EN 17334:2021

(Main)Glued-in rods in glued structural timber products - Testing, requirements and bond shear strength classification

Glued-in rods in glued structural timber products - Testing, requirements and bond shear strength classification

This document specifies test methods for the determination of the suitability of two component epoxy and two component polyurethane adhesives for glued-in steel rods in glued laminated timber (GLT) and glued solid timber (GST) according to EN 14080, cross laminated timber (CLT) according to EN 16351 and laminated veneer lumber (LVL) according to EN 14374.

NOTE 1 The English term "glued-in rods" has been chosen as the established term instead of "bonded-in rods".

It specifies performance requirements and the determination of characteristic bond strength values for such adhesives for the prefabrication under factory or factory-like conditions of joints between load-bearing timber products and steel rods only. This document does not cover the performance of adhesives for on-site gluing (except for factory-like conditions).

NOTE 2 Factory like conditions provide shelter from direct weathering and dirt, prevent undue movement of the joints during curing of the adhesive and provide temperature and relative humidity conditions and control as in factory production environment.

This document also covers glued-in rods in surface treated wood. It does not cover glued-in rods in modified and stabilized wood with considerably reduced swelling and shrinkage properties, e.g. acetylated wood, heat treated wood, polymer impregnated wood and preservative treated wood.

The joints are intended for load-bearing timber structures in service classes 1 and 2 according to EN 1995-1-1 which are loaded predominantly static or quasi static according to EN 1990 and EN 1991-1-1. The joints are intended for load-bearing timber structures which are not subjected to a prolonged exposure to temperatures over 60 °C.

A design procedure for glued-in rods in glued structural timber products is given in the informative Annex A.

NOTE 3 Several provisions of this document can apply to in situ repair and upgrading of existing timber structures including (cracked/fissured) solid wood beams. For adhesives for glued-in rods used in on-site repair or applications with solid timber additional provisions apply, e.g. related to rheology and site temperature conditions. Such provisions are not part of this document.

Eingeklebte Stangen in tragenden geklebten Holzprodukten - Prüfung, Anforderungen und Scherfestigkeitsklassifizierung

Dieses Dokument legt Prüfverfahren zur Bestimmung der Eignung von Zweikomponenten-Epoxid- und Zweikomponenten-Polyurethanklebstoffen für eingeklebte Stahlstangen in Brettschichtholz (GLT, en: glued laminated timber) und in Balkenschichtholz (GST, en: glued solid timber) nach EN 14080, in Brettsperrholz (CLT, en: cross laminated timber) nach EN 16351 und in Furnierschichtholz (LVL, en: laminated veneer lumber) nach EN 14374 fest.

ANMERKUNG 1 In der englischen Fassung wurde die übliche Benennung „glued-in rods“ anstelle von „bonded-in rods“ gewählt.

Es legt ausschließlich Leistungsanforderungen und die Bestimmung der charakteristischen Festigkeitswerte der Verklebung für solche Klebstoffe für die Vorfertigung von Verbindungen zwischen tragenden Holzprodukten und Stahlstangen unter Werksbedingungen oder werksähnlichen Bedingungen fest. Dieses Dokument ist nicht anwendbar für die Leistungsfähigkeit von Klebstoffen für das Kleben auf der Baustelle (außer unter werksähnliche Bedingungen).

ANMERKUNG 2 Werksähnliche Bedingungen bieten Schutz vor direkter Bewitterung und Schmutz, verhindern eine unzulässige Bewegung der Verbindungen während des Aushärtens des Klebstoffs und bieten Bedingungen und Kontrolle der Temperatur und relativen Luftfeuchte ähnlich wie in der Produktionsumgebung einer Fabrik.

Dieses Dokument ist außerdem anwendbar für in oberflächenbehandeltes Holz eingeklebte Stangen. Es ist nicht anwendbar für eingeklebte Stangen in modifiziertem und vergütetem Holz mit deutlich verringerten Quell- und Schwindeigenschaften, z. B. acetyliertes Holz, wärmebehandeltes Holz, polymerimprägniertes Holz und mit Holzschutzmitteln behandeltes Holz.

Die Verbindungen sind für tragende Holzkonstruktionen der Nutzungsklassen 1 und 2 nach EN 1995 1 1 vorgesehen, die vorwiegend statisch oder quasistatisch nach EN 1990 und EN 1991 1 1 belastet werden. Die Verbindungen sind für tragende Holzkonstruktionen vorgesehen, die nicht über eine längere Zeitspanne Temperaturen über 60 °C ausgesetzt sind.

Ein Verfahren zur Bemessung für eingeklebte Stangen in geklebten Holzprodukten ist im informativen Anhang A aufgeführt.

ANMERKUNG 3 Mehrere Bestimmungen dieses Dokuments können für die Reparatur und Nachrüstung bestehender Holzkonstruktionen vor Ort, einschließlich (gerissener/gespaltener) Vollholzbalken anwendbar sein. Für Klebstoffe für eingeklebte Stangen, die bei Reparaturen vor Ort oder bei Anwendungen mit Vollholz verwendet werden, gelten zusätzliche Bestimmungen, z. B. in Bezug auf Rheologie und Temperaturbedingungen vor Ort. Derartige Bestimmungen sind nicht Teil dieses Dokuments.

Goujons collés dans les produits en bois de structure collé - Essais, exigences et classification de la résistance au cisaillement du joint

Le présent document spécifie des méthodes d’essai visant à déterminer l’aptitude à l’emploi des adhésifs époxydiques et polyuréthanes bicomposants pour les goujons en acier collés dans du bois lamellé collé (GLT) et du bois massif reconstitué (GST) selon l’EN 14080, dans du bois lamellé croisé (CLT) selon l’EN 16351 et dans du lamibois (LVL) selon l’EN 14374.

NOTE 1 En anglais, le terme « glued-in rods » a été choisi comme terme consacré au lieu de « bonded-in rods ».

