prEN 10344

(Main)Malleable cast iron fittings with compression ends for steel pipes

Malleable cast iron fittings with compression ends for steel pipes

This standard specifies the requirements for the design, performance and testing of fittings made of malleable cast iron (see also clause 5 Materials) with compression ends for steel pipes. It applies to steel piping systems for different application fields, such as gas supply, distribution of water for general purposes and for human consumption, irrigation, fire fighting, aqueous liquids, compressed air and gaseous fuel systems.

It also applies to oil piping systems, provided the elastomeric sealing material is compatible with the oil and the operating conditions.

It contains requirements and tests relating to compression fittings which can be disconnected from smooth walled steel pipes or other cylindrical metal structural elements, which are applicable for dismantleable joints. The fittings can also incorporate other types of connection, such as threaded, flanged, compression ends for connection of polyethylene pipes, etc., and can also take on various structural shapes, such as, straight piece, elbow or T-piece, etc. Their range of sizes covers nominal sizes DN 6 to DN 100 (size 1/8 to 4).

Tempergussfittings mit Klemmanschlüssen für Stahlrohre

Diese Norm legt die Anforderungen an die Konstruktion, Anwendungsmerkmale und Prüfung von Tempergussfittings mit Klemmanschlüssen für Stahlrohre fest. Sie gilt für Rohrleitungssysteme aus Stahl für unterschiedliche Anwendungsbereiche, z. B. Gasversorgung, Wasserverteilung für allgemeine Zwecke sowie für Trinkwasser, Bewässerung, Löschwassersysteme, wässrige Lösungen, Druckluft und gasförmige Brennstoffe.

Diese Norm gilt ebenfalls für Rohrleitungen für Öl, sofern die Elastomer-Abdichtungen mit dem Öl und den Betriebsbedingungen kompatibel sind.

Die Norm enthält Anforderungen und Prüfungen für Klemmanschlüsse, die von glattwandigen Stahlrohren oder anderen zylindrischen Bauteilen aus Metall (im folgenden kurz „glatte Rohrverbindungen“ genannt)

demontiert werden können. Die Fittings können auch andere Verbindungsarten umfassen, z. B. Gewinde-, Flansch- und Klemmverbindungen für Rohre aus Polyethylen usw. und in unterschiedlichen Formen ausgeführt sein, z. B. als gerade Anschlüsse, Bogen oder T-Stücke, usw. Der Nennweitenbereich umfasst die Nennweiten DN 6 bis DN 100 (Größe ⅛ bis 4).

Raccords à compression en fonte malléable pour tubes d'acier

La présente norme spécifie les exigences de conception, de performances et d’essai des raccords à compression en fonte malléable pour tubes en acier. Elle s’applique aux réseaux de canalisations en acier utilisés dans des différents champs d’application, tels que l’alimentation en gaz, la distribution d’eau destinée à des usages généraux et à la consommation humaine, l’irrigation, la lutte contre l’incendie, les liquides aqueux, les systèmes à air comprimé et à combustibles gazeux.

La présente norme s’applique également aux réseaux de canalisations d'hydrocarbures, à la condition que le produit d’étanchéité élastomère soit compatible avec l’huile et les conditions de fonctionnement.

Elle spécifie des exigences et des essais relatifs aux raccords à compression pouvant être démontés à partir de tubes lisses en acier ou d’autres éléments structurels cylindriques en métal, utilisables pour les joints démontables. Les raccords peuvent également comporter d’autres types de connexions, telles que les extrémités de compression filetées ou à bride, utilisées pour des tubes en polyéthylène, entre autres. Ils peuvent aussi se présenter sous différentes formes : raccords droits, coudes ou tés. Leur gamme de dimensions comprend les dimensions nominales DN 6 à DN 100 (dimension 1/8 à 4).

