EN 12110:2002+A1:2008

(Main)Tunnelling machines - Air locks - Safety requirements

Tunnelling machines - Air locks - Safety requirements

This European Standard applies for the design, construction, equipping, marking and testing of air locks and pressure bulkheads, which are to be used in tunnelling work.

The oxygen breathing installation used to provide the breathing supply necessary to conduct a safe decompression is also covered by this standard.

1.2 This standard deals with all significant hazards, hazardous situations and events relevant to air locks and pressure bulkheads, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards.

1.3 This document is not applicable to machinery which is manufactured before the date of publication of this document by CEN.

Tunnelbaumaschinen - Druckluftschleusen - Sicherheitstechnische Anforderungen

1.1 Maschinenbeschreibung

Diese Europäische Norm gilt für Form, Aufbau, Ausstattung, Kennzeichnung und Prüfung von Druckluftschleusen und Druckwänden, die bei Tunnelbauarbeiten verwendet werden.

Die zur Versorgung mit Luft eingesetzte Sauerstoffanlage, die für die sichere Durchführung einer Druckentlastung erforderlich ist, fällt ebenfalls in den Anwendungsbereich dieser Norm.

1.2 Diese Norm behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungs-ereignisse, die auf Druckluftschleusen und Druckwände zutreffen, wenn sie bestimmungsgemäß und entsprechend den vorhersehbaren Bedingungen des Herstellers verwendet werden (siehe Abschnitt 4). Diese Norm beschreibt die entsprechenden Maßnahmen zur Beseitigung oder Verminderung der Risiken, die von den signifikanten Gefährdungen ausgehen.

1.3 Dieses Dokument gilt nicht für Maschinen, die hergestellt wurden, bevor CEN dieses Dokument veröffentlichte.

Machines pour la construction de tunnels - Sas de transfert - Prescriptions de sécurité

1.1 Description de la (des) machine(s)

La présente norme porte sur la conception, la fabrication, la fourniture, le marquage et les essais des sas de transfert

et de parois de cloison de pression destinés aux travaux de soutènement de tunnels.

Le respirateur à oxygène utilisé pour procurer la quantité d'air nécessaire pour effectuer la décompression en toute

sécurité est également couvert par cette norme.

1.2 La présente norme traite tous les phénomènes dangereux significatifs relatifs aux sas de transfert et les parois

de cloison de pression, lorsqu'ils sont utilisés normalement et dans les conditions prévues par le fabricant

(voir article 4). La présente norme spécifie les mesures techniques appropriées pour éliminer ou réduire les risques

dus aux phénomènes dangereux significatifs.

1.3 La présente Norme européenne s'applique en particulier à des machines fabriquées après la date

d'approbation de la norme par le CEN.

Stroji za gradnjo predorov - Zračne zapore - Varnostne zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 26-Aug-2008

- Withdrawal Date

- 20-May-2014

- Technical Committee

- CEN/TC 151 - Construction equipment and building material machines - Safety

- Drafting Committee

- CEN/TC 151/WG 4 - Tunnelling machines - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-May-2014

- Completion Date

- 21-May-2014

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 214, C 214, C 214, C 214, C 214, C 214, C 214, C OJ Date: 08-Sep-2009

Not Harmonized98/37/EC - MachineryOJ Ref: C 22, C 22, C 22, C 22, C 22, C 22, C 22, C 22, C, OJ Date: 28-Jan-2009

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 10-Oct-2009

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 12110:2002+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Tunnelling machines - Air locks - Safety requirements". This standard covers: This European Standard applies for the design, construction, equipping, marking and testing of air locks and pressure bulkheads, which are to be used in tunnelling work. The oxygen breathing installation used to provide the breathing supply necessary to conduct a safe decompression is also covered by this standard. 1.2 This standard deals with all significant hazards, hazardous situations and events relevant to air locks and pressure bulkheads, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. 1.3 This document is not applicable to machinery which is manufactured before the date of publication of this document by CEN.