Le présent document spécifie les exigences de performance et la détermination des valeurs caractéristiques de résistance du joint pour ces adhésifs, uniquement pour ce qui concerne la préfabrication en conditions d’usine ou dans des conditions similaires aux conditions d’usine des assemblages entre produits porteurs en bois et goujons en acier. Le présent document ne couvre pas les performances des adhésifs pour le collage sur site (à l’exception des conditions similaires aux conditions d’usine).

NOTE 2 Les conditions similaires aux conditions d’usine impliquent un abri contre l’exposition directe aux intempéries et à la saleté, empêchent un mouvement intempestif des assemblages pendant la polymérisation de l’adhésif et assurent des conditions de température et d’humidité relative et un contrôle semblables à ceux de l’environnement de production d’une usine.

Le présent document traite également des goujons collés dans du bois ayant reçu un traitement de surface. Il ne couvre pas les goujons collés dans les bois modifiés et stabilisés ayant des propriétés de retrait et de gonflement fortement réduites, par exemple les bois acétylés, les bois traités thermiquement, les bois imprégnés de polymère et les bois traités avec un produit de préservation.

Les assemblages sont destinés aux structures portantes en bois des classes de service 1 et 2 selon l’EN 1995 1 1, qui sont soumises à des charges essentiellement statiques ou quasi statiques selon l’EN 1990 et l’EN 1991 1 1. Les assemblages sont destinés à des structures portantes en bois qui ne sont pas soumises à une exposition prolongée à des températures supérieures à 60 °C.

Une méthode de calcul pour les goujons collés dans les produits en bois de structure collé est décrite dans l’Annexe A, informative.

NOTE 3 Plusieurs dispositions du présent document peuvent s’appliquer à la réparation et à la remise en état in situ de structures en bois existantes, y compris de poutres en bois massif (fissurées). S’agissant des adhésifs pour goujons collés utilisés pour des réparations sur site ou dans des applications avec bois massif, des dispositions supplémentaires s’appliquent, par exemple concernant la rhéologie et les conditions de température sur site. Ces dispositions ne figurent pas dans le présent document.

Vlepljene palice v lepljenih lesenih gradbenih proizvodih - Preskušanje, zahteve in klasifikacija strižne trdnosti spojev

General Information

- Status

- Published

- Publication Date

- 23-Mar-2021

- Withdrawal Date

- 29-Sep-2021

- Technical Committee

- CEN/TC 193 - Adhesives

- Drafting Committee

- CEN/TC 193/SC 1/WG 6 - Tests for adhesives for glued in rods

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 24-Mar-2021

- Due Date

- 12-Feb-2021

- Completion Date

- 24-Mar-2021

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 10080:2005 - Steel for the reinforcement of concrete - Weldable reinforcing steel - General - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 14080:2013 - Timber structures - Glued laminated timber and glued solid timber - Requirements - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 17334:2021 - "Glued‑in rods in glued structural timber products" (CEN) specifies test methods, performance requirements and bond shear strength classification for two‑component epoxy and polyurethane adhesives used to glue steel rods into prefabricated timber products. The standard applies to glued laminated timber (GLT/GST), cross‑laminated timber (CLT) and laminated veneer lumber (LVL) produced under factory or factory‑like conditions. It covers glued‑in rods in surface‑treated wood but excludes modified/stabilized wood (e.g., acetylated, heat treated, polymer‑impregnated or preservative treated). Joints are intended for load‑bearing structures in service classes 1 and 2 and for temperatures below 60 °C.

Key topics and technical requirements

EN 17334:2021 focuses on practical test methods and classification rather than on-site procedures. Main technical topics include:

- Adhesive scope: two‑component epoxy and polyurethane systems suitable for glued‑in rods.

- Bond strength testing: determination of characteristic bond shear strength (including longitudinal tensile shear tests).

- Durability tests: resistance to delamination, effects of wood shrinkage, compression shear and climatic changes.

- Specimen and test procedure requirements: detailed specimen build‑up, timber material and steel rod specifications, manufacturing of the bond and test schemes.

- Temperature and moisture resistance: bond temperature resistance tests and creep rupture tests at very high/low moisture content.

- Working properties: working life, open assembly time, curing time and determination of time to fully cured state under reference conditions.

- Results & reporting: expression of results, determination of declared characteristic bond shear strength values and mandatory test report contents.

- Informative design guidance: Annex A provides a design procedure for glued‑in rods in GLT, GST, LVL and CLT.

Applications and who uses EN 17334:2021

This standard is essential for stakeholders involved in prefabricated timber connections and adhesive qualification:

- Adhesive manufacturers validating two‑component epoxy and polyurethane formulas for glued‑in rod applications.

- Timber product manufacturers (GLT, CLT, LVL, GST) seeking certified adhesive systems for factory production.

- Testing laboratories and certification bodies performing bond shear strength, temperature and durability tests.

- Structural engineers and designers using declared characteristic bond strengths and the Annex A design procedure for specifying glued‑in rod joints.

- Contractors and restoration specialists for guidance on prefabricated glued‑in repairs (note: on‑site repairs may require additional provisions beyond EN 17334).

Related standards

Relevant cross‑references for specifications and test methods:

- EN 14080 (GLT/GST), EN 16351 (CLT), EN 14374 (LVL)

- EN 302 series (adhesive test methods)

- EN 1995‑1‑1 (timber design / service classes)

- EN 923 (adhesive terminology), EN 13183‑1 (moisture content)

- EN ISO 898‑1, EN ISO 3506‑1 (fastener/rod properties)