Fitingi iz temprane železove litine s prižemnimi priključki za železne cevi

General Information

- Status

- Not Published

- Technical Committee

- ECISS/TC 110 - Steel tubes, and iron and steel fittings

- Drafting Committee

- ECISS/TC 110/WG 3 - Fittings

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Due Date

- 01-Jun-2003

- Completion Date

- 11-Dec-2020

Overview

The prEN 10344 standard, developed by CEN, specifies comprehensive requirements for malleable cast iron fittings with compression ends specifically designed for steel pipes. This standard targets the design, performance, and testing of these fittings to ensure reliability and safety in various piping systems. It caters to a wide range of applications including gas supply, water distribution (both general use and human consumption), irrigation, firefighting, compressed air, gaseous fuels, and oil piping systems-with the latter contingent on compatibility of elastomeric sealing materials with oil and operating conditions.

Key attributes of these fittings are their capability to create dismantleable joints on smooth-walled steel pipes or other cylindrical metal components. The fittings may also include additional connection types such as threaded, flanged, or compressive connections suitable for polyethylene pipes. The standard covers various shapes including straight pieces, elbows, and T-pieces, with nominal sizes ranging from DN 6 to DN 100 (approximately 1/8 inch to 4 inches).

Key Topics

Materials

The fittings must be made from malleable cast iron, with specifications around chemical composition and performance. The standard also includes guidance on elastomer materials used for sealing, emphasizing compatibility with transported fluids (especially oil).Design Requirements

Specifications cover geometrical characteristics like minimum bore diameter, pipe threads, sealing surfaces, and load transmission. Transition fittings accommodating different piping materials (e.g., polyethylene) are also described.Corrosion Protection

The standard highlights the importance of corrosion resistance, detailing hot-dip galvanizing practices including coating mass, chemical composition, and surface quality, along with non-metallic coatings.Performance Criteria

Tests and requirements focus on crushing strength, internal pressure resistance, maximum deformation loads, leaktightness under various conditions (pressure cycling, temperature changes), and durability of both fittings and elastomeric seals.Testing and Quality Control

prEN 10344 outlines extensive test methods such as visual inspections, material tests, dimensional tolerances, and assembly tests. Cycle and vibration resistance, as well as pull-out resistance, are rigorously assessed to guarantee fitting reliability.Marking and Traceability

Guidelines for proper marking ensure easy identification of fittings, including size, material, and compliance status.

Applications

The standard applies broadly to steel piping systems across many industries:

Gas supply networks

Secure joints for gas transport, safe under pressure and temperature variations.Water distribution

Used in potable water and general-purpose water supply, including fire fighting systems.Irrigation systems

Reliable fittings withstand long-term exposure to aqueous liquids.Compressed air systems

Compression fittings ensure airtight and durable connections.Gaseous fuel systems

Compatibility of sealing materials is crucial for safety and performance.Oil piping systems

Fittings adapted to meet oil-specific sealing requirements under given operating conditions.Construction and Maintenance

Enables quick assembly and maintenance with dismantleable joints.Industrial and Commercial Piping

Useful in manufacturing plants, heating systems, and other installations where metal piping connections must be secure yet serviceable.

Related Standards

For proper implementation and compliance, prEN 10344 references several related standards:

- EN 1562: Founding specifications for malleable cast irons.

- EN 681-1 and EN 682: Requirements for elastomeric seals used in water and gas applications.

- EN 10226-1/2/3: Standards for pipe threads and thread inspection.

- EN 12294 and EN 12295: Leak tightness and pressure cycling tests for plastic piping joints.

- EN 13501-1: Fire classification of construction products.

- EN 10216-1 / EN 10217-1: Technical delivery for seamless and welded steel tubes used in pressure services.

- EN ISO 228-1/-2: Designation and tolerances for pipe threads where pressure-tight joints are not made.

These referenced standards ensure harmonization across materials, sealing components, thread specifications, and testing methodologies enhancing the reliability and interoperability of malleable cast iron fittings.

Keywords: malleable cast iron fittings, compression ends, steel pipes, pipe fittings standard, corrosion protection, sealing materials, gas supply piping, water distribution fittings, dismantleable joints, pipe threads, pressure-resistant fittings, testing and performance, CEN standards.

