EN 13956:2012

(Main)Flexible sheets for waterproofing - Plastic and rubber sheets for roof waterproofing - Definitions and characteristics

Flexible sheets for waterproofing - Plastic and rubber sheets for roof waterproofing - Definitions and characteristics

This European Standard specifies the definitions and characteristics of plastic and rubber sheets including sheets made out of their blends and alloys (thermoplastic rubber) for which the intended use is roof waterproofing. It specifies the requirements and test methods and provides for the evaluation of conformity of the products with the requirements of this European Standard.

NOTE For typical materials and applications, see Annex E.

Abdichtungsbahnen - Kunststoff- und Elastomerbahnen für Dachabdichtungen - Definitionen und Eigenschaften

Diese Europäische Norm legt die Definitionen und Eigenschaften von Kunststoff- und Elastomerbahnen einschließlich der aus deren Gemischen und Mischungen (thermoplastische Elastomere) hergestellten Bahnen fest, die hauptsächlich für Dachsysteme verwendet werden. Sie legt die Anforderungen und Prüfverfahren fest und schafft die Voraussetzungen für die Bewertung der Konformität der Produkte mit den Anforderungen dieser Europäischen Norm.

ANMERKUNG Siehe Anhang E hinsichtlich üblicher Werkstoffe und Anwendungen.

Feuilles souples d'étanchéité - Feuilles d'étanchéité de toiture plastiques et élastomères - Définitions et caractéristiques

La présente norme européenne spécifie les définitions et caractéristiques des feuilles plastiques et élastomères, y compris les feuilles composées de mélanges de plastiques et d’élastomères (caoutchouc thermoplastique) dont l’utilisation prévue est l’étanchéité des toitures. Elle spécifie les exigences et les méthodes d’essais et prévoit le cadre d’évaluation de la conformité des produits aux exigences de la présente norme.

NOTE Pour les matériaux et applications spécifiques, voir Annexe E.

Hidroizolacijski trakovi - Polimerni in elastomerni trakovi za tesnjenje streh - Definicije in lastnosti

Ta evropski standard določa definicije in lastnosti polimernih in elastomernih trakov ter trakov iz mešanic in zlitin navedenih materialov (termoplastična guma) za tesnjenje streh. Določa zahteve in preskusne metode ter predvideva vrednotenje skladnosti proizvodov z zahtevami iz tega evropskega standarda.

General Information

- Status

- Published

- Publication Date

- 18-Dec-2012

- Technical Committee

- CEN/TC 254 - Flexible sheets for water proofing

- Drafting Committee

- CEN/TC 254/SC 2 - Synthetic sheets

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 14-Jan-2025

- Completion Date

- 09-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 26-Dec-2012

- Effective Date

- 26-Dec-2012

- Effective Date

- 04-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13956:2012 is a European Standard published by CEN that defines terms, characteristics, test methods and conformity assessment for plastic and rubber flexible sheets for roof waterproofing (including blends and thermoplastic rubber). The standard covers factory-made waterproofing sheets intended for roofs and sets requirements for performance attributes, sampling, testing and documentation. Annex E gives guidance on typical materials and applications.

Key topics and requirements

- Scope and definitions: Precise terms for sheet types, layers (internal fabric, backing), overall and effective thickness, welding and bonding methods.

- Product characteristics: Requirements and test methods for:

- Visible defects (EN 1850-2)

- Dimensions, tolerances and mass per unit area (EN 1848-2, EN 1849-2). Example tolerances: length MDV tolerance –0% / +5%, width MDV tolerance –0.5% / +1%; straightness ≤ 50 mm; flatness ≤ 10 mm.

- Watertightness, water vapour transmission and chemical resistance

- Mechanical properties: tensile strength and elongation, tear resistance, joint peel and shear strength

- Durability and aging: UV, elevated temperature and water exposure, resistance to ozone, contact with bitumen

- Impact, static loading and hail resistance; resistance to root penetration

- Low temperature foldability and dimensional stability

- Fire performance: External fire exposure limited to Class F (as revised).