Keywords: EN 17334:2021, glued‑in rods, glued structural timber products, bond shear strength, epoxy adhesives, polyurethane adhesives, GLT, CLT, LVL, testing requirements, factory conditions.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 17334:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Glued-in rods in glued structural timber products - Testing, requirements and bond shear strength classification". This standard covers: This document specifies test methods for the determination of the suitability of two component epoxy and two component polyurethane adhesives for glued-in steel rods in glued laminated timber (GLT) and glued solid timber (GST) according to EN 14080, cross laminated timber (CLT) according to EN 16351 and laminated veneer lumber (LVL) according to EN 14374. NOTE 1 The English term "glued-in rods" has been chosen as the established term instead of "bonded-in rods". It specifies performance requirements and the determination of characteristic bond strength values for such adhesives for the prefabrication under factory or factory-like conditions of joints between load-bearing timber products and steel rods only. This document does not cover the performance of adhesives for on-site gluing (except for factory-like conditions). NOTE 2 Factory like conditions provide shelter from direct weathering and dirt, prevent undue movement of the joints during curing of the adhesive and provide temperature and relative humidity conditions and control as in factory production environment. This document also covers glued-in rods in surface treated wood. It does not cover glued-in rods in modified and stabilized wood with considerably reduced swelling and shrinkage properties, e.g. acetylated wood, heat treated wood, polymer impregnated wood and preservative treated wood. The joints are intended for load-bearing timber structures in service classes 1 and 2 according to EN 1995-1-1 which are loaded predominantly static or quasi static according to EN 1990 and EN 1991-1-1. The joints are intended for load-bearing timber structures which are not subjected to a prolonged exposure to temperatures over 60 °C. A design procedure for glued-in rods in glued structural timber products is given in the informative Annex A. NOTE 3 Several provisions of this document can apply to in situ repair and upgrading of existing timber structures including (cracked/fissured) solid wood beams. For adhesives for glued-in rods used in on-site repair or applications with solid timber additional provisions apply, e.g. related to rheology and site temperature conditions. Such provisions are not part of this document.

This document specifies test methods for the determination of the suitability of two component epoxy and two component polyurethane adhesives for glued-in steel rods in glued laminated timber (GLT) and glued solid timber (GST) according to EN 14080, cross laminated timber (CLT) according to EN 16351 and laminated veneer lumber (LVL) according to EN 14374. NOTE 1 The English term "glued-in rods" has been chosen as the established term instead of "bonded-in rods". It specifies performance requirements and the determination of characteristic bond strength values for such adhesives for the prefabrication under factory or factory-like conditions of joints between load-bearing timber products and steel rods only. This document does not cover the performance of adhesives for on-site gluing (except for factory-like conditions). NOTE 2 Factory like conditions provide shelter from direct weathering and dirt, prevent undue movement of the joints during curing of the adhesive and provide temperature and relative humidity conditions and control as in factory production environment. This document also covers glued-in rods in surface treated wood. It does not cover glued-in rods in modified and stabilized wood with considerably reduced swelling and shrinkage properties, e.g. acetylated wood, heat treated wood, polymer impregnated wood and preservative treated wood. The joints are intended for load-bearing timber structures in service classes 1 and 2 according to EN 1995-1-1 which are loaded predominantly static or quasi static according to EN 1990 and EN 1991-1-1. The joints are intended for load-bearing timber structures which are not subjected to a prolonged exposure to temperatures over 60 °C. A design procedure for glued-in rods in glued structural timber products is given in the informative Annex A. NOTE 3 Several provisions of this document can apply to in situ repair and upgrading of existing timber structures including (cracked/fissured) solid wood beams. For adhesives for glued-in rods used in on-site repair or applications with solid timber additional provisions apply, e.g. related to rheology and site temperature conditions. Such provisions are not part of this document.

EN 17334:2021 is classified under the following ICS (International Classification for Standards) categories: 83.180 - Adhesives. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17334:2021 has the following relationships with other standards: It is inter standard links to EN 13183-1:2002, EN 302-7:2023, EN 16351:2021, EN 10080:2005, EN 302-1:2023, EN ISO 3506-1:2020, EN 923:2015, EN 302-2:2023, EN ISO 898-1:2013, EN 302-8:2023, EN 302-5:2023, EN 14080:2013, EN 14358:2016, EN 302-6:2023, EN 302-4:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17334:2021 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/112, M/127. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 17334:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2021

Vlepljene palice v lepljenih lesenih gradbenih proizvodih - Preskušanje, zahteve in

klasifikacija strižne trdnosti spojev

Glued-in rods in glued structural timber products - Testing, requirements and bond shear

strength classification

Eingeklebte Stangen in tragenden geklebten Holzprodukten - Prüfung, Anforderungen

und Scherfestigkeitsklassifizierung

Goujons collés dans les produits en bois de structure collé - Essais, exigences et

classification de la résistance au cisaillement du joint

Ta slovenski standard je istoveten z: EN 17334:2021

ICS:

83.180 Lepila Adhesives

91.080.20 Lesene konstrukcije Timber structures

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17334

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2021

EUROPÄISCHE NORM

ICS 83.180

English Version

Glued-in rods in glued structural timber products -

Testing, requirements and bond shear strength

classification

Goujons collés dans les produits en bois de structure Eingeklebte Stangen in tragenden geklebten

collé - Essais, exigences et classification de la résistance Holzprodukten - Prüfung, Anforderungen und

au cisaillement du joint Scherfestigkeitsklassifizierung

This European Standard was approved by CEN on 8 February 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17334:2021 E

worldwide for CEN national Members.

