EN 13941-2:2019

(Main)District heating pipes - Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks - Part 2: Installation

District heating pipes - Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks - Part 2: Installation

This European Standard specifies requirements for design, calculation and installation of factory made thermal insulated bonded single and twin pipe systems for directly buried networks for continuous operation with treated hot water at various temperatures up to 120 ºC and occasionally with peak temperatures up to 140 ºC and maximum internal pressure 2,5 MPA. Flexible pipe systems according to EN 15632 are not under the scope of this standard.

The standard EN 13941, Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks consists of two parts:

a) EN 13941-1: Design;

b) EN 13941-2: Installation.

The requirements and stipulations in this part: prEN 13941-2, form an unbreakable unity with those of prEN 13941-1. This part shall therefore exclusively be used in combination with prEN 13941-1.

The principles of the standard may be applied to thermal insulated pipe systems with pressures higher than 2,5 MPa, provided that special attention is paid to the effects of pressure.

Adjacent pipes, not buried, but belonging to the network (e. g. pipes in ducts, valve chambers, road crossings above ground etc.) may be designed and installed according to this standard.

This standard presupposes the use of treated water, which by softening, demineralisation, de-aeration, adding of chemicals, or otherwise has been treated to effectively prevent internal corrosion and deposits in the pipes.

This standard is not applicable for such units as:

a) pumps;

b) heat exchangers;

c) boilers, tanks;

d) systems behind domestic substations.

Fernwärmerohre - Auslegung und Installation von gedämmten Einzel- und Doppelrohr-Verbundsystemen für direkt erdverlegte Heißwasser-Fernwärmenetze - Teil 2: Installation

Dieses Dokument legt Auslegungs-, Berechnungs- und Verlegungsanforderungen für werkmäßig hergestellte, gedämmte Einzel- und Doppelrohrverbundsysteme für erdverlegte Heizwasser-Fernwärmenetze fest, die für den Dauerbetrieb mit aufbereitetem Wasser bei unterschiedlichen Temperaturen bis 120 °C und gelegentlichen Spitzentemperaturen bis 140 °C für höchstens 300 h/a sowie bei maximalem Innendruck von 2,5 MPa vorgesehen sind.

Flexible Rohrsysteme nach EN 15632 liegen nicht im Anwendungsbereich dieser Norm.

Die Norm EN 13941, Auslegung und Installation von gedämmten Einzel- und Doppelrohr-Verbundsystemen für direkt erdverlegte Heizwasser-Fernwärmenetze besteht aus zwei Teilen:

a) EN 13941 1: Auslegung

b) EN 13941 2: Installation

Die Anforderungen in diesem Teil, EN 13941 2, bilden eine Einheit mit jenen aus EN 13941 1.

Die Grundsätze der Norm können auf wärmegedämmte Rohrleitungssysteme mit Drücken über 2,5 MPa angewendet werden, vorausgesetzt, die Auswirkungen dieses höheren Drucks werden besonders beachtet.

Angrenzende Rohre, die zum Netz gehören aber nicht erdverlegt sind (z. B. Rohre in Kanälen, Armaturenschächten, oberirdische Straßenüberquerungen usw.), können entsprechend dieser Norm ausgelegt und verlegt werden.

Die Norm setzt die Verwendung von aufbereitetem Wasser voraus, das durch Enthärtung, Entsalzung, Entlüftung, Zusatz von Chemikalien oder auf andere Art und Weise so behandelt worden ist, dass innere Korrosion und Ablagerungen in den Leitungen effektiv vermieden werden.

ANMERKUNG Für weitere Informationen zu den Qualitäten des in Fernwärmerohrsystemen zu verwendenden Wassers, siehe Literaturhinweis [8].

Dieses Dokument gilt nicht für Geräte bzw. Anlagen, wie z. B.:

a) Pumpen,

b) Wärmetauscher;

c) Kessel, Speicher;

d) Systeme hinter Hausregelstationen.

Tuyaux de chauffage urbain - Conception et installation des systèmes bloqués de tuyaux monotubes et bitubes isolés thermiquement pour les réseaux d’eau chaude enterrés directement - Partie 2 : Installation

La présente Norme européenne spécifie les exigences de conception, de calcul et d'installation de systèmes bloqués de tuyaux monotubes et bitubes isolés thermiquement fabriqués en usine pour les réseaux d'eau chaude enterrés directement pour une exploitation en continu avec de l'eau chaude traitée à différentes températures jusqu'à 120 °C, et occasionnellement avec des pics de température jusqu'à 140 °C et une pression interne maximale de 2,5 MPa. Les systèmes de tuyaux flexibles selon l'EN 15632 ne sont pas couverts par le domaine d'application de la présente Norme.

