens were either sprayed with salt water or periodically immersed and withdrawn;

- by exposing specimens in sea coast or mild industrial environments;

- by subjecting fabricated hardware to service conditions.

Use of the criteria established herein should, therefore, be limited to designs for service involving similar exposure conditions.

Weldments present a special problem in designing for resistance to stress-corrosion cracking. In addition to the susceptibility of the parent metals, it is also necessary to consider the filler metal and the microstructural effects of heat introduced by the welding operations and subsequent heat treatments. Because of the additional variables that shall be considered, susceptibility data are not as extensive for weldments as for alloys in mill form. Design criteria for weldments in this Standard are limited to aluminium alloys, selected stainless steels in the 300 series and other specific alloys listed in Table 1.

This Standard is intended to provide general criteria to be used in designing for resistance to stress-corrosion cracking. Specific test data and other detailed information are not included.

Raumfahrtproduktsicherung - Kriterien für die Werkstoffwahl zur Vermeidung von Spannungsrisskorrosion

Assurance produit des projets spatiaux - Sélection des matériaux en vue d'éviter leur fissuration par corrosion sous contrainte

La présente Norme européenne présente les critères à utiliser pour permettre de sélectionner les matériaux destinés aux satellites, aux équipements et aux installations associés afin d'éviter toute défaillance due à la fissuration par corrosion sous contrainte.

Dans les Tableaux 1, 2 et 3 de la présente norme, trois catégories de matériaux sont présentées. Ces matériaux sont des alliages de métaux possédant une résistance à la fissuration par corrosion sous contrainte élevée, moyenne et faible.

La susceptibilité des alliages à la fissuration par corrosion sous contrainte dont il est question dans la présente norme a été déterminée à température ambiante par les procédés ci-dessous :

¾ en effectuant des essais en laboratoire : les éprouvettes ont soit été vaporisées d'eau salée, soit régulièrement immergées dans l'eau salée puis retirées ;

¾ en exposant les éprouvettes près d'un littoral ou dans des environnements industriels humides ;

¾ en soumettant le matériel fabriqué aux conditions d'utilisation.

L'utilisation des critères établis dans la présente norme doit, par conséquent, être limitée aux conceptions d'équipements devant fonctionner dans des conditions d'exposition similaires.

Les assemblages soudés présentent un problème particulier dans leur conception quant à la résistance à la fissuration par corrosion sous contrainte. Outre la susceptibilité des métaux de base, il faut également tenir compte du métal d'apport et des effets de la chaleur sur la microstructure entraînés par les opérations de soudage et par les traitements thermiques consécutifs. Du fait des variables supplémentaires à prendre en compte, les données de susceptibilité ne sont pas aussi importantes pour les assemblages soudés que pour les alliages corroyés.

Space product assurance - Material selection for controlling stress-corrosion cracking

General Information

- Status

- Withdrawn

- Publication Date

- 23-Oct-2001

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/SS T02 - Aerospace

- Drafting Committee

- CEN/SS T02 - Aerospace

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 29-Oct-2014

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 05-Nov-2014

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 14101:2001 is a standard published by the European Committee for Standardization (CEN). Its full title is "Space product assurance - Material selection for controlling stress-corrosion cracking". This standard covers: This European Standard sets forth the criteria to be used in the selection of materials for spacecraft and associated equipment and facilities so that failure resulting from stress-corrosion is prevented. Three categories of materials are listed in Tables 1, 2 and 3 of this Standard. They represent metal alloys with a high, moderate and low resistance to stress-corrosion cracking. The stress-corrosion susceptibility of alloys included in this Standard was determined at ambient temperature - by means of laboratory tests in which specimens were either sprayed with salt water or periodically immersed and withdrawn; - by exposing specimens in sea coast or mild industrial environments; - by subjecting fabricated hardware to service conditions. Use of the criteria established herein should, therefore, be limited to designs for service involving similar exposure conditions. Weldments present a special problem in designing for resistance to stress-corrosion cracking. In addition to the susceptibility of the parent metals, it is also necessary to consider the filler metal and the microstructural effects of heat introduced by the welding operations and subsequent heat treatments. Because of the additional variables that shall be considered, susceptibility data are not as extensive for weldments as for alloys in mill form. Design criteria for weldments in this Standard are limited to aluminium alloys, selected stainless steels in the 300 series and other specific alloys listed in Table 1. This Standard is intended to provide general criteria to be used in designing for resistance to stress-corrosion cracking. Specific test data and other detailed information are not included.

This European Standard sets forth the criteria to be used in the selection of materials for spacecraft and associated equipment and facilities so that failure resulting from stress-corrosion is prevented. Three categories of materials are listed in Tables 1, 2 and 3 of this Standard. They represent metal alloys with a high, moderate and low resistance to stress-corrosion cracking. The stress-corrosion susceptibility of alloys included in this Standard was determined at ambient temperature - by means of laboratory tests in which specimens were either sprayed with salt water or periodically immersed and withdrawn; - by exposing specimens in sea coast or mild industrial environments; - by subjecting fabricated hardware to service conditions. Use of the criteria established herein should, therefore, be limited to designs for service involving similar exposure conditions. Weldments present a special problem in designing for resistance to stress-corrosion cracking. In addition to the susceptibility of the parent metals, it is also necessary to consider the filler metal and the microstructural effects of heat introduced by the welding operations and subsequent heat treatments. Because of the additional variables that shall be considered, susceptibility data are not as extensive for weldments as for alloys in mill form. Design criteria for weldments in this Standard are limited to aluminium alloys, selected stainless steels in the 300 series and other specific alloys listed in Table 1. This Standard is intended to provide general criteria to be used in designing for resistance to stress-corrosion cracking. Specific test data and other detailed information are not included.

EN 14101:2001 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14101:2001 has the following relationships with other standards: It is inter standard links to EN 16602-70-36:2014, EN 16601-00-01:2015, EN 13102:2005+A1:2008, EN 14165:2004, EN 14607-5-1:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14101:2001 is associated with the following European legislation: Standardization Mandates: M/237. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14101:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Space product assurance - Material selection for controlling stress-corrosion crackingRaumfahrtproduktsicherung - Kriterien für die Werkstoffwahl zur Vermeidung von SpannungsrisskorrosionAssurance produit des projets spatiaux - Sélection des matériaux en vue d'éviter leur fissuration par corrosion sous contrainteSpace product assurance - Material selection for controlling stress-corrosion cracking49.140Vesoljski sistemi in operacijeSpace systems and operationsICS:Ta slovenski standard je istoveten z:EN 14101:2001SIST EN 14101:2004en01-maj-2004SIST EN 14101:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14101October 2001ICS 49.140English versionSpace product assurance - Material selection for controllingstress-corrosion crackingAssurance produit des projets spatiaux - Sélection desmatériaux en vue d'éviter leur fissuration par corrosion souscontrainteThis European Standard was approved by CEN on 28 September 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2001 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14101:2001 ESIST EN 14101:2004

!"#$000000000000000000000000000SIST EN 14101:2004

=6F69635(0SIST EN 14101:2004

!"#394606F69(4014?=4

=)!!0SIST EN 14101:2004

*, **!/SIST EN 14101:2004

!"#00SIST EN 141

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...