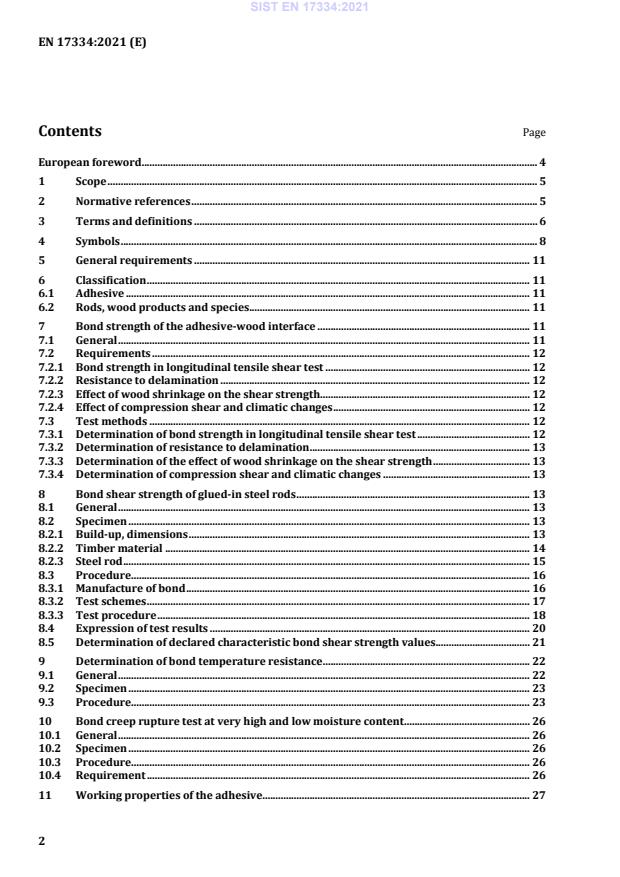

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols . 8

5 General requirements . 11

6 Classification . 11

6.1 Adhesive . 11

6.2 Rods, wood products and species. 11

7 Bond strength of the adhesive-wood interface . 11

7.1 General . 11

7.2 Requirements . 12

7.2.1 Bond strength in longitudinal tensile shear test . 12

7.2.2 Resistance to delamination . 12

7.2.3 Effect of wood shrinkage on the shear strength. 12

7.2.4 Effect of compression shear and climatic changes . 12

7.3 Test methods . 12

7.3.1 Determination of bond strength in longitudinal tensile shear test . 12

7.3.2 Determination of resistance to delamination . 13

7.3.3 Determination of the effect of wood shrinkage on the shear strength . 13

7.3.4 Determination of compression shear and climatic changes . 13

8 Bond shear strength of glued-in steel rods . 13

8.1 General . 13

8.2 Specimen . 13

8.2.1 Build-up, dimensions . 13

8.2.2 Timber material . 14

8.2.3 Steel rod . 15

8.3 Procedure. 16

8.3.1 Manufacture of bond . 16

8.3.2 Test schemes . 17

8.3.3 Test procedure . 18

8.4 Expression of test results . 20

8.5 Determination of declared characteristic bond shear strength values. 21

9 Determination of bond temperature resistance . 22

9.1 General . 22

9.2 Specimen . 23

9.3 Procedure. 23

10 Bond creep rupture test at very high and low moisture content . 26

10.1 General . 26

10.2 Specimen . 26

10.3 Procedure. 26

10.4 Requirement . 26

11 Working properties of the adhesive . 27

11.1 General . 27

11.2 Determination of working life under reference conditions . 27

11.3 Determination of open assembly time . 27

11.4 Determination of curing time under reference conditions . 27

11.5 Determination of time to fully cured state . 28

11.5.1 General . 28

11.5.2 Specimens and manufacture . 28

11.5.3 Number and treatment of the specimens . 30

11.5.4 Test procedures . 30

11.5.5 Expression of results . 31

11.5.6 Determination of time to fully cured state . 31

11.5.7 Declared time to fully cured state . 32

12 Test report . 32

12.1 The adhesive . 32

12.2 Preparation of specimens and testing procedure . 33

12.3 Test results . 33

Annex A (informative) Design procedure for glued in rods in GLT, GST, LVL and CLT. 34

Annex B (informative) Common alternatives for adhesive infill in drilled holes . 41

Bibliography . 42

European foreword

This document (EN 17334:2021) has been prepared by Technical Committee CEN/TC 193 “Adhesives”,

the secretariat of which is held by UNE.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2021, and conflicting national standards shall

be withdrawn at the latest by September 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document specifies test methods for the determination of the suitability of two component epoxy

and two component polyurethane adhesives for glued-in steel rods in glued laminated timber (GLT) and

glued solid timber (GST) according to EN 14080, cross laminated timber (CLT) according to EN 16351

and laminated veneer lumber (LVL) according to EN 14374.

NOTE 1 The English term “glued-in rods” has been chosen as the established term instead of “bonded-in rods”.

It specifies performance requirements and the determination of characteristic bond strength values for

such adhesives for the prefabrication under factory or factory-like conditions of joints between load-

bearing timber products and steel rods only. This document does not cover the performance of adhesives

for on-site gluing (except for factory-like conditions).

NOTE 2 Factory like conditions provide shelter from direct weathering and dirt, prevent undue movement of the

joints during curing of the adhesive and provide temperature and relative humidity conditions and control as in

factory production environment.

This document also covers glued–in rods in surface treated wood. It does not cover glued-in rods in

modified and stabilized wood with considerably reduced swelling and shrinkage properties, e.g.

acetylated wood, heat treated wood, polymer impregnated wood and preservative treated wood.

The joints are intended for load-bearing timber structures in service classes 1 and 2 according to

EN 1995-1-1 which are loaded predominantly static or quasi static according to EN 1990 and

EN 1991-1-1. The joints are intended for load-bearing timber structures which are not subjected to a

prolonged exposure to temperatures over 60 °C.

A design procedure for glued-in rods in glued structural timber products is given in the informative

Annex A.

NOTE 3 Several provisions of this document can apply to in situ repair and upgrading of existing timber

structures including (cracked/fissured) solid wood beams. For adhesives for glued-in rods used in on-site repair or

applications with solid timber additional provisions apply, e.g. related to rheology and site temperature conditions.

Such provisions are not part of this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 302-1, Adhesives for load-bearing timber structures — Test methods — Part 1: Determination of

longitudinal tensile shear strength

EN 302-2, Adhesives for load-bearing timber structures — Test methods — Part 2: Determination of

resistance to delamination

EN 302-4, Adhesives for load-bearing timber structures — Test methods — Part 4: Determination of the

effects of wood shrinkage on the shear strength

EN 302-5, Adhesives for load-bearing timber structures — Test methods — Part 5: Determination of

maximum assembly time under referenced conditions

EN 302-6, Adhesives for load-bearing timber structures — Test methods — Part 6: Determination of the

minimum pressing time under referenced conditions

EN 302-7, Adhesives for load-bearing timber structures — Test methods — Part 7: Determination of the

working life under referenced conditions

EN 302-8, Adhesives for load-bearing timber structures — Test methods — Part 8: Static load test of

multiple bond line specimens in compression shear

EN 923, Adhesives — Terms and definitions

EN 10080, Steel for the reinforcement of concrete — Weldable reinforcing steel — General

