prEN 17152-1

(Main)Plastics piping systems for non-pressure underground conveyance and storage of surface water - Boxes used for infiltration, attenuation and storage systems - Part 1: Specifications for boxes made of PP and PVC-U

Plastics piping systems for non-pressure underground conveyance and storage of surface water - Boxes used for infiltration, attenuation and storage systems - Part 1: Specifications for boxes made of PP and PVC-U

This document gives the definitions and specifies the minimum requirements for injection moulded, extruded and thermoformed thermoplastics cuboid shaped boxes, including integral components, used in underground systems for infiltration, attenuation and storage of surface water (e.g. storm water) and manufactured from polypropylene (PP) or unplasticized polyvinylchloride (PVC-U).

Product properties are determined by a combination of material specifications, design and manufacturing process.

These boxes are intended for buried underground use, e.g. in landscape, pedestrian or vehicular traffic areas.

A box can either be factory assembled, or site assembled from different components.

These boxes are intended to be used as elements in a modular system where the manufacturer states in the documentation how the components are assembled to create a complete infiltration, attenuation or storage system.

NOTE Non load bearing component(s) can be manufactured by various methods e.g. extrusion, injection moulding, rotational moulding, thermoforming and low-pressure injection moulding.

Kunststoff-Rohrleitungssysteme für die drucklose unterirdische Entwässerung für Nicht-Trinkwasser - Versickerungsblöcke zur Verwendung in Infiltrations-, Zwischenspeicher- und Speichersystemen - Teil 1: Festlegungen für Regenwasserabfluss-Versickerungsblöcke aus PP und PVC-U

Dieses Dokument enthält die Begriffsbestimmungen und legt die Mindestanforderungen an spritzgegossene, extrudierte und warmgeformte thermoplastische quaderförmige Versickerungsblöcke, einschließlich integrale Bestandteile, fest, die in unterirdischen Systemen zur Infiltration, Zwischenspeicherung und Speicherung von Oberflächenwasser (z. B. Regenwasserabfluss) verwendet werden und aus Polypropylen (PP) oder weichmacherfreiem Polyvinylchlorid (PVC-U) bestehen.

Die Produkteigenschaften werden durch eine Kombination aus Werkstoffspezifikationen, Konstruktion und Herstellungsprozess bestimmt.

Diese Versickerungsblöcke sind für den unterirdischen Einbau, z. B. in Grünflächen, in Fußgänger- oder in Straßenverkehrsbereichen, vorgesehen.

Ein Versickerungsblock kann entweder werksgefertigt sein oder am Einbauort aus verschiedenen Bauteilen zusammengebaut werden.

Diese Versickerungsblöcke sind für die Verwendung als Elemente in einem modularen System vorgesehen, für das der Hersteller in der Dokumentation eindeutig angegeben hat, wie die Bauteile montiert werden, sodass ein vollständiges Infiltrations-, Zwischenspeicher- oder Speichersystem entsteht.

ANMERKUNG Nicht-lasttragende Bauteile können nach verschiedenen Verfahren hergestellt werden, z. B. Extrusion, Spritzgießen, Rotationsformen, Warmformen oder Niederdruck-Spritzgießen.

Systèmes de canalisations en plastique pour le transport et le stockage souterrains sans pression des eaux de surface - Structures alvéolaires ultra-légères pour les systèmes d’infiltration, de rétention et de stockage - Partie 1 : Spécifications relatives aux structures alvéolaires ultra-légères fabriquées à partir de PP et de PVC-U

Le présent document fournit les définitions et spécifie les exigences minimales pour les structures alvéolaires ultra-légères (SAUL) thermoplastiques moulées par injection, extrudées et thermoformées de forme parallélépipédique, comportant des composants intégrés, utilisées dans les réseaux souterrains pour l’infiltration, la rétention et le stockage des eaux de surface (par exemple les eaux pluviales) et fabriquées à partir de polypropylène (PP) ou de polychlorure de vinyle non plastifié (PVC-U).

Les propriétés du produit sont déterminées par la combinaison des spécifications de la matière, de la conception et du processus de fabrication.

