FprEN 13001-3-6

(Main)Cranes - General design - Part 3-6: Limit states and proof of competence of machinery - Hydraulic cylinders

Cranes - General design - Part 3-6: Limit states and proof of competence of machinery - Hydraulic cylinders

This document is to be used together with the other generic parts of the EN 13001 series of standards, see Annex E, as well as pertinent crane type product EN standards, and as such they specify general conditions, requirements and methods to, by design and theoretical verification, prevent mechanical hazards of hydraulic cylinders that are part of the load carrying structures of cranes. Hydraulic piping, hoses and connectors used with the cylinders are not within the scope of this document, as well as cylinders made from other material than carbon steel.

NOTE 1 Specific requirements for particular crane types are given in the appropriate European product standards, see Annex E.

The significant hazardous situations and hazardous events that could result in risks to persons during intended use are identified in Annex F. Clauses 5 to 7 of this document provide requirements and methods to reduce or eliminate these risks:

a) exceeding the limits of strength (yield, ultimate, fatigue);

b) elastic instability (column buckling).

NOTE 2 EN 13001-3-6 deals only with the limit state method in accordance with EN 13001-1.

Krane - Konstruktion allgemein - Teil 3-6: Grenzzustände und Sicherheitsnachweis von Maschinenbauteilen - Hydraulikzylinder

Dieses Dokument ist gemeinsam mit den anderen allgemeinen Teilen der Normenreihe EN 13001, siehe Anhang E, anzuwenden sowie mit den einschlägigen EN-Produktnormen für Krane, die allgemeine Bedingungen, Anforderungen und Methoden festlegen, um so anhand der Konstruktion und des theoretischen Nachweises mechanische Gefährdungen der Hydraulikzylinder, die Teil der lasttragenden Struktur von Kranen sind, zu verhindern. Hydraulikleitungen, -schläuche und -anschlüsse von Zylindern fallen nicht in den Anwendungsbereich dieses Dokuments, genauso wie Zylinder, die aus anderen Werkstoffen als Kohlenstoffstahl bestehen.

ANMERKUNG 1 Besondere Anforderungen für spezielle Krantypen sind in den zutreffenden Europäischen Produktnormen angegeben; siehe Anhang E.

Die signifikanten Gefährdungssituationen und Gefährdungsereignisse, die bei bestimmungsgemäßer Verwendung zu Gefährdungen von Personen führen können, sind in Anhang F aufgeführt. Abschnitt 4 bis Abschnitt 7 dieses Dokuments enthalten Anforderungen und Verfahren zur Verringerung oder Beseitigung dieser Risiken:

a) Überschreitung der Festigkeitsgrenzwerte (Fließgrenze, Bruch- und Ermüdungsfestigkeit);

b) elastische Instabilität (knickstabähnliches Verhalten).

ANMERKUNG 2 EN 13001-3-6 behandelt ausschließlich die Methoden der Grenzzustände nach EN 13001-1.

Appareils de levage à charge suspendue - Conception générale - Partie 3-6 : États limites et vérification d'aptitude des éléments de mécanismes - Vérins hydrauliques

Le présent document doit être utilisé conjointement avec les autres parties génériques de la série des EN 13001, voir Annexe E, ainsi qu'avec les normes européennes pertinentes de type produit, pour appareil de levage à charge suspendue. Dans ce cadre, ils spécifient les conditions générales, les prescriptions et les méthodes visant à prévenir les dangers mécaniques liés aux vérins hydrauliques qui font partie des structures transmettant des charges dans les appareils de levage, par la conception et la vérification théorique. Les tuyaux, flexibles et raccords hydrauliques utilisés avec les vérins, ainsi que les vérins fabriqués dans un autre matériau que l'acier au carbone n'entrent pas dans le domaine d'application du présent document.

NOTE 1 Des prescriptions spécifiques pour des types particuliers d’appareil de levage à charge suspendue sont données dans la Norme européenne Produit appropriée au type particulier d’appareil de levage à charge suspendue, voir Annexe E.

Les situations et les événements dangereux significatifs susceptibles d’entraîner des risques pour les personnes lors d’une utilisation normale et d’une mauvaise utilisation raisonnablement prévisible sont identifiés à l’Annexe F. Les Articles 4 à 7 du présent document fournissent des prescriptions et des méthodes réduire ou éliminer ces risques :

a) dépassement des limites de résistance (élasticité, rupture, fatigue) ;

b) instabilité élastique (flambage de colonne).

NOTE 2 L'EN 13001-3-6 traite uniquement de la méthode des états limites selon l’EN 13001-1.

Žerjavi - Konstrukcija, splošno - 3-6. del: Mejna stanja in dokaz varnosti mehanizma - Hidravlični cilindri

General Information

- Status

- Not Published

- Publication Date

- 24-Mar-2026

- Technical Committee

- CEN/TC 147 - Cranes - Safety

- Drafting Committee

- CEN/TC 147/WG 2 - Design - General

- Current Stage

- 5060 - Closure of Vote - Formal Approval

- Start Date

- 15-Jan-2026

- Completion Date

- 15-Jan-2026

Relations

- Effective Date

- 17-Apr-2024

Overview

The FprEN 13001-3-6:2025 standard, developed by CEN, addresses the design and safety verification of hydraulic cylinders integral to crane load-bearing structures. It forms part of the comprehensive EN 13001 series focused on crane general design and safety, emphasizing limit states and proof of competence for machinery components, specifically hydraulic cylinders made of carbon steel.