EN 13183-1, Moisture content of a piece of sawn timber — Part 1: Determination by oven dry method

EN 14080:2013, Timber structures — Glued laminated timber and glued solid timber — Requirements

EN 14358, Timber structures — Calculation and verification of characteristic values

EN 14374, Timber structures — Structural laminated veneer lumber — Requirements

EN 16351, Timber structures — Cross laminated timber — Requirements

EN ISO 898-1, Mechanical properties of fasteners made of carbon steel and alloy steel — Part 1: Bolts,

screws and studs with specified property classes — Coarse thread and fine pitch thread (ISO 898-1)

EN ISO 3506-1, Fasteners — Mechanical properties of corrosion-resistant stainless steel fasteners — Part 1:

Bolts, screws and studs with specified grades and property classes (ISO 3506-1)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 923 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

two component epoxy adhesive

thermosetting synthetic resin derived from a exothermic polymerization reaction of an epoxide group

with amines, acid anhydrides, phenols, alcohols or thiols

3.2

two component polyurethane adhesive

urethane polymers which are cross-linked by the reaction between polyol or polyamine with isocyanate

3.3

service class 1

climatic conditions characterized by a moisture content in the materials corresponding to a temperature

of 20 °C and the relative humidity of the surrounding air only exceeding 65 % for a few weeks per year

Note 1 to entry: In service class 1, which comprises typical indoor conditions, the average moisture content in

most softwoods will not exceed 12 %.

[SOURCE: EN 1995-1-1:2004, 2.3.1.3, modified – Indoor conditions added in Note 1 to entry]

3.4

service class 2

climatic conditions characterized by a moisture content in the materials corresponding to a temperature

of 20 °C and the relative humidity of the surrounding air only exceeding 85 % for a few weeks per year

Note 1 to entry: In service class 2, to which most covered exterior conditions belong, the average moisture

content in most softwoods will not exceed 20 %.

[SOURCE: EN 1995-1-1:2004, 2.3.1.3, modified – Covered exterior conditions added in Note 1 to entry]

3.5

glue line

adhesive layer between the wood members

[SOURCE: EN 301:2017, 3.7]

3.6

thick glue line

glue line of nominal thickness in the range of 0,3 mm to 4,0 mm at the time of bonding

Note 1 to entry: Thick glue lines are achieved by using spacers, grooves or similar devices with a thickness of

0,3 mm to 4,0 mm when two plain members are glued together.

[SOURCE: EN 301:2017, 3.8, modified — Maximum thickness has been increased to 4 mm.]

3.7

close contact glue line

glue line thickness of maximum 0,1 mm

Note 1 to entry: Close contact glue line is considered to be achieved by pressing together two plane wood

members with a clamping pressure of (0,8 ± 0,1) N/mm without grooves, spacers or similar device.

[SOURCE: EN 301:2017, 3.9, modified — “considered to be” has been added.]

3.8

bond line

glue line including the two intermediate zones between adhesive and wood

[SOURCE: EN 15425:2017, 3.6]

4 Symbols

a cross-section length of specimen, in millimetres (mm)

a equation parameter, in newtons per square millimetre (N/mm )

0,250

a equation parameter, in newtons per square millimetre (N/mm )

0,500

a equation parameter, in newtons per square millimetre (N/mm )

a equation parameter, in newtons per square millimetre (N/mm )

a equation parameter, in newtons per square millimetre (N/mm )

a equation parameter, in newtons per square millimetre (N/mm )

b edge lengths of the net cross-section, in millimetres (mm)

c equation parameter, in newtons per cubic millimetre (N/mm )

c equation parameter, in newtons per cubic millimetre (N/mm )

d nominal rod diameter, in millimetres (mm)

d distance of displacement sensor to rod axis, in millimetre (mm)

d distance of displacement sensor fixation vs. specimen and grain face, in millimetre

(mm)

d diameter of drilled hole, in millimetres (mm)

drill

f apparent tensile strength, in newtons per square millimetre (N/mm )

t,app

F tension load in newtons (N)

t

F maximum load in tensile test, in newtons (N)

t,max

F maximum load in block shear test, in newtons (N)

v,max

F target load (temperature resistance test), in newtons (N)

target

F target load (creep rupture test at very high and low moisture content), in newtons

t,DOL

(N)

f block shear strength (monolithic adhesive specimen), in newtons per square

v

millimetre (N/mm )

f bond strength, in newtons per square millimetre (N/mm )

vr

f characteristic bond strength value of bond length of 200 mm

vr,200,k

f declared characteristic bond strength value (5 % quantile) of bond length range

vr,250,k,dc

l ≤ 250 mm, in newtons per square millimetre (N/mm )

a

f characteristic bond strength value of bond length of 400 mm

vr,400,k

declared characteristic bond strength value (5 % quantile) of bond length range

f

vr,la 500,≤ k,dc

250 mm < la ≤ 500 mm, in newtons per square millimetre (N/mm )

f characteristic bond strength value of bond length of 600 mm

vr,600,k

declared characteristic bond strength value (5 % quantile) of bond length range

f

vr,la 1000,≤ k,dc

500 mm < l ≤ 1 000 mm

a

f characteristic bond strength value of bond length range l

vr,la,k a

f mean bond strength for a bond line thickness of 2 mm, in newtons per square

vr,la,2mm,mean

millimetre (N/mm )

f mean bond strength for a bond line thickness of 4 mm, in newtons per square

vr,la,4mm,mean

millimetre (N/mm )

f mean bond strength for a bond line thickness of 6 mm, in newtons per square

vr,la,6mm,mean

millimetre (N/mm )

f characteristic bond strength value (5 % quantile), in newtons per square millimetre

vr,la,tB,k

(N/mm )

f arithmetic mean bond strength value in newtons per square millimetre (N/mm )

vr,la,tB,mean

f declared characteristic bond shear strength (5 % quantile), in newtons per square

vr,k,dc

millimetre (N/mm )

f density influenced bond shear strength, in newtons per square millimetre (N/mm )

vr,ρ

f density corrected bond shear strength, in newtons per square millimetre (N/mm )

vr,ρref

k bond strength ratio between two bond line thicknesses

d,la

l total length of timber specimen, in millimetres (mm)

l nominal bonded length of steel rod, in millimetres (mm)

a

l maximum declared rod length, in millimetres (mm)

a,dc,max

l minimum declared rod length, in millimetres (mm)

a,dc,min

l length to fix the rod in the grips of the test machine, in millimetres (mm)

clamping

l length of drill hole, in millimetres (mm)

drill

l length of the rod inside the drill hole that is not able to take load (e.g. spacers), in

not bonded

millimetres (mm)

l distance between the grounds of the drilled holes in the specimen, in millimetres

m

(mm)

l edge lengths of the net cross-section, in millimetres (mm)

v

l total rod length, in millimetres (mm)

rod,tot

𝜌𝜌 density of the timber specimen at 12 % moisture content, in kilograms per cubic

metre (kg/m )

