EN 1473:2021

(Main)Installation and equipment for liquefied natural gas - Design of onshore installations

Installation and equipment for liquefied natural gas - Design of onshore installations

This document gives guidelines for the design, construction and operation of all onshore liquefied natural gas (LNG) installations for the liquefaction, storage, vaporization, transfer and handling of LNG and natural gas (NG).

This document is applicable for plants with an LNG storage capacity above 200 t.

The designated boundary limits are LNG inlet/outlet by the ship’s manifold including vapour return connection, the truck loading/unloading connection including vapour return, the rail car loading/unloading connection including vapour return and the natural gas in and outlet boundary by piping systems.

Terminals or plant types have one or more boundary limits as described in this scope (see Figure 1).

A short description of each of these installations is given in Annex G.

Feed gas for LNG liquefaction installations (plant) can be from gas field, associated gas from oil field, piped gas from transportation grid or from renewables.

Floating solutions (for example FPSO, FSRU, SRV), whether off-shore or near-shore, are not covered by this document even if some concepts, principles or recommendations could be applied. However, in case of berthed FSRU with LNG transfer across the jetty, the following recommendations apply for the jetty and topside facilities.

In case of solutions using floating storage unit (FSU) and land-based re-gasification solution, the on-shore part is covered by these standard recommendations.

Plants with a storage inventory from 5 t up to 200 t are covered by [5].

Anlagen und Ausrüstung für Flüssigerdgas - Auslegung von landseitigen Anlagen

Dieses Dokument gibt Leitlinien für die Planung, den Bau und den Betrieb von allen landseitigen Flüssigerdgasanlagen für die Verflüssigung von Erdgas sowie für die Lagerung, die Verdampfung, die Weiterleitung und den Umgang mit LNG und Erdgas (NG, en: natural gas).

Dieses Dokument ist anzuwenden für Anlagen mit einer LNG-Lagerkapazität von mehr als 200 t.

Die vorgesehenen Anlagengrenzen sind der LNG Ein- und Austritt durch die Schiffsübergabestelle einschließlich Dampfrücklaufanschluss, der Anschluss für die Be- und Entladung von Tankwagen einschließlich Dampfrückführung, der Anschluss für die Be- und Entladung von Schienenfahrzeugen einschließlich Dampfrückführung und die Ein- und Austrittsgrenze von Erdgas durch Rohrleitungssysteme.

Anlandeterminals oder Anlagentypen haben eine oder mehrere Abgrenzungen, wie in diesem Anwendungsbereich beschrieben (siehe Bild 1).

[Bild 1]

Eine kurze Beschreibung jeder dieser Anlagen ist in Anhang G enthalten.

Einspeisegas für LNG-Verflüssigungsanlagen kann aus einem Erdgasfeld, Erdölbegleitgas aus einer Erdöllagerstätte, Pipelinegas aus einem Gasleitungsnetz oder aus erneuerbaren Quellen sein.

Schwimmende Lösungen (z. B. FPSO, FSRU, SRV), ob auf See oder in Küstennähe, werden in diesem Dokument nicht behandelt, auch wenn einige Begriffe, Grundsätze oder Empfehlungen auf sie angewendet werden könnten. Bei fest vertäuten LNG-Wiederverdampfungsanlagen (FSRU) mit LNG-Transfer über einen Schiffsanleger gelten die nachfolgenden Empfehlungen für den Schiffsanleger (inklusive der Einrichtungen auf dem Schiffsanleger).

Bei Lösungen in Form von schwimmenden Lagern (FSU) und Wiederverdampfung an Land wird der landseitige Teil durch die Empfehlungen dieser Norm abgedeckt.

Anlagen mit einem Lagerbestand von 5 t bis zu 200 t werden in [5] behandelt.

Installation et équipements de gaz naturel liquéfié - Conception des installation terrestres

Le présent document donne des lignes directrices relatives à la conception, à la construction et au fonctionnement de toutes les installations terrestres de gaz naturel liquéfié (GNL) destinées à la liquéfaction, au stockage, à la vaporisation, au transfert et à la manipulation du GNL et du gaz naturel (GN).

Le présent document est valable pour les installations comportant un stockage de GNL d’une capacité supérieure à 200 t.

Les limites de propriété prévues correspondent à l’entrée/la sortie du GNL à la bride du navire incluant la connexionde retour gaz, les connexions de chargement/déchargement des camions incluant le retour gaz, la connexion de chargement/déchargement des trains incluant le retour gaz, ainsi que les limites de propriété en entrée et sortie du gaz naturel par les réseaux de tuyauterie.

Les différents types de terminaux ou d’installations possèdent une ou plusieurs limites de propriété, comme indiqué dans le présent domaine d’application (voir Figure 1).

Une description succincte de ces différentes installations est donnée dans l’Annexe G.

Le gaz alimentant les terminaux de liquéfaction de GNL (installation) peut être du gaz de champ, du gaz associé à un champ de pétrole, du gaz de canalisation provenant du réseau de transport ou de sources d’énergie renouvelables.

Les solutions flottantes (FPSO, FSRU, SRV), qu’elles soient off-shore ou à proximité du rivage, ne sont pas couvertes par ce document, même si certains concepts, principes ou recommandations pourraient être appliquées. Toutefois, en cas de FSRU amarré avec transfert de GNL à travers la jetée, les recommandations suivantes s’appliquent pour la jetée et les installations de superstructures.

