EN 1854:2010

(Main)Pressure sensing devices for gas burners and gas burning appliances

Pressure sensing devices for gas burners and gas burning appliances

This European Standard specifies the safety, construction and performance requirements for pressure sensing devices.

This European Standard covers type testing only.

It applies to pressure sensing devices for the measurement of pressures of combustible gases of the first, second and third families, air, combustion products for maximum inlet pressures up to 500 kPa (5 bar).

It applies to all types of pressure sensing devices, including electronic, differential and inferential types.

It specifies requirements for pressure sensing devices which are intended to be applied to steam boilers and as such need to meet increased reliability requirements. These devices are classified as PSD-S in this European Standard.

Druckwächter für Gasbrenner und Gasgeräte

Diese Europäische Norm legt die Anforderungen an Sicherheit, Konstruktion und Funktion von Druckwächtern fest. Diese Europäische Norm befasst sich ausschließlich mit der Typprüfung. Sie gilt für Druckwächter zur Messung der Drücke von brennbaren Gasen der ersten, zweiten oder dritten Gasfamilie, Luft und Verbrennungsprodukte für maximale Eingangsdrücke bis 500 kPa (5 bar). Sie gilt für alle Arten von Druckwächtern, einschließlich elektronischer Ausführungen sowie für Differenzdruck-wächter und indirekt messende Typen. Es werden auch Anforderungen an Druckwächter festgelegt, die für den Einsatz an Dampfkesseln vor-gesehen sind und die erhöhte Anforderungen an die Zuverlässigkeit erfüllen müssen. Diese Druckwächter werden in der vorliegenden Europäischen Norm als PSD-S klassifiziert.

Dispositifs de surveillance de pression pour brûleurs à gaz et appareils à gaz

La présente Norme européenne spécifie les exigences de sécurité, de construction et de fonctionnement des

dispositifs de surveillance de pression.

La présente Norme européenne ne couvre que les essais de type.

Elle s’applique aux dispositifs de surveillance de pression pour le contrôle des pressions de gaz combustibles

de la 1e, 2e ou 3e famille, de l’air, des produits de combustion et de leurs mélanges pour des pressions amont

maximales allant jusqu’à 500 kPa (5 bar).

Elle s’applique à tous les types de dispositifs de surveillance de pression, y compris électroniques,

différentiels et inférentiels.

Elle spécifie les exigences des dispositifs de surveillance de pression qui sont destinés à être utilisés dans

des chaudières à vapeur et qui, en tant que tels, doivent respecter des exigences de fiabilité plus strictes. Ces

dispositifs appartiennent à la catégorie des pressostats de classe « S » dans le présent document.

Tlačna zaznavala za plinske gorilnike in plinske aparate

Ta evropski standard določa zahteve za varnost, konstrukcijo in delovanje tlačnih zaznaval. Ta evropski standard zajema zgolj preskušanje tipov. Velja za tlačna zaznavala za merjenje tlaka vnetljivih plinov prve, druge ali tretje družine, zraka in produktov izgorevanja, za maksimalni notranji tlak do in vključno 500 kPa (5 barov). Velja za vse tipe tlačnih zaznaval, vključno z elektronskimi, diferenčnimi in inferenčnimi. Opredeljuje zahteve za tlačna zaznavala, ki so namenjena za uporabo pri parnih kotlih in morajo kot taka izpolnjevati zahteve po večji zanesljivosti. Ta zaznavala so v tem evropskem standardu klasificirana kot PSD-S.

General Information

- Status

- Withdrawn

- Publication Date

- 25-May-2010

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 58 - Safety and control devices for burners and appliances burning gaseous or liquid fuels

- Drafting Committee

- CEN/TC 58/WG 12 - Electronics

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-Dec-2022

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 22-May-2010

- Effective Date

- 12-Aug-2015

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 1854:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Pressure sensing devices for gas burners and gas burning appliances". This standard covers: This European Standard specifies the safety, construction and performance requirements for pressure sensing devices. This European Standard covers type testing only. It applies to pressure sensing devices for the measurement of pressures of combustible gases of the first, second and third families, air, combustion products for maximum inlet pressures up to 500 kPa (5 bar). It applies to all types of pressure sensing devices, including electronic, differential and inferential types. It specifies requirements for pressure sensing devices which are intended to be applied to steam boilers and as such need to meet increased reliability requirements. These devices are classified as PSD-S in this European Standard.

This European Standard specifies the safety, construction and performance requirements for pressure sensing devices. This European Standard covers type testing only. It applies to pressure sensing devices for the measurement of pressures of combustible gases of the first, second and third families, air, combustion products for maximum inlet pressures up to 500 kPa (5 bar). It applies to all types of pressure sensing devices, including electronic, differential and inferential types. It specifies requirements for pressure sensing devices which are intended to be applied to steam boilers and as such need to meet increased reliability requirements. These devices are classified as PSD-S in this European Standard.

