EN 16602-60:2015

(Main)Space product assurance - Electrical, electronic and electromechanical (EEE) components

Space product assurance - Electrical, electronic and electromechanical (EEE) components

This standard defines the requirements for selection, control, procurement and usage of EEE components for space projects.

This standard differentiates between three classes of components through three different sets of standardization requirements (clauses) to be met.

The three classes provide for three levels of trade-off between assurance and risk. The highest assurance and lowest risk is provided by class 1 and the lowest assurance and highest risk by class 3. Procurement costs are typically highest for class 1 and lowest for class 3. Mitigation and other engineering measures may decrease the total cost of ownership differences between the three classes. The project objectives, definition and constraints determine which class or classes of components are appropriate to be utilised within the system and subsystems.

a. Class 1 components are described in Clause 4.

b. Class 2 components are described in Clause 5

c. Class 3 components are described in Clause 6.

The requirements of this document apply to all parties involved at all levels in the integration of EEE components into space segment hardware and launchers.

This standard may be tailored for the specific characteristics and constraints of a space project in conformance with ECSS-S-ST-00.

Raumfahrtproduktsicherung - Elektrische, elektronische und elektromechanische (EEE) Bauteile

Assurance produit des projets spatiaux - Composants électriques, électroniques et électromécaniques (EEE)

Zagotavljanje varnih proizvodov v vesoljski tehniki - Električne, elektronske in elektromehanske komponente

Ta standard določa zahteve za izbiro, nadzor, nabavo in uporabo električnih, elektronskih in elektromehanskih komponent (EEE) v vesoljski tehniki. Ta standard razlikuje med tremi razredi komponent s pomočjo treh različnih naborov standardizacijskih zahtev (določil), ki morajo biti izpolnjene. Ti trije razredi določajo tri ravni kompromisov med zagotovili in tveganjem. Največje zagotovilo in najmanjše tveganje zagotavlja razred 1, najmanjše zagotovilo in največje tveganje pa razred 3. Stroški nabave so običajno najvišji za razred 1 in najnižji za razred 3. Ukrepi za blažitev in drugi inženirski ukrepi lahko zmanjšajo skupne stroške lastniških razlik med temi tremi razredi. Cilji projekta, njegova opredelitev in omejitve določajo, kateri razred ali razredi komponent so ustrezni za uporabo v sistemu in podsistemih. a. Komponente razreda 1 so opisane v točki 4. b. Komponente razreda 2 so opisane v točki 5 c. Komponente razreda 3 so opisane v točki 6. Zahteve tega dokumenta veljajo za vse vpletene strani na vseh ravneh integracije električnih, elektronskih in elektromehanskih komponent v vesoljski strojni opremi in lansirnikih. Ta standard se lahko prilagodi posameznim lastnostim in omejitvam vesoljskega projekta v skladu s standardom ECSS-S-ST-00.

General Information

- Status

- Withdrawn

- Publication Date

- 11-Aug-2015

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/CLC/TC 5 - Space

- Drafting Committee

- CEN/CLC/TC 5 - Space

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 28-Jun-2023

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 05-May-2021

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 16602-60:2015 is a standard published by the European Committee for Standardization (CEN). Its full title is "Space product assurance - Electrical, electronic and electromechanical (EEE) components". This standard covers: This standard defines the requirements for selection, control, procurement and usage of EEE components for space projects. This standard differentiates between three classes of components through three different sets of standardization requirements (clauses) to be met. The three classes provide for three levels of trade-off between assurance and risk. The highest assurance and lowest risk is provided by class 1 and the lowest assurance and highest risk by class 3. Procurement costs are typically highest for class 1 and lowest for class 3. Mitigation and other engineering measures may decrease the total cost of ownership differences between the three classes. The project objectives, definition and constraints determine which class or classes of components are appropriate to be utilised within the system and subsystems. a. Class 1 components are described in Clause 4. b. Class 2 components are described in Clause 5 c. Class 3 components are described in Clause 6. The requirements of this document apply to all parties involved at all levels in the integration of EEE components into space segment hardware and launchers. This standard may be tailored for the specific characteristics and constraints of a space project in conformance with ECSS-S-ST-00.

