EN 13022-2:2006

(Main)Glass in building - Structural sealant glazing - Part 2: Assembly rules

Glass in building - Structural sealant glazing - Part 2: Assembly rules

This European Standard deals with the assembling and bonding of glass elements in a frame, window, door or curtain walling construction, or directly into the building by means of structural bonding of the glass element into or onto framework or directly into the building.

It gives information to the assembler to enable him to organise his work and comply with requirements regarding quality control.

Structural sealant glazing can be incorporated into the façade as follows:

· either vertically; or

· up to 7° from the horizontal, i.e. 83o from the vertical..

This European Standard only deals with the bonding to glass surfaces, i.e. coated or uncoated, and metallic surfaces, i.e. aluminium (anodized or coated), stainless steel, as considered in clause G.2 of EN 15434.

Glas im Bauwesen - Geklebte Verglasungen - Teil 2: Verglasungsvorschriften

Diese Europäische Norm gilt für die Montage und die Verklebung von Verglasungselementen in Rahmen, Fenster, Türen oder Vorhangfassadenkonstruktionen und die Montage von Verglasungselementen durch lastübertragendes Verkleben in oder auf eine Unterkonstruktion oder direkt in oder auf das Gebäude.

Sie enthält Angaben für den Monteur zur Unterstützung bei der Einteilung seiner Arbeit und zum Erreichen der Übereinstimmung mit den Anforderungen an die Qualitätskontrolle.

Verklebte Verglasungen können wie folgt in der Fassade eingefügt werden:

- entweder vertikal oder

- bis 7° von der Horizontalen, d. h. 83° von der Vertikalen.

Diese Europäische Norm behandelt nur die Verklebung an Glasoberflächen, wie beschichtete oder unbeschichtete, und an metallischen Oberflächen, wie Aluminium (eloxiert oder beschichtet), Edelstahl, nach Abschnitt G.2 von EN 15434.

Verre dans la construction - Vitrage extérieur collé - Partie 2 : Règles d'assemblage

La présente Norme européenne traite de l’assemblage des éléments de verre sur une fenêtre, une porte ou

une façade rideau, ou directement sur le bâtiment par le biais du collage de l'élément de verre sur ou dans

l'ossature, voire directement sur le bâtiment.

La présente norme donne des informations à l’assembleur lui permettant d'organiser son travail et de

satisfaire aux exigences relatives au contrôle qualité.

Le vitrage extérieur collé peut être intégré à la façade comme suit :

- verticalement, ou ;

- incliné jusqu’à 7° par rapport à l’horizontale, soit 83° par rapport à la verticale.

La présente Norme européenne ne couvre que le collage sur un support verrier, par exemple à couches ou

sans couches, et les surfaces métalliques, par exemple, aluminium (anodisé ou thermolaqué), acier

inoxydable, comme prévu à l’Article G.2 de l’EN 15434.

Steklo v gradbeništvu – Strukturna zasteklitev – 2. del: Pravila za zastekljevanje

General Information

- Status

- Withdrawn

- Publication Date

- 09-May-2006

- Withdrawal Date

- 27-Apr-2010

- Technical Committee

- CEN/TC 129 - Glass in building

- Drafting Committee

- CEN/TC 129/WG 16 - Structural glazing

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 28-Apr-2010

- Completion Date

- 28-Apr-2010

- Directive

- 89/106/EEC - Construction products

Relations

- Merged Into

EN 13022-2:2006+A1:2010 - Glass in building - Structural sealant glazing - Part 2: Assembly rules - Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Amended By

EN 13022-2:2006/FprA1 - Glass in building - Structural sealant glazing - Part 2: Assembly rules - Effective Date

- 04-Jul-2009

Frequently Asked Questions

EN 13022-2:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Glass in building - Structural sealant glazing - Part 2: Assembly rules". This standard covers: This European Standard deals with the assembling and bonding of glass elements in a frame, window, door or curtain walling construction, or directly into the building by means of structural bonding of the glass element into or onto framework or directly into the building. It gives information to the assembler to enable him to organise his work and comply with requirements regarding quality control. Structural sealant glazing can be incorporated into the façade as follows: · either vertically; or · up to 7° from the horizontal, i.e. 83o from the vertical.. This European Standard only deals with the bonding to glass surfaces, i.e. coated or uncoated, and metallic surfaces, i.e. aluminium (anodized or coated), stainless steel, as considered in clause G.2 of EN 15434.

This European Standard deals with the assembling and bonding of glass elements in a frame, window, door or curtain walling construction, or directly into the building by means of structural bonding of the glass element into or onto framework or directly into the building. It gives information to the assembler to enable him to organise his work and comply with requirements regarding quality control. Structural sealant glazing can be incorporated into the façade as follows: · either vertically; or · up to 7° from the horizontal, i.e. 83o from the vertical.. This European Standard only deals with the bonding to glass surfaces, i.e. coated or uncoated, and metallic surfaces, i.e. aluminium (anodized or coated), stainless steel, as considered in clause G.2 of EN 15434.