EN 1854:2010 is classified under the following ICS (International Classification for Standards) categories: 23.060.40 - Pressure regulators. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1854:2010 has the following relationships with other standards: It is inter standard links to EN 1854:2006, EN 1854:2022, EN 60730-2-6:2008, EN 60529:1991, EN 61058-1:2002, EN 175301-803:2006, EN 13611:2007, EN 13953:2003, EN ISO 75-2:2013, EN ISO 75-1:2020, EN ISO 75-3:2025, EN 267:2020, EN ISO 13577-2:2023, EN 746-3:2021, EN 676:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1854:2010 is associated with the following European legislation: EU Directives/Regulations: 2009/142/EC, 90/396/EEC; Standardization Mandates: M/327, M/BC/CEN/89/6. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1854:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Druckwächter für Gasbrenner und GasgeräteDispositifs de surveillance de pression pour brûleurs à gaz et appareils à gazPressure sensing devices for gas burners and gas burning appliances27.060.20Plinski gorilnikiGas fuel burners23.060.40Pressure regulatorsICS:Ta slovenski standard je istoveten z:EN 1854:2010SIST EN 1854:2010en,fr,de01-november-2010SIST EN 1854:2010SLOVENSKI

STANDARDSIST EN 1854:20061DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1854

May 2010 ICS 23.060.40 Supersedes EN 1854:2006English Version

Pressure sensing devices for gas burners and gas burning appliances

Dispositifs de surveillance de pression pour brûleurs à gaz et appareils à gaz

Druckwächter für Gasbrenner und Gasgeräte This European Standard was approved by CEN on 15 April 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1854:2010: ESIST EN 1854:2010

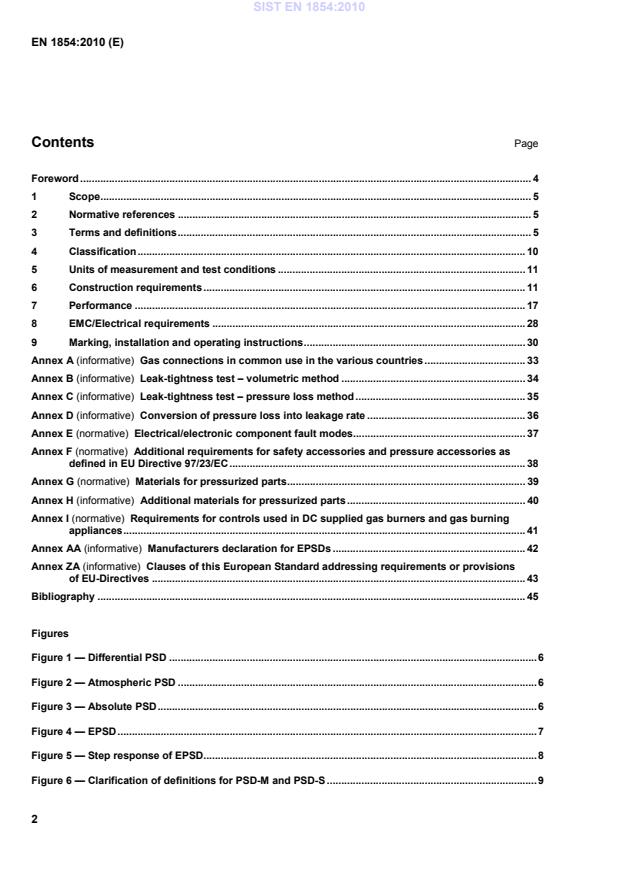

Gas connections in common use in the various countries . 33Annex B (informative)

Leak-tightness test – volumetric method . 34Annex C (informative)

Leak-tightness test – pressure loss method . 35Annex D (informative)

Conversion of pressure loss into leakage rate . 36Annex E (normative)

Electrical/electronic component fault modes . 37Annex F (normative)

Additional requirements for safety accessories and pressure accessories as defined in EU Directive 97/23/EC . 38Annex G (normative)

Materials for pressurized parts . 39Annex H (informative)

Additional materials for pressurized parts . 40Annex I (normative)

Requirements for controls used in DC supplied gas burners and gas burning appliances . 41Annex AA (informative)

Manufacturers declaration for EPSDs . 42Annex ZA (informative)

Clauses of this European Standard addressing requirements or provisions of EU-Directives . 43Bibliography . 45 Figures Figure 1 — Differential PSD . 6Figure 2 — Atmospheric PSD . 6Figure 3 — Absolute PSD . 6Figure 4 — EPSD . 7Figure 5 — Step response of EPSD. 8Figure 6 — Clarification of definitions for PSD-M and PSD-S . 9SIST EN 1854:2010

(IEC 60730-2-6:2007, modified) EN 61058-1:2002, Switches for appliances — Part 1: General requirements (IEC 61058-1:2000 + A1:2001, modified) EN 175301-803, Detail Specification: Rectangular connectors — Flat contacts, 0,8 mm thickness, locking screw not detachable EN ISO 75 (all parts), Plastics — Determination of temperature of deflection under load IEC 60730-1:2007, Automatic electrical controls for household and similar use — Part 1: General requirements 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 13611:2007 and the following apply. 3.101 pressure sensing device PSD device which senses pressure and provides a signal NOTE Different types of PSDs are given in Figures 1 to 3. SIST EN 1854:2010