En cas de solution de type unité de stockage flottante (FSU) et de solution terrestre de re-gazification, la partie sur la rive est couverte par les présentes recommandations normalisées.

Les installations d’une capacité de stockage comprise entre 5 t et 200 t sont couvertes par [35].

Napeljave in oprema za utekočinjeni zemeljski plin - Načrtovanje kopenskih napeljav

General Information

- Status

- Published

- Publication Date

- 18-May-2021

- Withdrawal Date

- 29-Nov-2021

- Technical Committee

- CEN/TC 282 - Installation and equipment for LNG

- Drafting Committee

- CEN/TC 282 - Installation and equipment for LNG

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 19-May-2021

- Due Date

- 13-Sep-2020

- Completion Date

- 19-May-2021

Relations

- Effective Date

- 26-May-2021

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN IEC 60079-11:2024 - Explosive atmospheres - Part 11: Equipment protection by intrinsic safety "i" - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 60079-2:2014 - Explosive atmospheres - Part 2: Equipment protection by pressurized enclosure "p" - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN IEC 60079-18:2025 - Explosive atmospheres - Part 18: Equipment protection by encapsulation "m" - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

Overview

EN 1473:2021 (equivalent to EN 1473:2021) provides comprehensive guidelines for the design, construction and operation of onshore liquefied natural gas (LNG) installations. It applies to plants with an LNG storage capacity above 200 t and sets out functional recommendations covering liquefaction, storage, vaporization, transfer and handling of LNG and natural gas (NG). The standard supersedes EN 1473:2016 and includes structural updates such as incorporation of pressurized storage and improved risk assessment and tank classification.

Key technical topics and requirements

- Scope & boundaries - Defines plant boundaries (ship manifold and vapour return, truck and rail loading/unloading with vapour return, NG pipeline in/out).

- Site assessment - Geotechnical, meteorological, environmental, hydrology, seismic and social considerations for siting LNG facilities.

- Risk management - Hazard identification, consequence assessment, frequency estimation, and safety improvement measures; normative risk-assessment methodologies are emphasized.

- Design requirements - Civil, mechanical, piping, electrical, rotating equipment, storage units, marine transfer systems, regasification and send‑out units, liquefaction units, buildings, utilities and process controls.

- Process safety & control - Automation, process safety systems, Boil‑Off Gas (BOG) management, flare/vent systems and custody transfer metering.

- Specific equipment guidance - Normative annexes address thermal radiation thresholds, LNG pumps, vaporizers, pipe design criteria and other equipment-specific requirements.

- Testing, materials & measurements - Includes references to relevant EN standards for pumps, flanges, materials and measurement systems.

Practical applications

- Design and engineering of new onshore LNG terminals and liquefaction/regasification plants.

- Construction and commissioning guidance to ensure safety and regulatory compliance.

- Operational procedures and safety management for plant operators, including BOG handling, custody transfer and loading/unloading operations.

- Basis for revamps, debottlenecking and life‑extension projects (subject to local authority limits).

- Guidance for jetty and topside facilities when an FSRU is berthed; floating offshore solutions (FSRU, FPSO) are generally excluded except where on‑shore elements apply.

Who should use this standard

- LNG terminal designers and process engineers

- Civil, mechanical and electrical engineering teams

- Project managers, contractors and EPC firms

- Plant operators and maintenance teams

- Regulators, safety assessors and risk consultants

Related standards and regulatory context

EN 1473:2021 references many normative EN standards (pumps, flanges, Eurocodes) and expects alignment with applicable directives such as Seveso, PED and ATEX where relevant. Plants with storage inventories from 5 t to 200 t are addressed by other documents (see referenced standards).

Keywords: EN 1473:2021, SIST, LNG design, onshore LNG installations, liquefied natural gas, LNG storage, regasification, LNG safety, Boil‑Off Gas.

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

EN 1473:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Installation and equipment for liquefied natural gas - Design of onshore installations". This standard covers: This document gives guidelines for the design, construction and operation of all onshore liquefied natural gas (LNG) installations for the liquefaction, storage, vaporization, transfer and handling of LNG and natural gas (NG). This document is applicable for plants with an LNG storage capacity above 200 t. The designated boundary limits are LNG inlet/outlet by the ship’s manifold including vapour return connection, the truck loading/unloading connection including vapour return, the rail car loading/unloading connection including vapour return and the natural gas in and outlet boundary by piping systems. Terminals or plant types have one or more boundary limits as described in this scope (see Figure 1). A short description of each of these installations is given in Annex G. Feed gas for LNG liquefaction installations (plant) can be from gas field, associated gas from oil field, piped gas from transportation grid or from renewables. Floating solutions (for example FPSO, FSRU, SRV), whether off-shore or near-shore, are not covered by this document even if some concepts, principles or recommendations could be applied. However, in case of berthed FSRU with LNG transfer across the jetty, the following recommendations apply for the jetty and topside facilities. In case of solutions using floating storage unit (FSU) and land-based re-gasification solution, the on-shore part is covered by these standard recommendations. Plants with a storage inventory from 5 t up to 200 t are covered by [5].

