EN 12245:2009

(Main)Transportable gas cylinders - Fully wrapped composite cylinders

Transportable gas cylinders - Fully wrapped composite cylinders

This European Standard specifies minimum requirements for the materials, design, construction, prototype testing and routine manufacturing inspections of composite gas cylinders for compressed, liquefied and dissolved gases.

NOTE 1 For the purposes of this European Standard, the word “cylinder” includes tubes (seamless transportable pressure receptacles of a water capacity exceeding 150 litres and of not more than 3 000 litres).

This European Standard is applicable to cylinders that comprise a liner of metallic material (welded or seamless) or non-metallic material (or a mixture thereof), reinforced by a wound composite consisting of fibres of glass, carbon or aramid (or a mixture thereof) embedded in a matrix.

This European Standard is also applicable to composite cylinders without liners.

This European Standard is not applicable to gas cylinders which are partially covered with fibres and commonly called "hoop wrapped" cylinders. For hoop wrapped composite cylinders, see EN 12257.

NOTE 2 This European Standard does not address the design, fitting and performance of removable protective sleeves. Where these are fitted, they should be considered separately.

This European Standard is primarily for industrial gases other than LPG but may also be applied to LPG.

NOTE 3 For dedicated LPG cylinders, see EN 14427.

Ortsbewegliche Gasflaschen - Vollumwickelte Flaschen aus Verbundwerkstoffen

Diese Europäische Norm legt Mindestanforderungen an die Werkstoffe, Gestaltung und Konstruktion, Proto¬typprüfungen und routinemäßige Inspektionen während der Herstellung von Gasflaschen aus Verbundwerk¬stoffen für verdichtete, verflüssigte und gelöste Gase fest.

ANMERKUNG 1 Für die Anwendung dieser Europäischen Norm umfasst das Wort „Flasche“ Großflaschen (nahtlose, ortsbewegliche Druckbehälter mit einem Fassungsraum von mehr als 150 Liter und nicht mehr als 3 000 Liter).

Diese Europäische Norm gilt für Flaschen, die einen Liner aus metallischem Werkstoff (geschweißt oder nahtlos) oder nichtmetallischem Werkstoff (oder einer Kombination daraus) umfassen, der mit einem in einer Matrix eingebetteten Wickelverbund aus Glas , Kohlenstoff oder Aramidfasern (oder einer Kombination daraus) verstärkt ist.

Diese Europäische Norm gilt auch für Flaschen aus Verbundwerkstoffen ohne Liner.

Diese Europäische Norm gilt nicht für Gasflaschen, die teilweise mit Fasern eingehüllt sind und allgemein als „umfangsgewickelte“ Flaschen bezeichnet werden. Zu umfangsgewickelten Flaschen aus Verbundwerkstoffen siehe EN 12257.

ANMERKUNG 2 Diese Europäische Norm behandelt nicht die Konstruktion, Anbringung und Leistung von abnehmbaren Schutzhülsen. Sind derartige Schutzhüllen angebracht, sollten sie separat betrachtet werden.

Diese Europäische Norm ist hauptsächlich für andere industrielle Gase als LPG bestimmt, kann jedoch auch für Flüssiggas angewendet werden.

ANMERKUNG 3 Zu Flaschen speziell für Flüssiggas, siehe EN 14427.

Bouteilles à gaz transportables - Bouteilles entièrement bobinées en matériaux composites

La présente Norme européenne spécifie les exigences minimales relatives aux matériaux, à la

conception, à la construction, aux essais de qualification de modèle et aux contrôles courants de

production, des bouteilles à gaz en matériaux composites pour gaz comprimés, liquéfiés et dissous.

NOTE 1 Pour les besoins de la présente Norme européenne, le mot « bouteille » englobe les tubes

(conteneurs sous pression transportables d’une capacité en eau supérieure à 150 litres mais non supérieure à 3

000 litres).

La présente Norme européenne s'applique aux bouteilles constituées d'un liner métallique (avec ou

sans soudure), ou non métallique (ou constitué d'un mélange de ces matériaux), renforcé par un

enroulement composite en fibres de verre, de carbone ou d'aramide (ou un mélange de ces

matériaux) noyées dans une matrice.

La présente Norme européenne s'applique également aux bouteilles à gaz en composite sans liner.

