EN 1344:2002

(Main)Clay pavers - Requirements and test methods

Clay pavers - Requirements and test methods

This European Standard specifies the requirements of pavers and accessories manufactured from clay for use in the flexible form of construction (pavers laid with narrow sand-filled joints on a sand bed) and in the rigid form of construction (pavers laid with cementitious mortar joints on a similar mortar bed, itself placed on a rigid base).

The standard applies to rectangular and other shaped units intended as construction products mainly for exterior use in pavements but which may also be used internally. The flexible form of construction will be subjected to pedestrian and vehicular traffic, while the rigid form of construction is usually subjected to pedestrian traffic. It excludes products intended for refractory and chemical engineering applications and clay floor tiles. It also excludes clay masonry units. This Standard does not deal with the tactility or visibility of units.

This European Standard specifies the characteristics and classes of performance measured according to test methods given in normative annexes. It provides for product marking and for the evaluation of conformity of the product to this European Standard.

Pflasterziegel - Anforderungen und Prüfverfahren

Diese Europäische Norm beschreibt die Anforderungen an aus Ton hergestellte Pflaster- und Ergänzungsziegel, die in ungebundener Verlegungsform verwendet werden (Pflasterziegel, die mit schmalen sandgefüllten Fugen auf einem Sandbett verlegt werden), und für solche, die in gebundener Verlegungsform verwendet werden (Pflasterziegel, die mit Zementmörtelfugen auf einem Zementmörtelbett verlegt werden, das sich selbst auf einem gebundenen Untergrund befindet).

Diese Norm bezieht sich auf rechtwinklige und nicht rechtwinklig geformte Pflasterziegel, die als Bauprodukte vorwiegend in Außenbereichen Anwendung finden, die aber auch in Innenbereichen verwendet werden können. Die ungebundene Verlegungsform bezieht sich auf den Fußgänger- und Fahrzeugverkehr, während sich die gebundene Verlegungsform üblicherweise auf den Fußgängerverkehr beschränkt. Sie behandelt keine Produkte für den Feuergebundene - und Säurebau und keine keramische Bodenfliesen. Sie behandelt ebenfalls keine Tonziegel, die für den Mauerwerksbau verwendet werden. Diese Norm behandelt nicht die taktilen Eigenschaften und die Erkennbarkeit von Pflasterziegeln.

Diese Europäische Norm enthält Angaben zu den Eigenschaften und Leistungsklassen, die nach den in den normativen Anhängen angegebenen Prüfverfahren gemessen werden. Sie ermöglicht die Produktkennzeichnung und die Konformitätsbeurteilung des Produkts nach den Anforderungen dieser EN.

Diese Europäische Norm enthält Angaben zu den Eigenschaften und Leistungsklassen, die nach den in den normativen Anhängen angegebenen Prüfverfahren gemessen werden. Sie ermöglicht die Produktkennzeichnung und die Konformitätsbeurteilung des Produkts nach den Anforderungen dieser EN.

Pavés en terre cuite - Spécifications et méthodes d'essais

La présente Norme européenne spécifie les exigences relatives aux pavés et accessoires fabriqués à partir d'argile, destinés à être utilisés dans une forme souple de construction (pavés posés sur un lit de sable avec des joints étroits remplis de sable) et dans une forme rigide de construction (pavés posés avec des joints en mortier de ciment sur un lit en mortier similaire, lui-même placé sur une base rigide).

La norme s'applique aux éléments de forme rectangulaire et autres, utilisés comme produits de construction, principalement destinés à un usage extérieur, en revêtements de chaussées, mais qui peuvent aussi être utilisés pour un usage intérieur. La forme souple de construction sera soumise à un trafic piétonnier et à la circulation de véhicules, alors que la forme rigide de construction est habituellement soumise à un trafic piétonnier. Elle exclut les produits destinés à des applications dans les domaines des réfractaires et du génie chimique ainsi que les carreaux de revêtement de sol en terre cuite. Elle exclut également les éléments de maçonnerie en argile. Cette norme ne traite pas de la tactibilité ou de la visibilité de ces éléments.

La présente Norme européenne spécifie les caractéristiques et les classes de performance mesurées selon les méthodes d'essais décrites en annexes normatives. Elle indique les dispositions concernant le marquage et l'évaluation de la conformité des produits à cette norme européenne.

