EN 14616:2004

(Main)Thermal spraying - Recommendations for thermal spraying

Thermal spraying - Recommendations for thermal spraying

This European Standard includes general guidelines for the workmanlike production of metallic, metal-ceramic, oxide-ceramic and plastic coatings by means of thermal spraying on metallic and non-metallic parent materials.

It offers recommendations for an appropriate and practical spray set-up, faultless manufacturing, monitoring, quality assurance and for non-destructive and destructive tests on the component and accompanying specimen. It describes details about negative effects which can occur. It gives advice on how to prevent such effects. Permissible coating loads and evaluation categories for quality are not the subject of this standard, as they are dependent on the operating conditions.

This standard can be used for contract purposes.

Thermisches Spritzen - Empfehlungen für das thermische Spritzen

Dieses Dokument enthält allgemeine Anleitungen für das fachgerechte Herstellen von metallischen, metall-

keramischen, oxidkeramischen und Kunststoff-Beschichtungen durch thermisches Spritzen auf metallische

und nichtmetallische Grundwerkstoffe.

Sie gibt Empfehlungen für eine geeignete und praktische Anwendung, einwandfreie Fertigung, Überwachung,

Qualitätssicherung und zu zerstörungsfreien und zerstörenden Prüfungen am Bauteil und an Begleitproben.

Sie beschreibt Einzelheiten über mögliche nachteilige Auswirkungen, die auftreten können. Sie gibt Hinweise,

wie solche Effekte zu verhindern sind. Zulässige Beanspruchung der Beschichtung und Bewertungsgruppen

der Qualität sind nicht Gegenstand dieser Norm, da jene von den Betriebsbedingungen abhängig sind.

Dieses Dokument kann zu Vertragszwecken herangezogen werden.

Projection thermique - Recommandations pour la projection thermique

Le présent document donne des lignes directrices générales quant à la production en atelier par projection

thermique de revêtements métalliques, cermets, céramiques et plastiques sur des matériaux de base

métalliques et non métalliques.

Il donne des recommandations sur le montage pratique de l’appareillage de projection, la fabrication, la

surveillance de la fabrication, l’assurance qualité et le contrôle destructif et non destructif des composants et

des échantillons correspondants. Il décrit les effets négatifs que ce procédé peut avoir et donne des conseils

sur la manière de les éviter.

Il ne traite pas des charges de revêtement admissibles ni des catégories d’évaluation dans la mesure où

celles-ci dépendent des conditions de fonctionnement.

Le présent document peut avoir une valeur contractuelle.

Vroče brizganje – Priporočila za vroče brizganje

General Information

- Status

- Withdrawn

- Publication Date

- 02-Nov-2004

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 240 - Thermal spraying and thermally spraying coatings

- Drafting Committee

- CEN/TC 240 - Thermal spraying and thermally spraying coatings

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 14-Oct-2015

- Completion Date

- 09-Feb-2026

Relations

- Replaced By

EN ISO 12679:2015 - Thermal spraying - Recommendations for thermal spraying (ISO 12679:2011) - Effective Date

- 17-Sep-2014

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 14616:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Thermal spraying - Recommendations for thermal spraying". This standard covers: This European Standard includes general guidelines for the workmanlike production of metallic, metal-ceramic, oxide-ceramic and plastic coatings by means of thermal spraying on metallic and non-metallic parent materials. It offers recommendations for an appropriate and practical spray set-up, faultless manufacturing, monitoring, quality assurance and for non-destructive and destructive tests on the component and accompanying specimen. It describes details about negative effects which can occur. It gives advice on how to prevent such effects. Permissible coating loads and evaluation categories for quality are not the subject of this standard, as they are dependent on the operating conditions. This standard can be used for contract purposes.

This European Standard includes general guidelines for the workmanlike production of metallic, metal-ceramic, oxide-ceramic and plastic coatings by means of thermal spraying on metallic and non-metallic parent materials. It offers recommendations for an appropriate and practical spray set-up, faultless manufacturing, monitoring, quality assurance and for non-destructive and destructive tests on the component and accompanying specimen. It describes details about negative effects which can occur. It gives advice on how to prevent such effects. Permissible coating loads and evaluation categories for quality are not the subject of this standard, as they are dependent on the operating conditions. This standard can be used for contract purposes.