This standard defines the requirements for selection, control, procurement and usage of EEE components for space projects. This standard differentiates between three classes of components through three different sets of standardization requirements (clauses) to be met. The three classes provide for three levels of trade-off between assurance and risk. The highest assurance and lowest risk is provided by class 1 and the lowest assurance and highest risk by class 3. Procurement costs are typically highest for class 1 and lowest for class 3. Mitigation and other engineering measures may decrease the total cost of ownership differences between the three classes. The project objectives, definition and constraints determine which class or classes of components are appropriate to be utilised within the system and subsystems. a. Class 1 components are described in Clause 4. b. Class 2 components are described in Clause 5 c. Class 3 components are described in Clause 6. The requirements of this document apply to all parties involved at all levels in the integration of EEE components into space segment hardware and launchers. This standard may be tailored for the specific characteristics and constraints of a space project in conformance with ECSS-S-ST-00.

EN 16602-60:2015 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16602-60:2015 has the following relationships with other standards: It is inter standard links to EN 16602-60:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16602-60:2015 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16602-60:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Raumfahrtproduktsicherung - Elektrische, elektronische und elektromechanische (EEE) BauteileAssurance produit des projets spatiaux - Composants électriques, électroniques et électromécaniques (EEE)Space product assurance - Electrical, electronic and electromechanical (EEE) components49.140Vesoljski sistemi in operacijeSpace systems and operations49.060Aerospace electric equipment and systemsICS:Ta slovenski standard je istoveten z:EN 16602-60:2015SIST EN 16602-60:2015en,fr,de01-oktober-2015SIST EN 16602-60:2015SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16602-60

August 2015 ICS 49.140

English version

Space product assurance - Electrical, electronic and electromechanical (EEE) components

Assurance produit des projets spatiaux - Composants électriques, électroniques et électromécaniques (EEE)

Raumfahrtproduktsicherung - Elektrische, elektronische und elektromechanische (EEE) Bauteile This European Standard was approved by CEN on 16 November 2014.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels © 2015 CEN/CENELEC All rights of exploitation in any form and by any means reserved worldwide for CEN national Members and for CENELEC Members. Ref. No. EN 16602-60:2015 E SIST EN 16602-60:2015

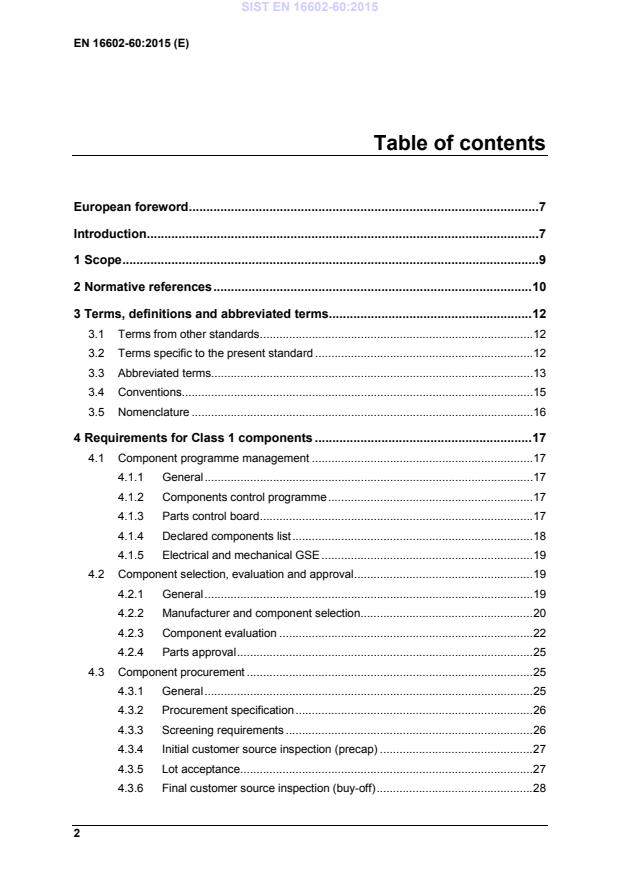

Tables Table 4-1: Document requirements list for Class 1 components . 36 Table 5-1: Document requirements list for Class 2 components . 54 Table 6-1:Document requirements list for Class 3 components . 71 Table 7-1:

Quality levels for Class 1 components . 72 Table 7-2: Quality levels for Class 2 components . 76 SIST EN 16602-60:2015

Important elements of EEE component requirements include: a. component programme management, b. component selection, evaluation and approval, c. procurement, d. handling and storage, e. component quality assurance, f. specific components, and g. documentation. The main tools which can be used to reach the objective are: a. concurrent engineering, b. standardization of component types,

c. characterization of components, d. assessment of component manufacturers including declared competencies and processes, e. testing, screening, lot acceptance and periodic testing, f. procurement specifications, g. control and inspection, h. control of nonconforming materials, i. assessment and use of existing component data,

j. application of specific control to mitigate risk for components with limited data or confidence, and k. information management. The basic approach is as follows: • The customer of a given space project defines the EEE component requirements within the boundaries of this standard. They appear in the appropriate clauses of the project requirements as defined in ECSS-M-ST-10. • The supplier defines a component control plan to implement those requirements into a system which enables, for instance, to control the selection, approval, procurement, handling in a schedule compatible with his requirements, and in a cost-efficient way. • The supplier ensures that the applicable parts requirements are passed down to lower level suppliers and ensure that they are compliant to these parts requirements. SIST EN 16602-60:2015

EN reference Reference in text Title EN 16601-00-01 ECSS-S-ST-00-01 ECSS system — Glossary of terms EN 16601-10 ECSS-M-ST-10 Space project management — Project planning and implementation EN 16602-10-09 ECSS-Q-ST-10-09 Space product assurance — Nonconformance control system EN 16602-20 ECSS-Q-ST-20 Space product assurance — Quality assurance EN 16602-30-11 ECSS-Q-ST-30-11 Space product assurance — Derating — EEE components EN 16602-60-02 ECSS-Q-ST-60-02 Space product assurance — ASIC and FPGA development EN 16602-60-05 ECSS-Q-ST-60-05 Space product assurance — Generic procurement requirements for hybrid microcircuits EN 16602-60-12 ECSS-Q-ST-60-12 Space product assurance — Design, selection, procurement and use of die form monolithic microwave integrated circuits (MMICs) EN 16602-60-13 ECSS-Q-ST-60-13 Commercial electrical, electronic and electromechanical (EEE) components EN 16602-60-14 ECSS-Q-ST-60-14 Space product assurance – Relifing procedure – EEE components EN 16602-60-15 ECSS-Q-ST-60-15 Radiation hardness assurance – EEE components EN 16602-70 ECSS-Q-ST-70 Space product assurance — Materials, mechanical parts and processes

ESCC 20200 ESCC: Component Manufacturer Evaluation

ESCC 22800 ESCC: ESA/SCC Non conformance Control System

ESCC 22900 ESCC Basic Specification: Total Dose Steady-State SIST EN 16602-60:2015

ESCC 24900 Minimum requirements for controlling environmental contamination of components

ESCC 25500 Methodology for the detection of pure tin in the external surface finish of case and leads of EEE components

ESCC QPL ESCC qualified part list (https://escies.org)

ESCC EPPL ESCC European preferred parts list (https://escies.org)

ESCC QML ESCC qualified manufacturers list (https://escies.org)

MIL QPLs MIL qualified parts lists

MIL QMLs MIL qualified manufacturers lists

NPSL NASA Parts Selection List

JAXA QPL JAXA qualified parts list

ESCC, MIL & JAXA specifications and standards called in the document

3.2.3 commercial component part neither designed, nor manufactured with reference to military or space standards