This standard guides designers and manufacturers in applying theoretical and practical methods to prevent mechanical hazards such as strength exceedance and elastic instability (buckling), ensuring safety during crane operation. It excludes hydraulic piping, hoses, connectors, and cylinders made from materials other than carbon steel.

Key Topics

Scope and Integration

FprEN 13001-3-6 is intended for combined use with other generic parts of the EN 13001 series and specific crane type standards. It specifies essential conditions and verification methods applicable to hydraulic cylinders as part of crane machinery.Mechanical Hazard Prevention

The standard focuses on reducing risks related to:- Exceeding yield, ultimate, and fatigue strength limits

- Elastic instability or column buckling of hydraulic cylinders

Limit State Design Method

The standard adopts the limit state method per EN 13001-1 guidelines, providing a framework for structural reliability assessment under static and fatigue loading conditions.Static Strength Proof

Requirements for documenting and analyzing material properties, design stresses (including for welded and bolted connections), linear and nonlinear stress analyses, and detailing load cases and boundary conditions.Fatigue Strength and Stability

Procedures for fatigue strength verification, including stress history analysis, fatigue-critical details such as welds and threads, and guidelines for proving elastic stability against buckling.Documentation and Material Specifications

Stipulations on material grades (carbon steel), flattening test conditions, and resistance factors to ensure quality and conformity.Hazard Identification

Annex F lists significant hazardous situations and events to be proactively addressed to reduce risks to personnel during intended use.

Applications

Crane Manufacturing

Enables manufacturers to design hydraulic cylinders that meet stringent safety and performance criteria, essential for cranes used in construction, logistics, and heavy industry.Safety Compliance and Certification

Assists regulatory bodies and health and safety organizations to verify compliance with European machinery safety directives related to cranes.Maintenance and Inspection

Provides a technical basis for service providers and maintenance teams to assess structural integrity and detect potential fatigue or buckling issues early.Engineering Design and Simulation

Offers validated engineering methods for static and dynamic analysis of hydraulic cylinders under various loading conditions, supporting improved crane reliability and lifecycle management.

Related Standards

EN 13001 Series

The general framework for crane design, including:- Part 1: General principles

- Other product-specific EN standards for different crane types (see Annex E for selection guidance).

EN 10277:2018

Norms for bright steel products relevant for material quality verification in hydraulic cylinders.EN 10297-1:2003

Standards for seamless circular steel tubes that apply to cylinder tube manufacturing.

Practical Value and Benefits

- Ensures hydraulic cylinders in cranes are designed to withstand operational stresses and fatigue over their service life.

- Mitigates risk of mechanical failure that could endanger operators and bystanders.

- Harmonizes design requirements across European markets, facilitating easier compliance and product acceptance.

- Supports efficient documentation and verification processes during design and certification stages.

- Enhances safety and reliability, contributing to longer, safer crane operation with reduced downtime.

By adhering to FprEN 13001-3-6:2025, crane designers and manufacturers can confidently meet European safety standards for hydraulic cylinders, ultimately safeguarding operational effectiveness and workforce well-being. This standard is critical for stakeholders aiming to maintain high craftsmanship and safety in crane technology.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

FprEN 13001-3-6 is a draft published by the European Committee for Standardization (CEN). Its full title is "Cranes - General design - Part 3-6: Limit states and proof of competence of machinery - Hydraulic cylinders". This standard covers: This document is to be used together with the other generic parts of the EN 13001 series of standards, see Annex E, as well as pertinent crane type product EN standards, and as such they specify general conditions, requirements and methods to, by design and theoretical verification, prevent mechanical hazards of hydraulic cylinders that are part of the load carrying structures of cranes. Hydraulic piping, hoses and connectors used with the cylinders are not within the scope of this document, as well as cylinders made from other material than carbon steel. NOTE 1 Specific requirements for particular crane types are given in the appropriate European product standards, see Annex E. The significant hazardous situations and hazardous events that could result in risks to persons during intended use are identified in Annex F. Clauses 5 to 7 of this document provide requirements and methods to reduce or eliminate these risks: a) exceeding the limits of strength (yield, ultimate, fatigue); b) elastic instability (column buckling). NOTE 2 EN 13001-3-6 deals only with the limit state method in accordance with EN 13001-1.

This document is to be used together with the other generic parts of the EN 13001 series of standards, see Annex E, as well as pertinent crane type product EN standards, and as such they specify general conditions, requirements and methods to, by design and theoretical verification, prevent mechanical hazards of hydraulic cylinders that are part of the load carrying structures of cranes. Hydraulic piping, hoses and connectors used with the cylinders are not within the scope of this document, as well as cylinders made from other material than carbon steel. NOTE 1 Specific requirements for particular crane types are given in the appropriate European product standards, see Annex E. The significant hazardous situations and hazardous events that could result in risks to persons during intended use are identified in Annex F. Clauses 5 to 7 of this document provide requirements and methods to reduce or eliminate these risks: a) exceeding the limits of strength (yield, ultimate, fatigue); b) elastic instability (column buckling). NOTE 2 EN 13001-3-6 deals only with the limit state method in accordance with EN 13001-1.

FprEN 13001-3-6 is classified under the following ICS (International Classification for Standards) categories: 23.100.20 - Cylinders; 53.020.20 - Cranes. The ICS classification helps identify the subject area and facilitates finding related standards.