La présente Norme européenne ne s'applique pas aux bouteilles à gaz partiellement recouvertes de

fibres et couramment appelées « bouteilles frettées ». Pour les bouteilles frettées en matériaux

composites, voir l’EN 12257.

NOTE 2 La présente Norme européenne ne traite pas de la conception, du montage et des performances des

gaines de protection amovibles. Lorsque celles-ci sont montées, il convient de les considérer séparément.

La présente Norme européenne concerne principalement les gaz industriels autres que le GPL mais

elle peut également s’appliquer au GPL.

NOTE 3 Pour les bouteilles à GPL, voir l’EN 14427.

Premične plinske jeklenke - Popolnoma obvite jeklenke iz kompozitnih mas

General Information

- Status

- Withdrawn

- Publication Date

- 20-Jan-2009

- Withdrawal Date

- 08-Nov-2011

- Technical Committee

- CEN/TC 23 - Transportable gas cylinders

- Drafting Committee

- CEN/TC 23/SC 1/WG 4 - Composite cylinders

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Nov-2011

- Completion Date

- 09-Nov-2011

Relations

- Effective Date

- 28-Jan-2009

- Effective Date

- 10-Sep-2011

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 26-Dec-2009

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 12245:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Transportable gas cylinders - Fully wrapped composite cylinders". This standard covers: This European Standard specifies minimum requirements for the materials, design, construction, prototype testing and routine manufacturing inspections of composite gas cylinders for compressed, liquefied and dissolved gases. NOTE 1 For the purposes of this European Standard, the word “cylinder” includes tubes (seamless transportable pressure receptacles of a water capacity exceeding 150 litres and of not more than 3 000 litres). This European Standard is applicable to cylinders that comprise a liner of metallic material (welded or seamless) or non-metallic material (or a mixture thereof), reinforced by a wound composite consisting of fibres of glass, carbon or aramid (or a mixture thereof) embedded in a matrix. This European Standard is also applicable to composite cylinders without liners. This European Standard is not applicable to gas cylinders which are partially covered with fibres and commonly called "hoop wrapped" cylinders. For hoop wrapped composite cylinders, see EN 12257. NOTE 2 This European Standard does not address the design, fitting and performance of removable protective sleeves. Where these are fitted, they should be considered separately. This European Standard is primarily for industrial gases other than LPG but may also be applied to LPG. NOTE 3 For dedicated LPG cylinders, see EN 14427.

This European Standard specifies minimum requirements for the materials, design, construction, prototype testing and routine manufacturing inspections of composite gas cylinders for compressed, liquefied and dissolved gases. NOTE 1 For the purposes of this European Standard, the word “cylinder” includes tubes (seamless transportable pressure receptacles of a water capacity exceeding 150 litres and of not more than 3 000 litres). This European Standard is applicable to cylinders that comprise a liner of metallic material (welded or seamless) or non-metallic material (or a mixture thereof), reinforced by a wound composite consisting of fibres of glass, carbon or aramid (or a mixture thereof) embedded in a matrix. This European Standard is also applicable to composite cylinders without liners. This European Standard is not applicable to gas cylinders which are partially covered with fibres and commonly called "hoop wrapped" cylinders. For hoop wrapped composite cylinders, see EN 12257. NOTE 2 This European Standard does not address the design, fitting and performance of removable protective sleeves. Where these are fitted, they should be considered separately. This European Standard is primarily for industrial gases other than LPG but may also be applied to LPG. NOTE 3 For dedicated LPG cylinders, see EN 14427.

EN 12245:2009 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders; 23.020.35 - Gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12245:2009 has the following relationships with other standards: It is inter standard links to EN 12245:2002, EN 12245:2009+A1:2011, EN 13432:2000, EN ISO 18830:2017, EN ISO 10210:2017, EN 14048:2002, EN 12245:2009/AC:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12245:2009 is associated with the following European legislation: EU Directives/Regulations: 2008/68/EC, 94/55/EC, 96/49/EC, 96/86/EC, 96/87/EC; Standardization Mandates: M/086. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12245:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Ortsbewegliche Gasflaschen - Vollumwickelte Flaschen aus VerbundwerkstoffenBouteilles a gaz transportables - Bouteilles entierement bobinées en matériaux compositesTransportable gas cylinders - Fully wrapped composite cylinders23.020.30MHNOHQNHPressure vessels, gas cylindersICS:Ta slovenski standard je istoveten z:EN 12245:2009SIST EN 12245:2009en,fr,de01-april-2009SIST EN 12245:2009SLOVENSKI