Opečni tlakovci - Zahteve in preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 19-Mar-2002

- Withdrawal Date

- 01-Oct-2013

- Technical Committee

- CEN/TC 178 - Paving units and kerbs

- Drafting Committee

- CEN/TC 178/WG 3 - Clay products

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 02-Oct-2013

- Completion Date

- 02-Oct-2013

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 09-Oct-2013

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

CEN/TS 15209:2008 - Tactile paving surface indicators produced from concrete, clay and stone - Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 1344:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Clay pavers - Requirements and test methods". This standard covers: This European Standard specifies the requirements of pavers and accessories manufactured from clay for use in the flexible form of construction (pavers laid with narrow sand-filled joints on a sand bed) and in the rigid form of construction (pavers laid with cementitious mortar joints on a similar mortar bed, itself placed on a rigid base). The standard applies to rectangular and other shaped units intended as construction products mainly for exterior use in pavements but which may also be used internally. The flexible form of construction will be subjected to pedestrian and vehicular traffic, while the rigid form of construction is usually subjected to pedestrian traffic. It excludes products intended for refractory and chemical engineering applications and clay floor tiles. It also excludes clay masonry units. This Standard does not deal with the tactility or visibility of units. This European Standard specifies the characteristics and classes of performance measured according to test methods given in normative annexes. It provides for product marking and for the evaluation of conformity of the product to this European Standard.

This European Standard specifies the requirements of pavers and accessories manufactured from clay for use in the flexible form of construction (pavers laid with narrow sand-filled joints on a sand bed) and in the rigid form of construction (pavers laid with cementitious mortar joints on a similar mortar bed, itself placed on a rigid base). The standard applies to rectangular and other shaped units intended as construction products mainly for exterior use in pavements but which may also be used internally. The flexible form of construction will be subjected to pedestrian and vehicular traffic, while the rigid form of construction is usually subjected to pedestrian traffic. It excludes products intended for refractory and chemical engineering applications and clay floor tiles. It also excludes clay masonry units. This Standard does not deal with the tactility or visibility of units. This European Standard specifies the characteristics and classes of performance measured according to test methods given in normative annexes. It provides for product marking and for the evaluation of conformity of the product to this European Standard.

EN 1344:2002 is classified under the following ICS (International Classification for Standards) categories: 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1344:2002 has the following relationships with other standards: It is inter standard links to EN 1344:2013, ISO 48:2010, EN 15316-4-5:2007, EN 2084:2005, EN 15316-4-6:2007, EN 14042:2003, EN 12676-1:2000, EN ISO 6149-2:2007, EN 1745:2020, EN ISO 10321:1996, CEN/TS 15209:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1344:2002 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/119, M/122. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1344:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Clay pavers - Requirements and test methodsPavés en terre cuite - Spécifications et méthodes d'essaisPflasterziegel - Anforderungen und PrüfverfahrenTa slovenski standard je istoveten z:EN 1344:2002SIST EN 1344:2002en93.080.20ICS:SLOVENSKI

STANDARDSIST EN 1344:200201-september-2002

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1344March 2002ICS 93.080.20English versionClay pavers - Requirements and test methodsPflasterziegel - Anforderungen und PrüfverfahrenThis European Standard was approved by CEN on 23 December 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1344:2002 E

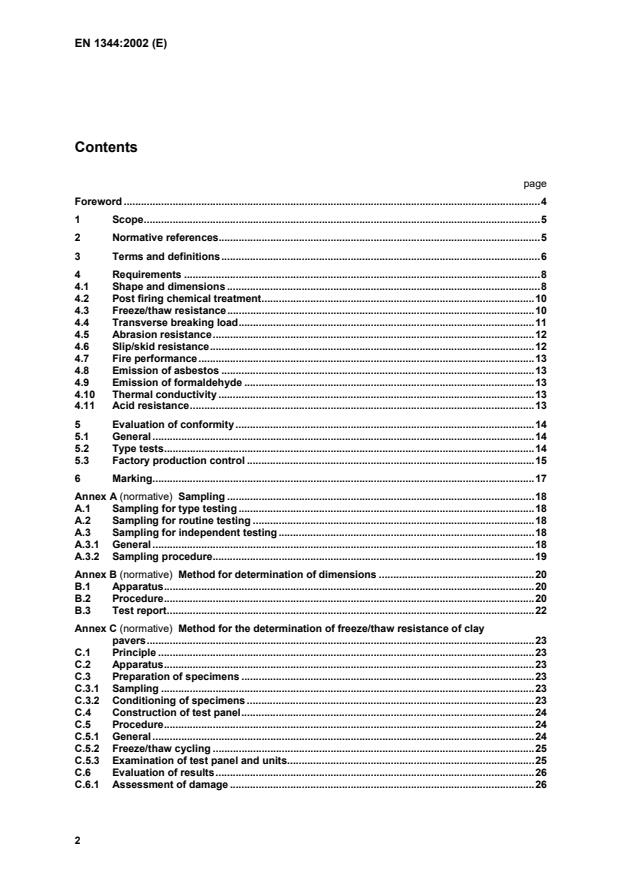

Sampling.18A.1Sampling for type testing.18A.2Sampling for routine testing.18A.3Sampling for independent testing.18A.3.1General.18A.3.2Sampling procedure.19Annex B (normative)