- Conformity and factory production control (FPC): Procedures for initial type testing, frequency of FPC testing and indirect testing options; requirements for product data sheets, marking, labelling and packaging.

- Annexes: Normative applicability of characteristics, test frequency, and informative annexes with chemical resistance, product-data examples and typical system structures.

Applications

EN 13956 is used to specify and verify flexible roofing membranes for:

- Flat and pitched roofs including vehicle parking decks and roof gardens

- New construction and replacement roofing contracts

- Product selection in projects requiring documented resistance to weathering, mechanical stress, chemicals or root penetration It helps ensure materials meet harmonized European performance levels for waterproofing durability and safety.

Who uses this standard

- Manufacturers for product design, declaration of performance and factory production control

- Specifiers, architects and consultants when selecting roofing membranes

- Roofing contractors and installers to understand jointing, welding and installation-related properties

- Testing laboratories and certification bodies carrying out type testing and conformity assessment

- Procurement and compliance officers assessing CE marking and regulatory requirements

Related standards (examples)

EN 1928 (watertightness), EN 12311‑2 (tensile properties), EN 12310‑2 (tear resistance), EN 12691 (impact), EN 12730 (static loading), EN 13501‑1/5 (fire classification), EN 13948 (root resistance). These referenced standards define specific test methods cited by EN 13956.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13956:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Flexible sheets for waterproofing - Plastic and rubber sheets for roof waterproofing - Definitions and characteristics". This standard covers: This European Standard specifies the definitions and characteristics of plastic and rubber sheets including sheets made out of their blends and alloys (thermoplastic rubber) for which the intended use is roof waterproofing. It specifies the requirements and test methods and provides for the evaluation of conformity of the products with the requirements of this European Standard. NOTE For typical materials and applications, see Annex E.

This European Standard specifies the definitions and characteristics of plastic and rubber sheets including sheets made out of their blends and alloys (thermoplastic rubber) for which the intended use is roof waterproofing. It specifies the requirements and test methods and provides for the evaluation of conformity of the products with the requirements of this European Standard. NOTE For typical materials and applications, see Annex E.

EN 13956:2012 is classified under the following ICS (International Classification for Standards) categories: 01.040.91 - Construction materials and building (Vocabularies); 91.100.50 - Binders. Sealing materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13956:2012 has the following relationships with other standards: It is inter standard links to EN 13956:2005, EN 13956:2005/AC:2006, EN ISO 11925-2:2026, EN 1928:2000, EN 12311-2:2013, EN 12316-2:2013, EN 12691:2018, EN 13948:2007, EN 13583:2012, EN 13501-5:2016, EN 1548:2007, EN 1931:2000, EN 1847:2009, EN ISO 11925-2:2020, EN 1848-2:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13956:2012 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/102. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13956:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Hidroizolacijski trakovi - Polimerni in elastomerni trakovi za tesnjenje streh - Definicije in lastnostiAbdichtungsbahnen - Kunststoff- und Elastomerbahnen für Dachabdichtungen - Definitionen und EigenschaftenFeuilles souples d'étanchéité - Feuilles d'étanchéité de toiture plastiques et élastomères - Définitions et caractéristiquesFlexible sheets for waterproofing - Plastic and rubber sheets for roof waterproofing - Definitions and characteristics91.100.50Veziva. Tesnilni materialiBinders. Sealing materials91.060.20StreheRoofs01.040.91Gradbeni materiali in gradnja (Slovarji)Construction materials and building (Vocabularies)ICS:Ta slovenski standard je istoveten z:EN 13956:2012SIST EN 13956:2013en,fr,de01-februar-2013SIST EN 13956:2013SLOVENSKI

STANDARDSIST EN 13956:2005/AC:2006SIST EN 13956:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13956

December 2012 ICS 01.040.91; 91.100.50 Supersedes EN 13956:2005English Version

Flexible sheets for waterproofing - Plastic and rubber sheets for roof waterproofing - Definitions and characteristics

Feuilles souples d'étanchéité - Feuilles d'étanchéité de toiture plastiques et élastomères - Définitions et caractéristiques