FprEN 13001-3-6 has the following relationships with other standards: It is inter standard links to EN 13001-3-6:2018+A1:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

FprEN 13001-3-6 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2023/1230; Standardization Mandates: M/396, M/605. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

FprEN 13001-3-6 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN 13001-3-6:2025

01-marec-2025

Žerjavi - Konstrukcija, splošno - 3-6. del: Mejna stanja in dokaz varnosti

mehanizma - Hidravlični cilindri

Cranes - General design - Part 3-6: Limit states and proof of competence of machinery -

Hydraulic cylinders

Krane - Konstruktion allgemein - Teil 3-6: Grenzzustände und Sicherheitsnachweis von

Maschinenbauteilen - Hydraulikzylinder

Appareils de levage à charge suspendue - Conception générale - Partie 3-6 : États

limites et vérification d'aptitude des éléments de mécanismes - Vérins hydrauliques

Ta slovenski standard je istoveten z: prEN 13001-3-6

ICS:

23.100.20 Hidravlični valji Cylinders

53.020.20 Dvigala Cranes

oSIST prEN 13001-3-6:2025 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN 13001-3-6:2025

oSIST prEN 13001-3-6:2025

DRAFT

EUROPEAN STANDARD

prEN 13001-3-6

NORME EUROPÉENNE

EUROPÄISCHE NORM

January 2025

ICS 23.100.20; 53.020.20 Will supersede EN 13001-3-6:2018+A1:2021

English Version

Cranes - General design - Part 3-6: Limit states and proof

of competence of machinery - Hydraulic cylinders

Appareils de levage à charge suspendue - Conception Krane - Konstruktion allgemein - Teil 3-6:

générale - Partie 3-6 : États limites et vérification Grenzzustände und Sicherheitsnachweis von

d'aptitude des éléments de mécanismes - Vérins Maschinenbauteilen - Hydraulikzylinder

hydrauliques

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 147.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 13001-3-6:2025 E

worldwide for CEN national Members.

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

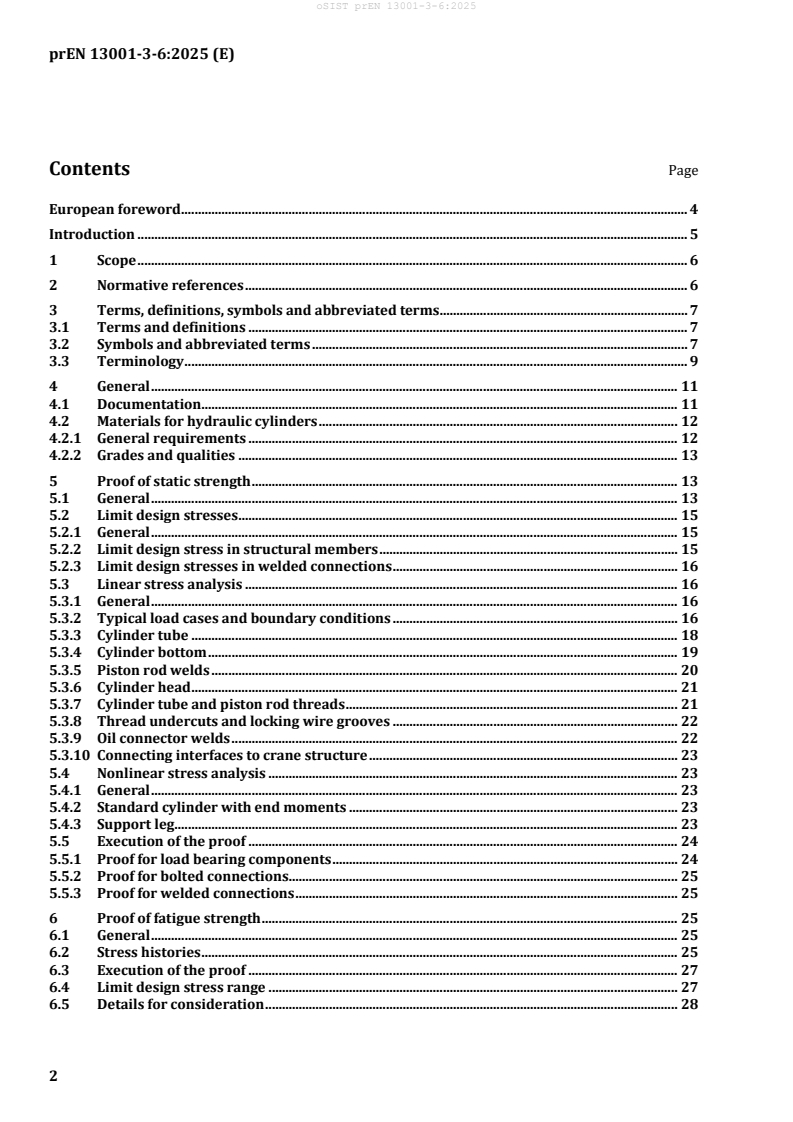

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions, symbols and abbreviated terms . 7