Ces SAUL sont destinées à des utilisations souterraines enterrées, par exemple dans les espaces verts ou les zones de circulation de piétons ou de véhicules.

Une SAUL peut être assemblée en usine ou sur site à partir de différents composants.

Ces SAUL sont destinées à être utilisées comme éléments dans un système modulaire, pour lequel le fabricant a indiqué dans la documentation comment les composants sont assemblés pour créer un système d’infiltration, de rétention ou de stockage complet.

NOTE Les composants non porteurs peuvent être fabriqués selon différentes méthodes, par exemple extrusion, moulage par injection, moulage par rotation, thermoformage et moulage par injection basse pression.

Cevni sistemi iz polimernih materialov, ki delujejo po težnostnem principu in so položeni v zemljo, za transport in shranjevanje nepitne vode - Zaboji za sisteme infiltriranja, reduciranja in hrambe - 1. del: Specifikacije za zaboje, iz PP in PVC-U

General Information

- Status

- Not Published

- Publication Date

- 04-Jan-2028

- Technical Committee

- CEN/TC 155 - Plastics piping systems and ducting systems

- Drafting Committee

- CEN/TC 155/WG 26 - Storm Water Management

- Current Stage

- 4020 - Submission to enquiry - Enquiry

- Start Date

- 18-Dec-2025

- Due Date

- 19-Aug-2026

- Completion Date

- 18-Dec-2025

Relations

- Effective Date

- 08-Oct-2025

Overview

prEN 17152-1 specifies requirements for plastics piping systems designed for the non-pressure underground conveyance and storage of surface water, including storm water. This standard, developed by CEN, focuses on the specifications for cuboid-shaped modular boxes made from polypropylene (PP) and unplasticized polyvinylchloride (PVC-U). These boxes, utilized in infiltration, attenuation, and storage systems, play a crucial role in sustainable surface water management.

The document applies to boxes produced via injection moulding, extrusion, and thermoforming, suitable for installation underground in areas such as landscapes, pedestrian zones, and vehicular pathways. Manufacturers may supply these modular elements factory-assembled or as components for onsite assembly, ensuring flexibility and adaptability in various civil engineering and construction projects.

Key Topics

- Material Requirements: Defines characteristics for PP and PVC-U, emphasizing mechanical strength, durability, and resistance to environmental factors.

- Manufacturing Methods: Boxes may be injection-moulded, extruded, or thermoformed. Integral components can be produced by several processes, such as rotational moulding or low-pressure injection moulding.

- Box Design & Modularity: Specifies cuboid shape with or without sidewalls. Components must fit together as per the manufacturer's documented assembly method, ensuring reliable performance in modular installations.

- Mechanical and Physical Properties: Sets minimum requirements for dimensions, porosity, weight, compression strength, and other physical properties.

- Marking and Documentation: Requires detailed product marking and comprehensive documentation for traceability, installation, and conformance assessment.

- Testing & Compliance: References standard test methods for determining compression strength, creep behaviour, and material quality. Conformity assessment procedures are outlined to verify compliance.

Applications

The modular PP and PVC-U boxes governed by prEN 17152-1 are essential for:

- Infiltration Systems: Facilitate the controlled infiltration of surface water into subsurface soils, reducing runoff and promoting groundwater recharge.

- Attenuation Systems: Temporarily store storm water underground, releasing it gradually to mitigate peak flows and flooding during heavy rainfall events.

- Storage Systems: Provide dedicated underground storage for surface water, supporting water management in urban and rural settings.

Typical use cases include:

- Urban development projects managing storm water above and below landscaped areas

- Sustainable drainage systems (SuDS) in municipal streets and car parks

- Pedestrian or light vehicular traffic zones where non-pressure water management is required

- Retrofitting existing stormwater infrastructure to improve resilience and capacity

These systems help meet regulatory requirements, reduce flood risk, and support environmental stewardship through effective water management.

Related Standards

prEN 17152-1 is part of a wider family of standards dedicated to plastics piping systems for surface water management:

- EN 17150: Test method for determination of short-term compression strength of boxes

- prEN 17151-1 / prEN 17151-2: Test methods for long-term compression strength and creep behaviour

- CEN/TS 17152-4: Guidance for structural design of modular systems

- EN ISO 179-1, EN ISO 306, EN ISO 472: General standards for plastics, including testing and terminology

Recommended installation practices are guided by CEN/TR 17179, supporting best practices for modular system deployment.