𝜌𝜌 reference density, in kilograms per cubic metre (kg/m )

ref

s slip displacement

t bond line thickness, in millimetres (mm) (t = (d − d)/2)

b b drill

t total bond line thickness, in millimetres (mm) (t = 2 t )

B B b

T Temperature, in degrees Celsius (°C)

T applied temperature, in degrees Celsius (°C)

app

T target temperature at bond line, in degrees Celsius (°C)

bond,target

t loading time

t cooling down period, in hours (h)

cool

tcycle,1 time of first heating-cooling-load-cycle, in hours (h)

t time of second heating-cooling-load-cycle, in hours (h)

cycle,2

t heating period, in hours (h)

heat

t total time of both temperature-load cycles, in hours (h)

total

t time of the attainment of the target load, in minutes

ramp

t constant temperature period, in hours (h)

rod60

u percentage target wood moisture content (%)

target

V density correction exponent

Δu difference in average moisture contents between the moist and dry state, in percent

(%)

Additional symbols of Annex A:

A stress design relevant cross-section of steel rod, in square millimetres (mm )

ef

a minimum distance of axially loaded glued-in rods (in grain direction), in millimetres

(mm)

a minimum distance of axially loaded glued-in rods (perpendicular grain direction), in

millimetres (mm)

a , a minimum edge distance of axially loaded glued-in rods, in millimetres (mm)

1,c 2,c

a minimum distance of axially loaded glued-in rods (loaded end grain face), in

3,t

millimetres (mm)

a minimum distance of axially loaded glued-in rods (unloaded end grain face), in

3,c

millimetres (mm)

a minimum distance of axially loaded glued-in rods (loaded edge), in millimetres

4,t

(mm)

a minimum distance of axially loaded glued-in rods (unloaded edge), in millimetres

4,c

(mm)

γ partial factor for material properties, also accounting for model uncertainties and

M

dimensional variations

F design value for the withdrawal (pull-out) capacity, in newtons (N)

ax,Rd

F , F design values of shear force at both sides of the connection, in newtons (N)

v,Ed,1 v,Ed,2

f design value of bond shear strength, in newtons per square millimetre (N/mm )

vr,d

f declared characteristic bond strength value (5 % quantile) of bond length range l ,

vr,la,dc,k a

in newtons per square millimetre (N/mm )

f design value of yield strength of steel rod, in newtons per square millimetre

y,d

(N/mm )

F , F design value and characteristic value of resistance to tension perpendicular to grain

90,Rd 90,Rk

of the loaded member, in newtons (N)

h, b depth and width of timber member, in millimetres (mm)

h projected rod embedment length perpendicular to grain, in millimetres (mm)

e

kmod modification factor for duration of load and moisture content

l minimum bond length, in millimetres (mm)

a,min

5 General requirements

Adhesives for structural purpose shall produce joints of such strength and durability that the integrity of

the bond in the glued-in rod joint is maintained throughout the expected lifetime of the structure.

6 Classification

6.1 Adhesive

If the adhesive meets the requirements of Clause 7 to Clause 10 it shall be classified as type I. The

classification of the adhesive consists of:

— number of this document and year of publication;

— type of adhesive (I);

— bond temperature resistance, in degrees Celsius °C;

— maximum bond length, in millimetres;

— maximum bond line thickness, in millimetres;

— working properties (adhesives tested for working properties according to Clause 11 are specified by

the letter “w” at the end of the designation code).

EXAMPLE EN 17334:2021-I-60-500-4 w.

6.2 Rods, wood products and species

The type of rod (rebars, rods with metric thread), the tested rod dimensions d and l , the applicable wood

a

product (GLT, GST, CLT including lay-up and LVL including lay-up) and wood species shall be declared.

7 Bond strength of the adhesive-wood interface

7.1 General

Adhesives complying with this document shall meet the performance requirements specified in 7.2.1 to

7.2.4 when tested in accordance with the following test methods:

a) tensile shear test (see 7.3.1) using bonded specimens made from beech (Fagus sylvatica L.);

b) delamination test (see 7.3.2) on bonded specimens made from Norway spruce (Picea abies L.). The

test with Norway spruce also covers silver fir (Abies alba) and Scots pine (Pinus sylvestris). If the

adhesive is to be used on wood from other conifers species, also prepare four laminated members

using representative samples from those species and perform the delamination test according to

7.3.2;

c) shrinkage stress test (see 7.3.3) on bonded specimens made from Norway spruce (Picea abies L.);

d) multiple compression shear test (see 7.3.4) on bonded specimens made from beech (Fagus

sylvatica L.).

These adhesives shall be applied according to the manufacturer's instructions.

7.2 Requirements

7.2.1 Bond strength in longitudinal tensile shear test

When tested in accordance with 7.3.1, the tensile shear strength values of close contact glue lines and

thick glue lines shall meet the requirements given in Table 1.

Table 1 — Minimum mean tensile shear strengths for close contact and thick glue lines on beech

specimens (in N/mm )

Thick glue line Thick glue line Thick glue line

Close contact

Treatment

glue line

1,0 mm 3,0 mm 4,0 mm

Designation according

Type Ι Type Ι Type I Type Ι

to EN 302-1

A1 10,0 8,0 7,0 6,0

A2 6,0 4,0 3,5 3,0

A3 8,0 6,4 5,6 4,8

A4 6,0 4,0 3,5 3,0

A5 8,0 6,4 5,6 4,8

A7 8,0 5,5 5,0 4,5

NOTE Treatment A8 is not included in Table 1 due to the temperature limitation given in the scope.