Abdichtungsbahnen - Kunststoff- und Elastomerbahnen für Dachabdichtungen - Definitionen und Eigenschaften This European Standard was approved by CEN on 27 October 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13956:2012: ESIST EN 13956:2013

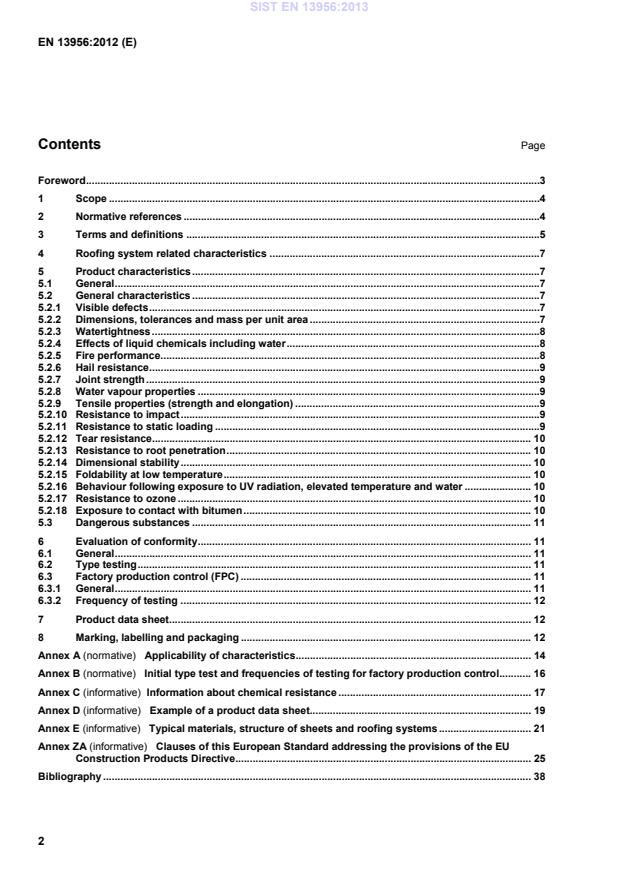

Applicability of characteristics . 14Annex B (normative)

Initial type test and frequencies of testing for factory production control. 16Annex C (informative)

Information about chemical resistance . 17Annex D (informative)

Example of a product data sheet. 19Annex E (informative)

Typical materials, structure of sheets and roofing systems . 21Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive . 25Bibliography . 38 SIST EN 13956:2013

new extended mounting and fixing rules;

introduction of indirect testing for factory production control. According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

EN 1850-2, Flexible sheets for waterproofing — Determination of visible defects — Part 2: Plastic and rubber sheets for roof waterproofing EN 1928, Flexible sheets for waterproofing — Bitumen, plastic and rubber sheets for roof waterproofing — Determination of watertightness EN 1931, Flexible sheets for waterproofing — Bitumen, plastic and rubber sheets for roof waterproofing — Determination of water vapour transmission properties EN 12310-2, Flexible sheets for waterproofing — Determination of resistance to tearing — Part 2: Plastic and rubber sheets for roof waterproofing EN 12311-2, Flexible sheets for waterproofing — Determination of tensile properties — Part 2: Plastic and rubber sheets for roof waterproofing SIST EN 13956:2013

3.10 surface profile (surface structure) raised area on the surface of the sheet creating a difference between the effective and overall thickness exceeding 0,1 mm or a backing exceeding 80 g/m2 3.11 internal fabric layer of woven or non-woven fabric of synthetic or mineral fibres incorporated in the sheet Note 1 to entry: This layer may or may not constitute reinforcement. 3.12 backing layer of woven or non-woven fabric of synthetic or mineral fibres or other material fixed to the bottom of the sheet Note 1 to entry: This layer may or may not constitute reinforcement. 3.13

overall thickness d thickness of the sheet excluding any surface profile 3.14 effective thickness

deff thickness of the sheet providing the waterproofing function including any surface texture or backing equal to or less than 80 g/m2 but excluding any surface profile and backing greater than 80g/m2 3.15 welding process of jointing by softening the surfaces to be united, either by heat or with the aid of a solvent (solvent welding, solvent bonding), and then pressing the softened surfaces together 3.16 adhesive bonding process of jointing by applying adhesives to the surfaces to be united or by applying an adhesive tape, and then applying pressure SIST EN 13956:2013