This document gives guidelines for the design, construction and operation of all onshore liquefied natural gas (LNG) installations for the liquefaction, storage, vaporization, transfer and handling of LNG and natural gas (NG). This document is applicable for plants with an LNG storage capacity above 200 t. The designated boundary limits are LNG inlet/outlet by the ship’s manifold including vapour return connection, the truck loading/unloading connection including vapour return, the rail car loading/unloading connection including vapour return and the natural gas in and outlet boundary by piping systems. Terminals or plant types have one or more boundary limits as described in this scope (see Figure 1). A short description of each of these installations is given in Annex G. Feed gas for LNG liquefaction installations (plant) can be from gas field, associated gas from oil field, piped gas from transportation grid or from renewables. Floating solutions (for example FPSO, FSRU, SRV), whether off-shore or near-shore, are not covered by this document even if some concepts, principles or recommendations could be applied. However, in case of berthed FSRU with LNG transfer across the jetty, the following recommendations apply for the jetty and topside facilities. In case of solutions using floating storage unit (FSU) and land-based re-gasification solution, the on-shore part is covered by these standard recommendations. Plants with a storage inventory from 5 t up to 200 t are covered by [5].

EN 1473:2021 is classified under the following ICS (International Classification for Standards) categories: 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1473:2021 has the following relationships with other standards: It is inter standard links to EN 1473:2016, EN 61800-7-202:2016, EN IEC 61800-1:2021, EN IEC 60079-11:2024, EN 61800-9-1:2017, EN IEC 60079-14:2024, IEC 60364-5-559:1999, EN 61800-4:2003, EN IEC 60079-17:2024, EN 61800-7-1:2016, EN 60079-10-2:2015, EN 60079-2:2014, EN 61800-7-304:2016, EN IEC 60079-18:2025, EN IEC 62305-4:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1473:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2021

Nadomešča:

SIST EN 1473:2016

Napeljave in oprema za utekočinjeni zemeljski plin - Načrtovanje kopenskih

napeljav

Installation and equipment for liquefied natural gas - Design of onshore installations

Anlagen und Ausrüstung für Flüssigerdgas - Auslegung von landseitigen Anlagen

Installations et équipements de gaz naturel liquéfié - Conception des installations

terrestres

Ta slovenski standard je istoveten z: EN 1473:2021

ICS:

75.200 Oprema za skladiščenje Petroleum products and

nafte, naftnih proizvodov in natural gas handling

zemeljskega plina equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1473

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2021

EUROPÄISCHE NORM

ICS 75.200 Supersedes EN 1473:2016

English Version

Installation and equipment for liquefied natural gas -

Design of onshore installations

Installation et équipements de gaz naturel liquéfié - Anlagen und Ausrüstung für Flüssigerdgas - Auslegung

Conception des installation terrestres von landseitigen Anlagen

This European Standard was approved by CEN on 15 February 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1473:2021 E

worldwide for CEN national Members.