7.2.2 Resistance to delamination

When tested in accordance with 7.3.2 the limits on delamination for specimens of any bond line thickness

shall be less or equal than 5 % in any specimen.

7.2.3 Effect of wood shrinkage on the shear strength

When tested in accordance with 7.3.3 the average shear strength after climatic treatment shall not be

lower than 1,5 N/mm .

7.2.4 Effect of compression shear and climatic changes

When tested in accordance with 7.3.4, not more than one of six specimens is allowed to fail during the

test period. The mean creep deformation of all the bond lines in each of the remaining test specimens

shall not exceed 0,05 mm after the test.

If a failure within a specimen occurs as a solid wood failure without any interference with the bond line,

the specimen shall not be counted and four of the five remaining specimens shall fulfil the requirements.

In case more than two specimens in a test series collapse due to solid wood failure (low wood quality),

the whole test shall be repeated.

7.3 Test methods

7.3.1 Determination of bond strength in longitudinal tensile shear test

The tests shall be made in accordance with EN 302-1, but with glue line thicknesses close contact, 1,0 mm

and 4,0 mm. In case the glue line thickness t in use is ≤ 1 mm the tests shall be made with a glue line

b

thickness of 3 mm instead of 4 mm. The specimens with thick glue lines shall be prepared with a

pressureless preparation of the specimens.

7.3.2 Determination of resistance to delamination

The tests shall be made in accordance with EN 302-2, with the following exceptions: the test with close

contact glueline may be replaced by a test with a defined glue line thickness of 0,2 mm achieved by

spacers.

The tests with a glueline thickness of 4 mm shall be performed except for the case that the glue line

thickness in use t is ≤ 1 mm where the tests shall be made with a glue line thickness of 3 mm instead of

b

4 mm.

The specimens with thick glue lines shall be prepared with a pressureless preparation of the specimens.

Different from EN 302-2 the tests with bonded members with close contact glue line or a glue line

thickness of 0,2 mm shall be performed exclusively with two specimens with long assembly time.

7.3.3 Determination of the effect of wood shrinkage on the shear strength

The tests shall be made in accordance with EN 302-4, but with a glue line thickness of 2 mm.

7.3.4 Determination of compression shear and climatic changes

The tests shall be made in accordance with EN 302-8 but with a temperature of 60 °C in the first cycle.

8 Bond shear strength of glued-in steel rods

8.1 General

The bond shear strength of the glued-in rod which depends essentially on the bond length shall be

determined by single rod pull-out tests with symmetrically built-up specimens. Different ranges of glued-

in rod lengths and bond line thicknesses, if relevant, shall be tested for the intended wood products,

species, rod types and hole dimensions for determination and declaration of characteristic bond strength

values.

The adhesives shall be used as recommended by the manufacturer.

8.2 Specimen

8.2.1 Build-up, dimensions

The specimen consists of a quadratic cross-section of timber into the ends of which two steel rods are

glued-in parallel to grain centrically at the opposite end grain faces (see Figure 1). The absolute size of

the specimen depends on the nominal rod diameter d, and on the bond length l . The cross-section edge

a

length a and the total length l of the timber piece shall be determined according to Formula (1) and

Formula (2):

ad≥ 7,5 (1)

l=2 +l l =3,4 l (2)

am a

where

d is the nominal rod diameter;

l is the nominal bonded length of steel rod;

a

l is the distance between the tips of the opposite rods.

m

Dimensions in millimetres

Key

a) GLT-side view 1 test rod

b) GLT-cross section 2 fibre direction

c) CLT-side view

d) CLT-cross section

Figure 1 — Geometry and loading scheme of GLT, GST, LVL and CLT ramp load specimens.

Examples of cross-sectional dimensions

In the case that the rod is not glued-in over the total length embedded in the timber specimen, then the

bond length l in Formula (2) shall be replaced by l (see 8.3.1).

a drill

8.2.2 Timber material

8.2.2.1 Moisture content

The timber materials specified in 8.2.2.2 to 8.2.2.4 shall have an average moisture content of (12 ± 2) %

at time of the rod bonding process and at testing unless specified differently in Clause 9 and Clause 10.

8.2.2.2 Glulam and glued solid timber

The glulam (GLT) and glued solid timber (GST) shall conform to EN 14080 and shall be of strength class

GL 24h or C24. Test results for glued solid timber may also be applied to glulam.

Tests shall be carried out with all species for which the adhesive is intended to be classified. Norway

spruce (Picea abies, PCAB) and silver fir (Abies alba, ABAL) may be taken as one species. Test results

obtained for species PCAB/ABAL apply also to glued-in rods in GLT and/or GST made of Scots pine (Pinus

sylvestris PNSY). The use of softwoods with coloured heartwood, e.g. Douglas fir (PSMN) and European

or Sibirian larch (Larix decidua (SADC), Larix Sibirica (LASI)) has to be tested separately.

The cross-sectional build-up of the specimen shall be symmetric with regard to lamination thicknesses.

The thickness t of the centre lamination containing the glued-in rod shall be in the range of 38 mm to

45 mm for GLT and minimally 60 mm in case of GST. All laminations of the timber piece may have finger

joints at any location except for the centre lamination which shall have no finger joints within the bond

length l .

a

8.2.2.3 Cross laminated timber

Cross laminated timber (CLT) shall conform to EN 16351 and shall be built up from timber layers of

class C24. Concerning the wood species see 8.2.2.2. The built-up shall be symmetric, either 3- or 5-layer.

In case of non edge-bonded cross layers the ratio of width to thickness of the boards shall be at least 4.

The thickness of the inner cross-layer containing centrically the glued-in rod shall exceed the drill hole

diameter by at least 16 mm.