L'EN 13941, Tuyaux de chauffage urbain — Conception et installation des systèmes bloqués de tuyaux monotubes et bitubes isolés thermiquement pour les réseaux d'eau chaude enterrés directement se compose des deux parties suivantes :

a) EN 13941-1 : Conception ;

b) EN 13941-2 : Installation.

Les exigences et dispositions de la présente partie prEN 13941-2 et celles du prEN 13941-1 constituent un tout indivisible. La présente partie doit donc exclusivement être utilisée conjointement avec le prEN 13941-1.

Les principes de la présente Norme peuvent être appliqués à des systèmes de tuyaux isolés thermiquement avec des pressions supérieures à 2,5 MPa, pourvu qu'il soit porté une attention spéciale aux effets de la pression.

Les tuyaux adjacents, non enterrés, mais appartenant au réseau (par exemple tubes en caniveaux, chambres à vannes, traversées de route en aérien, etc.) peuvent être conçus et installés conformément à la présente Norme.

La présente Norme présuppose l'utilisation d'eau traitée, par adoucissement, déminéralisation, désaération, ajout de substances chimiques, ou par tout autre moyen permettant d'éviter efficacement la corrosion interne et les dépôts dans les tuyaux.

La présente Norme n'est pas applicable aux éléments tels que :

a) pompes ;

b) échangeurs thermiques ;

c) chaudières, réservoirs ;

d) systèmes sous-tendant des sous-stations domestiques.

Cevi za daljinsko ogrevanje - Projektiranje in vgradnja toplotno izoliranih spojenih eno- in dvocevnih sistemov za neposredno zakopana vročevodna omrežja - 2. del: Vgradnja

Ta evropski standard določa zahteve za projektiranje, izračun in vgradnjo tovarniško izdelanih toplotno izoliranih spojenih eno- in dvocevnih sistemov za neposredno zakopana omrežja za neprekinjeno delovanje z obdelano vročo vodo pri različnih temperaturah do 120 °C in občasnih najvišjih temperaturah do 140 °C ter najvišjemu notranjemu tlaku 2,5 MPa. Ta standard ne zajema gibkih cevnih sistemov v skladu s standardom EN 15632.

Standard EN 13941 – Projektiranje in vgradnja toplotno izoliranih spojenih eno- in dvocevnih sistemov za neposredno zakopana vročevodna je sestavljen iz dveh delov:

a) Standard EN 13941-1: Zasnova

b) Standard EN 13941-2: Vgradnja

Zahteve in določbe iz tega dela standarda: prEN 13941-2 tvorijo neločljivo enotnost z zahtevami in določbami standarda prEN 13941-1. Ta del se zato uporablja izključno skupaj s standardom prEN 13941-1.

Načela standarda se lahko uporabljajo za toplotno izolirane cevne sisteme s tlaki, višjimi od 2,5 MPa, če je posebna pozornost namenjena učinkom tlaka.

Sosednje cevi, ki niso zakopane, vendar pripadajo omrežju (npr. cevi v jaških, ventilskih komorah, cestnih prehodih nad tlemi itd.), je mogoče projektirati in vgraditi na podlagi tega standarda.

Ta standard predpostavlja uporabo obdelane vode, ki z mehčanjem, demineralizacijo, razzračevanjem, dodajanjem kemikalij ali z drugo obdelavo učinkovito preprečuje notranjo korozijo in nastajanje oblog na ceveh.

Ta standard se ne uporablja za enote, kot so:

a) črpalke,

b) izmenjevalniki toplote,

c) kotli, rezervoarji,

d) sistemi za domačimi razdelilnimi postajami.