This European Standard applies for the design, construction, equipping, marking and testing of air locks and pressure bulkheads, which are to be used in tunnelling work. The oxygen breathing installation used to provide the breathing supply necessary to conduct a safe decompression is also covered by this standard. 1.2 This standard deals with all significant hazards, hazardous situations and events relevant to air locks and pressure bulkheads, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. 1.3 This document is not applicable to machinery which is manufactured before the date of publication of this document by CEN.

EN 12110:2002+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 91.220 - Construction equipment; 93.060 - Tunnel construction. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12110:2002+A1:2008 has the following relationships with other standards: It is inter standard links to EN 12110:2002, EN 12110:2014, EN 60529:1991, EN 60204-1:1997, EN 61310-1:1995, EN ISO 11202:1995, EN 140:1998, EN 292-2:1991. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12110:2002+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12110:2002+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

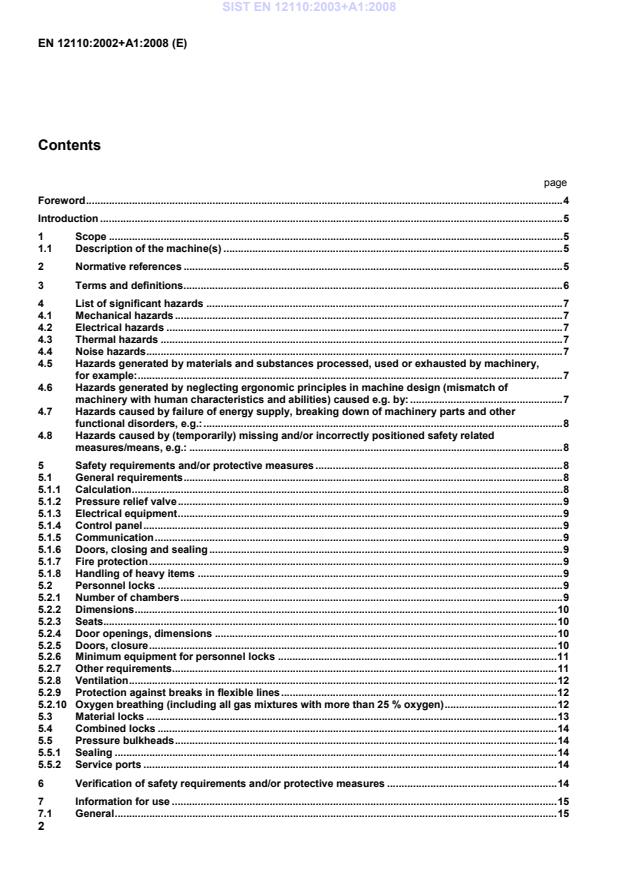

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Tunnelbaumaschinen - Druckluftschleusen - Sicherheitstechnische AnforderungenMachines pour la construction de tunnels - Sas de transfert - Prescriptions de sécuritéTunnelling machines - Air locks - Safety requirements93.060Gradnja predorovTunnel construction91.220Gradbena opremaConstruction equipmentICS:Ta slovenski standard je istoveten z:EN 12110:2002+A1:2008SIST EN 12110:2003+A1:2008en01-november-2008SIST EN 12110:2003+A1:2008SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12110:2002+A1

August 2008 ICS 91.220; 93.060 Supersedes EN 12110:2002English Version

Tunnelling machines - Air locks - Safety requirements

Machines pour la construction de tunnels - Sas de transfert - Prescriptions de sécurité

Tunnelbaumaschinen - Druckluftschleusen - Sicherheitstechnische Anforderungen This European Standard was approved by CEN on 2 September 2002 and includes Amendment 1 approved by CEN on 9 July 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12110:2002+A1:2008: ESIST EN 12110:2003+A1:2008