3.1 Terms and definitions . 7

3.2 Symbols and abbreviated terms . 7

3.3 Terminology . 9

4 General . 11

4.1 Documentation . 11

4.2 Materials for hydraulic cylinders . 12

4.2.1 General requirements . 12

4.2.2 Grades and qualities . 13

5 Proof of static strength . 13

5.1 General . 13

5.2 Limit design stresses . 15

5.2.1 General . 15

5.2.2 Limit design stress in structural members . 15

5.2.3 Limit design stresses in welded connections . 16

5.3 Linear stress analysis . 16

5.3.1 General . 16

5.3.2 Typical load cases and boundary conditions . 16

5.3.3 Cylinder tube . 18

5.3.4 Cylinder bottom . 19

5.3.5 Piston rod welds . 20

5.3.6 Cylinder head . 21

5.3.7 Cylinder tube and piston rod threads . 21

5.3.8 Thread undercuts and locking wire grooves . 22

5.3.9 Oil connector welds . 22

5.3.10 Connecting interfaces to crane structure . 23

5.4 Nonlinear stress analysis . 23

5.4.1 General . 23

5.4.2 Standard cylinder with end moments . 23

5.4.3 Support leg . 23

5.5 Execution of the proof . 24

5.5.1 Proof for load bearing components . 24

5.5.2 Proof for bolted connections . 25

5.5.3 Proof for welded connections . 25

6 Proof of fatigue strength . 25

6.1 General . 25

6.2 Stress histories . 25

6.3 Execution of the proof . 27

6.4 Limit design stress range . 27

6.5 Details for consideration . 28

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

6.5.1 General . 28

6.5.2 Bottom weld. 28

6.5.3 Notch stress at oil connectors . 31

6.5.4 Cylinder head . 31

6.5.5 Piston rod . 33

6.5.6 Cylinder head bolts . 35

6.5.7 Cylinder head flange weld . 35

6.5.8 Mechanical interfaces . 38

7 Proof of elastic stability . 38

7.1 General . 38

7.2 Critical buckling load . 38

7.3 Limit compressive design force . 40

7.4 Execution of the proof . 41

Annex A (informative) Critical buckling load for common buckling cases . 42

A.1 General . 42

A.2 Buckling case A . 43

A.3 Buckling case B . 43

A.4 Buckling case C . 44

A.5 Buckling case D . 44

A.6 Buckling case E . 44

A.7 Buckling case F . 45

A.8 Buckling case G . 45

Annex B (informative) Second order analysis of two important cases . 46

B.1 Compressed cylinder with end moments and angular misalignment . 46

B.2 Compressed cylinder with lateral end force and angular misalignment . 47

B.3 Axial stresses for cases in B.1 and B.2 . 48

Annex C (informative) Shell section forces and moments for cylinder bottom . 49

Annex D (informative) Fatigue analysis of bottom weld for more complex cases . 52

Annex E (informative) Selection of a suitable set of crane standards for a given application . 55

Annex F (informative) List of hazards . 57

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Regulation (EU) 2023/1230 aimed to be covered. 58

Bibliography . 59

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

European foreword

This document (prEN 13001-3-6:2025) has been prepared by Technical Committee CEN/TC 147 “Cranes

- Safety”, the secretariat of which is held by SFS.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 13001-3-6:2018+A1:2021.

prEN 13001-3-6:2025 includes the following significant technical changes with respect to

EN 13001-3-6:2018+A1:2021:

— conditions for flattening test of tube material were changed (4.2.1);

— conservative default value for efficiency of active cylinders was changed (5.1);

— the specific resistance factor for material was changed (5.2.2).

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

Introduction

This document is a type-C standard as stated in EN ISO 12100.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by

the above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in the case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate in the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

1 Scope

This document is to be used together with the other generic parts of the EN 13001 series of standards,

see Annex E, as well as pertinent crane type product EN standards, and as such they specify general

conditions, requirements and methods to, by design and theoretical verification, prevent mechanical

hazards of hydraulic cylinders that are part of the load carrying structures of cranes. Hydraulic piping,

hoses and connectors used with the cylinders are not within the scope of this document, as well as

cylinders made from other material than carbon steel.

NOTE 1 Specific requirements for particular crane types are given in the appropriate European product

standards, see Annex E.

The significant hazardous situations and hazardous events that could result in risks to persons during

intended use are identified in Annex F. Clauses 4 to 7 of this document provide requirements and

methods to reduce or eliminate these risks:

a) exceeding the limits of strength (yield, ultimate, fatigue);

b) elastic instability (column buckling).

NOTE 2 EN 13001-3-6 deals only with the limit state method in accordance with EN 13001-1.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 10277:2018, Bright steel products — Technical delivery conditions

EN 10297-1:2003, Seamless circular steel tubes for mechanical and general engineering purposes —

Technical delivery conditions — Part 1: Non-alloy and alloy steel tubes

EN 10305-1:2016, Steel tubes for precision applications — Technical delivery conditions — Part 1:

Seamless cold drawn tubes

EN 10305-2:2016, Steel tubes for precision applications — Technical delivery conditions — Part 2: Welded

cold drawn tubes

EN 13001-2:2021, Crane safety — General design — Part 2: Load actions

EN 13001-3-1:2012+A2:2018, Cranes — General design — Part 3-1: Limit States and proof competence of

steel structure

EN ISO 148-1:2016, Metallic materials — Charpy pendulum impact test — Part 1: Test method

(ISO 148-1:2016)

EN ISO 683-1:2018, Heat-treatable steels, alloy steels and free-cutting steels — Part 1: Non-alloy steels for

quenching and tempering (ISO 683-1:2016)

EN ISO 683-2:2018, Heat-treatable steels, alloy steels and free-cutting steels — Part 2: Alloy steels for

quenching and tempering (ISO 683-2:2016)

EN ISO 5817:2023, Welding — Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) — Quality levels for imperfections (ISO 5817:2023)

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

ISO 724:2023, ISO general-purpose metric screw threads — Basic dimensions

3 Terms, definitions, symbols and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.2 Symbols and abbreviated terms

The essential symbols and abbreviated terms are given in Table 1.