STANDARDSIST EN 12245:20021DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12245January 2009ICS 23.020.30Supersedes EN 12245:2002

English VersionTransportable gas cylinders - Fully wrapped composite cylindersBouteilles à gaz transportables - Bouteilles entièrementbobinées en matériaux compositesOrtsbewegliche Gasflaschen - Vollumwickelte Flaschenaus VerbundwerkstoffenThis European Standard was approved by CEN on 29 November 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12245:2009: ESIST EN 12245:2009

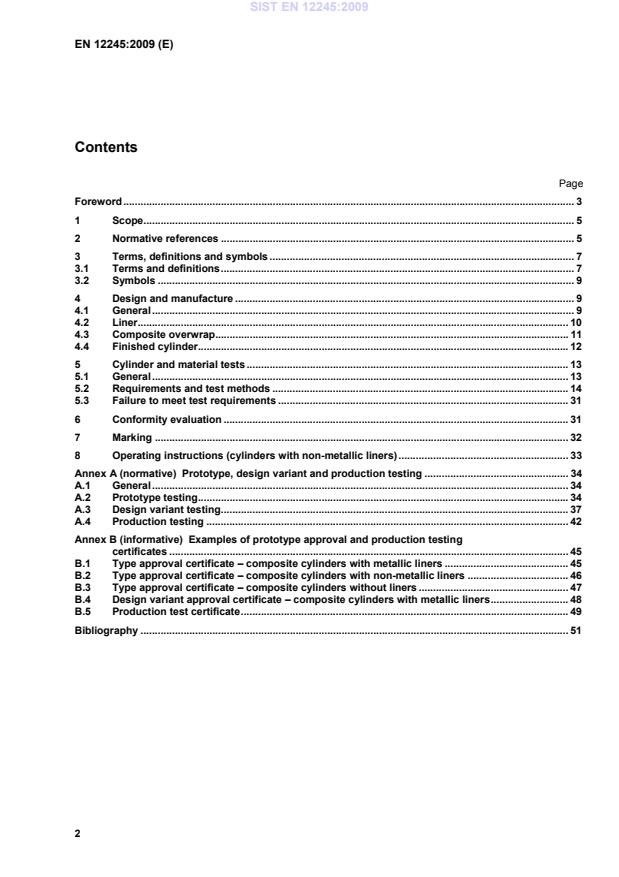

Prototype, design variant and production testing . 34A.1General . 34A.2Prototype testing . 34A.3Design variant testing. 37A.4Production testing . 42Annex B (informative)

Examples of prototype approval and production testing certificates . 45B.1Type approval certificate – composite cylinders with metallic liners . 45B.2Type approval certificate – composite cylinders with non-metallic liners . 46B.3Type approval certificate – composite cylinders without liners . 47B.4Design variant approval certificate – composite cylinders with metallic liners . 48B.5Production test certificate . 49Bibliography . 51 SIST EN 12245:2009

1 Scope This European Standard specifies minimum requirements for the materials, design, construction, prototype testing and routine manufacturing inspections of composite gas cylinders for compressed, liquefied and dissolved gases. NOTE 1 For the purposes of this European Standard, the word “cylinder” includes tubes (seamless transportable pressure receptacles of a water capacity exceeding 150 litres and of not more than 3 000 litres). This European Standard is applicable to cylinders that comprise a liner of metallic material (welded or seamless) or non-metallic material (or a mixture thereof), reinforced by a wound composite consisting of fibres of glass, carbon or aramid (or a mixture thereof) embedded in a matrix. This European Standard is also applicable to composite cylinders without liners. This European Standard is not applicable to gas cylinders which are partially covered with fibres and commonly called "hoop wrapped" cylinders. For hoop wrapped composite cylinders, see EN 12257. NOTE 2 This European Standard does not address the design, fitting and performance of removable protective sleeves. Where these are fitted, they should be considered separately. This European Standard is primarily for industrial gases other than LPG but may also be applied to LPG. NOTE 3 For dedicated LPG cylinders, see EN 14427.