4 Roofing system related characteristics Testing shall be carried out according to Table A.1. 5 Product characteristics 5.1 General 5.1.1 Where a tolerance is limited by this European Standard it does not have to be declared by the manufacturer. 5.1.2 When tested for purposes other than initial type testing or factory production control, the tests to determine product characteristics indicated in this European Standard shall be started within 1 month of delivery from the manufacturer. 5.2 General characteristics 5.2.1 Visible defects The product shall be free of visible defects in accordance with EN 1850-2. 5.2.2 Dimensions, tolerances and mass per unit area The length, width, straightness and flatness shall be determined in accordance with EN 1848-2 and shall meet the requirements given in Table 1. The values for straightness and flatness only apply to sheets supplied in the form of rolls. The values for straightness and flatness do not apply to folded sheets. SIST EN 13956:2013

Thickness and mass per unit area shall be determined in accordance with EN 1849-2, except that where the surface structure is caused by the inner layer, the mechanical thickness measurement method shall be applied and the result shall meet the requirements given in Table 2. Terms and definitions of this European Standard shall have priority over those given in EN 1849-2. Table 2 — Thickness and mass per unit area requirements Effective thickness: Thickness of the sheet providing the waterproofing function including any surface texture but excluding any surface profile and backing greater than 80 g/m2. The measured effective thickness shall lie within the declared tolerance of the MDV. The tolerance of the MDV shall lie within – 5 % and + 10 %. Single measurement: Each single measurement value shall lie within the declared tolerance of the MDV. The tolerance of the MDV shall lie within ± 10 %. Mass: The mass per unit area shall lie within the declared tolerance of the MDV. The tolerance of the MDV shall lie within – 5 % and + 10 %.

5.2.3 Watertightness The watertightness shall be determined in accordance with EN 1928 using method B at an applied water pressure of 10 kPa (0,1 bar) and shall give a pass result. 5.2.4 Effects of liquid chemicals including water Information on the effect of liquid chemicals on plastics and rubber is given in Annex C. When further information on resistance to liquid chemicals is required, tests shall be conducted according to EN 1847 at a temperature of 23 °C for 28 days. 5.2.5 Fire performance 5.2.5.1 External fire performance The classification of the product in accordance with EN 13501-5 is limited to class F. NOTE It is currently considered that there are no national requirements specific to flexible sheets for roof waterproofing alone on external fire performance. The external fire performance of a roof is dominated by its build up. 5.2.5.2 Reaction to fire Where required, the product shall be tested and classified in accordance with EN 13501-1, Table 1. According to EN ISO 11925-2, the test is required to be undertaken on the exposed surface of the delivered flexible sheet (surface or edge exposure) free hanging without any substrate in one direction only, and the reinforcement shall be stated by the manufacturer as “organic” or “inorganic”. a) Test results from EN ISO 11925-2 for a given product shall apply to all colours (including black, white). SIST EN 13956:2013

Surface cracks according to EN 1297:2004, Table B.1, Grades 0, 1 and 2 will give a pass result for the visual examination. Grade 3 will give a fail result. The purpose of testing in accordance to EN 1297 is to characterise the long-term ageing behaviour of plastic and rubber sheets. The test does not give results corresponding to the service conditions in practice. Results should only be used to compare products of similar thickness, construction and composition, and they cannot be used for general durability classification. The chosen exposure duration for artificial ageing in accordance to EN 1297 has no relevance to a real product lifetime. NOTE Sheets passing ETAG 006 requirements are considered to comply with the criteria for behaviour following exposure to UV radiation, elevated temperature and water. 5.2.17 Resistance to ozone Where required, the sheet shall be tested according to EN 1844 and the sheet shall show no cracks. This test is only required for sheets made of rubber materials. 5.2.18 Exposure to contact with bitumen Where required, the behaviour of the sheet where it may come in contact with bitumen shall be determined in accordance with EN 1548. The sheet is compatible with bitumen if: a) for sheets with an inner layer, the percentage loss in mass is less than or equal to 5 %; b) for sheets without an inner layer or backing, the change in Young's Modulus is less than or equal to 50 %. Results obtained by this test method from sheets without an inner layer or backing can be applied to sheets manufactured with same chemical formulation but having inner reinforcement layers or backing. The results obtained on a given thickness apply to any product of the same formulation with greater thickness. By SIST EN 13956:2013