Adherence to prEN 17152-1 contributes to the longevity, safety, and efficiency of underground plastics piping solutions designed for surface water management, supporting sustainable infrastructure across Europe.

Frequently Asked Questions

prEN 17152-1 is a draft published by the European Committee for Standardization (CEN). Its full title is "Plastics piping systems for non-pressure underground conveyance and storage of surface water - Boxes used for infiltration, attenuation and storage systems - Part 1: Specifications for boxes made of PP and PVC-U". This standard covers: This document gives the definitions and specifies the minimum requirements for injection moulded, extruded and thermoformed thermoplastics cuboid shaped boxes, including integral components, used in underground systems for infiltration, attenuation and storage of surface water (e.g. storm water) and manufactured from polypropylene (PP) or unplasticized polyvinylchloride (PVC-U). Product properties are determined by a combination of material specifications, design and manufacturing process. These boxes are intended for buried underground use, e.g. in landscape, pedestrian or vehicular traffic areas. A box can either be factory assembled, or site assembled from different components. These boxes are intended to be used as elements in a modular system where the manufacturer states in the documentation how the components are assembled to create a complete infiltration, attenuation or storage system. NOTE Non load bearing component(s) can be manufactured by various methods e.g. extrusion, injection moulding, rotational moulding, thermoforming and low-pressure injection moulding.

This document gives the definitions and specifies the minimum requirements for injection moulded, extruded and thermoformed thermoplastics cuboid shaped boxes, including integral components, used in underground systems for infiltration, attenuation and storage of surface water (e.g. storm water) and manufactured from polypropylene (PP) or unplasticized polyvinylchloride (PVC-U). Product properties are determined by a combination of material specifications, design and manufacturing process. These boxes are intended for buried underground use, e.g. in landscape, pedestrian or vehicular traffic areas. A box can either be factory assembled, or site assembled from different components. These boxes are intended to be used as elements in a modular system where the manufacturer states in the documentation how the components are assembled to create a complete infiltration, attenuation or storage system. NOTE Non load bearing component(s) can be manufactured by various methods e.g. extrusion, injection moulding, rotational moulding, thermoforming and low-pressure injection moulding.

prEN 17152-1 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 17152-1 has the following relationships with other standards: It is inter standard links to EN 17152-1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 17152-1 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2026

Cevni sistemi iz polimernih materialov, ki delujejo po težnostnem principu in so

položeni v zemljo, za transport in shranjevanje nepitne vode - Zaboji za sisteme

infiltriranja, reduciranja in hrambe - 1. del: Specifikacije za zaboje, iz PP in PVC-U

Plastics piping systems for non-pressure underground conveyance and storage of

surface water - Boxes used for infiltration, attenuation and storage systems - Part 1:

Specifications for boxes made of PP and PVC-U

Kunststoff-Rohrleitungssysteme für die drucklose unterirdische Entwässerung für Nicht-

Trinkwasser - Versickerungsblöcke zur Verwendung in Infiltrations-, Zwischenspeicher-

und Speichersystemen - Teil 1: Festlegungen für Regenwasserabfluss-

Versickerungsblöcke aus PP und PVC-U

Systèmes de canalisations en plastique pour le transport et le stockage souterrains sans

pression des eaux de surface - Structures alvéolaires ultra-légères pour les systèmes

d’infiltration, de rétention et de stockage - Partie 1 : Spécifications relatives aux

structures alvéolaires ultra-légères fabriquées à partir de PP et de PVC-U

Ta slovenski standard je istoveten z: prEN 17152-1

ICS:

23.040.03 Cevovodi za zunanje sisteme Pipeline and its parts for

transporta vode in njihovi deli external water conveyance

systems

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

December 2025

ICS 23.040.01 Will supersede EN 17152-1:2019

English Version

Plastics piping systems for non-pressure underground

conveyance and storage of surface water - Boxes used for

infiltration, attenuation and storage systems - Part 1:

Specifications for boxes made of PP and PVC-U

Systèmes de canalisations en plastique pour le Kunststoff-Rohrleitungssysteme für die drucklose

transport et le stockage souterrains sans pression des unterirdische Entwässerung für Nicht-Trinkwasser -

eaux de surface - Structures alvéolaires ultra-légères Versickerungsblöcke zur Verwendung in Infiltrations-,

pour les systèmes d'infiltration, de rétention et de Zwischenspeicher- und Speichersystemen - Teil 1:

stockage - Partie 1 : Spécifications relatives aux Festlegungen für Regenwasserabfluss-

structures alvéolaires ultra-légères fabriquées à partir Versickerungsblöcke aus PP und PVC-U

de PP et de PVC-U

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 155.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 17152-1:2025 E

worldwide for CEN national Members.

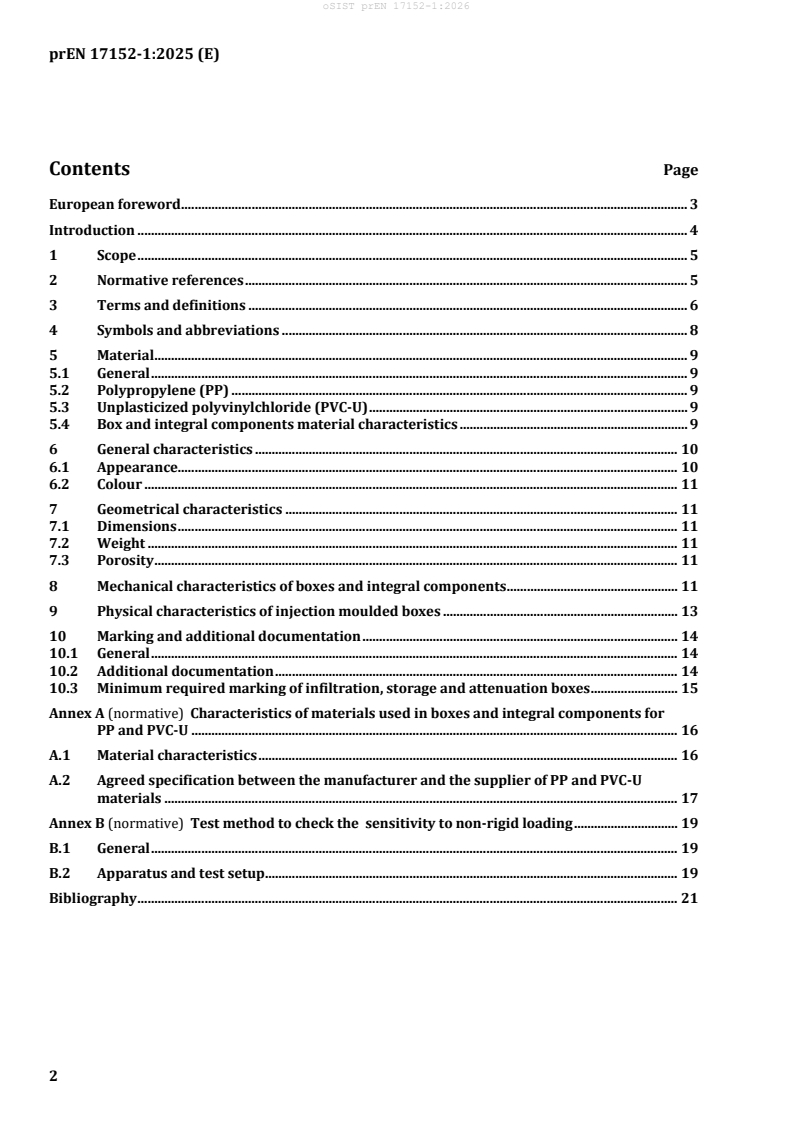

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols and abbreviations . 8

5 Material . 9

5.1 General . 9

5.2 Polypropylene (PP) . 9

5.3 Unplasticized polyvinylchloride (PVC-U) . 9

5.4 Box and integral components material characteristics . 9

6 General characteristics . 10

6.1 Appearance . 10

6.2 Colour . 11

7 Geometrical characteristics . 11

7.1 Dimensions . 11

7.2 Weight . 11

7.3 Porosity . 11

8 Mechanical characteristics of boxes and integral components . 11

9 Physical characteristics of injection moulded boxes . 13

10 Marking and additional documentation . 14

10.1 General . 14

10.2 Additional documentation . 14

10.3 Minimum required marking of infiltration, storage and attenuation boxes . 15

Annex A (normative) Characteristics of materials used in boxes and integral components for