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC".18 Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC".19 Bibliography.20

pressurised environment and atmospheric pressure, see:

5.2.7 4.2 Electrical hazards 4.2.1 Electrical contact, direct or indirect, see: 5.1.3 4.2.2 External influences on electrical equipment, see: 5.1.3 4.3 Thermal hazards 4.3.1 Burns and scalds, by a possible contact of persons, by flames or

explosions and also by the radiation of heat sources, see:

5.1.3, 5.1.7, 5.2.7,

5.2.10.5, 7.2 4.3.2 Health-damaging effects by hot or cold work environment, see: 5.2.6.1, 5.2.7, 5.4 4.4 Noise hazards 4.4.1 Hearing losses (deafness), other physiological disorders

(e.g. loss of balance, loss of awareness, etc.), see:

5.2.7, 5.4 4.4.2 Interference with speech communication, acoustic signals, etc., see: 5.2.7, 5.4, 7.2 4.5 Hazards generated by materials and substances processed, used or exhausted by machinery, for example: 4.5.1 Hazards resulting from contact with or inhalation of harmful fluids, gases,

mists, fumes and dusts, see: 5.1.7, 5.2.6.2, 5.2.8, 5.2.10.1 4.5.2 Fire or explosion hazards especially under increased air pressure, see: 5.1.3, 5.1.4, 5.1.7, 5.2.7, 5.2.10.1, 5.2.10.2, 5.2.10.3 4.5.3 Use of oxygen, see clause:

5.2.10 4.6 Hazards generated by neglecting ergonomic principles in machine design (mismatch of machinery with human characteristics and abilities) caused e.g. by: 4.6.1 Unhealthy postures or excessive efforts, see: 5.1.8, 5.2.2, 5.2.3 4.6.2 Inadequate consideration of human anatomy, see: 5.2.2, 5.2.3, 5.2.4 SIST EN 12110:2003+A1:2008

5.2.9, 5.2.10.6 4.7.4 Loss of communication, see: 5.1.5 4.8 Hazards caused by (temporarily) missing and/or incorrectly positioned safety related measures/means, e.g.: 4.8.1 All kinds of safety related (protection) devices, see: 5.1.3 5.1.5, 5.2.6.1,

5.2.6.2, 5.3, 5.5.2 4.8.2 Safety signs, see: 5.3, 7.1, 7.2 4.8.3 All kinds of information or warning devices, see: 5.2.6.1, 7 4.8.4 Means of access for emergency personnel into the confined pressurised

part of the machine, see: 5.2.1, 5.2.2, 5.2.4, 5.2.5 4.8.5 Emergency devices, in particular means of evacuation of a casualty from

the confined pressurised part of the machine, see: 5.2.1, 5.2.2

4.8.6 Essential equipment and accessories for safe adjusting and/or maintaining

see: 5.2.6.1, 5.3, 5.4 4.8.7 Equipment for evacuating gases, etc, see: 5.2.6.2, 5.2.8, 5.2.10.3,

5.2.10.6, 5.4 5 Safety requirements and/or protective measures Machinery shall comply with the safety requirements and/or protective measures of this clause. Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of EN 292 for hazards relevant but not significant, which are not dealt with by this document (e.g. sharp edges). 5.1 General requirements 5.1.1 Calculation The design pressure shall be 1,1 times the maximum working pressure. Where bulkheads cannot be tested the design pressure shall be 1,5 times the maximum working pressure. The calculation shall be carried out according to the finite elements method. The calculations shall be part of the technical documentation. SIST EN 12110:2003+A1:2008

5.1.4 Control panel Control equipment and indicating instruments which are outside the air lock shall be assembled in a control panel. They shall be easily readable and so designed, constructed, arranged and marked that function and switching direction can be clearly recognised, in compliance with EN 61310-1:1995. They shall be illuminated with a nominal intensity of at least 100 lux. Emergency lighting shall be available

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...