The characteristics of the product, determined in accordance with the test methods specified in this European Standard, shall be listed in a technical data sheet. The technical data sheet shall give the following information: a) product trade name and manufacturer's name;

b) origin/source of manufacture or traceable code;

c) type of application and roofing system (see also Table A.1); d) results of tests (see also Table A.1) according to intended end use system where relevant; e) certification mark, if any; f) consumer information, e.g.

1) restrictions concerning use

where the product is not suitable for all installation conditions, it is essential that the manufacturer declare those installation conditions for which the product is suitable; 2) restrictions storage; 3) safety precautions during installation and disposal; g) description of the product (e.g. type of base material, type of reinforcement, mass or thickness, type of surfaces). An example of a product data sheet is shown in Annex D. 8 Marking, labelling and packaging The following information shall be indicated on each roll and/or in the accompanying technical or commercial documentation: a) production date or identification number; SIST EN 13956:2013

(normative)

Applicability of characteristics Table A.1 gives the relevant characteristics depending on the roofing system and/or regulatory requirements. Table A.1 — Roofing system-related characteristics (1 of 2)

Clause

Testing for Type of application/roofing system Exposed sheets Covered sheets Adhered Mechanically fastened Gravel ballasted Roof gardens, park decks or similar 5.2.1 Visible defects + + + + 5.2.2 Length + + + + 5.2.2 Width + + + + 5.2.2 Straightness ± ± ± ± 5.2.2 Flatness ± ± ± ± 5.2.2 Mass per unit area + + + + 5.2.2 Effective thickness + + + + 5.2.3 Water tightness + + + + 5.2.5.1 External fire performance - - - - 5.2.5.2 Reaction to fire ± ± ± ± 5.2.7 Joint peel resistance ± + - - 5.2.7 Joint shear resistance + + + + 5.2.9 Tensile strength + + + + 5.2.9 Elongation + + + + 5.2.10 Resistance to impact + + + + 5.2.11 Resistance to static loading - - + + 5.2.12 Tear resistance - + - - 5.2.13 Resistance to root penetration

- - - + a 5.2.14 Dimensional stability + + + + 5.2.15 Foldability at low

temperature + + + + 5.2.16 UV exposure (1 000 h) + + - - 5.2.4 Effects of liquid chemicals, including water

± ± ± ± 5.2.6 Hail resistance

± ± - -

+ b + b + b - 5.2.18 Exposure to bitumen ± ± ± ± Key + Relevant. - Not relevant. ± Dependant on roofing system, material, climatic condition or regulatory requirement. a For sheets used as root barriers in roof gardens only. b For rubber sheets only.

(normative)

Initial type test and frequencies of testing for factory production control B.1 Type testing Initial type testing is necessary for all characteristics, which are relevant in relation to the roofing system, material, climatic condition or regulatory requirement. Initial type testing does not need to be repeated as long as the stated product properties remain valid.

For characteristics under 5.2.5.1 External fire performance and 5.2.13 Resistance to root penetration the type testing is a system test. B.2 Testing for factory production control (FPC) The minimum frequencies of testing for factory production control are given in Table B.1. All other relevant characteristics shall be controlled indirectly (e.g. by control of product composition). Table B.1 — Frequencies of testing for FPC

Clause

Characteristic Minimum frequencies of testing per batch week month year 5.2.1 Visible defects 1