EN 13022-2:2006 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13022-2:2006 has the following relationships with other standards: It is inter standard links to EN 13022-2:2006+A1:2010, EN 15434:2006+A1:2010, EN 13022-2:2006/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13022-2:2006 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13022-2:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Glass in building - Structural sealant glazing - Part 2: Assembly rulesSteklo v gradbeništvu – Strukturna zasteklitev – 2. del: Pravila za zastekljevanjeVerre dans la construction - Vitrage extérieur collé - Partie 2 : Regles d'assemblageGlas im Bauwesen - Geklebte Verglasungen - Teil 2: VerglasungsvorschriftenTa slovenski standard je istoveten z:EN 13022-2:2006SIST EN 13022-2:2006en81.040.20Steklo v gradbeništvuGlass in buildingICS:SLOVENSKI

STANDARDSIST EN 13022-2:200601-oktober-2006

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13022-2May 2006ICS 81.040.20 English VersionGlass in building - Structural sealant glazing - Part 2: AssemblyrulesVerre dans la construction - Vitrage extérieur collé - Partie2 : Règles d'assemblageGlas im Bauwesen - Geklebte Verglasungen - Teil 2:VerglasungsvorschriftenThis European Standard was approved by CEN on 13 March 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13022-2:2006: E

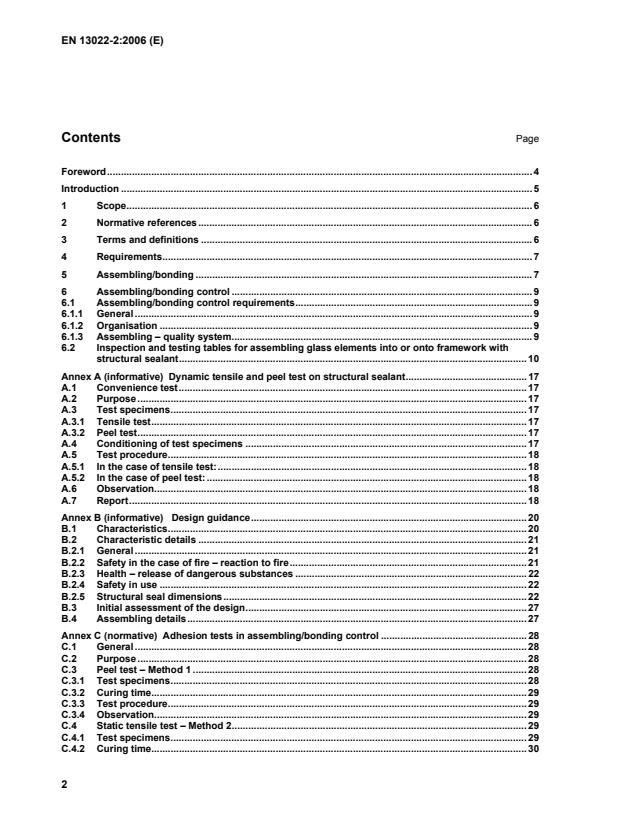

Dynamic tensile and peel test on structural sealant.17 A.1 Convenience test.17 A.2 Purpose.17 A.3 Test specimens.17 A.3.1 Tensile test.17 A.3.2 Peel test.17 A.4 Conditioning of test specimens.17 A.5 Test procedure.18 A.5.1 In the case of tensile test:.18 A.5.2 In the case of peel test:.18 A.6 Observation.18 A.7 Report.18 Annex B (informative)

Design guidance.20 B.1 Characteristics.20 B.2 Characteristic details.21 B.2.1 General.21 B.2.2 Safety in the case of fire – reaction to fire.21 B.2.3 Health – release of dangerous substances.22 B.2.4 Safety in use.22 B.2.5 Structural seal dimensions.22 B.3 Initial assessment of the design.27 B.4 Assembling details.27 Annex C (normative)

Adhesion tests in assembling/bonding control.28 C.1 General.28 C.2 Purpose.28 C.3 Peel test – Method 1.28 C.3.1 Test specimens.28 C.3.2 Curing time.29 C.3.3 Test procedure.29 C.3.4 Observation.29 C.4 Static tensile test – Method 2.29 C.4.1 Test specimens.29 C.4.2 Curing time.30

Two-component sealant: check on the thoroughness of mixing and air inclusions.32 D.1 General.32 D.2 Purpose.32 D.3 Test specimen.32 D.4 Test procedure.32 D.5 Report.33 Annex E (informative)

Sealants, hardness measurements.34 E.1 General.34 E.2 Purpose.34 E.3 Definitions.34 E.3.1 Curing time.34 E.3.2 Free surface.34 E.4 Instruments.34 E.5 Calibration.35 E.6 Test specimens.35 E.7 Test procedure.35 E.8 Report.36 Annex F (informative)

Provisions for voluntary involvement of third party(ies).37 F.1 General.37 F.2 Voluntary tasks for third parties.37 F.3 Marking and labelling.37 Bibliography.38