Method for determination of dimensions.20B.1Apparatus.20B.2Procedure.20B.3Test report.22Annex C (normative)

Method for the determination of freeze/thaw resistance of claypavers.23C.1Principle.23C.2Apparatus.23C.3Preparation of specimens.23C.3.1Sampling.23C.3.2Conditioning of specimens.23C.4Construction of test panel.24C.5Procedure.24C.5.1General.24C.5.2Freeze/thaw cycling.25C.5.3Examination of test panel and units.25C.6Evaluation of results.26C.6.1Assessment of damage.26

Method for the determination of transverse breaking load.31D.1Principle.31D.2Apparatus.31D.3Procedure.31D.4Calculation.31D.4.1Calculation of transverse breaking load.31D.4.2Optional calculation of bending tensile strength.32D.5Test report.32Annex E (normative)

Method for the determination of abrasion resistance.33E.1Principle.33E.2Sampling.33E.3Material.33E.4Apparatus.33E.5Test specimens.33E.6Procedure.34E.7Expression of results.34E.8Test report.34Annex F (normative)

Method for the determination of unpolished slip/skid resistancevalue (USRV).38F.1Principle.38F.2Apparatus.38F.2.1Pendulum friction tester.38F.3Sampling.43F.4Procedure.44F.5Calculation of unpolished slip/skid resistance value (USRV).44F.6Test report.44Annex G (normative)

Method for the determination of acid resistance.46G.1Principle.46G.2Reagents.46G.3Apparatus.46G.4Procedure.46G.5Expression of results.47G.6Test report.47Annex ZA (informative)

Clauses of this European Standard addressing the provisions ofthe EU Construction Products Directive (89/106/EEC).48

The flexible form of constructionwill be subjected to pedestrian and vehicular traffic, while the rigid form of construction is usuallysubjected to pedestrian traffic.

It excludes products intended for refractory and chemical engineeringapplications and clay floor tiles.

It also excludes clay masonry units.

This Standard does not dealwith the tactility or visibility of units.This European Standard specifies the characteristics and classes of performance measuredaccording to test methods given in normative annexes. It provides for product marking and for theevaluation of conformity of the product to this European Standard.2 Normative referencesThis European Standard incorporates by dated or undated reference, provisions from otherpublications. These normative references are cited at the appropriate places in the text, and thepublications are listed hereafter. For dated references, subsequent amendments to or revision of anyof these publications apply to this European Standard only when incorporated in it by amendment orrevision. For undated references the latest edition of the publication referred to applies (includingamendments).ISO 48, Rubber, vulcanized or thermoplastic. Determination of hardness (hardness between 10 IRHDand 100 IRHD).ISO 630, Structural steels.ISO 3310, Test sieves – Technical requirements and testing.ISO 4662, Rubber — Determination of rebound resilience of vulcanizates.ISO 7619, Rubber — Determination of indentation hardness by means of pocket hardness meters.ISO 8486, Bonded Abrasives — Grain Size Analysis — Designation and determination of grain sizedistribution of macrogrits F4 to F220.prEN 1745, Masonry and masonry products — Method for determining design thermal values.

Fittings for usein flexible paving allow completion of the pavement at the perimeter and around obstructions bybonding with pavers laid in a prescribed pattern (e.g. squares, bishops mitre units).

Fittings for usewith rigid paving being bedded, jointed and pointed in mortar may be used to fulfil functions in bothrigid laid paving, such as the provision of surface water drainage, e.g. channel units, or to fulfilparticular functions in flexible paving schemes and/or to provide edge restraint for flexible pavements3.3work dimensionany dimension of a paver specified for its manufacture to which the actual dimension should conformwithin specified permissible deviations (see Figure 1)NOTEFor rectangular pavers, the dimensions of length, width and thickness are indicated in Figure 1.Some pavers may be used in two or more orientations.3.4spacer nibsmall protruding profile on side face of paver (see Figure 1)NOTEAs the spacer nib is intended to project into the joint, its presence is ignored when stating plan workdimensions e.g. for the length and width of rectangular pavers.3.5chamferbevelled or rounded arris on paver (see Figure 2)3.6wearing facesurface intended to be seen when in use3.7overall lengthlonger side of the rectangle with the smallest area able to enclose the paver excluding any spacernibs3.8overall widthshorter side of the rectangle with the smallest area able to enclose the paver excluding any spacernibs3.9overall thicknessdistance between the upper wearing face of the paver and the opposite face of the paver