3.2.4 concurrent engineering engineering activity taking place in the context of simultaneous design of the product, the production process and all associated product usages, in an integrated, multifunctional team, with external organizational constraints minimized 3.2.5 destructive physical analysis series of inspections, tests and analyses performed on a sample of components to verify that the material, design and workmanship used for its construction, as well as the construction itself, meet the requirements of the relevant specification and are suitable for the intended application 3.2.6 franchised distributor distributor officially and contractually authorised by the manufacturer 3.2.7 parts engineer professional engineer with demonstratable specialisation in EEE components SIST EN 16602-60:2015

NOTE 1 Space qualified parts are a subset of the qualified parts defined in clause 3.2.9. NOTE 2 Parts belonging to JAXA QPL are considered as space qualified provided the equivalence of the generic JAXA specification with the ESCC or MIL generic specifications has been established. 3.3 Abbreviated terms For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01 and the following apply: Abbreviation Meaning ASIC Application specific integrated circuit CCD charge coupled device CCP Component control plan CDR critical design review CECC CENELEC electronic components committee CENELEC Comité Européen de Normalisation Electrotechnique CI

conformance inspection CN change notice CoC certificate of conformance CPPA centralized parts procurement agent CR change request CSI customer source inspection CSV comma-separated values DCL declared components list DPA destructive physical analysis DRD document requirement definition EEE electrical, electronic, electromechanical SIST EN 16602-60:2015

WFR Weibull failure rate SIST EN 16602-60:2015

c. The term “for review” means that raised reviewers comments are considered and dispositioned. d. The term “for information” means that no comments are expected about

the delivered item. e. For the purpose of clear understanding of this document, hereunder is a listing of component categories which are covered by the term EEE component, encapsulated or non-encapsulated, irrespective of the quality level: 1. Capacitors 2. Connectors 3. Crystals 4. Discrete semiconductors (including diodes, transistors) 5. Filters 6. Fuses 7. Magnetic components (e.g. inductors, transformers, including in-house products) 8. Monolithic Microcircuits

(including MMICs) 9. Hybrid circuits 10. Relays 11. Resistors, heaters 12. Surface acoustic wave devices

13. Switches (including mechanical, thermal) 14. Thermistors 15. Wires and Cables 16. Optoelectronic Devices (including opto-couplers, LED, CCDs, displays, sensors) 17. Passive Microwave Devices (including, for instance, mixers, couplers, isolators and switches) NOTE

Microwave switches consisting of multiple EEE components are considered as equipment. The requirements of this standard are applicable to the EEE parts they incorporate and to microwave switches having a simple design (single EEE part). SIST EN 16602-60:2015

(b) conformity of procurement data, (c) post-procurement data, and (d) application of alerts recommendations. NOTE

For (a) to (c), assessment is made by comparison of procurement documentation versus approval document. 4.1.4 Declared components list a. For each equipment, its supplier shall issue a DCL in an editable and sortable electronic format, as a minimum compatible with CSV, identifying all component types needed. NOTE

CSV is a common file format that can be used to transfer data between database or spreadsheet tables (a spreadsheet program is for example Excel®). b. The list specified in 4.1.4a shall be kept under configuration control (issue and identification of changes).

c. The DCL shall be issued as a minimum at PDR and CDR (as designed) and before TRR (as built). d. After equipment CDR, all modifications affecting the PAD information shall be implemented, in the "as design" DCL, through the CN / CR process and submitted to the customer for approval. NOTE

For PAD generation, see 4.2.4d. e. The “as design” DCL shall be sent to the customer for approval. SIST EN 16602-60:2015

2. manufactured from materials identical to the flight opposite part, and 3. ensured to be visibly clean before each connection to flight hardware. b. Flight hardware connector interfaces to GSE shall interface to a flight compatible connector, as per 4.1.5a. NOTE

This connector can be installed on the test harness or can be a saver. 4.2 Component selection, evaluation and approval 4.2.1 General a. The supplier shall ensure that the following requirements are met during his selection process: 1. Project requirements (e.g. quality levels, component policy, manufacturing and delivery schedules and budgets, quantities), 2. Design requirements (e.g. component type, case,

dimensions, materials), 3. Production requirements (e.g. packaging, thermal and storage constraints, component mounting process), 4. Operational requirements (e.g. electrical, mechanical, radiation, reliability, assembly, and lifetime). NOTE