General Information

- Status

- Withdrawn

- Publication Date

- 16-Apr-2019

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 107 - Pre-fabricated district heating pipe systems

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 15-Dec-2021

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 29-Sep-2021

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13941-2:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "District heating pipes - Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks - Part 2: Installation". This standard covers: This European Standard specifies requirements for design, calculation and installation of factory made thermal insulated bonded single and twin pipe systems for directly buried networks for continuous operation with treated hot water at various temperatures up to 120 ºC and occasionally with peak temperatures up to 140 ºC and maximum internal pressure 2,5 MPA. Flexible pipe systems according to EN 15632 are not under the scope of this standard. The standard EN 13941, Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks consists of two parts: a) EN 13941-1: Design; b) EN 13941-2: Installation. The requirements and stipulations in this part: prEN 13941-2, form an unbreakable unity with those of prEN 13941-1. This part shall therefore exclusively be used in combination with prEN 13941-1. The principles of the standard may be applied to thermal insulated pipe systems with pressures higher than 2,5 MPa, provided that special attention is paid to the effects of pressure. Adjacent pipes, not buried, but belonging to the network (e. g. pipes in ducts, valve chambers, road crossings above ground etc.) may be designed and installed according to this standard. This standard presupposes the use of treated water, which by softening, demineralisation, de-aeration, adding of chemicals, or otherwise has been treated to effectively prevent internal corrosion and deposits in the pipes. This standard is not applicable for such units as: a) pumps; b) heat exchangers; c) boilers, tanks; d) systems behind domestic substations.

This European Standard specifies requirements for design, calculation and installation of factory made thermal insulated bonded single and twin pipe systems for directly buried networks for continuous operation with treated hot water at various temperatures up to 120 ºC and occasionally with peak temperatures up to 140 ºC and maximum internal pressure 2,5 MPA. Flexible pipe systems according to EN 15632 are not under the scope of this standard. The standard EN 13941, Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks consists of two parts: a) EN 13941-1: Design; b) EN 13941-2: Installation. The requirements and stipulations in this part: prEN 13941-2, form an unbreakable unity with those of prEN 13941-1. This part shall therefore exclusively be used in combination with prEN 13941-1. The principles of the standard may be applied to thermal insulated pipe systems with pressures higher than 2,5 MPa, provided that special attention is paid to the effects of pressure. Adjacent pipes, not buried, but belonging to the network (e. g. pipes in ducts, valve chambers, road crossings above ground etc.) may be designed and installed according to this standard. This standard presupposes the use of treated water, which by softening, demineralisation, de-aeration, adding of chemicals, or otherwise has been treated to effectively prevent internal corrosion and deposits in the pipes. This standard is not applicable for such units as: a) pumps; b) heat exchangers; c) boilers, tanks; d) systems behind domestic substations.

EN 13941-2:2019 is classified under the following ICS (International Classification for Standards) categories: 23.040.07 - Pipeline and its parts for district heat; 23.040.10 - Iron and steel pipes; 91.140.10 - Central heating systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13941-2:2019 has the following relationships with other standards: It is inter standard links to EN 13941:2009+A1:2010, EN 13941-2:2019+A1:2021, HD 308 S2:2001, EN ISO 15609-2:2019, EN 253:2019+A1:2023, EN ISO 17637:2016, EN 15698-2:2025, EN ISO 3834-1:2021, EN 14419:2009, EN ISO 9606-1:2017, EN 13018:2016, EN ISO 3834-3:2021, EN 448:2025, EN 488-1:2025, EN ISO 11666:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13941-2:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2019

Nadomešča:

SIST EN 13941:2009+A1:2010

Cevi za daljinsko ogrevanje - Projektiranje in vgradnja toplotno izoliranih spojenih

eno- in dvocevnih sistemov za neposredno zakopana vročevodna omrežja - 2. del:

Vgradnja

District heating pipes - Design and installation of thermal insulated bonded single and

twin pipe systems for directly buried hot water networks - Part 2: Installation

Fernwärmerohre - Auslegung und Installation von gedämmten Einzel- und Doppelrohr-

Verbundsystemen für direkt erdverlegte Heizwasser-Fernwärmenetze - Teil 2:

Installation

Tuyaux de chauffage urbain - Conception et installation des systèmes bloqués de tuyaux

préisolés pour les réseaux enterrés d'eau chaude - Partie 2 : Installation

Ta slovenski standard je istoveten z: EN 13941-2:2019

ICS:

23.040.07 Cevovodi za daljinsko Pipeline and its parts for

ogrevanje in njihovi deli district heat

91.140.10 Sistemi centralnega Central heating systems

ogrevanja

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13941-2

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2019

EUROPÄISCHE NORM

ICS 23.040.07; 23.040.10; 91.140.10 Supersedes EN 13941:2009+A1:2010

English Version

District heating pipes - Design and installation of thermal

insulated bonded single and twin pipe systems for directly

buried hot water networks - Part 2: Installation

Tuyaux de chauffage urbain - Conception et installation Fernwärmerohre - Auslegung und Installation von

des systèmes bloqués de tuyaux monotubes et bitubes gedämmten Einzel- und Doppelrohr-Verbundsystemen

isolés thermiquement pour les réseaux d'eau chaude für direkt erdverlegte Heizwasser-Fernwärmenetze -

enterrés directement - Partie 2 : Installation Teil 2: Installation

This European Standard was approved by CEN on 14 December 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13941-2:2019 E

worldwide for CEN national Members.