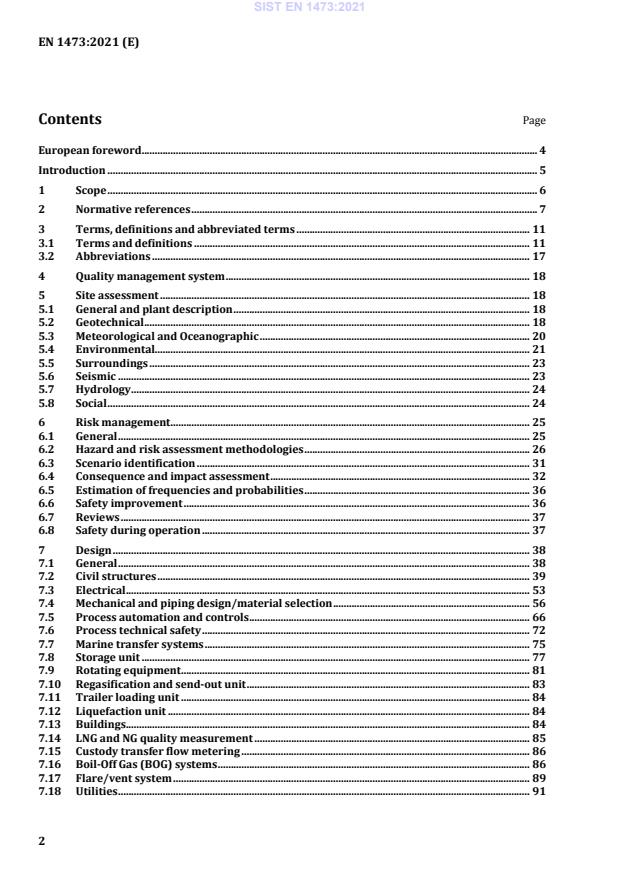

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 7

3 Terms, definitions and abbreviated terms . 11

3.1 Terms and definitions . 11

3.2 Abbreviations . 17

4 Quality management system . 18

5 Site assessment . 18

5.1 General and plant description . 18

5.2 Geotechnical . 18

5.3 Meteorological and Oceanographic . 20

5.4 Environmental. 21

5.5 Surroundings . 23

5.6 Seismic . 23

5.7 Hydrology . 24

5.8 Social . 24

6 Risk management . 25

6.1 General . 25

6.2 Hazard and risk assessment methodologies . 26

6.3 Scenario identification . 31

6.4 Consequence and impact assessment . 32

6.5 Estimation of frequencies and probabilities . 36

6.6 Safety improvement . 36

6.7 Reviews . 37

6.8 Safety during operation . 37

7 Design . 38

7.1 General . 38

7.2 Civil structures . 39

7.3 Electrical . 53

7.4 Mechanical and piping design/material selection . 56

7.5 Process automation and controls . 66

7.6 Process technical safety . 72

7.7 Marine transfer systems . 75

7.8 Storage unit . 77

7.9 Rotating equipment . 81

7.10 Regasification and send-out unit . 83

7.11 Trailer loading unit . 84

7.12 Liquefaction unit . 84

7.13 Buildings . 84

7.14 LNG and NG quality measurement . 85

7.15 Custody transfer flow metering . 86

7.16 Boil-Off Gas (BOG) systems . 86

7.17 Flare/vent system . 89

7.18 Utilities . 91

Annex A (normative) Thermal radiation threshold values . 94

Annex B (normative) Definitions of reference flow rates . 97

Annex C (informative) Seismic classification . 101

Annex D (normative) Specific requirements for LNG pumps . 103

Annex E (normative) Specific requirements for LNG vaporizers . 109

Annex F (normative) Criteria for the design of pipes . 115

Annex G (informative) Description of the different types of onshore LNG installations . 116

Annex H (informative) Trailer loading unit . 118

Annex I (informative) Frequency ranges . 120

Annex J (informative) Classes of consequence . 121

Annex K (informative) Levels of risk . 122

Annex L (informative) Typical process steps of liquefaction . 124

Annex M (informative) Odorant systems . 133

Bibliography . 136

European foreword

This document (EN 1473:2021) has been prepared by Technical Committee CEN/TC 282 “Installation

and equipment for LNG”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2021, and conflicting national standards

shall be withdrawn at the latest by November 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1473:2016.

Due to the incorporation of pressurized storage the standard has been re-structured and revised. In

comparison with EN 1473:2016, the following changes have been made:

— duplications detected and deleted;

— terms and definitions adjusted;

— normative references updated;

— changed subject in Annex H;

— risk assessment requirements improved;

— storage tanks classification improved.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

The objective of this document is to give functional guidelines for on-shore LNG installations. It

recommends procedures and practices that will result in safe and environmentally acceptable design,

construction and operation of LNG plants.

Given the wide range of facilities from small to large, with high and low risk profile, etc., the

acceptability criteria could vary depending on the project and are subject to conclusions by the

normative risk assessment.

Seveso, PED, and ATEX Directives are expected to be followed. Where national and/or local regulations

exist in which some of the requirements are equal or more stringent than in this document, it is up to

agreement with national and/or local regulators to determine which of the requirements apply.

It does not need to be applied retrospectively, but application is recommended when major

modifications of existing installations are being considered.

This document is also recommended for debottlenecking, revamping and plant life extension in the

limits that will be defined by the local authority. The appliance of the European Directives to the

existing facilities is part of the limits to be defined together with the local authority.

In case of plant expansion, this document is applicable for the new facilities. The application of these

recommendations for the tie-ins and connections to the existing facilities will be defined by the local

authority. The limits of such application should consider the practicality of such appliance. In the same

way, the limits of the European Directives appliance will be accurately defined with the local authority.

1 Scope

This document gives guidelines for the design, construction and operation of all onshore liquefied

natural gas (LNG) installations for the liquefaction, storage, vaporization, transfer and handling of LNG

and natural gas (NG).

This document is applicable for plants with an LNG storage capacity above 200 t.

The designated boundary limits are LNG inlet/outlet by the ship’s manifold including vapour return

connection, the truck loading/unloading connection including vapour return, the rail car

loading/unloading connection including vapour return and the natural gas in and outlet boundary by

piping systems.

Terminals or plant types have one or more boundary limits as described in this scope (see Figure 1).

Figure 1 — Boundary limits of onshore liquefied natural gas (LNG) installations

A short description of each of these installations is given in Annex G.

Feed gas for LNG liquefaction installations (plant) can be from gas field, associated gas from oil field,

piped gas from transportation grid or from renewables.

Floating solutions (for example FPSO, FSRU, SRV), whether off-shore or near-shore, are not covered by

this document even if some concepts, principles or recommendations could be applied. However, in

case of berthed FSRU with LNG transfer across the jetty, the following recommendations apply for the

jetty and topside facilities.

In case of solutions using floating storage unit (FSU) and land-based re-gasification solution, the on-

shore part is covered by these standard recommendations.

Plants with a storage inventory from 5 t up to 200 t are covered by [5].

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 809, Pumps and pump units for liquids - Common safety requirements

EN 1092-1, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 1: Steel flanges

EN 1127-1, Explosive atmospheres - Explosion prevention and protection - Part 1: Basic concepts and

methodology

EN 1474-2, Installation and equipment for liquefied natural gas - Design and testing of marine transfer

systems - Part 2: Design and testing of transfer hoses

EN 1514-1, Flanges and their joints - Dimensions of gaskets for PN-designated flanges - Part 1: Non-

metallic flat gaskets with or without inserts

EN 1591 (all parts), Flanges and their joints - Design rules for gasketed circular flange connections

EN 1776, Gas infrastructure - Gas measuring systems - Functional requirements

EN 1990, Eurocode - Basis of structural design

EN 1991 (all parts), Eurocode 1: Actions on structures

EN 1992 (all parts), Eurocode 2: Design of concrete structures

EN 1993 (all parts), Eurocode 3: Design of steel structures

EN 1994-1-1, Eurocode 4: Design of composite steel and concrete structures - Part 1-1: General rules and

rules for buildings

EN 1994-1-2, Eurocode 4 - Design of composite steel and concrete structures - Part 1-2: General rules -

Structural fire design

EN 1997-1:2004, Eurocode 7: Geotechnical design - Part 1: General rules

EN 1997 (all parts), Eurocode 7 - Geotechnical design

EN 1998 (all parts), Eurocode 8: Design of structures for earthquake resistance

EN 10204, Metallic products - Types of inspection documents

EN 12065, Installations and equipment for liquefied natural gas - Testing of foam concentrates designed

for generation of medium and high expansion foam and of extinguishing powders used on liquefied natural

gas fires

EN 12162, Liquid pumps - Safety requirements - Procedure for hydrostatic testing

As impacted by EN 1997-1:2004/AC:2009.