2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 720-2, Transportable gas cylinders — Gases and gas mixtures — Part 2: Determination of flammability and oxidizing potential of gases and gas mixtures EN 1964-1, Transportable gas cylinders — Specification for the design and construction of refillable transportable seamless steel gas cylinders of water capacities from 0,5 litre up to and including 150 litres — Part 1: Cylinders made of seamless steel with an Rm value of less than 1100 MPa EN 1964-2, Transportable gas cylinders — Specification for the design and construction of refillable transportable seamless steel gas cylinders of water capacities from 0,5 litre up to and including 150 litres — Part 2: Cylinders made of seamless steel with an Rm value of 1100 MPa and above EN 1964-3, Transportable gas cylinders — Specification for the design and construction of refillable transportable seamless steel gas cylinders of water capacities from 0,5 litre up to and including 150 litres — Part 3:. Cylinders made of seamless stainless steel with an Rm value of less than 1100 MPa EN 1975, Transportable gas cylinders — Specification for the design and construction of refillable transportable seamless aluminium and aluminium alloy gas cylinders of capacity from 0,5 litre up to 150 litres EN 12862, Transportable gas cylinders — Specification for the design and construction of refillable transportable welded aluminium alloy gas cylinders SIST EN 12245:2009

pbL

burst pressure of liner, in bar 1) above atmospheric pressure pbmin minimum burst pressure of composite cylinder obtained during design variant approval testing, in bar 1) above atmospheric pressure ph hydraulic test pressure of composite cylinder, in bar 1) above atmospheric pressure pmax maximum developed pressure at 65 °C, in bar 1) above atmospheric pressure 4 Design and manufacture 4.1 General A fully wrapped composite gas cylinder may be manufactured with a metallic or non-metallic liner or without a liner. Cylinders without a liner may be manufactured from two parts joined together with adhesive. An optional exterior coating may be used to provide external protection and when this is an integral part of the design shall be permanent. The cylinder may also include additional parts (e.g. rings and bases). Cylinders shall be designed with one or two openings along the central axis only.

1) 1 bar = 105 Pa = 0,1 MPa. SIST EN 12245:2009

EN 1964-1 or EN 1964-2, as appropriate; b) seamless stainless steel liners:

EN 1964-3; c) seamless aluminium alloy liners:

EN 1975; d) welded steel liners:

EN 13322-1 or prEN 14638-3, as appropriate; e) welded stainless steel liners:

EN 13322-2 or EN 14638-1, as appropriate; f) welded aluminium liners:

EN 12862; g) steel tubes (i.e. > 150 l):

EN ISO 11120. The relevant sections are those covering materials, thermal treatments, neck design, construction and workmanship and mechanical tests. NOTE This excludes the design requirements, since these are specified by the manufacturer for the design of the composite cylinder. For liners with water capacity above 150 l manufactured of stainless steel, aluminium or welded steel, the relevant sections of the appropriate standard also apply. The liner material shall be compatible with the gases intended to be used as determined by EN ISO 11114-1 and EN ISO 11114-4. 4.2.2 Non-metallic liners A cylinder with a non-metallic liner shall be designed as if the liner will be non-load sharing. The liner material shall be compatible with the gases intended to be used as determined by EN ISO 11114-2. Where a metal end boss is used in a non-metallic liner, it shall be considered part of the liner material and shall fulfil the material requirements specified in the relevant standard, as listed in 4.2.1. The drawing of the liner shall include the specification of the material and material properties of the boss. Important material properties shall be specified in the design and are those such as: a) minimum yield stress; b) minimum tensile strength; c) minimum elongation of the boss material; d) compatibility with the contained gas as determined by EN ISO 11114-1. The metal end boss bearing the cylinder thread shall be designed to withstand the torque applied in fitting the valve to the cylinder and the tests specified in Test 16 (see 5.2.16) and Test 17 (see 5.2.17). 4.2.3 Design drawing A fully dimensioned drawing of the liner shall be supplied which includes the specification of the material and material properties. Material and liner properties to be specified on the drawing are: a) for metallic liners: SIST EN 12245:2009