Some manufacturers may be able to supply pavers having a smaller range than indicated by class R1 inwhich case an appropriate declaration may be made.The requirement for dimensional deviations does not apply to associated fittings.4.2 Post firing chemical treatmentThe test methods for freeze thaw resistance, transverse breaking load, abrasion resistance andunpolished slip/skid resistance are determined using pavers which have had no post firing chemicaltreatment applied to them.

If following testing to establish the performance of the paver andaccessories in accordance with the requirements of this European Standard, the manufacturer wishesto apply a post firing chemical treatment, the products shall be tested both with and without the postfiring chemical treatment.

The testing shall be in accordance with the requirements of the relevantclause of this European Standard and the results shall be stated in accordance with the requirementsof the relevant clause.4.3 Freeze/thaw resistanceIt shall be stated whether the pavers are intended to meet the criteria for freeze/thaw resistanceincluded in the method given in annex C.

Manufacturers who are able to supply pavers withmore than one orientation should state the orientation upon which the test was performed.Table 3 — Transverse breaking loadClassTransverse breaking load not less than (N/mm)Mean valueMinimum individual valueT0No declarationNo declarationT13015T23024T38050T48064NOTE 1

This requirement for transverse breaking load does not apply to accessories or topavers whose overall length is less than 80 mm.NOTE 2

Class TO is only suitable for pavers intended for use for rigid laying where the paversare laid with cementitious mortar joints on a similar mortar bed itself placed on a rigid base.NOTE 3

The manufacturer may declare a mean value and minimum individual value higherthan those corresponding to class T4.NOTE 4

The manufacturer may declare a mean and minimum bending tensile strength valuecalculated from the formula given in D.4.2.

If the pavers may beused in more than one orientation, the values for the intended wearing faces shall be declared.NOTEThe unpolished slip/skid resistance value relates to pavers as manufactured and helps to ensureadequate slip/skid on installation.When sampled in accordance with annex A, and tested in accordance with annex F the mean USRVof the sub-sample of five pavers shall be not less than the value for the appropriate declared classgiven in Table 5 and be classified accordingly.Table 5 — Classification of unpolished slip/skid resistance value (SRV)ClassMean SRVU0No determinationU135U245U355NOTESome manufacturers may declare higher values.

Reference is made to theCommission decision 96/603/EC.4.7.2 External fire performanceClay pavers used as a roof covering are deemed to satisfy the requirements for external fireperformance without the need for testing.

See Commission decision 2000/553/EC.4.8 Emission of asbestosClay pavers shall not contain asbestos material.4.9 Emission of formaldehydeClay pavers shall not contain formaldehyde.

After manufacture, any applied surface coating will eithernot contain formaldehyde or will not release formaldehyde that is in excess of safety levels.4.10 Thermal conductivityIf clay pavers are used internally and if required, design data on thermal conductivity shall be takenfrom prEN 1745.4.11 Acid resistanceWhere there is a requirement for resistance to acid attack as the result of accidental spillage of acid intrafficked areas, the percentage loss in mass of a sample of five pavers sampled in accordance withannex A and tested in accordance with annex G shall not exceed 7 %. Pavers meeting thisrequirement may be designated “Class C”. Manufacturers may declare a lower value than 7 %.No post-firing surface chemical treatment shall be applied to the pavers or accessories prior to testing.

Tests previouslyperformed in accordance with the provisions of this standard (same product, same characteristic, testmethod, sampling procedure, etc.) may be taken into account.Whenever a major change in the source, proportions or nature of raw materials occurs, or when thereis a major change in processing conditions (e.g. firing times and temperatures) this constitutes a newproduct type.The type tests shall be the tests called up in this standard for the following list of properties, consistentwith the product types and their intended use.Dimensions and dimensional deviations : freeze/thaw resistance; transverse breaking load; abrasion resistance; unpolished slip/skid resistance value; acid resistance (where required).