Key 1 sensing element

2 inlet 1 3 inlet 2/reference

Figure 1 — Differential PSD

Key 1 sensing element 2 inlet 1 3 reference

Figure 2 — Atmospheric PSD

Key 1 sensing element 2 inlet 1

Figure 3 — Absolute PSD

3.102 set point pressure to which the PSD is adjusted to operate 3.103 switching pressure inlet pressure at which the PSD operates 3.104 set point range declared range of adjustment of the PSD between the highest and lowest set points 3.105 upper switching pressure pressure at which the PSD operates during an increase in pressure 3.106 lower switching pressure pressure at which the PSD operates during a decrease in pressure 3.107 electronic pressure sensing device EPSD assembly of electronic based pressure sensing element and signal conditioner NOTE Figure 4, clarifies the EPSD. SIST EN 1854:2010

Key 1 EPSD 2 Central Unit 3 Electronic pressure sensing element 4 Signal Conditioner 5 Interface 6 Switching Figure 4 — EPSD 3.108 electronic pressure sensing element part of the EPSD, which transforms the signal to be sensed (e.g. pressure) to another physical value (e.g. force, voltage) 3.109 signal conditioner transforms the signal from the sensing element into the output signal of the EPSD NOTE The signal conditioner may consist of functional electronics as well as electronics which cause the sensor output to be classified as class B or C in accordance with EN 13611:2007. 3.110 response time time counted from start of the step change input signal (e.g. pressure) until the output signal (e.g. voltage, current) is within the settling tolerance for the first time NOTE For further information refer to Figure 5.

Key 1

step function (y1) 2 step response (y2) 3 overshoot value

settling tolerance

5 steady state value

6 response time

7 settling time t time Figure 5 — Step response of EPSD 3.111 step response output signal change of a device having a step change input signal 3.112 steady state value value of the output signal after step response input remains constant 3.113 settling tolerance difference between the current output signal and its steady state value declared by the manufacturer 3.114 settling time time counted from start of the step change input signal until the output signal remains within the settling tolerance 3.115 overshoot value biggest deviation between the output signal and its steady state value after step change of the inlet signal exceeding the settling tolerance for the first time 3.116 withstand pressure pressure that is withstood without degraded characteristic after returning below the maximum inlet pressure NOTE The withstand pressure can be equal to maximum inlet pressure. 3.117 deviation difference between the declared or indicated set point and the pressure measured before the endurance test SIST EN 1854:2010

Key1

minimum inlet pressure 2

maximum inlet pressure 3

withstand pressure 4

set point 5

switching pressure (before endurance) 6

switching pressure (after endurance) 7

deviation 8

drift 9

hysteresis 10

lowest set point 11

highest set point 12

set point range X P-inlet/P-differential

Figure 6 — Clarification of definitions for PSD-M and PSD-S SIST EN 1854:2010

a) Clarifications of hysteresis, maximum inlet and withstand pressure b) Clarifications of drift, transfer ratio,linearity and offset Key 1 hysteresis 2 maximum inlet pressure 3 withstand pressure X P-inlet/P-differential Y output signal Key 1

drift 2

transfer ratio 3

linearity 4

offset X pressure Y output signal Figure 7 — Clarification of definitions for EPSD 3.121 transfer ratio positive or negative rotation of the sensor characteristic with the point of rotation as the intersection of the characteristic and the x-axis NOTE For illustration refer to Figure 7. 3.122 linearity linearity is the worst case deviation of straightness of the actual transfer function from the ideal straight line NOTE For illustration refer to Figure 7. 3.123 offset positive or negative deviation of the intersection of the sensor characteristic and the y-axis NOTE For illustration refer Figure 7. 3.124 resolution minimum incremental output change 4 Classification 4.1 Classes of control EN 13611:2007, 4.1 is replaced by the following: SIST EN 1854:2010

EN 13611:2007, 6.6.4.2, a), b) and d). If EN 13611:2007, 6.6.4.2, d) applies (continues to operate) the EPSD shall continue to function in accordance with the performance requirements as specified in Clause 7, especially with 7.101.2. 6.6.4.3 Second fault Shall be according to EN 13611:2007, 6.6.4.3 with the following modification: EN 13611:2007, 6.6.4.3, a) is not applicable. 6.6.4.4 Fault introduced during lock-out or safety- shut-down EN 13611:2007, 6.6.4.4 is not applicable. 6.6.5 Circuit and construction evaluation Shall be according to EN 13611:2007, 6.6.5. 7 Performance 7.1 General EN 13611:2007, 7.1 shall be replaced by the following: Controls shall operate correctly under all combinations of the following: from the minimum inlet pressure to the maximum inlet pressure, ambient temperature range from 0 °C to 60 °C or wider limits, if declared by the manufacturer; in all mounting positions declared by the manufacturer;

voltage or current range from 85 % to 110 % of the rated supply value or from 85 % of the minimum rated value to 110 % of the maximum rated value. If there is a mounting position(s) declared by the manufacturer where the PSD cannot operate from minimum inlet pressure to the maximum inlet pressure, the range of inlet pressures for that mounting position(s) shall be declared separately. SIST EN 1854:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...