Table 1 — Symbols and abbreviations

Symbols Description

A% Percentage elongation at fracture

a Weld throat thickness

A , B , C , D Constants

i i i i

A Stress area

s

D Piston diameter

d Rod diameter

D Diameter of axles

a,i

D Pressure affected diameter

p

D Weld diameter

w

E Modulus of elasticity

F Compressive force

F Compressive force

A

FE Finite Elements

f Limit design stress

Rd

f Limit design stress, normal

Rdσ

f Limit design stress, shear

Rdτ

F Lateral force

S

F External design force

Sd

f Ultimate strength

u

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

f Limit design weld stress

w,Rd

f Yield strength

y

h thickness of the cylinder bottom

I Moment of inertia, generic

I Moment of inertia of the tube

I Moment of inertia of the rod

L Overall length of the cylinder

L Length of the cylinder tube

L Length of the cylinder rod

m Slope of the log Δσ – log N curve

M Shell section bending moment, acting at the intersection between tube and

bottom

MB Bending moment

N Compressive force

N Critical buckling load

k

N Limit compressive design force

Rd

p Maximum pressure in piston side chamber

i1

p Maximum pressure in rod side chamber

i2

p Outer pressure

o

p Design pressure

Sd

R Middle radius of the tube (R = R + t/2)

i

r Inner radius of the tube

i

R Inner radius of the tube

i

r Outer radius of the tube

o

r Outer radius of the piston rod

r

s Stress history parameter (see EN 13001-3-1)

t Wall thickness of the tube

T Shell section transverse force, acting at the intersection between tube and bottom

x, y Longitudinal and lateral coordinates

α Angular misalignment, radians

γ General resistance factor (γ = 1,1, see EN 13001-2)

m m

γ Fatigue strength specific resistance factor (see EN 13001-3-1)

mf

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

γ Total resistance factor (γ = γ · γ )

R R m s

γ Specific resistance factor

s

Δσ Stress range

Δσ Bending stress range in the tube

b

Δσ Characteristic fatigue strength

c

Δσ Membrane stress range in the tube (axial)

m

Δσ Limit design stress range

Rd

Δσ Design stress range

Sd

Δp Design pressure range on piston side

Sd

δ Maximum displacement

max

κ Reduction factor for buckling

λ Slenderness

λ Friction parameters

i

μ Friction factors

i

ν Poisson’s ratio (ν = 0,3 for steel)

σ Axial stress in the tube

a

σ Lower extreme value of a stress range

b

σ Radial stress in the tube

r

σ Design stress, normal

Sd

σ Tangential stress in the tube (hoop stress)

t

σ Upper extreme value of a stress range

u

σ Weld design stress, normal

w,Sd

τ Design stress, shear

Sd

τ Weld design stress, shear

w,Sd

3.3 Terminology

Terms which are used in this European Standard for the main parts of hydraulic cylinder are indicated in

Figure 1 to Figure 3.

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

Key

1 bushing

2 rod head

3 cylinder head

4 oil connector

5 piston rod

6 cylinder tube

7 spacer

8 piston

9 nut

10 cylinder bottom

11 grease nipple

12 piston side chamber

13 rod side chamber

Figure 1 — Complete cylinder

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

Key

1 wiper

2 O-ring

3 secondary seal

4 guide ring (2 × )

5 primary seal

6 backup ring

7 O-ring

Figure 2 — Cylinder head

Key

1 seal

2 pressure element

3 guide ring (2 × )

Figure 3 — Piston

The figures above show some specific design features in order to exemplify the terminology. Other

designs may be used.

4 General

4.1 Documentation

The documentation of the proof of competence shall include:

— design assumptions including calculation models;

— applicable loads and load combinations;

— material grades and qualities;

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

— weld quality levels, in accordance with EN ISO 5817:2023 and EN 13001-3-1:2012+A2:2018;

— relevant limit states;

— results of the proof of competence calculation, and tests when applicable.

4.2 Materials for hydraulic cylinders

4.2.1 General requirements

The materials for cylinder tubes and piston rods shall fulfil the following requirements:

— The impact toughness shall be tested in accordance with EN ISO 148-1:2016 and shall meet the

requirements stated in EN 13001-3-1:2012+A2:2018. Samples shall be cut out in the longitudinal

direction. For cylinder tubes and tubes for pressurized piston rods, samples shall also be cut out in

the transversal direction. The samples shall be prepared such that the axis of the notch is

perpendicular to the surface of the tube.

Key

1 sample cut out in longitudinal direction

2 sample cut out in transversal direction

Figure 4 — Sample for impact toughness testing

— Impact testing in the transversal direction of the tube material may be replaced by a flattening test

in accordance with EN ISO 8492:2013. Two flattening tests are required for welded tubes, one with

the weld aligned with the press direction and one where the weld is placed 90 degrees from the press

direction. The tube section shall be flattened down to a height H given by:

1+⋅C t

( )

H=

t

C+

D

o

where

C is a factor that depends on the yield strength of the tube,

C is 0,07 for f ≤ 400 MPa and C is 0,05 for f > 400 MPa;

y y

D is the outer diameter of the tube;

o

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

t is the wall thickness of the tube.