The supplier of each product is responsible for the selection of components, which enable the performance, lifetime, environmental, material, safety, quality and reliability requirements of the product of which they form a part, to be satisfied in all respects. SIST EN 16602-60:2015

b. Components shall be selected on the basis of proven qualification, characterization,

and previous space experience and data, relevant with regard to the requirements for the programme, from manufacturers or sources (preferably European) employing effective Product Assurance Programmes in manufacturing and test. c. Preference shall be given to components which necessitate the least evaluation or qualification effort.

d. Starting with the design phase of the project the supplier shall ensure maximum use of preferred (see 4.2.2.3) and qualified components to achieve an effective component reduction and standardization.

e. When selecting items, the supplier shall check the current data, applicability of the basis of qualification, problem notifications and alerts, and adequacy of specifications.

f. The supplier shall implement a type reduction activity. 4.2.2.2 Parts and material restriction a. The supplier shall ensure that non-hermetically sealed materials of components meet the requirements of ECSS-Q-ST-70 regarding off-gassing, out-gassing, flammability, toxicity and any other criteria specified for the intended use.

b. The supplier shall evaluate the robustness of selected EEE components against the stresses induced by the assembly techniques to be employed. c. With respect to health and safety, beryllium oxide (except if identified in the procurement specification), cadmium, lithium, magnesium, mercury, zinc, radioactive material and all material which can cause safety hazards shall not be used. d. For limited life duration, known instability, safety hazards or reliability risk reasons, the EEE components listed below shall not be used: 1. EEE components with pure tin (less than 3% Pb in case of SnPb alloy) used as a finish on the leads, terminations and external surfaces of components and packages. 2. Hollow core resistors, 3. Potentiometers (except for mechanism position monitoring), SIST EN 16602-60:2015

4. MIL QPL's and QML's. c. Parts subject to export restrictions or regulations shall not be preferred.

4.2.2.4 Radiation hardness a. The radiation requirements for EEE components are project specific. b. The supplier who is responsible for the design of the piece of hardware shall demonstrate the compliance of its components selection with the radiation constraints of the project. SIST EN 16602-60:2015

d. Due consideration shall be given to the mission orbit and trajectory, the duration, the associated spatial and temporal variations of the radiation environment as well as all protective factors such as shielding.

e. The supplier shall assess the actual radiation tolerance of the selected components for compliance with the radiation requirements in term of total dose, displacement damage and Single Events Effects (SEE).

f. The supplier shall identify components which are not compliant with the radiation requirements as critical radiation sensitive components.

g. The supplier shall implement a Radiation Hardness Assurance Programme, in conformance with the requirements of ECSS-Q-ST-60-15, documented by a plan to be approved by the customer, for radiation sensitive components, covering the collection of all relevant information and specifying the necessary actions in terms of evaluation and procurement testing, planning and control.

h. The supplier shall issue an Equipment Radiation Analysis document identifying all sensitive components w.r.t. the relevant radiation effects, possibly their impact and giving an adequate engineering solution (e.g. local shielding, design solution, specific test, and RVT) for the relevant equipment. i. The Equipment Radiation Analysis document shall be submitted to the customer for approval. NOTE

More detailed information about the above requirements is given in ECSS-E-ST-10-12 and ECSS-Q-ST-60-15. 4.2.2.5 Derating a. The supplier shall implement derating rules for components used in his designs in accordance with the requirements of ECSS-Q-ST-30-11. b. For wire link fuses, the current derating factor shall be 50 % with an additional derating of 0,2 %/°C for an increase in the temperature of fuse body above 25 °C. 4.2.3 Component evaluation 4.2.3.1 General a. The supplier shall perform a component evaluation in absence of an approved demonstration that a component has the ability to conform to the requirements for functional performance, quality, dependability, and environmental resistance as required for the project. b. The supplier shall plan and carry out the evaluation. SIST EN 16602-60:2015

d. An evaluation plan shall be sent to the customer for approval, and include the following elements: 1. Component Manufacturer Asses

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...