intended for air and oxidising gases (see ISO 10156 for definition of oxidising gases)); 4) glass transition temperature as determined by differential scanning calorimetry; 5) composition; 6) compatibility with the contained gas as determined by EN ISO 11114-2; 7) end boss design in accordance with 4.2.2. 4.2.4 Design of ends The external diameter and thickness of the formed neck end of the liner shall be designed to withstand the torque applied in fitting the valve to the cylinder and the tests specified in Test 16 (see 5.2.16) and Test 17 (see 5.2.17). 4.2.5 Neck ring When a neck ring is provided, it shall be of a material compatible with that of the cylinder, and shall be securely attached by a method appropriate to the liner (or cylinder for cylinders without liner) or boss material. 4.3 Composite overwrap 4.3.1 Materials Material requirements for the fibre and matrix or the pre-impregnated material shall be as specified by the manufacturer. 4.3.2 Winding Appropriate procedures shall be defined for the winding and curing process to ensure good repeatability and traceability. Parameters to be specified and monitored are: SIST EN 12245:2009

EN ISO 11114-2. The auto-ignition temperature in oxygen gas shall be determined in accordance with EN ISO 11114-3 for cylinders intended for air, oxygen and oxidising gases. Where a metal end boss is used in a cylinder without liner, the drawing of the cylinder shall include the specification of the material and material properties of the boss in accordance with 4.2.2.2. 4.4.3 Autofrettage Internal pressurisation to autofrettage pressure of cylinders with metallic liners can be part of the manufacturing process; if so this operation shall be executed after polymerisation of the composite for thermosetting resins or after the consolidation process for thermoplastics. During the autofrettage operation, the parameters to be recorded are: a) autofrettage pressure; b) length of application of the autofrettage pressure; c) expansion at autofrettage pressure; d) permanent expansion after autofrettage. If autofrettage is used, a check shall be made on all cylinders that the procedure has been effectively performed. 4.4.4 Manufacturing requirements for the finished cylinder The internal and external surfaces of the finished cylinder shall be free of defects which can adversely affect the safe working of the cylinder. In addition, there shall be no visible foreign matter present inside the cylinder (e.g. resin, swarf or other debris). 5 Cylinder and material tests 5.1 General This clause describes tests to be conducted on fully wrapped composite cylinders, cylinder liners and the materials used in manufacture of cylinders for prototype testing of new cylinder designs, design SIST EN 12245:2009

ISO 8521 or ASTM D 2290-92 and ASTM D 2291-83; ISO 3341 or ASTM D 2343-03; 2) for carbon:

ISO10618 or ASTM D 4018-93; b) shear properties:

ISO 14130 or ASTM D 2344-84; c) matrix properties:

glass transition temperature: ASTM D 3418-99;

heat distortion temperature: ISO 75 -3;

viscosity:

ASTM D 2196-86.

Equivalent tests in accordance with alternative standards or test specifications acceptable to the inspection body may be applied. 5.2.1.1.2 Criteria The mechanical properties shall meet the minimum requirements for the design as specified by the manufacturer. 5.2.1.2 Additional tests for cylinders without liners 5.2.1.2.1 Procedure Additional tests on the composite materials and adhesives (if applicable) to establish their other physical properties shall be carried out in accordance with: a) tensile strength:

ISO 527-1 and ISO 527-2; b) tensile modulus:

ISO 527-1 and ISO 527-2; c) elongation:

ISO 527-1 and ISO 527-2; d) heat distortion temperature: ISO 3146 for thermoplastics; ISO 75-1 and ISO 75-3 for thermoset materials; SIST EN 12245:2009

ISO 1628-3 for thermoplastics; ISO 2884-1 or ASTM D 2196-86 for thermosets; g) composition:

test specification acceptable to the inspection body. Equivalent tests in accordance with alternative standards or test specifications acceptable to the inspection body may be applied. 5.2.1.2.2 Criteria The mechanical properties shall meet the minimum requirements for the design as specified by the manufacturer. 5.2.2 Test 2 – Liner material tests 5.2.2.1 Procedure Tests on the liner material shall be carried out for: a) seamless steel – as described in EN 1964-1, EN 1964-2 or EN ISO 11120, as appropriate; b) seamless stainless steel – as described in EN 1964-3; c) welded steel – as described in EN 13322-1 or prEN14638-3, as appropriate; d) seamless aluminium – as described in EN 1975; e) welded stainless steel – as described in EN 13322-2 or EN 14638-1; f) welded aluminium – as described in EN 12862; g) non-metallic materials: 1) thermoplastics: i) viscosity – ISO 1628-3: ii) melting point – ISO 3146; iii) water content – ISO 15512; iv) density – ISO 1183; v) melting flow index – ISO 1133; vi) chemical resistance – ISO 175; vii) auto-ignition test – EN ISO 11114-3 (air, oxygen and oxidising gases only). 2) thermosets and elastomerics: i) viscosity - ISO 2884-1 or ASTM D 2196-86; ii) elongation at break – ISO 527-1 and ISO 527-2; SIST EN 12245:2009