Material used in other parts shall meet the requirements stated in EN 13001-3-1:2012+A2:2018.

4.2.2 Grades and qualities

European Standards specify materials and specific values. This document gives a preferred selection.

Steels in accordance with the following European Standards shall be used as material for cylinder tubes

and piston rods:

— EN ISO 683-1:2018;

— EN ISO 683-2:2018;

— EN 10277:2018;

— EN 10297-1:2003;

— EN 10305-1:2016;

— EN 10305-2:2016.

Alternatively, other steel grades and qualities than those listed in this clause may be used as material for

cylinder tubes and piston rods, provided that the following conditions apply:

— the design value of f is limited to f /1,1 for materials with f /f < 1,1;

y u u y

— the percentage elongation at fracture A % ≥ 14 % on a gauge length LS5,65× (where S is the

0 0

original cross-sectional area);

Grades and qualities of materials used in other parts of cylinders or mounting interfaces of cylinders shall

be selected in accordance with EN 13001-3-1:2012+A2:2018.

5 Proof of static strength

5.1 General

A proof of static strength by calculation is intended to prevent excessive deformations due to yielding of

the material, elastic instability and fracture of structural members or connections. Dynamic factors given

in EN 13001-2:2021 or relevant product standards are used to produce equivalent static loads to

simulate dynamic effects. Also, load increasing effects due to deformation shall be considered. The use of

the theory of plasticity for calculation of ultimate load bearing capacity is not considered acceptable

within the terms of this document. The proof shall be carried out for structural members and connections

while taking into account the most unfavourable load effects from the load combinations A, B or C in

accordance with EN 13001-2:2021 or relevant product standards.

Cylinder actions are either active or passive. The action is active when the force from the cylinder exerts

a positive work on the crane structure, elsewise the action is passive. As the forces applied to the cylinder

by the crane structure are computed in accordance with EN 13001-2:2021, they are already increased by

the partial safety factors γ and relevant dynamic factors. Formulae (1) and (2) give design pressures p

p Sd

caused by forces acting on the cylinder from the crane structure. In addition, additional pressures p

Sde

caused by internal phenomena in the hydraulic circuit shall be considered and added to the design

pressures p . Such internally generated pressures can be caused e.g. by regenerative connections,

Sd

pressure drop in return lines or cushioning.

=

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

In case a cylinder is intended to be tested as a component at higher pressure than the design pressure

p , this load case shall also be taken into account in the proof of static strength, and in which case the

Sd

test pressure shall be multiplied by a partial safety factor γ equal to 1,05.

p

The design pressure p in the piston side chamber or in the rod side chamber shall be computed from

Sd

the design force F taking into account the force direction and the cylinder efficiency η due to friction.

Sd

An efficiency factor Ψ is used to handle the effect of cylinder friction. For active cylinders Ψ has the value

of 1/η and for passive cylinders Ψ has the value of η.

For the piston side chamber, the design pressure is given by:

4⋅ F

Sd

p ⋅Ψ (1)

Sd

π⋅ D

where

F is the external design force;

Sd

D is the piston diameter.

Ψ is set to η for passive cylinders and to 1/η for active cylinders.

For the rod side chamber, the design pressure is given by:

4⋅ F

Sd

pp⋅Ψ+ (2)

Sd Sde

π⋅ Dd−

( )

where

F is the external design force;

Sd

D is the piston diameter;

d is the rod diameter;

Ψ is set to η for passive cylinders and to 1/η for active cylinders;

p is additional pressure caused by internal phenomena.

Sde

Unless justified information (e.g. obtained by test) for the value of η is used, Ψ shall be assigned the value

of 1,05 for active cylinders and the value of 1,0 for passive cylinders.

NOTE The cylinder efficiency η due to friction is assumed to be evaluated at the working pressure.

This document is based on nominal stresses, i.e. stresses calculated using traditional elastic strength of

materials theory which in general neglect localized stress non-uniformities. When more accurate

alternative methods of stress calculation are used, such as finite element analysis, using those stresses

for the proof given in this document can yield inordinately conservative results.

=

=

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

5.2 Limit design stresses

5.2.1 General

The limit design stresses shall be calculated from:

Limit desing stresses ff= function ,γ (3)

( )

Rd k R

where

f is the characteristic values (or nominal value);

k

γ is the total resistance factor γ γγ⋅ ;

R

R m s

γ is the general resistance factor γ = 1,1 (see EN 13001-2:2021);

m m

γ is the specific resistance factor applicable to specific structural components as given in the

s

clauses below.

NOTE f is equivalent to R /γ in EN 13001-1.

Rd d m

5.2.2 Limit design stress in structural members

The limit design stress f , used for the design of structural members, shall be calculated from:

Rd

f

y

f = for normal stresses (4)

Rdσ

γ

Rm

f

y

f = for shear stresses (5)

Rdτ

γ ⋅ 3

Rm

with

γ γγ⋅

Rm m sm

where

f is the minimum value of the yield stress of the material;

y

γ is the specific resistance factor for material.

sm

γsm = 0,95 is the value for steel not loaded perpendicular to the rolling plane.