5.2.2 Width 1

5.2.2 Straightness

5.2.2 Flatness

5.2.2 Effective thickness or mass per unit area 1

5.2.9 Tensile strength

1 a

5.2.9 Elongation

1 a

5.2.12 Tear resistance

1 a 5.2.15 Dimensional stability

2 b a Where a manufacturer is continuously producing numerous different sheets, which contain the same core (type and mass) and the same type of coating, the frequency of these tests, which relate essentially to the core, may be considered on the total number of these different sheets. b Not necessary for sheets with non-woven glass mat carrier or composite reinforcement containing glass. SIST EN 13956:2013

(informative)

Information about chemical resistance The best judgement about the long-term fitness for purpose of membranes under chemical environments is based on practical experience. Table C.1 describes the chemical resistance concerning common substances (where the behaviour of all synthetic membranes in the market is assumed to be equal). The judgement is based on the changes of mechanical performance but note that changes in colour are not considered. The statements are valid for room temperature (23 °C) with a typical test period of 28 days. It is the responsibility of the manufacturer to inform the customer about chemical resistance. It is recognised that a large amount of data concerning the chemical resistance is available. The table shown here is based on: – Kunststoff Handbuch Band II Polyvinylchlorid, Krekeler/Wick (Hsg.), Carl Hanser Verlag München, 1963, – Kunststoff-Tabellen, Carlowitz, 4. Auflage, Carl Hanser Verlag München, 1995. If detailed information or the behaviour concerning further substances is required, please refer to the original literature. Table C.1 — Chemical resistance of plastic and rubber sheets (1 of 2) Substance Concentration % Resistance Inorganic acids Sulphuric acid ≤ 25+ > 25 and ≤ 98∆ > 98- Sulphurous acid≤ 6+ Oleum

- Nitric acid ≤ 5+ > 5 and ≤ 50∆ > 50- Hydrochloric acid ≤ 10+ > 10∆

+ Butyric acid

∆ Acetic acid ≤ 10 + > 10 ∆ Oleic acid

∆ Oxalic acid

+ Phenols

∆ Phthalic acid

+ Tartaric acid, aqueous

+ Citric acid, aqueous

+ Inorganic bases Ammonium hydroxide, aqueous

∆ Potassium hydroxide, aqueous

∆ Sodium hydroxide ≤ 10 + > 10 and ≤ 50 ∆ > 50 - Organic bases Pyridine and derivates

∆ Triethanolamin

∆ Salt solutions Chlorides

+ Nitrates

+ Sulphates

+ Different substances Drinking water

+ Beer

+ Glycol

∆ Soap solution

+ Liquid manure

∆ Key +

All polymeric materials are resistant. ∆ Not stable in all cases (see literature or to be checked). - None of the polymeric materials are resistant.

(informative)

Example of a product data sheet Date and reference of this technical data sheet. Product trade name. Manufacturer/supplier. Origin /source of manufacturing. Type of application and roofing system (see Annex A). Product performance, see Table D.11). Certification mark where relevant. Consumer information2). Description of product (e.g. type of base material, type of reinforcement, thickness). Table D.1 — Information from testing (where relevant according to

roofing system, see Table A.1) (1 of 2) Clause Characteristic Test method Unit Tolerance Expression of results Value or statement 5.2.1 Visible defects EN 1850-2

Pass

5.2.2 Length EN 1848-2 m -0 % and +5 % MDV

5.2.2 Width EN 1848-2 m -0,5 % and +1 % MDV

5.2.2 Straightness EN 1848-2 mm

MLV ≤ 5.2.2 Flatness EN 1848-2 mm

MLV ≤ 5.2.2 Mass per unit area EN 1849-2 kg/m2 -5% and +10 % MDV

5.2.2 Effective thickness EN 1849-2 mm -5 % and +10 %a MDV

5.2.3 Water tightness EN 1928 Method B kPa

Pass ≥ 5.2.5.1 External fire performance CEN/TS 1187

In accordance with EN 13501-5 F

1) See ZA.3, which limits information to be given in association with CE marking. 2) For example, restrictions concerning use and storage and safety precaution during installation and disposal. SIST EN 13956:2013

EN 13501-1 (see Note in 5.2.5.2)