PP and PVC-U . 16

A.1 Material characteristics . 16

A.2 Agreed specification between the manufacturer and the supplier of PP and PVC-U

materials . 17

Annex B (normative) Test method to check the sensitivity to non-rigid loading . 19

B.1 General . 19

B.2 Apparatus and test setup . 19

Bibliography . 21

European foreword

This document (prEN 17152-1:2025) has been prepared by Technical Committee CEN/TC 155 “Plastics

piping systems and ducting systems”, the secretariat of which is held by NEN.

This document is currently submitted to the CEN Enquiry.

This document supersedes EN 17152-1:2019+AC:2020.

The main changes with respect to EN 17152-1:2019+AC:2020 are listed below:

— Table A.1 added minimum number of test specimen;

— Table 2 new optional tests added;

— Clause 3 new definitions added (e.g. reference value and declared value);

— reference to new improved prEN 17151-1;

— subclause 10.2 improved with more information;

— editorial improvements through the document.

This standard is supported by separate standards on test methods to which normative references are

made.

EN 17152-series consists of the following parts under the general title Plastics piping systems for non-

pressure underground conveyance and storage of surface water - Boxes used for infiltration, attenuation

and storage systems:

— Part 1: Specifications for boxes made of PP and PVC-U [this document];

— Part 3: Assessment of conformity (CEN/TS);

— Part 4: Guidance for structural design of modular systems (CEN/TS).

Recommended practices for installation are described in CEN/TR 17179 [1].

These products are always used in a modular system consisting of multiple boxes.

National standards for pipes and fittings for the transport of surface water are not considered to be

conflicting with this standard and can thus be allowed to coexist.

Introduction

The products covered by this document are part of surface water management system.

This document is intended to reflect the current state of knowledge of determining and predicting the

long-term lifetime of product groups mentioned in the scope while maintaining reasonable testing times

for producers and developers of these systems.

1 Scope

This document gives the definitions and specifies the minimum requirements for injection moulded,

extruded and thermoformed thermoplastics cuboid shaped boxes, including integral components, used

in underground systems for infiltration, attenuation and storage of surface water (e.g. storm water) and

manufactured from polypropylene (PP) or unplasticized polyvinylchloride (PVC-U).

Product properties are determined by a combination of material specifications, design and

manufacturing process.

These boxes are intended for buried underground use, e.g. in landscape, pedestrian or vehicular traffic

areas.

A box can either be factory assembled, or site assembled from different components.

These boxes are intended to be used as elements in a modular system where the manufacturer states in

the documentation how the components are assembled to create a complete infiltration, attenuation or

storage system.

NOTE Non load bearing component(s) can be manufactured by various methods e.g. extrusion, injection

moulding, rotational moulding, thermoforming and low-pressure injection moulding.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 17150:2019, Plastics piping systems for non-pressure underground conveyance and storage of non-

potable water — Test method for determination of short-term compression strength of boxes

prEN 17151-1:2025, Plastics piping systems for non-pressure underground conveyance and storage of

surface water — Part 1: Test method for determination of long-term compression strength of boxes

prEN 17151-2:2025, Plastics piping systems for non-pressure underground conveyance and storage of

surface water — Part 2: Test method for determination of creep behaviour of boxes

CEN/TS 17152-4:2025, Plastics piping systems for non-pressure underground conveyance and storage of

non-potable water — Boxes used for infiltration, attenuation and storage systems — Part 4: Guidance for

structural design of modular systems

EN ISO 179-1, Plastics — Determination of Charpy impact properties — Part 1: Non-instrumented impact

test (ISO 179-1)

EN ISO 306, Plastics — Thermoplastic materials — Determination of Vicat softening temperature (VST)