Frequently Asked Questions

prEN 10344 is a draft published by the European Committee for Standardization (CEN). Its full title is "Malleable cast iron fittings with compression ends for steel pipes". This standard covers: This standard specifies the requirements for the design, performance and testing of fittings made of malleable cast iron (see also clause 5 Materials) with compression ends for steel pipes. It applies to steel piping systems for different application fields, such as gas supply, distribution of water for general purposes and for human consumption, irrigation, fire fighting, aqueous liquids, compressed air and gaseous fuel systems. It also applies to oil piping systems, provided the elastomeric sealing material is compatible with the oil and the operating conditions. It contains requirements and tests relating to compression fittings which can be disconnected from smooth walled steel pipes or other cylindrical metal structural elements, which are applicable for dismantleable joints. The fittings can also incorporate other types of connection, such as threaded, flanged, compression ends for connection of polyethylene pipes, etc., and can also take on various structural shapes, such as, straight piece, elbow or T-piece, etc. Their range of sizes covers nominal sizes DN 6 to DN 100 (size 1/8 to 4).

This standard specifies the requirements for the design, performance and testing of fittings made of malleable cast iron (see also clause 5 Materials) with compression ends for steel pipes. It applies to steel piping systems for different application fields, such as gas supply, distribution of water for general purposes and for human consumption, irrigation, fire fighting, aqueous liquids, compressed air and gaseous fuel systems. It also applies to oil piping systems, provided the elastomeric sealing material is compatible with the oil and the operating conditions. It contains requirements and tests relating to compression fittings which can be disconnected from smooth walled steel pipes or other cylindrical metal structural elements, which are applicable for dismantleable joints. The fittings can also incorporate other types of connection, such as threaded, flanged, compression ends for connection of polyethylene pipes, etc., and can also take on various structural shapes, such as, straight piece, elbow or T-piece, etc. Their range of sizes covers nominal sizes DN 6 to DN 100 (size 1/8 to 4).

prEN 10344 is classified under the following ICS (International Classification for Standards) categories: 23.040.10 - Iron and steel pipes; 23.040.40 - Metal fittings. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 10344 is associated with the following European legislation: Standardization Mandates: M/131. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 10344 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI oSIST prEN 10344:2006

PREDSTANDARD

september 2006

Fitingi iz temprane železove litine s prižemnimi priključki za železne cevi

Malleable cast iron fittings with compression ends for steel pipes

ICS 23.040.40 Referenčna številka

© Standard je založil in izdal Slovenski inštitut za standardizacijo. Razmnoževanje ali kopiranje celote ali delov tega dokumenta ni dovoljeno

EUROPEAN STANDARD

DRAFT

NORME EUROPÉENNE

EUROPÄISCHE NORM

June 2006

ICS

English Version

Malleable cast iron fittings with compression ends for steel pipes

Raccords à compression en fonte malléable pour tubes Tempergussfittings mit Klemmanschlüssen für Stahlrohre

d'acier

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee ECISS/TC 29.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the Management Centre has the same

status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,

Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2006 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 10344:2006: E

worldwide for CEN national Members.