EN 12483, Liquid pumps - Pump units with frequency inverters - Guarantee and compatibility tests

EN 13445 (all parts), Unfired pressure vessels

EN 13458 (all parts), Cryogenic vessels - Static vacuum insulated vessels

EN 13480 (all parts), Metallic industrial piping

EN 13766, Thermoplastic multi-layer (non-vulcanized) hoses and hose assemblies for the transfer of liquid

petroleum gas and liquefied natural gas - Specification

EN 14197 (all parts), Cryogenic vessels - Static non-vacuum insulated vessels

EN 14620 (all parts), , Design and manufacture of site built, vertical, cylindrical, flat-bottomed steel tanks

for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and -165 °C

EN 60079-0, Explosive atmospheres - Part 0: Equipment - General requirements (IEC 60079-0)

EN 60079-1, Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"

(IEC 60079-1)

EN 60079-2, Explosive atmospheres - Part 2: Equipment protection by pressurized enclosure "p"

(IEC 60079-2)

EN 60079-5, Explosive atmospheres - Part 5: Equipment protection by powder filling "q" (IEC 60079-5)

EN 60079-6, Explosive atmospheres - Part 6: Equipment protection by liquid immersion "o" (IEC 60079-6)

EN 60079-7, Explosive atmospheres - Part 7: Equipment protection by increased safety "e" (IEC 60079-7)

EN 60079-10-1, Explosive atmospheres - Part 10-1: Classification of areas - Explosive gas atmospheres

(IEC 60079-10-1)

EN 60079-10-2, Explosive atmospheres - Part 10-2: Classification of areas - Explosive dust atmospheres

(IEC 60079-10-2)

EN 60079-11, Explosive atmospheres - Part 11: Equipment protection by intrinsic safety "i"

(IEC 60079-11)

EN 60079-13, Explosive atmospheres - Part 13: Equipment protection by pressurized room "p" and

artificially ventilated room "v" (IEC 60079-13)

EN 60079-14, Explosive atmospheres - Part 14: Electrical installations design, selection and erection

(IEC 60079-14)

EN 60079-15, Explosive atmospheres - Part 15: Equipment protection by type of protection "n"

(IEC 60079-15)

EN 60079-17, Explosive atmospheres - Part 17: Electrical installations inspection and maintenance

(IEC 60079-17)

EN 60079-18, Explosive atmospheres - Part 18: Equipment protection by encapsulation "m"

(IEC 60079-18)

EN 60079-19, Explosive atmospheres - Part 19: Equipment repair, overhaul and reclamation

(IEC 60079-19)

EN 60079-20-1, Explosive atmospheres - Part 20-1: Material characteristics for gas and vapour

classification - Test methods and data (IEC 60079-20-1)

EN 60079-25, Explosive atmospheres - Part 25: Intrinsically safe electrical systems (IEC 60079-25)

EN 60204-1, Safety of machinery - Electrical equipment of machines - Part 1: General requirements

(IEC 60204-1)

EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529)

EN 61508 (all parts), Functional safety of electrical/electronic/programmable electronic safety-related

systems (IEC 61508 series)

EN 61800 (all parts), Adjustable speed electrical power drive systems (IEC 61800 all parts)

EN 62305 (all parts), Protection against lightning (IEC 62305 all parts)

EN ISO 1460, Metallic coatings - Hot dip galvanized coatings on ferrous materials - Gravimetric

determination of the mass per unit area (ISO 1460)

EN ISO 1461, Hot dip galvanized coatings on fabricated iron and steel articles - Specifications and test

methods (ISO 1461)

EN ISO 3452-1, Non-destructive testing - Penetrant testing - Part 1: General principles (ISO 3452-1)

EN ISO 6974 (all parts), Natural gas - Determination of composition with defined uncertainty by gas

chromatography (ISO 6974 all parts)

EN ISO 6976, Natural gas - Calculation of calorific values, density, relative density and Wobbe indices from

composition (ISO 6976)

EN ISO 9606-1, Qualification testing of welders - Fusion welding - Part 1: Steels (ISO 9606-1)

EN ISO 9712, Non-destructive testing - Qualification and certification of NDT personnel (ISO 9712)

EN ISO 9906, Rotodynamic pumps - Hydraulic performance acceptance tests - Grades 1, 2 and 3

(ISO 9906)

EN ISO 10380, Pipework - Corrugated metal hoses and hose assemblies (ISO 10380)

EN ISO 10497, Testing of valves - Fire type-testing requirements (ISO 10497)

EN ISO 10715, Natural gas - Sampling guidelines (ISO 10715)

EN ISO 10723, Natural gas - Performance evaluation for analytical systems (ISO 10723)

EN ISO 12241, Thermal insulation for building equipment and industrial installations - Calculation rules

(ISO 12241)