EN 14616:2004 is classified under the following ICS (International Classification for Standards) categories: 25.220.20 - Surface treatment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14616:2004 has the following relationships with other standards: It is inter standard links to EN ISO 12679:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14616:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Thermisches Spritzen - Empfehlungen für das thermische SpritzenProjection thermique - Recommandations pour la projection thermiqueThermal spraying - Recommendations for thermal spraying25.220.20Površinska obdelavaSurface treatmentICS:Ta slovenski standard je istoveten z:EN 14616:2004SIST EN 14616:2005en01-januar-2005SIST EN 14616:2005SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14616November 2004ICS 25.220.20English versionThermal spraying - Recommendations for thermal sprayingProjection thermique - Recommandations pour la projectionthermiqueThermisches Spritzen - Empfehlungen für das thermischeSpritzenThis European Standard was approved by CEN on 13 September 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14616:2004: ESIST EN 14616:2005

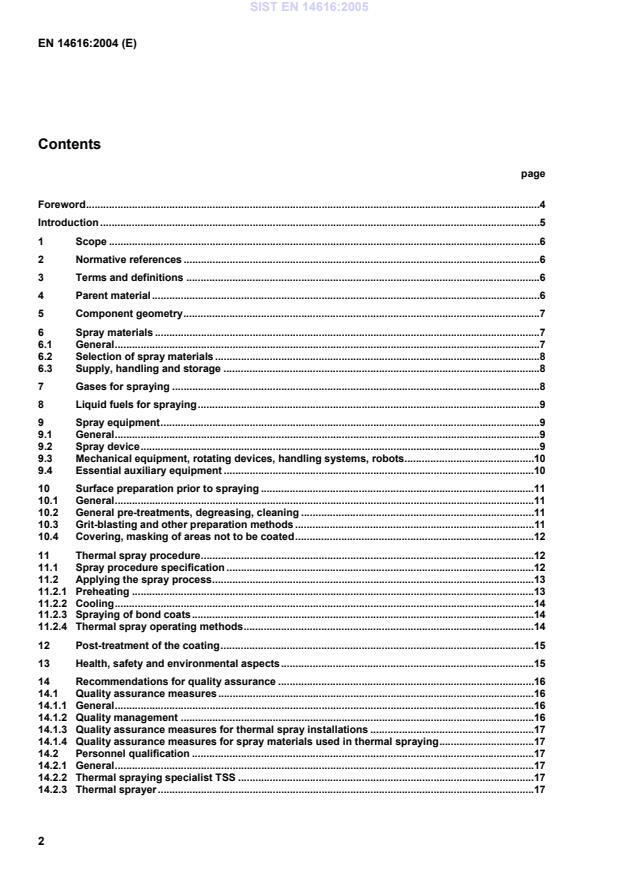

Structure of available standards in the field of thermal spraying.20 Bibliography.21