5.2.7 Joint peel resistance EN 12316-2 N/50 mm

MLV ≥ 5.2.7 Joint shear resistance EN 12317-2 N/50 mm

MLV ≥ 5.2.9 Tensile strength EN 12311-2 N/50 mm or N/mm2

MLV ≥ 5.2.9 Elongation EN 12311-2 %

MLV ≥ 5.2.10 Resistance to impact EN 12691 mm

MLV ≥

5.2.11 Resistance to static load EN 12730 Method B kg

MLV ≥ 5.2.12 Tear resistance EN 12310-2 N

MLV ≥ 5.2.13 Res. to root penetration b EN 13948

Pass

5.2.14 Dimensional stability EN 1107-2 %

MLV ≤ 5.2.15 Foldability at low temp. EN 495-5 ºC

MLV ≤ 5.2.16 UV exposure EN 1297 Visual

Pass

5.2.4 Liquid chem. incl. water c EN 1847

See Annex C

5.2.6 Hail resistance d EN 13583 m/s

MLV ≥ 5.2.8 Water vapour properties EN 1931

±30% MDV

5.2.17 Resistance to ozone e EN 1844

Pass

5.2.18 Exposure to bitumen EN 1548

Pass

Key a Single values within ± 10 % b

For sheets used as root barriers in roof gardens only c On request only d Where required e Rubber materials only

(informative)

Typical materials, structure of sheets and roofing systems E.1 Typical materials E.1.1 General Three groups of synthetic materials are used in the application of flexible sheets for waterproofing: plastics, rubbers and thermoplastic rubbers. Within these three groups, there are various materials, which can be different in their nature and way of manufacturing. In the following there are listed some typical materials for the individual groups. Other materials may be possible, because this European Standard should not hinder further development. For some materials short code designations have been established in the marketplace that differ from normative codes. E.1.2 Plastics CSM or PE-CS Chlorosulfonyl polyethylene EEA Ethylene/ethyl acrylate

Ethylene/ethyl acrylate terpolymer (stated in full in words) EBA Ethylene/butyl acrylate ECB or EBT

Ethylene, copolymer, bitumen EVAC Ethylene/vinyl acetate FPO or PO-F Flexible polyolefin

FPP or PP-F

Flexible polypropylene PE Polyethylene PE-C Chlorinated polyethylene PIB Polyisobutylene PP Polypropylene PVC Polyvinylchloride

E.1.3 Rubbers BR Butadiene rubber CR Chloroprene rubber CSM Chlorosulfonyl polyethylene rubber EPDM Terpolymer of ethylene, propylene and a diene with residual unsaturatedportionofdieneinthesidechainIIR Isobutene-isoprene rubber (butyl rubber) NBR Acrylonitrile-butadiene rubber (nitrile rubber)

Elastomeric alloys MPR Melt processible rubber SEBS Styrene ethylene butylene styrene TPE

Thermoplastic elastomers, not cross-linked TPE-X

Thermoplastic elastomers, cross-linked TPS or TPS-SEBS SEBS-copolymers TPV Thermoplastic rubber vulcanisate

E.2 Installation Plastic and rubber sheets for roof waterproofing are normally installed as a single layer roof waterproofing membrane. The joints between sheets are often welded by the action of heat or solvent but they may also be sealed using adhesive or adhesive tape or in the case of rubber material hot bonded. In all cases, it is important that the sheets are jointed by the method recommended by the manufacturer. The roof waterproofing sheet may be fastened to the substructure with adhesive, be mechanically fastened, or can be ballasted. The sheet has different requirements for each method of application and it is important that the manufacturer’s advice is sought as to the suitability of the sheet for the application. At perimeter details, it is normal to use special trims and these are often made from metal, which can be laminated with a material compatible with the main roof membrane, to enable the trim to be jointed to the main membrane. However when the sheet is applied, it is important that the system can withstand the expected wind uplift forces. With mechanically fastened membranes fastenings can be varied to meet the exposure conditions. With ballasted roofs, the membrane is loose laid, with only the perimeter being fastened, which allows for maximum movement of the substrate. The weight of the ballast (e.g. gravel or paving) has to provide the resistance to wind uplift forces. Separation layers are sometimes needed to prevent reaction between the insul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...