EN ISO 12944 (all parts), Paints and varnishes - Corrosion protection of steel structures by protective

paint systems (ISO 12944 all parts)

EN ISO 13709, Centrifugal pumps for petroleum, petrochemical and natural gas industries (ISO 13709)

EN ISO 15607, Specification and qualification of welding procedures for metallic materials - General rules

(ISO 15607)

EN ISO 15609-1, Specification and qualification of welding procedures for metallic materials - Welding

procedure specification - Part 1: Arc welding (ISO 15609-1)

EN ISO 15614-1, Specification and qualification of welding procedures for metallic materials - Welding

procedure test - Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

(ISO 15614-1)

EN ISO 16903:2015, Petroleum and natural gas industries - Characteristics of LNG, influencing the design,

and material selection (ISO 16903:2015)

EN ISO 16904, Petroleum and natural gas industries - Design and testing of LNG marine transfer arms for

conventional onshore terminals (ISO 16904)

EN ISO 17636-1, Non-destructive testing of welds - Radiographic testing - Part 1: X- and gamma-ray

techniques with film (ISO 17636-1)

EN ISO 17636-2, Non-destructive testing of welds - Radiographic testing - Part 2: X- and gamma-ray

techniques with digital detectors (ISO 17636-2)

EN ISO 17637, Non-destructive testing of welds - Visual testing of fusion-welded joints (ISO 17637)

EN ISO 17640, Non-destructive testing of welds - Ultrasonic testing - Techniques, testing levels, and

assessment (ISO 17640)

EN ISO 20519, Ships and marine technology - Specification for bunkering of liquefied natural gas fuelled

vessels (ISO 20519)

EN ISO 21012, Cryogenic vessels - Hoses (ISO 21012)

EN ISO 28460, Petroleum and natural gas industries - Installation and equipment for liquefied natural gas

- Ship-to-shore interface and port operations (ISO 28460)

EN ISO 28921 (all parts), Industrial valves - Isolating valves for low-temperature applications (ISO 28921

all parts)

IEC 60364 (all parts), Low-voltage electrical installations

IEC 61511, Functional safety - Safety instrumented systems for the process industry sector

ISO 6578, Refrigerated hydrocarbon liquids - Static measurement - Calculation procedure

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1.1

abnormal operation

operation of the plant, or plant thereof, under the effect of internal failures or under the effect of

foreseeable influences outside the specified operational conditions

[SOURCE: ISO 23552-1:2007, 3.10]

3.1.2

accidental event

event that arises from an uncontrolled or unplanned situation with safety and/or environmental

consequences

3.1.3

action

a) set of forces (loads) applied to the structure (direct action) or

b) set of imposed deformation or accelerations (indirect action)

Note 1 to entry: Imposed deformation or acceleration could be caused, for example, by temperature changes,

moisture variation, uneven settlement or earthquakes.

3.1.4

base slab

continuous concrete base supporting the tank (either on the ground or elevated)

3.1.5

boil-off gas

BOG

natural gas resulting from slow evaporation of LNG at its equilibrium state or rapid evaporation of LNG,

also called flashing, inside equipment

3.1.6

boundary

property line on land or water inside of which the operator/owner has full control and authority, or

exclusive use

3.1.7

bund wall

raised impermeable structure, able to withstand the hydrostatic pressure and temperature of the

spilled liquid, around the perimeter of an impounding area for the confinement of hydrocarbon spills,

usually associated with storage areas

3.1.8

condensate

hydrocarbon liquids (liquid state at standard conditions) produced from primary separation of natural

gas from a reservoir

Note 1 to entry: Natural gas condensates consist primarily of pentanes and heavier components, although

quantities of propane and butane could be dissolved within the mixture.

3.1.9

control room

core functional entity, and its associated physical structure, where control room operators are stationed

to carry out centralized control, monitoring and administrative responsibilities

[SOURCE: EN ISO 11064-5:2008, 3.9]

3.1.10

control room operator

individual whose primary duties relate to the conduct of monitoring and control functions, usually at a

control workstation, either on their own or in conjunction with other personnel both within the control

room or outside

Note 1 to entry: In special cases based on the evaluated risk, control room operators may perform their duties

for the installation via remote access.

[SOURCE: EN ISO 11064-3:1999, 3.5]

3.1.11

conventional onshore LNG terminal

LNG export or receiving terminal that is located on-shore and has a marine transfer facility for the

loading or unloading of LNG carriers

Note 1 to entry: The transfer facility is located in a harbour or other coastal location and consists of a fixed

structure, or wharf, capable of withstanding the berthing loads of a fully laden LNG carrier of a given specification

and mooring the vessel safely alongside. The structure is connected to the shore by a trestle, tunnel or other

means, facilitating the LNG transfer and ancillary services and providing safe access and egress for personnel

performing maintenance or operational duties.

3.1.12

emergency shut down

ESD

method that safely and effectively stops the whole plant or individual sections to minimize incident

escalation

3.1.13

fire area

area of the plant delimited by physical boundaries or separations from other fire areas by boundaries

such as site roads

Note 1 to entry: Multiple trains in a large plant are each a fire area. Different processing units each separated by

plant roads are individual fire areas. A fire area is often self-defining in that it may be a single plant unit, a storage

or utility area or a separate operating area such as a road tanker loading bay.

Note 2 to entry: The typical firewater ring main routing often encloses each fire area.