Introduction Thermal spraying compasses processes used in the production of coatings and free standing bodies in for which spray materials are surface melted, melted off or melted and then propelled onto suitably prepared workpiece surfaces. The workpiece surfaces are not surface melted. In order to achieve specific coating properties, the spray coating can undergo additional post-treatment, either thermal or otherwise, for example, sealing. Thermally sprayed coatings serve to improve the surface properties of a workpiece by manufacturing or repair operations. This can be done, for example, in relation to wear, corrosion, heat transfer or heat insulation, electrical conductivity or insulation, appearance and/or for restoring the part to working order. In certain cases, a spray coating can render a surface being solderable. Chiefly due to their bonding mechanism, thermally sprayed coatings without thermal post-treatment can be distinguished from coatings applied with other processes such as deposition welding, brazing, physical vapour deposition (PVD) or chemical vapour deposition (CVD). The advantages of thermal spraying are: the workpieces to be coated are only slightly heated so that distortion and any other undesired structural changes to the parent material are avoided. This does not apply if the coatings are thermally treated during or after the spray process; the application is not dependent on the size of the workpiece or component. The operation can be stationary or mobile depending on the spray process; even geometrical complex components can be coated using the appropriate spray set-up; the untreated surface of spray coatings generally provides a good bond coat for paintings; depending on the spray process and spray material, different coating thickness can be applied, although a coating thickness of approximately 10 µm is currently considered to be the lower limit. Process-related disadvantages are as follows: the bond strength of thermally sprayed coatings without thermal post-treatment derives from adhesive forces only; the bond strength can be influenced due to expansion mismatch between coating and substrate material, especially in case of high operation temperature; spray coatings are micro porous; the thicker the spray coating, the higher the residual stresses in the coating; and the degree of multi-axial stress thus increases; spray coatings without additional thermal post-treatment are sensitive to edge pressure, localised and linear loads and to impact stresses; there are restrictions in relation to the geometric dimensions, e.g. for the inner coatings of workpieces whose inner diameter is too small. SIST EN 14616:2005

hard phases embedded in a matrix material;

oxide ceramics, plastics, as well as various hybrid materials. 6.2 Selection of spray materials An important task for the designer and/or person responsible for the spray technology is the selection of the spray material which is most suited to the application. Fundamental to the selection are the demand's profile of the coating, the subsequent operating conditions and the most suitable spray process. Corrosion and/or wear loads, for example, can determine the demand's profile. The operating conditions in a tribological system can be determined by an increased operating temperature or by operating temperatures which fluctuate in level and, in some cases, also speed. The most suitable spray process distinguishes itself in terms of its ability to fulfil coating requirements such as density, bond strength, porosity, purity, etc. Here, the relevant process data such as temperature level in the flame, in the arc or in the plasma, the dwell time of the spray particles in the hot zone and the particle velocity in flight and on impact on the substrate play a decisive role. The most important spray materials have been standardised. Specified in standards are: chemical composition of the material and its supply form as powder with its special features based on manufacturing process, particle shape and particle size distribution, or as wire, rod or cord. The following standards apply: for powder EN 1274; for wires, rods and cords EN ISO 14919. 6.3 Supply, handling and storage The supply form and its constancy from batch to batch, especially with spray powders, plays a fundamental role in assuring a uniform quality for the finished coating. For this reason, it is recommended that manufacturing, supply and distribution be assessed and monitored by a suitable quality management system. Details concerning such a procedure are described in EN 12074. 7 Gases for spraying Industrial gases are used in all thermal spray processes. Depending on the spray process, these gases or their mixtures are employed as a fuel, combustion accelerator, plasma gas, shroud gas, propelling or atomising gas, powder feed gas or for cooling the part to be coated or even the spray gun. The physical and chemical characteristics of the industrial gases used for thermal spraying differ quite markedly from each other. Paying attention to these parameters, a gas or gas mixture, which fulfils the process and material requirements, can be selected for any thermal spray application. The following gases are mainly used: as a fuel gas: acetylene (C2H2), propane (C3H8), propylene (C3H6), ethane (C2H4), hydrogen (H2), natural gas; as a plasma gas: argon (Ar), helium (He), hydrogen (H2), nitrogen (N2) and their mixtures; SIST EN 14616:2005

N-paraffin, test benzene or petroleum. A low sulphur content has to be kept due to environmental reasons. Flash point, evaporation point and purity have to be considered as well as additional instructions from the equipment supplier. 9 Spray equipment 9.1 General The thermal spray equipment includes the spray device with all the electrical and gas supply and regulating equipment, possibly the handling system, plus the peripheral installations such as exhaust and filter systems, spray booth and soundproofing. Modern installations often include additional equipment for monitoring spray parameters and motion sequences by means of video cameras. 9.2 Spray device Spray device is defined in EN 657 as the equipment required for thermal spraying. SIST EN 14616:2005

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...