The factory production control system shall consist ofprocedures for the internal control of production to ensure that products placed on the market conformto this standard and the manufacturer’s declared values.The internal control shall consist of regular inspections, checks and tests and the utilization of theresults to control raw or incoming materials, equipment, the production process and the finishedproduct.5.3.2 Raw materialsThe documentation shall include the specifications of all raw materials and the procedures to beoperated to ensure that they comply. However, because of the widely differing nature of argillaceousdeposits, it is not appropriate in this standard to specify what particular tests shall be used, nor theirfrequency.5.3.3 Production processThe relevant features of the plant and production process shall be defined and documented giving thefrequency of the inspection checks and tests, together with the criteria required both on equipmentand on work in progress. The action to be taken when control values or criteria are not met shall begiven. Weighing and measuring equipment shall be calibrated and the procedure, frequency andcriteria documented.NOTECalibration need not necessarily require the involvement of a third party.There are many types of plant and production process used in the manufacture of clay pavers andcomplementary fittings and the establishment of a suitable system of production process control willdepend on the features of the specific process. Therefore, it is not appropriate in this standard tospecify particular tests to be used, nor their frequency.5.3.4 Finished product testingThe documentation shall incorporate a sampling plan for the testing of finished products, the results ofwhich shall be recorded. All test equipment shall be calibrated and the procedure, frequency andcriteria be given in the documentation.The frequency of testing of the finished product for the purpose of factory production control shall beindicated in the documentation.

In pavers intended for flexiblelaying, if the mid point of each dimension leads to contact with the spacer nib, the position ofmeasurement shall be moved to avoid the spacer nib whilst still remaining as close as possible to themid point of each dimension.

The panel is subsequently cooled until all of the water which has been absorbed is frozenand the water near to one face is repeatedly thawed and refrozen.

Damage caused by the freezingand thawing action is assessed and used to determine the freeze/thaw resistance of the pavers.C.2 ApparatusAn appropriate testing machine capable of generating the freeze-thaw cycles specified inclause C.5.2. and ensuring uni-directional freezing and thawing through one face of the units.A water tank, made of plastic or steel.A drying oven capable of maintaining a temperature of 120 °C and of providing forced air circulation.A weighing instrument capable of weighing specimens to an accuracy of 1 g.A heat flow meter for carrying out the calibration procedure described in C.8.C.3 Preparation of specimensC.3.1 SamplingThe method of sampling shall be in accordance with this standard.

Ten units shall be sampled inorder to construct a panel as described in C.4.Each unit shall be numbered and examined.

Any existing damage shall be marked and recordedusing the description given in Table C.1 and shown diagrammatically in Figure C.1.C.3.2 Conditioning of specimensThe units shall be dried in an oven at (105 ± 5) °C to a constant mass.

Weigh the specimens andrecord their dry mass, Md.

Constant mass shall be considered to have been reached if, during thedrying process in subsequent weighings with not less than a 24 h interval, the loss in mass betweenthe two determinations is less then 0,2 % of the total mass.

Allow the specimens to cool to ambienttemperature before they are weighed.

Then the temperature is decreased to room temperature within a period of 2 hoursto 5 hours. This is done by gradually putting tap water of room temperature into the tank.

In thiscondition the products remain until the total immersion time from the start of the process is at least44 hours and not more than 56 hours.

Before the freeze/thaw procedure starts all products areweighed in air and optionally in water in order to calculate the water absorption and optionally the netdry density by means of the following formulae.)/(%100ddsms,mmmmmW3m/kg1000wsddmmmPwherePd=

the net dry density, (kg/m3) (optional)md=

the mass of the specimen after drying at (105 ± 5) °C, (grams)Ws,m=

the water absorption, (% m/m)ms=

the mass of the wet specimen after soaking in water at (80 ± 3) °C, measured in air

(grams)mw=

the mass of the test specimen after soaking in water at (80 ± 3) °C, measured

suspended in water, (grams) (optional)C.4 Construction of test panelThe samples are then assembled as a panel with their wearing surfaces exposed and with amaximum height of 600 mm.

The joints between the pavers shall be sealed with thin foam rubber(closed pore approximately 3 mm thick).

The edges of the panel are insulated with at least 25 mm ofextruded polystyrene board of closed cell structure and the back with at least 50 mm of extrudedpolystyrene.

The joint between the paver and the polystyrene insulation at the perimeter of the testpanel shall be sealed with foam rubber.C.5 ProcedureC.5.1 GeneralAll faces of the panel except that exposed to freeze/thaw cycling conditions shall be enclosed in aclose fitting jacket of extruded polystyrene foam board with a density of less than 40 kg/m3.

Theminimum thickness of the jacket shall be 50 mm at the face and 25 mm around the perimeter of thetest panel.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...