This Part of the standard is one of a series of interrelated standard parts dealing with: glass products for structural sealant glazing systems,

installation of glass products in a structural manner on building façades; UV-resistant and structural sealant for use in structural sealant glazing. The interrelated parts are: EN 13022-1: Glass in building — Structural sealant glazing — Part 1: Glass products for structural sealant glazing systems for supported and unsupported monolithic and multiple glazing EN 13022-2: Glass in building — Structural sealant glazing — Part 2: Assembly rules EN 15434: Glass in building — Product standard for structural and/or ultra-violet resistant sealant (for use with structural sealant glazing and/or insulating glass units with exposed seals) According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

2 Normative references The following referenced documents are indispensable for the application of this European Standard. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 13022-1:2006, Glass in building — Structural sealant glazing — Part 1: Glass products for structural sealant glazing systems for supported and unsupported monolithic and multiple glazing EN 15434:2006, Glass in building — Product standard for structural and/or ultra-violet resistant sealant (for use with structural sealant glazing and/or insulating glass units with exposed seals) EN ISO 9001:2000, Quality management systems — Requirements (ISO 9001:2000)

3 Terms and definitions For the purposes of this European Standard, the terms and definitions given in EN 13022-1:2006,

EN 15434:2006 and the following apply. 3.1 structural bonding assembling of glass elements into or onto window, door or curtain walling framework by means of a structural seal 3.2. structural sealant elastic sealant used for making a structural seal

1) ETA: European Technical Agreement

1.1.1 packaging and label Visual See purchase specification Each delivery No 1.1.2 identification Visual See purchase specification Each delivery Yes 1.2 Glass products

1.2.1 packaging and label Visual See purchase specification Each delivery No 1.2.2 identification (according to relevant standards) Visual See purchase specification Each delivery Yes 1.2.3 dimensions Measurement See purchase specification Each package and thickness No 1.3 Structural sealant

1.3.1 packaging and label Visual See purchase specification Each delivery No 1.3.2 shelf life Visual Suppliers’ specification Each delivery Yes 1.3.3

Convenience test tensile test (when no delivery information (1) (on the sealant or) from the sealant supplier is available and

adhesion test (may be carried out together or combined with section 2, line 2.3.1) Annex A and Annex C Peel and tensile tests Annex A Strength ≥ supplier's declared value Minimum breaking value: 0,70 MPa Minimum elongation value: 50 % Rupture 100 % cohesive

Each delivery of sealant, glass or framework (2)

Yes 1.4 Bond breaker material

1.4.1 packaging and labelling Visual See purchase specification Each delivery No 1.4.2 identification Visual See purchase specification Each delivery Yes 1.5 Spacer material

1.5.1 packaging and labelling Visual See purchase specification Each delivery No 1.5.2 identification Visual See purchase specification Each delivery Yes

1.6.1 packaging and labelling Visual See purchase specification Each delivery No 1.6.2 identification Visual See purchase specification Each delivery Yes 1.7 Finishing material

1.7.1 packaging and labelling Visual See purchase specification Each delivery No 1.7.2 identification Visual See purchase specification Each delivery Yes To be continued

Ref.

Material, inspection or test Recommended method (decision to be made by assembler)

Requirement Recommended frequency (decision to be made by designer)

Record 1.8 Retaining devices

1.8.1 packaging and labelling Visual See purchase specification Each delivery No 1.8.2 identification Visual See purchase specification Each delivery Yes 1.9 Retaining clips

1.9.1 packaging and labelling Visual See purchase specification Each delivery No 1.9.2 identification Visual See purchase specification Each delivery Yes 1.10 Cleaning products

1.10.1 packaging and labelling Visual See purchase specification Each delivery No 1.10.2 identification Visual See purchase specification Each delivery Yes 1.11 Primer

1.11.1 packaging and labelling Visual See purchase specification Each delivery No 1.11.2 identification Visual See purchase specification Each delivery Yes To be continued

Ref.

Material, inspection or test Recommended method (decision to be made by assembler)

Requirement Recommended frequency (decision to be made by designer)

Record 2.1 Component preparation

2.1.1 dry and clean framework surface Visual No visible contamination Continually No 2.1.2 dry and clean glass surface Visual No visible contamination Continually No 2.2 Structural sealant application

2.2.1 preparation (including application primer) and positioning glass elements and/or framework Visual Assembling manual Continually No 2.2.2 extrusion of structural sealant and application retaining clips Visual Assembling manual Continually No 2.2.3 storage after initial cure Visual Assembling manual Continually No 2.2.4 installation on building with retaining devices Visual Assembling manual Continually No 2.2.5 finishing work Visual Assembling manual Continually No 2.2.6 application weather sealant Visual Assembling manual Continually No 2.3 Structural sealant

2.3.1 adhesion on relevant substrates Annex C Method 1 or 2 Annex C (2 x per working day): 2 specimens Yes 2.3.2 mixing ratio See equipment and sealant specifications See sealant specification See assembling control manual Yes 2.3.3 thoroughness of mixing Mixing check (Annex D) No marbling Each working day: 1 Yes 2.3.4 air inclusions (during 2.3.3 thoroughness of mixing) Visual

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...