(ISO 306)

EN ISO 472:2013, Plastics — Vocabulary (ISO 472/2013)

EN ISO 527-1, Plastics — Determination of tensile properties — Part 1: General principles (ISO 527-1)

EN ISO 527-2, Plastics — Determination of tensile properties — Part 2: Test conditions for moulding and

extrusion plastics (ISO 527-2)

EN ISO 527-3, Plastics — Determination of tensile properties — Part 3: Test conditions for films and sheets

(ISO 527-3)

EN ISO 580:2005, Plastics piping and ducting systems — Injection-moulded thermoplastics fittings -

Methods for visually assessing the effects of heating (ISO 580:2005)

EN ISO 899-1, Plastics — Determination of creep behaviour — Part 1: Tensile creep (ISO 899-1)

EN ISO 899-2, Plastics — Determination of creep behaviour — Part 2: Flexural creep by three-point loading

(ISO 899-2)

EN ISO 1043-1:2011, Plastics — Symbols and abbreviated terms — Part 1: Basic polymers and their

special characteristics (ISO 1043-1:2011)

EN ISO 1133-1, Plastics — Determination of the melt mass-flow rate (MFR) and melt volume-flow rate

(MVR) of thermoplastics — Part 1: Standard method (ISO 1133-1)

EN ISO 1167-1, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination

of the resistance to internal pressure — Part 1: General method (ISO 1167-1)

EN ISO 1167-2, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination

of the resistance to internal pressure — Part 2: Preparation of pipe test pieces (ISO 1167-2)

EN ISO 1183-1, Plastics — Methods for determining the density of non-cellular plastics — Part 1: Immersion

method, liquid pyknometer method and titration method (ISO 1183-1)

EN ISO 3126, Plastics piping systems — Plastics components — Determination of dimensions (ISO 3126)

EN ISO 3451-1, Plastics — Determination of ash — Part 1: General methods (ISO 3451-1)

EN ISO 3451-5, Plastics — Determination of ash — Part 5: Poly(vinyl chloride) (ISO 3451-5)

EN ISO 11357-3, Plastics — Differential scanning calorimetry (DSC) — Part 3: Determination of

temperature and enthalpy of melting and crystallization (ISO 11357-3)

EN ISO 11357-6, Plastics — Differential scanning calorimetry (DSC) — Part 6: Determination of oxidation

induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT) (ISO 11357-6)

EN ISO 11358-1, Plastics — Thermogravimetry (TG) of polymers — Part 1: General principles

(ISO 11358-1)

EN ISO 13229, Thermoplastics piping systems for non-pressure applications — Unplasticized poly(vinyl

chloride) (PVC-U) pipes and fittings — Determination of the viscosity number and K-value (ISO 13229)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 472:2013, EN ISO 1043-

1:2011 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

As impacted by EN ISO 1043-1:2011/A1:2016.

3.1

box

thermoplastic cuboid shaped element, with or without sidewalls, used to create a modular system

3.2

integral component

load bearing component contributing to the overall strength of the box

3.3

modular system

system made of repeating boxes

3.4

attenuation system

modular system designed to reduce the peak flow from a given site by providing a temporary

underground surface water storage facility

3.5

infiltration system

modular system designed to provide a temporary underground storage facility from which surface water

soaks into the surrounding ground

3.6

storage system

modular system designed to provide an underground storage facility for surface water

3.7

porosity

total available volume for water storage divided by the total envelope cuboid volume for a box

3.8

long-term compression strength

95 % lower confidence limit (LCL) of the applied stress for which the sample would survive 50 years

without creep rupture, in kN/m

3.9

material

material specified for a particular component in a box

3.10

virgin material

plastics material in the form of pellets, granules, powder, floc, etc. that has not been subjected to use or

processing other than that required for its initial manufacture

Note 1 to entry: Does not contain any reworked plastics material and/or plastics recyclate.

Note 2 to entry: Sometimes also referred to as “primary material” or “primary plastics feedstock”.

Note 3 to entry: It is understood that the addition of additives such as stabilizers and pigments is still resulting

into a virgin (plastics) material.

[SOURCE: EN 14541-1:2022]

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...