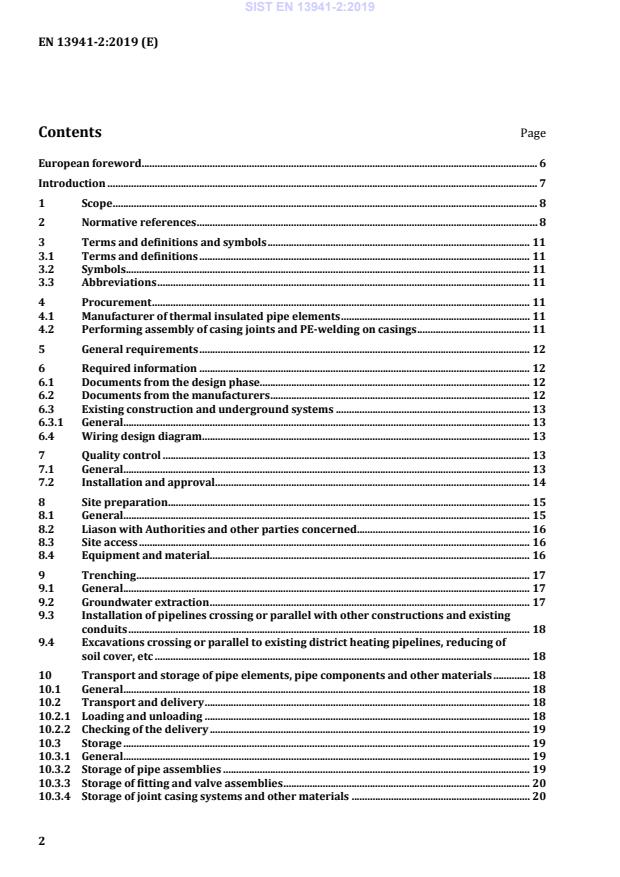

Contents Page

European foreword . 6

Introduction . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions and symbols . 11