Note 3 to entry: Pipe racks joining plant areas are not considered to affect fire area considerations.

3.1.14

fire zone

area of the plant or process system within a fire area that requires it to be isolated by ESD valves in the

event of a fire to control and minimize the fire event, or in the event of a process upset or malfunction to

minimize the extent of the process upset

3.1.15

flammable gas

gas or vapour which, when mixed with air in certain proportions, will form a combustible gas mixture

3.1.16

flare

system to ignite the vapour on a safe location in a controlled manner

3.1.17

flash gas

gas resulting from sudden evaporation of LNG due to change of equilibrium condition

3.1.18

foundation

element of the construction required to support equipment

3.1.19

frequency

number of occurrences per unit of time

3.1.20

harm

physical injury or damage to the health of people or damage to property or the environment

[SOURCE: ISO/TS 16901:2015, 3.13]

3.1.21

hazard

potential source of harm

[SOURCE: ISO/TS 16901:2015, 3.14]

3.1.22

impounding area

area defined at the site for the purpose of collecting any accidental spill of hydrocarbons

3.1.23

impounding basin

container or leak-tight area connected to an impounding area or spill collection area where liquid

hydrocarbon spills can be collected and safely confined and controlled

3.1.24

inner tank

metallic self-supporting cylindrical primary container

3.1.25

leakage

situation in which liquid or gas escapes through an opening

Note 1 to entry: Openings leading to leakage can consist of holes, cracks, etc.

3.1.26

liquefied natural gas

LNG

colourless and odorless cryogenic fluid in the liquid state at normal pressure composed predominantly

of methane which can contain minor quantities of ethane, propane, butane, nitrogen, or other

components normally found in natural gas

[SOURCE: EN ISO 16903:2015, 3.3]

3.1.27

LNG bunkering station

LNG station where LNG is brought by road, rail, waterway, cryogenic pipe from a neighbouring

terminal, and delivering LNG to ships using LNG as a marine fuel

Note 1 to entry: Delivery of the LNG can be done by road, sea or by fixed dispenser along the jetty.

3.1.28

local regulation

set of rules, laws, national agreements, international conventions which apply to a site

3.1.29

low pressure tank

equipment for the storage of LNG at pressure below 50 kPa (0,5 bar)

3.1.30

maximum allowable pressure

PS

maximum pressure for which the equipment is designed, as specified by the manufacturer

3.1.31

normal operation

operation including intermittent operation such as ship loading or unloading, start-up, maintenance,

planned shutdown and commissioning

3.1.32

operating basis earthquake

OBE

maximum earthquake for which no damage is sustained and restart and safe operation can continue

Note 1 to entry: This higher probability event would result in no commercial loss to the installation and public

safety is ensured.

3.1.33

operating company

company responsible for the operation of the installation

3.1.34

operating personnel

any person who is authorized to act on the control of the plant, remotely or locally

3.1.35

PASQUILL stability class

factors that are determined as a function of the wind speed and solar radiation

Note 1 to entry: See [19].

Note 2 to entry: The six factors are:

— A: extremely unstable;

— B: moderately unstable;

— C: lightly unstable;

— D: neutral;

— E: lightly stable;

— F: moderately stable.

3.1.36

plant

site area inside of which public access is unauthorized, e.g. the whole location under the control of an

operator where dangerous substances are present in one or more installations, including common or

related infrastructures or activities

3.1.37

pool fire

turbulent diffusion fire burning above a horizontal pool of vaporising hydrocarbon fuel where the fuel

has zero or low initial momentum

]

[SOURCE: https://www.hse.gov.uk/offshore/strategy/pool.htm

3.1.38

pooling

consequence of an event when liquid product is leaving the LNG containment and spilled and retained

on a not sloped surface and not transferred to the spill collection system

3.1.39

pressurized tank

equipment for the storage of LNG at pressure above 50 kPa (0,5 bar)

3.1.40

process shut down system

PSD

system that safely and effectively stops individual units within the plant for process reasons

3.1.41

risk

combination of the consequence and the frequency of a specific hazard occurring within a specified

period under specified circumstances

3.1.42

roll-over

uncontrolled mass movement of stored liquid, correcting an unstable state of stratified liquids of

different densities and resulting in a significant evolution of product vapour

3.1.43

roof

structure on top of a shell or wall containing the vapour pressure and sealing off the contents from the

atmosphere

3.1.44

safe shutdown earthquake

SSE

maximum earthquake event for which the essential fail-safe functions and mechanisms are designed to

be preserved

Note 1 to entry: Permanent damage can be expected of this lower probability event, but without the loss of

overall integrity and containment. The installation would not remain in continuous service without a detailed

examination and structural assessment at the ultimate limit state.

3.1.45

safety integrity level

SIL

level of integrity required of a safety related system in terms of EN 61508 (all parts)

3.1.46

safety management system

management process which defines and monitors the organizational structure, responsibilities,

procedures, processes and resources for determining and implementing the major accident prevention

policy

3.1.47

spill

to cause liquid especially accidentally or unintentionally to flow, or run out so as to be lost or wasted

3.1.48

spill collection area

area at LNG production or transfer areas where leakages can be confined or controlled, often by the use

of kerbing and/or controlled sloping of paved areas

3.1.49

storage system

storage unit

low pressure or pressurized tank

3.1.50

transfer area

loading area/unloading area

area containing a piping system where flammable liquids or gases are introduced into or removed from

the plant or where piping connections are connected or disconnected routinely

3.1.51

validated model

mathematical model, the scientific basis of which is accepted to be sound and is proven to provide

mathematical outputs to the relevant mathematical problem, and is shown to cover the full range of

usage of the model and which has been calibrated or checked using realistic test data or results for LNG

3.1.52

vapour barrier

barrier to prevent entry of water vapour and other atmospheric gases into the insulation

3.1.53

vent stack

system to vent vapour to a safe location in a controlled manner

Note 1 to entry: Reference [21] requires that the vent be designed with the assumption that it could become

ignited and cause damage or injury due to thermal radiation.