In case of glued-in rods in CLT it can be differentiated between products with glued narrow edges and

unglued narrow edges with permissible gaps. In case of non-edge-bonded layers further provisions shall

be fulfilled in order to prevent leakage of the adhesive through unbonded edges:

— steel rods shall be bonded parallel to the fibre in the middle third of the width of a single board;

— grooves in the boards are not permissible;

— the length of the drill hole l shall not exceed 250 mm.

drill

In the case that there is evidence of adhesive leakage into internal grooves, cracks, etc. the bonding

process has to be adjusted and/or the specimen shall be rejected.

8.2.2.4 Laminated veneer lumber

Laminated veneer lumber (LVL) shall conform to EN 14374. Concerning the wood species see 8.2.2.2. The

test results apply to the specifically tested built-up and strength class as given in the Declaration of

Performance (DoP) of the tested material.

8.2.3 Steel rod

Weldable reinforcing steel bars (rebars) shall conform to EN 10080. Threaded rods made of carbon steel

shall conform to EN ISO 898-1. Threaded rods made of stainless steel shall conform to EN ISO 3506-1.

The required strength class or yield strength of the rod depends on the bond length and the rod diameter

in order to achieve a bond and/or wood failure without rod yielding.

The nominal diameter of the rods may vary from 6 mm to 30 mm.

NOTE For threaded rods made of carbon steel, strength classes 4.8, 5.6, 5.8 and 8.8 are commonly used. For

threaded rods made of stainless steel, strength classes 45, 50, 60, 70 and 80 are commonly used.

In the general case, unless requested different by the adhesive manufacturer the following rod

dimensions d and l are required:

a

d/l [in mm]: 16/200; 16/400 or 20/400; 20/600 or 24/600.

a

The total rod length may include, if requested by the manufacturer, a possibly not bonded rod length,

l , of maximally 50 mm.

not bonded

The total rod length l shall be determined according to Formula (3):

rod,tot

l = +l l + l (3)

rod,tot a not bonded clamping

where

l is the nominal bonded length of the steel rod, in millimetres (mm);

a

l is the not bonded length of up to 50 mm (including), if any, starting from the cross

not bonded

cut;

l is the clamping length ≈ 100 mm.

clamping

In case the manufacturer requests to deviate from the general specimen configuration, specified in 8.2.1

and 8.2.3 different dimensions may apply. These dimensions shall be stated according to Clause 6.

8.3 Procedure

8.3.1 Manufacture of bond

The holes for both glued-in rods shall be drilled centrically in the centre lamination or the LVL parallel to

length axis and grain direction by an apt drilling device. In case of CLT with non edge-bonded cross layers

special precautions have to be taken at the manufacture of the glued-in rod joint. The drill hole shall be

aligned parallel to the board faces and the rod shall not protrude outside of the centre board. The drilling

shall be performed at least one hour before the gluing process. No charring during drilling shall occur.

Depending on the gluing process the two drill holes of each specimen may be manufactured at different

times. After drilling, the hole shall be cleaned from chips and milling dust according to the provisions of

the manufacturer. The drill length l shall be either equal to the bond length l or, dependant on the

drill a

recommendation of the adhesive manufacturer, shall have a length of l = l + l whereby l

drill a not bonded not bonded

shall in any case be maximally 50 mm.

The diameter of the drill hole, d , depends on the nominal rod diameter d, the rod type (steel rod with

drill

metric thread, rebar) and the provisions of the manufacturer regarding bond line thickness which is

restricted to max. t ≤ 3 mm (total bond line thickness t = 2t).

B B

The diameter of the drill hole shall be minimally d + 2 mm and maximally d + 6 mm.

NOTE The bonding process and hereby the adhesive infill into the drill hole and the timing of the rod insertion

(before or after adhesive infill/injection) can vary dependent on the adhesive manufacturer’s provisions. Annex B

shows three common alternatives of the bonding process.

The bonding process is in general performed at ambient temperature of (20 + 2) °C and a relative

humidity within the range of 20 % to 70 %, unless required different by the adhesive manufacturer. In

any case the room and timber temperature shall be measured at the time of bonding and room

temperature and relative humidity shall be monitored during bonding and curing time. In specific cases

where the adhesive manufacturer wishes to use preheated timber and/or heated adhesive and to employ

elevated temperature in the premises during curing, it is required to measure and record the respective

temperatures (wood, adhesive, room).

In case of drill holes with a diameter d > d + 2 mm it is required to centre the glued-in rod during curing

drill

by specific provisions, i.e. distance holders such as wedges, or plastic rings. With regard to the verification

of an impeccable bonding, see 8.3.3.

With regard to the drilling of the holes and the bonding operation the recommendations of the

manufacturer shall be followed and documented.

8.3.2 Test schemes

8.3.2.1 Test scheme with varying configurations of rod length, rod diameter and bond line

thicknesses

Depending on the intended use of the adhesive with regard to bond length, nominal rod diameter and

maximum total bond line thickness the specimen configurations and numbers according to Table 2,

Table 3 and Table 4 apply. When performing the tests with different rod lengths according to Table 2,

Table 3 and Table 4 it is assumed that the bond strength evaluation reflects the bond strength

relationship with rod length as specified in 8.5. In case bond strength shall be specified as a single value

for a specific rod diameter, diameter of drilled hole and rod length range configuration, see 8.3.2.2.

Table 2 — Specimen configurations and minimum specimen numbers for bond shear strength

tests for total bond line thicknesses up to 6 mm

Bond length Nominal rod Minimum number of specimens dependent

Bond length

configuration diameter on total bond line thickness

l d t = 2 t

a B b

2 mm 4 mm 6 mm

– mm mm – – –

a a

short 200 16 10 5 5

a a

medium 400 16 (or 20) 10 5 5

a a

long 600 20 (or 24) 10 5 5

a

If the use of the adhesive is intended exclusively for a total bond line thickness tB = 2 mm no tests with

tB = 4 mm and 6 mm are required.

Table 3 — Specimen configurations and minimum specimen numbers for bond shear strength

tests for a total bond line thickness up to 4 mm

Bond length Bond length Nominal rod Minimum number of specimens dependent

configuration diameter on tota

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...