b) burst initiation shall be in the cylindrical part, except in cases where the liner outside diameter is less than 3 times the overall length, and the liner shall remain in one piece. 5.2.3.3 Parameters to monitor and record a) burst pressure; b) the number of pieces; c) failure description; d) pressure/time curve or pressure/volume curve. 5.2.4 Test 4 – Pressure test of finished cylinders at ambient temperature 5.2.4.1 Procedure Where cylinders are subjected to autofrettage, the pressure test may immediately follow or be part of the autofrettage operation. SIST EN 12245:2009

5.2.5.3 Parameters to monitor and record a) burst pressure; b) number of pieces; c) description of failure; d) pressure/time curve or pressure/volume curve. SIST EN 12245:2009

b) number of cycles achieving upper cyclic pressure; c) minimum and maximum cyclic pressures; d) cycle frequency; e) test medium used; f) mode of failure, if appropriate. 5.2.6.2 For limited life 5.2.6.2.1 Procedure This test shall be conducted in accordance with the procedure as described in 5.2.6.1 and consists of two parts run sequentially and continuously. Different criteria apply to the two parts as shown in Table 1. SIST EN 12245:2009

1st part 2nd part Number of cycles 0 to N N to 2N but 2N no more than 12 000

0 to Nd Nd to 2Nd but 2Nd no more than 24 000 Criteria No leakage/burst = Pass

No leakage or burst Leakage = Pass

Pass 1st part Burst = Fail

5.2.6.2.3 Parameters to monitor and record a) temperature of the cylinder; b) number of cycles, achieving upper cyclic pressure; c) minimum and maximum cyclic pressures; d) cycle frequency; e) test medium used; f) mode of failure, if appropriate. 5.2.7 Test 7 – Immersion in salt water 5.2.7.1 General This test is required for cylinder designs intended for underwater applications and is optional for other applications. 5.2.7.2 Procedure The cylinder shall be finished as for the intended application and without external coating unless this is an integral part of the design. SIST EN 12245:2009

Figure 1 — Positions for the impact test After the full sequence of drops has been completed: a) one of the two cylinders shall be subjected to Test 5 (see 5.2.5); SIST EN 12245:2009

(pb ≥ 2,0 ph); For the second cylinder: b) meet the requirements of 5.2.6. 5.2.9.1.3 Parameters to monitor and record a) visual appearance after each drop - position and dimensions of impact damage; b) burst pressure; c) description of failure; d) parameters specified in 5.2.6. 5.2.9.2 For cylinders over 80 litres water capacity 5.2.9.2.1 Procedure One empty cylinder, fitted with sealing device to protect threads and sealing surfaces, shall be subjected to a sequence of drops from a maximum height of 1,8 m on to a smooth flat concrete surface or as prescribed: a) horizontally on to the cylinder sidewall; b) vertically on to the cylinder base (however maximum potential energy of 1 220 Nm shall not be exceeded); c) vertically on to the other end of the cylinder (however maximum potential energy of 1 220 Nm shall not be exceeded); d) at an angle of 45° to strike the shoulder of the cylinder (however the drop height shall be such that the centre of gravity of the cylinder is 1,8 m from the floor with the shoulder a minimum of 0,6 m (2 ft) the from floor. Where this is not possible, the drop angle should be adjusted to maintain a minimum height of 0,6 m and a centre of gravity of 1,8 m). The cylinder shall then be subjected to 12 000 pressurisation cycles from zero to 2/3 times test pressure in accordance with the procedure detailed in 5.2.6. 5.2.9.2.2 Criteria The cylinders shall withstand 3 000 pressurisation cycles at the test pressure ph x 2/3 without failure by burst or leakage. The test shall continue for a further 9 000 cycles, or until the cylinder fails by leakage, whichever is the sooner. In either case, the cylinder shall be deemed to have passed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...