For tensile stresses perpendicular to the plane of rolling (see Figure 5), the material shall be suitable for

carrying perpendicular loads and be free of lamellar defects. EN 13001-3-1:2012+A2:2018 specifies the

values of γ for material loaded perpendicular to the rolling plane.

sm

Example from cylinder tube bottom, where plate steel is used (eye is welded). The figure shows a tensile

load perpendicular to plane of rolling where:

=

=

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

Key

1 is the plane of rolling

2 is the direction of stress/load

Figure 5 — Tensile load perpendicular to plane of rolling

5.2.3 Limit design stresses in welded connections

The limit design weld stress f used for the design of a welded connection shall be in accordance with

w,Rd

EN 13001-3-1:2012+A2:2018.

5.3 Linear stress analysis

5.3.1 General

5.3 comprises typical details for consideration that are relevant for the proof of static strength. Details

that are only relevant for fatigue analysis (e.g. shell bending of tube) are not dealt with in 5.3. In cases or

conditions not covered here, other recognized sources or static pressure/force testing shall be used.

5.3.2 Typical load cases and boundary conditions

Before executing calculations, boundary conditions and loading shall be investigated. Typical conditions

to be determined are:

— external forces and directions;

— type of cylinder;

— cylinder tube and rod mounting to the machine;

— forces/stresses due to thread pre-tightening;

— direction of gravity.

Different load cases shall be considered when calculating static strength for cylinders.

Typical load cases are shown in Figure 6 to Figure 10 here below.

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

Figure 6 — Pushing cylinder with supported bottom

Figure 7 — Pushing cylinder, flange mounted with unsupported bottom

Figure 8 — Pulling cylinder or pushing cylinder with pressurized rod chamber

Figure 9 — Pushing cylinder at end of stroke

Figure 10 — Pulling cylinder at end of stroke

The worst load condition or combination shall be used when calculating stresses σ or σ for a feature.

Sd w,Sd

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

5.3.3 Cylinder tube

Cylinder tube stresses shall be computed from three components. For calculation of each component,

forces and pressures shall be determined in accordance with 5.3.2.

Figure 11 — Stresses in cylinder tube

The tangential stress (hoop stress) is given by:

2 2

r r

o i

+ 1 + 1

r r

σ rp= ⋅ + p⋅ (6)

( )

ti o

r r

o i

−−1 1

rr

io

For cylindrical shells such as tubes or hollow rods that are also loaded by an outer pressure, the

combination of inner and outer pressure that gives the largest absolute value of the tangential (hoop)

stress shall be used.

Maximum radial stress magnitude in the tube occurs at the inner radius r or the at the outer radius r

i o

and is given by:

σ =−p orσ =−p (7)

r i r o

For the cylinder arrangement shown in Figure 6, maximum axial stress in the tube is given by:

4⋅ r

o

σ M⋅ (8)

ab

π⋅ r − r

( )

oi

For the cylinder arrangements shown in Figure 8 and Figure 10, maximum axial stress in the tube is given

by:

2 2

p ⋅−r r

)

i2 ( i r 4⋅ r

o

σ +⋅M (9)

ab

2 2

r − r

π⋅ r − r

oi ( )

oi

=

=

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

For the cylinder arrangement shown in Figure 7 and Figure 9, maximum axial stress in the tube is given

by:

p ⋅ r 4⋅ r

i1 i o

σ +⋅M (10)

ab

2 2

r − r

π⋅ r − r

)

oi ( oi

where

r is an arbitrary radius of the tube;

r is the inner radius of the tube;

i

r is the outer radius of the tube;

o

r is the outer radius of the piston rod;

r

p is the inner pressure;

i

p is the inner maximum pressure in piston side chamber;

i1

p is the inner maximum pressure in rod side chamber;

i2

p is the outer pressure;

o

M is any bending moment acting on the cylinder tube (e.g. dead weight).

b

The von Mises equivalent stress shall be computed for the location having the most severe stress as:

σ σ++−σ σ σσ−σσ−σ σ (11)

Sd t r a t a t r r a

5.3.4 Cylinder bottom

5.3.4.1 Bottom plate

The stress in an unsupported bottom plate, in a cylinder with the ratio outer diameter to inner diameter

in the range 1,07 to 1,24, shall be calculated as:

341 3 D+⋅2 tD

σ = p⋅ −⋅ ⋅ (12)

Sd i

350 7 D h

where

p is the inner pressure;

i

D is the inner diameter;

t is the tube thickness;

h is the bottom thickness.

=

=

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

Figure 12 — Stresses in unsupported cylinder bottom

5.3.4.2 Bottom weld

Bottom welds shall be calculated for different load cases in accordance with 5.3.2.

Figure 13 — Bottom weld

The bottom weld is loaded by the axial force in the tube, caused by internal pressure (Figure 7 and

Figure 8) or by pushing cylinder coming to end of stroke (Figure 9).

F

Sdt

σ = (13)

w,Sd

2⋅π⋅ R⋅ a

where

F is the design axial force acting in the tube;

Sdt

a is the effective throat thickness of the weld, see EN 13001-3-1:2012+A2:2018, Annex C;

R is the middle radius of the weld.

5.3.5 Piston rod welds

Piston rod welds shall be calculated for different load cases according to 5.3.2, in the same way as the

calculation of bottom welds.