3.1 Terms and definitions . 11

3.2 Symbols. 11

3.3 Abbreviations . 11

4 Procurement . 11

4.1 Manufacturer of thermal insulated pipe elements . 11

4.2 Performing assembly of casing joints and PE-welding on casings . 11

5 General requirements . 12

6 Required information . 12

6.1 Documents from the design phase. 12

6.2 Documents from the manufacturers . 12

6.3 Existing construction and underground systems . 13

6.3.1 General . 13

6.4 Wiring design diagram . 13

7 Quality control . 13

7.1 General . 13

7.2 Installation and approval . 14

8 Site preparation . 15

8.1 General . 15

8.2 Liason with Authorities and other parties concerned . 16

8.3 Site access . 16

8.4 Equipment and material . 16

9 Trenching . 17

9.1 General . 17

9.2 Groundwater extraction . 17

9.3 Installation of pipelines crossing or parallel with other constructions and existing

conduits . 18

9.4 Excavations crossing or parallel to existing district heating pipelines, reducing of

soil cover, etc . 18

10 Transport and storage of pipe elements, pipe components and other materials . 18

10.1 General . 18

10.2 Transport and delivery . 18

10.2.1 Loading and unloading . 18

10.2.2 Checking of the delivery . 19

10.3 Storage . 19

10.3.1 General . 19

10.3.2 Storage of pipe assemblies . 19

10.3.3 Storage of fitting and valve assemblies . 20

10.3.4 Storage of joint casing systems and other materials . 20

11 Pipe laying . 20

11.1 General . 20

11.2 Installation in the trench . 21

11.3 Welding and testing of welds . 21

11.3.1 Welding of the steel service pipe and testing of the welds . 21

11.4 Venting and Draining . 30

11.5 Test for leak tightness and strength . 34

11.5.1 General . 34

11.5.2 Visual test with over pressure by air . 34

11.5.3 Visual test below atmospheric pressure by air . 35

11.5.4 Hydrostatic test . 35

11.6 Joint Casing . 39

11.6.1 General . 39

11.6.2 Joints . 39

11.6.3 Site prepared components . 39

11.7 Surveillance system . 42

11.8 Expansion cushions . 43

11.9 Electrical and telecommunication cable of the systems . 45

11.10 Requirements for horizontal directional drilling (HDD) . 45

11.11 Requirements for critical locations . 45

11.11.1 Wall penetrations . 45

11.11.2 Connections to other pipe systems . 46

11.11.3 Pipe laying in protection tubes. 46

11.11.4 Protection against external impact for above ground installations . 46

11.12 Position of pipeline . 46

12 Backfilling . 47

12.1 General . 47

12.2 Bedding material and composition . 48

13 Commissioning . 49

14 Operation. 49

15 Documentation . 49

15.1 Information on operation and maintenance . 49

15.1.1 Range of application . 49

15.1.2 Documentation — aims and uses. 49

15.1.3 Technical documentation . 50

15.1.4 Drawings of the technical documentation . 54

15.1.5 As-built documentation. 58

15.2 Documentation under the scope of the PED . 58

Annex A (informative) Venting and Draining . 59

A.1 General . 59

A.2 Venting and draining devices . 59

A.3 Draining devices for large pipeline dimensions . 61

A.4 Venting of new pipe sections . 62

A.4.1 Venting by house connection pipeline . 62

A.4.2 Venting by venting cabinets . 63

Annex B (informative) Recommendations for HDD . 65

B.1 General . 65

B.2 Depth under roads . 65

B.3 Minimum intermediate distances . 66

B.4 Casing and casing field joints . 66

B.5 Drilling fluid composition . 66

B.6 Drilling fluid pressures . 66

B.7 Borehole dimensions and borehole stability . 67

B.8 Ballasting . 67

B.9 Installation of pipe bundles . 68

B.10 Determination of position and route corrections . 68

B.11 Registration and control of HDD . 69

B.12 Drilling Tolerances . 69

B.13 Verification of design and methodology for the pullback operation . 70

B.14 As-Built information . 70

Annex C (informative) Qualification of fitters installing joints in pre-insulated bonded pipe

networks . 71

C.1 Knowledge and skills . 71

C.2 Background for training and testing . 71

C.3 Subjects for training and testing . 71

C.3.1 General . 71

C.3.2 Casing of polyethylene (PE) . 72

C.3.2.1 Important construction characteristics and properties . 72

C.3.2.2 Technological behaviour of PE . 72

C.3.2.3 Mechanical properties of PE . 72

C.3.2.4 Conditions for casing elements under load . 73

C.3.3 Surveillance . 73

C.3.4 PUR-foam system . 73

C.3.4.1 PUR-foam as a two component material . 73

C.3.4.2 Insulation procedures on job site . 73

C.3.5 Joint types/jointing systems . 74

C.3.5.1 General . 74

C.3.5.2 Shrink sleeve joint with mastic/adhesive sealing . 74

C.3.5.3 Welded joints/systems . 74

C.3.6 Installation of joints . 75

C.3.6.1 General . 75

C.3.6.2 Installation of surveillance system . 75

C.3.6.3 Sealed joints . 76

C.3.6.4 Welded joints . 77

C.3.6.5 Insulation of joints . 77

C.3.6.6 Documentation . 78

Annex D (informative) Quality control program and documentation . 79

Annex E (normative) Commissioning . 91

E.1 Commissioning . 91

E.1.1 General . 91

E.1.2 Filling with water for initial operation . 92

E.1.3 Surveillance system . 92

Annex F (informative) Operation . 93

Bibliography . 94

European foreword

This document (EN 13941-2:2019) has been prepared by Technical Committee CEN/TC 107

“Prefabricated district heating and district cooling pipe systems”, the secretariat of which is held by DS.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2019, and conflicting national standards shall

be withdrawn at the latest by October 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13941:2009+A1:2010.

EN 13941, District heating pipes — Design and installation of thermal insulated bonded single and twin

pipe systems for directly buried hot water networks consists of the following parts:

— Part 1: Design;

— Part 2: Installation.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

Introduction

This document has been prepared by CEN/TC 107/WG 13 „Prefabricated district heating and district

cooling pipe system“.

According to the scope of CEN/TC 107:

— the task of CEN/TC 107/WG 13 is to specify rules for design, calculation and installation for factory

made thermal insulated bonded single and twin pipe systems for directly buried hot water

networks.;

— CEN/TC 107/WG 13 also contributes to rules for functional tests for thermal-insulated bonded pipe

systems for underground hot water networks;

When use is made of the standard, the different sections of which it is made up are to be interpreted as

being interdependent and, because of this, cannot be dissociated.