3.1.54

zip failure

when a steel tank wall ruptures almost instantaneously over its full height and is torn off from the

bottom plate in whole or in part, which will allow the stored liquid to spread around in an uncontrolled

way

3.2 Abbreviations

BLEVE boiling liquid expanding vapour explosion

BTA bow-tie analysis

CAD computer-aided design

CCTV closed circuit television camera

ESD emergency shut down

EPS emergency power supply

ETM event tree method

FERA fire and explosion risk analysis

FMEA failure mode effect analysis

FTM fault tree method

GC geotechnical category

HAZID hazard identification study

HAZOP hazard and operability study

HVAC heating, ventilation, aircon and cooling

KO knockout

LOPA layer of protection analysis

OBE operating basis earthquake

PCS process control system

QRA quantified risk assessment

SIL safety integrity level

SIS safety instrumented system

SSE safe shutdown earthquake

UPS uninterruptible power supply

4 Quality management system

A quality management system should demonstrate adequate capability for the design/development,

manufacture, testing, installation, commissioning, decommissioning and servicing of the plant and its

associated equipment.

5 Site assessment

5.1 General and plant description

The design, procurement, construction and operation phases shall all be implemented in accordance

with the requirements of the Quality, Health, Safety and Environment management systems.

Furthermore, each phase shall be controlled by an acceptable Safety Management System.

In case of plant expansion or debottlenecking, the environmental and safety impacts shall be appraised

in accordance with the following recommendations. The potential consequences shall be analysed and

current local regulation is expected to be taken into account.

In case of revamping for life extension, the environmental and safety impacts shall be appraised in

accordance with the following recommendations. The appliance of the current local regulation, and the

extent of such appliance, is expected to be agreed upon with the local authority.

In case of revamping without life extension and without debottlenecking, the principle of non-

retroactivity shall prevail.

A functional description of the installation shall be written by plant area and/or by process function, for

use in the safety assessment.

5.2 Geotechnical

5.2.1 Characteristics of the soil

Site studies shall be executed to address the specific risks related to the project scope and location. The

extent of information required depends on the nature, the phase and complexity of the facilities to be

constructed, the nature and complexity of the ground and the acceptable risk level related to direct

effects and economic damage that can result.

The site study shall include a soil survey including:

— the geotechnical survey that will enable the geo-mechanical characteristics of the subsoil to be

defined;

— the geological and tectonic investigation.

The geological characteristics of the region shall be investigated in sufficient detail to provide a clear

understanding of the physical processes that formed the area, as well as the potential for the future

seismic activity.

A more specific survey shall be done on the site and its vicinity to detect the presence of karst, gypsum,

swelling clays, soluble salt deposits, liquefiable soil, etc. and their relative impact shall be evaluated.

Site studies will include both geophysical and geotechnical desktop and survey studies and will in

general be phased. The primary objectives of site studies are one or more of the following:

— data acquisition for geological purposes, such as establishing the general stratigraphy between

boreholes/CPTs, weathering profiles, erosional or structural features (buried channels, cavities,

faults, dykes, etc.);

— derivation of ground parameters (shear wave velocity and stiffness, electrical and thermal

conductivity);

— resource assessment, such as location and nature of aquifers, sand and gravel deposits, rock for

aggregates;

— detection of geotechnical hazards, such as karst, gypsum, swelling clays, soluble slat deposits, soil

liquefaction, mass movement;

— detection of voids and buried objects, such as mine workings, natural cavities, old foundations,

buried tanks;

— detection of environmental hazards, such as hydrocarbon pollution, mine tailings.

The site investigation shall provide information on properties and behaviour under the full range of

conditions that can be expected on the site and might include the following:

— soil classification, strength, stiffness, compressibility and consolidation;

— temporary or permanent changes as a result of the construction project or natural phenomena such

as: changes in stress and associated strain, changes in water content and associated volume

changes, changes in groundwater level and flow pattern, changes in temperature and electrical

potential, and changes in soil properties such as strength and compressibility;

— effects of earthquakes, e.g. liquefaction and lateral spread;

— aggressiveness to materials placed in the ground, such as concrete and steel;

— potential borrow areas and quarries for construction materials (fill and aggregates).

The soil investigation report shall include the risks of geotechnical failure mechanisms following:

— seismically active faults;

— slope stability;

— liquefiable soils;

— lateral spreading;

— tsunami and seiche.

NOTE Seiche usually occurs in lakes and means a cyclical variation in the level of inland lakes.

A soil and groundwater contamination study shall be done prior to construction. This study may be part

of site selection. Ground investigation and testing shall be in accordance with EN 1997-2.

Geotechnical and foundation design shall be as per EN 1997-1. Geotechnical and foundation design of

structures for earthquake resistance shall be as per EN 1998-5.

5.2.2 Marine geotechnical characteristics for jetty des

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...