F

Sdw

σ = (14)

w,Sd

2⋅π⋅ R⋅ a

where

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

F is the maximum design force acting in the rod;

Sdw

a is the effective throat thickness of the weld, see EN 13001-3-1:2012+A2:2018, Annex C;

R is the middle radius of the weld.

5.3.6 Cylinder head

Depending on the design, the cylinder head has a governing stress area A , which is the smallest area that

c

carries the axial load. Axial force can be caused by internal pressure, external force or pre-tightening. The

stresses in the cylinder head shall be calculated for the different load cases in accordance with 5.3.2. The

design stress shall be computed as:

F

Sdh

σ = (15)

Sd

A

c

where

F is the maximum axial design force acting on the head;

Sdh

A is the critical stress area for the axial force holding the cylinder head.

c

5.3.7 Cylinder tube and piston rod threads

Stresses in cylinder tube threads and piston rod threads shall be calculated for the different load cases in

accordance with 5.3.2. The design stress shall be computed as:

F

Sdr

σ = (16)

Sd

A

s

2⋅ F

Sdr

τ = (17)

Sd

π⋅ Ld⋅

where

F is the maximum design force acting on the cylinder head or the piston rod head;

Sdr

A is the stress area of the threaded cylinder tube or piston rod (equivalent to stress area of bolt or

s

nut);

L is the effective threaded length, maximum 0,9 · d ;

d is the pitch diameter of the thread in accordance to ISO 724:2023.

It shall be considered that the tube diameter can increase due to the internal pressure and thus decrease

the shear area in Formula (17).

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

5.3.8 Thread undercuts and locking wire grooves

Stresses in thread undercuts or locking wire grooves shall be calculated for the different load cases in

accordance with 5.3.2.

The design stress shall be computed as:

F

Sdu

σ = (18)

Sd

A

c

where

F is the maximum design force acting at the undercut;

Sdu

A is the critical stress area at the undercut or locking wire groove.

c

Figure 14 — Undercuts at thread run out

5.3.9 Oil connector welds

This clause considers oil connectors welded to the tube. The design stress σ shall be computed as:

w,Sd

F

Sdo

σ = (19)

w,Sd

A

with

A=π⋅ D ⋅ a (20)

w

and

pD⋅π⋅

Sd p

F = (21)

Sdo

where

p is the design pressure for chamber side;

Sd

D is the pressure affected diameter;

p

a is the effective throat thickness of the weld, see EN 13001-3-1:2012+A2:2018, Annex C;

D is the effective weld diameter.

w

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

Figure 15 — Welded oil connector

5.3.10 Connecting interfaces to crane structure

The design stresses in parts connecting the cylinder to the crane structure shall be calculated in

accordance with EN 13001-3-1:2012+A2:2018.

5.4 Nonlinear stress analysis

5.4.1 General

Nonlinear stress analysis takes into account the force balance in the deformed shape of the cylinder and

can be governing when the compressive force acts together with bending moment or lateral force, or due

to the angular misalignment α between rod and tube caused by the play at the guide rings. Nonlinear

stress analysis may be omitted if lateral forces and bending moments are negligible, and if the maximum

displacement δ due to the angular misalignment α is smaller than L/600, where L is the overall length

max

of the cylinder. If the misalignment is unknown, δ shall be set to L/300. The omission of a second order

max

analysis shall be justified.

In particular the cases described in 5.4.2 and 5.4.3 might require nonlinear stress analysis. The nonlinear

stress analyses may either be made with FE-analysis or by the analytical equations given in Annex B.

5.4.2 Standard cylinder with end moments

Standard cylinder with the same configuration as in buckling case D (see 7.2), loaded by a compressive

force F and by moments M and M caused by axle frictions acting at the bushings at the cylinder’s ends,

1 2

and with an angular misalignment α between the cylinder tube and the piston rod caused by play at guide

rings, see Figure 16.

Figure 16 — Cylinder with end moments from axle frictions and angular misalignment

5.4.3 Support leg

Support leg cylinder loaded by a compressive force F and by a lateral force F , and with an angular

A S

misalignment α between the cylinder tube and the piston rod caused by play at guide rings, see Figure 17.

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

Figure 17 — Support leg cylinder with lateral force and angular misalignment

5.5 Execution of the proof

5.5.1 Proof for load bearing components

For the load bearing components (e.g. tube, rod, lugs) it shall be proven that:

σ ≤ f and τ ≤ f (22)

Sd Rdσ Sd Rdτ

where

σ is the design normal stress or the von Mises equivalent stress;

Sd

τ is the design shear stress;

Sd

f , f are the corresponding limit design stresses in accordance with 5.2.2.

Rdσ Rdτ

oSIST prEN 13001-3-6:2025

prEN 13001-3-6:2025 (E)

5.5.2 Proof for bolted connections

Bolted connections shall be proofed in accordance with EN 13001-3-1:2012+A2:2018.

5.5.3 Proof for welded connections

For the weld it shall be proven that:

σ ≤ f (23)

w,Sd w,Rd

where

σ is the design weld stress;

w,Sd

f is the limit design weld stress in accordance with EN 13001-3-1:2012+A2:2018.

w,Rd

6 Proof of fatigue strength

6.1 General

The proof of fatigue strength is intended to prevent risk of failure due to formation and propagation of

critical cracks in load carrying part of a hydraulic cylinder under cyclic loading.

For the execution of the proof of fatigue strength, the cumulative damages caused by variable stress cycles

shall be c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...