The revision of EN 13941:2009+A1:2010 involves the subdivision of the document in two separate

documents:

— EN 13941-1, District heating pipes — Design and installation of thermal insulated bonded single and

twin pipe systems for directly buried hot water networks — Part 1: Design;

— EN 13941-2, District heating pipes — Design and installation of thermal insulated bonded single and

twin pipe systems for directly buried hot water networks — Part 2: Installation.

This volume (Part 2) consists of a main part and six annexes.

Annex E is normative. Annexes A, B, C, D, and F are informative.

This standard contains a number of requirements aimed at ensuring the sound execution of distribution

networks for district heating.

The requirements contained in this document should be assessed and applied in compliance with the

intentions of the standard and in due consideration of the development taking place in the field it

concerns. It is therefore assumed that the user of the standard has the requisite technical insight and

that the user of the standard has adequate knowledge of legal and other external regulations that are of

consequence to the practical application of the document.

Some paragraphs of this standard are possibly covered by national regulations in some countries

NOTE

which naturally apply instead of this standard.

1 Scope

This document specifies requirements for design, calculation and installation of factory made thermal

insulated bonded single and twin pipe systems for buried hot water networks for continuous operation

with treated water at various temperatures up to 120 °C and occasionally peak temperatures up to

140 °C for maximum 300 h/a, and maximum internal pressure 2,5 MPa.

Flexible pipe systems according to the EN 15632 series are not under the scope of this standard.

The standard EN 13941, Design and installation of thermal insulated bonded single and twin pipe systems

for directly buried hot water networks consists of two parts:

a) EN 13941-1: Design;

b) EN 13941-2: Installation.

The requirements in this part, EN 13941-2, form a unity with those of EN 13941-1.

The principles of the standard may be applied to thermal insulated pipe systems with pressures higher

than 2,5 MPa, provided that special attention is paid to the effects of this higher pressure.

Adjacent pipes, not buried, but belonging to the network (e.g. pipes in ducts, valve chambers, road

crossings above ground etc.) may be designed and installed according to this standard.

This standard presupposes the use of treated water, which by softening, demineralization, de-aeration,

adding of chemicals, or otherwise has been treated to effectively prevent internal corrosion and

deposits in the pipes.

NOTE For further information on water qualities to be used in district heating pipe systems, see bibliographic

entry [8].

This document is not applicable for such units as:

a) pumps;

b) heat exchangers;

c) boilers, tanks;

d) systems behind domestic substations.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 253, District heating pipes — Bonded single pipe systems for directly buried hot water networks —

Factory made pipe assembly of steel service pipe, polyurethane thermal insulation and outer casing of

polyethylene

EN 448, District heating pipes - Preinsulated bonded pipe systems for directly buried hot water networks -

Fitting assemblies of steel service pipes, polyurethane thermal insulation and outer casing of polyethylene

EN 488, District heating pipes - Preinsulated bonded pipe systems for directly buried hot water networks -

Steel valve assembly for steel service pipes, polyurethane thermal insulation and outer casing of

polyethylene

EN 489, District heating pipes - Preinsulated bonded pipe systems for directly buried hot water networks -

Joint assembly for steel service pipes, polyurethane thermal insulation and outer casing of polyethylene

EN 10204, Metallic products - Types of inspection documents

EN 13018, Non-destructive testing - Visual testing - General principles

EN 13480-5, Metallic industrial piping - Part 5: Inspection and testing

prEN 13941-1, District heating pipes - Design and installation of thermal insulated bonded single and twin

pipe systems for directly buried hot water networks — Part 1: Design

EN 14419:2009, District heating pipes - Preinsulated bonded pipe systems for directly buried hot water

networks - Surveillance systems

EN 15698 (all parts), District heating pipes — Bonded twin pipe systems for directly buried hot water

networks

EN 17248, District heating and district cooling pipe systems - Terms and definitions

EN ISO 3452-1, Non-destructive testing - Penetrant testing - Part 1: General principles (ISO 3452-1)

EN ISO 3834-1, Quality requirements for fusion welding of metallic materials - Part 1: Criteria for the

selection of the appropriate level of quality requirements (ISO 3834-1)

EN ISO 3834-3, Quality requirements for fusion welding of metallic materials - Part 3: Standard quality

requirements (ISO 3834-3)

EN ISO 3834-4, Quality requirements for fusion welding of metallic materials - Part 4: Elementary quality

requirements (ISO 3834-4)