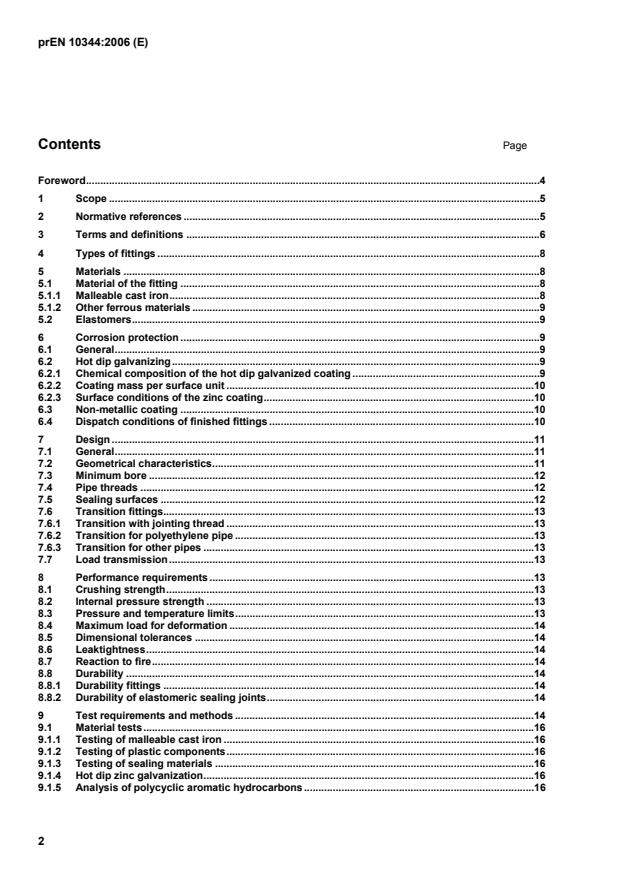

Contents Page

Foreword.4

1 Scope .5

2 Normative references .5

3 Terms and definitions .6

4 Types of fittings .8

5 Materials .8

5.1 Material of the fitting .8

5.1.1 Malleable cast iron.8

5.1.2 Other ferrous materials .9

5.2 Elastomers.9

6 Corrosion protection .9

6.1 General.9

6.2 Hot dip galvanizing.9

6.2.1 Chemical composition of the hot dip galvanized coating .9

6.2.2 Coating mass per surface unit .10

6.2.3 Surface conditions of the zinc coating.10

6.3 Non-metallic coating .10

6.4 Dispatch conditions of finished fittings .10

7 Design .11

7.1 General.11

7.2 Geometrical characteristics.11

7.3 Minimum bore .12

7.4 Pipe threads .12

7.5 Sealing surfaces .12

7.6 Transition fittings.13

7.6.1 Transition with jointing thread .13

7.6.2 Transition for polyethylene pipe .13

7.6.3 Transition for other pipes .13

7.7 Load transmission.13

8 Performance requirements .13

8.1 Crushing strength.13

8.2 Internal pressure strength .13

8.3 Pressure and temperature limits.13

8.4 Maximum load for deformation .14

8.5 Dimensional tolerances .14

8.6 Leaktightness.14

8.7 Reaction to fire.14

8.8 Durability .14

8.8.1 Durability fittings .14

8.8.2 Durability of elastomeric sealing joints.14

9 Test requirements and methods .14

9.1 Material tests.16

9.1.1 Testing of malleable cast iron .16

9.1.2 Testing of plastic components.16

9.1.3 Testing of sealing materials .16

9.1.4 Hot dip zinc galvanization.16

9.1.5 Analysis of polycyclic aromatic hydrocarbons .16

9.2 Component tests .16

9.2.1 Visual inspection .16

9.2.2 Geometrical characteristics .16

9.2.3 Verification of threads.17

9.2.4 Leaktightness of fitting body .17

9.3 Assembly tests .17

9.3.1 Leaktightness under internal pressure .17

9.3.2 Leaktightness under vacuum.17

9.3.3 Leaktightness under pressure cycling.18

9.3.4 Leaktightness under temperature cycling .18

9.3.5 Leaktightness after repeated movements.20

9.3.6 Resistance to pull-out .21

9.3.7 Resistance to vibrations .21

9.3.8 Leaktightness after temperature changes .22

9.3.9 Leaktightness at low temperature after temperature changes.22

10 Evaluation of conformity.23

10.1 General.23

10.2 Type testing.23

10.3 Factory production control by the manufacturer.23

11 Assessment of conformity.23

12 Designation of fittings.24

12.1 Elements of the designation.24

12.2 Additional notes on designation of size.24

12.3 Examples of designation .24

13 Marking .25

Annex A (informative) Quality management system .26

Annex ZA (informative) Clauses of this European Standard addressing the provisions of EU

Construction Products Directive .27

ZA.1 General.27

ZA.2 Procedure for attestation of conformity.28

ZA.2.1 System of attestation of conformity .28

ZA.2.2 EC Declaration of conformity .29

ZA.3 CE marking and labelling.29

Bibliography.31

Foreword

This document (prEN 10344:2006) has been prepared by Technical Committee ECISS/TC 29 “Steel tubes and

fittings for steel tubes”, the secretariat of which is held by UNI.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a mandate given to CEN by the European Commission and the European

Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, B, C or D, which is an integral part of this document.