EN ISO 5579, Non-destructive testing - Radiographic testing of metallic materials using film and X- or

gamma rays - Basic rules (ISO 5579)

EN ISO 5817:2014, Welding - Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) - Quality levels for imperfections (ISO 5817:2014)

EN ISO 9606-1, Qualification testing of welders - Fusion welding - Part 1: Steels (ISO 9606-1)

EN ISO 9712, Non-destructive testing - Qualification and certification of NDT personnel (ISO 9712)

EN ISO 9934-1, Non-destructive testing - Magnetic particle testing - Part 1: General principles (ISO 9934-

1)

EN ISO 10675-1, Non-destructive testing of welds - Acceptance levels for radiographic testing - Part 1:

Steel, nickel, titanium and their alloys (ISO 10675-1)

EN ISO 11666, Non-destructive testing of welds - Ultrasonic testing - Acceptance levels (ISO 11666:2018)

EN ISO 14731:2006, Welding coordination - Tasks and responsibilities (ISO 14731:2006)

Under preparation. Stage at time of publication: prEN 17248:2018.

EN ISO 14732, Welding personnel - Qualification testing of welding operators and weld setters for

mechanized and automatic welding of metallic materials (ISO 14732)

EN ISO 15609-1, Specification and qualification of welding procedures for metallic materials - Welding

procedure specification - Part 1: Arc welding (ISO 15609-1)

EN ISO 15609-2, Specification and qualification of welding procedures for metallic materials - Welding

procedure specification - Part 2: Gas welding (ISO 15609-2)

EN ISO 15610, Specification and qualification of welding procedures for metallic materials - Qualification

based on tested welding consumables (ISO 15610)

EN ISO 15613, Specification and qualification of welding procedures for metallic materials - Qualification

based on pre-production welding test (ISO 15613)

EN ISO 15614-1, Specification and qualification of welding procedures for metallic materials - Welding

procedure test - Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys (ISO

15614-1)

EN ISO 16810, Non-destructive testing - Ultrasonic testing - General principles (ISO 16810)

EN ISO 17636-1, Non-destructive testing of welds - Radiographic testing - Part 1: X- and gamma-ray

techniques with film (ISO 17636-1)

EN ISO 17636-2, Non-destructive testing of welds - Radiographic testing - Part 2: X- and gamma-ray

techniques with digital detectors (ISO 17636-2)

EN ISO 17637, Non-destructive testing of welds - Visual testing of fusion-welded joints (ISO 17637)

EN ISO 17638, Non-destructive testing of welds - Magnetic particle testing (ISO 17638)

EN ISO 17640, Non-destructive testing of welds - Ultrasonic testing - Techniques, testing levels, and

assessment (ISO 17640)

EN ISO 23277, Non-destructive testing of welds - Penetrant testing - Acceptance levels (ISO 23277)

EN ISO 23278, Non-destructive testing of welds - Magnetic particle testing - Acceptance levels (ISO 23278)

ISO 6761, Steel tubes — Preparation of ends of tubes and fittings for welding

HD 308 S2, Identification of cores in cables and flexible cords

3 Terms and definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 17248 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.2 Symbols

For the purposes of this document, the symbols and indices given in EN 13941-1 apply.

3.3 Abbreviations

For the purposes of this document, the abbrevations given in EN 13941-1 apply.

4 Procurement

4.1 Manufacturer of thermal insulated pipe elements

For the quality control program and documentation for suitable thermal insulated pipe elements see

Annex D.

NOTE For the quality control of factory made thermal insulated pipe elements see for example EHP 001 [1]

and EHP 003 [15].

4.2 Performing assembly of casing joints and PE-welding on casings

For the assembly of casing joints and PE-welding on casings the following points need to be considered:

a) the work shall be performed only by qualified fitters and PE-welders:

— An example for a scheme for the required knowlage and skills for fitters and PE welders is

)

given in Annex C .

NOTE Other qualification schemes for fitters and PE welders may exist at national level

b) Experienced and qualified management personnel as foreman and quality inspector:

The Supervising personnel and quality inspection personnel shall be trained as fitter and PE-

welder;

c) Appropriate and serviceable tools, equipment and machinery.

For the quality control program and service life documentation for assembling of joints and PE-welding

on the casing, see Table D.6 and Table D.8.

Under preparation. Stage at time of publication: prEN 17248:2018.

5 General requirements

Any pipe installation shall be made on basis of design documentation that is sufficiently detailed to

ensure execution of the project presupposed quality.

The installation of a pipe system shall be done

— in accordance with the installation plan and the instructions of the manufacturers of either the

system or the pipe and components, as applicable,

— in accordance with the design documentation so to ensure the adequate safety of fitters and other

personnel on-site as well as any third persons,

— that installation and operation do not harm to other structures or construction works, e.g. roads.

Project classes including the required design documentation shall be determined according to

EN 13941-1.

For the installation and assembly of pipe elements and pipe components only materials and methods,

which meet the specified instructions and standards shall be used.

Pipeline sections, which cannot be installed in compliance with this standard such as other than pipe

sections with pipe elements, e.g. bridge crossings, water course crossings, protection pipes should be

installed by skilled personnel according to the project drawings and corresponding other standards,

and codes.

If changes are made during installation, the design documentation shall be changed accordingly. The

constructive and static consequences of any changes that may become necessary shall be examined.

The risk assessment of the pipe system is being described in EN 13941-1.

The environmental requirements according to the legislators have to be followed. These requirements

can differ from place to place and are depending on the authority in charge.

It is permissible to use alternative rules from the notes given in this standard, provided that it is shown

that the alternative rule accords with the relevant principles and it is at least equivalent with regard to

the resistance, serviceability and durability achieved by the system.

6 Required information

6.1 Documents from the design phase

A full set of updated data, in accordance with EN 13941-1 shall be available at the construction site, The

information shall include at least the latest information about the local situation, vertical cover,

dimensions of all existing and planned underground systems, including related facilities, such as shafts .

It shall be checked that the expansion cushions, as delivered at the construction site, comply with the

requirements ofEN 13941-1

6.2 Documents from the manufacturers

The following documents shall be provided by the manufacturer on request:

— a installation manual.

In the installation manual, the manufacturer shall provide instructions about how to install the pipe

elements and the pipe components. It should also give recommendation about handling, storage on-

site, welding, jointing, backfilling in accordance with Clauses 10, 11 and 12.

6.3 Existing construction and underground systems

6.3.1 General

A full set of all detail plans of existing underground systems, like route plans, shaft drawings, detail and

manufacturing drawings as well as static calculations should provide all information to prevent damage

to existing underground systems.

National and local regulations and requirements on the location of service conduits, ducts and associate

installations shall be complied with.

NOTE At works in the earth there is always the danger that existing underground systems get damaged. To

the most important underground systems rank among:

— district heating pipelines;

— gas and water pipelines;

— electric cable;

— telecommunication cable;

— sewerages and rainwater pipelines;

— underground railway;

— and other ones.

6.4 Wiring design diagram

To locate any deviation as precisely as possible, a technical documentation according to EN 14419 is

required.

During installation a wiring design diagram for each measuring section is required, consisting of:

— drawing with legend;

— wiring diagram including all measuring elements, all connected branches and their respective

destination;

— drawing showing the location of connection points, etc.

7 Quality control

7.1 General

For basics of quality control see EN 13941-1.

The range of documented information shall be defined in relation to the kind of the work and the

project class.

All components and materials and all activities carried out (e.g. civil engineering work, pipe installation,

assembling of joints, testing and evaluating of test results) shall be documented in an appropriate

manner.

The construction progress should be documented in form of daily reports which should include the

essential information from the work on-site. Depending on the kind of project, the following

information can be necessary:

— Date and location

— Information on the weather

— Present, supervising persons with duration of presence

— Information about the personnel and machine used

— Information on subcontractors working

— Information on construction site safety

— Type, extent and duration of the work

— Instructions given by the supervisor for the on–site construction, the purchaser or his

representative

— Special incidents, e.g. such as accidents

— Transferred and received documents

— Interrupts and hindrances

— Names of persons responsible for on-site construction

— Steel welds, PE-welds, casing joints, surveillance systems, preheating and expansion cushions

A detailed overview of the technical documentation is written in Table 8.

The daily reports shall lead chronologically together in a general report at the end of the construction

work.

For special situations, it is recommended to perform a visual proof with clearly identifiable photos as

support measures. This can be for example:

— difficult installation situations in the near of supply systems by other owners (e.g. electricity, water,

telecommunication);

— performed works (e.g. assembling of expansion cushions).

7.2 Installation and approval

Further information on the qualitiy control are given in Annex D.

8 Site preparation

8.1 General

In consitency with national regulations, the site preparation for pipelines and facilities shall be such

that the safety i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...