This standard includes the following annexes :

Annex A (informative) : Quality management system.

Annex ZA (informative) : Clauses of this European Standard addressing the provisions of the EU Construction

Products Directive.

1 Scope

This standard specifies the requirements for the design, performance and testing of malleable cast iron fittings with

compression ends for steel pipes. It applies to steel piping systems for different application fields, such as gas supply,

distribution of water for general purposes and for human consumption, irrigation, fire fighting, aqueous liquids,

compressed air and gaseous fuel systems.

It also applies to oil piping systems, provided the elastomeric sealing material is compatible with the oil and the

operating conditions.

It contains requirements and tests relating to compression fittings which can be disconnected from smooth walled

steel pipes or other cylindrical metal structural elements, which are applicable for dismantleable joints. The fittings

can also incorporate other types of connection, such as threaded, flanged, compression ends for connection of

polyethylene pipes, etc., and can also take on various structural shapes, such as, straight piece, elbow or T-piece,

etc. Their range of sizes covers nominal sizes DN 6 to DN 100 (size 1/8 to 4).

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references,

only the edition cited applies. For undated references, the latest edition of the referenced document (including any

amendments) applies.

EN 549, Rubber materials for seals and diaphragms for gas appliances and gas equipment.

EN 681-1, Elastomeric seals – Material requirements for pipe joint seals used in water and drainage applications –

Part 1 : Vulcanized rubber.

EN 682, Elastomeric seals – Material requirements for joint seals used in pipes and fittings carrying gas and

hydrocarbon fluids.

EN 751-1, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hot water –

Part 1 : Anaerobic jointing compounds.

EN 751-2, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hot water –

Part 2 : Non-hardening jointing compounds.

EN 751-3, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hot water –

Part 3 : Unsintered PTFE tapes.

EN 1562, Founding – Malleable cast irons.

EN 10204, Metallic products – Types of inspection documents.

EN 10208-1, Steel pipes for pipelines for combustible fluids – Technical delivery conditions – Part 1 : Pipes of

requirement class A.

EN 10216-1, Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 1 : Non-alloy steel

tubes with specified room temperature properties.

EN 10217-1, Welded steel tubes for pressure purposes – Technical delivery conditions – Part 1 : Non-alloy steel

tubes with specified room temperature properties.

EN 10226-1, Pipe threads where pressure-tight joints are made on the threads – Part 1 : Taper external threads and

parallel internal threads – Dimensions, tolerances and designation.

EN 10226-2, Pipe threads where pressure-tight joints are made on the threads – Part 2 : Taper external threads and

taper internal threads – Dimensions, tolerances and designation.

EN 10226-3, Pipe threads where pressure-tight joints are made on the threads – Part 3 : Verification by means of

limit gauges.

EN 10255, Non-alloy steel tubes suitable for welding and threading – Technical delivery conditions.

EN 10284, Malleable cast iron fittings with compression ends for polyethylene piping systems.

EN 10305-1, Precision steel tubes – Part 1 : Seamless cold drawn tubes.

EN 10305-2, Precision steel tubes – Part 3 : Welded cold drawn tubes.

EN 10305-3, Precision steel tubes – Part 2 : Welded cold sized tubes.

EN 12294, Plastic piping systems – Systems for hot and cold water – Test method for leaktightness under vacuum.

EN 12295, Plastics piping systems – Thermoplastics pipes and associated fittings for hot and cold water – Test

method for resistance of joints to pressure cycling.

EN 13501-1, Fire classification of construction products and building elements – Part 1 : Classification using test

data from reaction to fire tests.

EN ISO 228-1, Pipe threads where pressure-tight joints are not made on the threads – Part 1 : Designation,

dimensions and tolerances.

EN ISO 228-2, Pipe threads where pressure-tight joints are not made on the threads – Part 2 : Verification by means

of limit gauges.

ISO 1460, Metallic coatings – Hot dip galvanized coatings on ferrous materials – Gravimetric determination of the

mass per unit area.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

generals

3.1.1

fitting

connecting piece for pipes

3.1.2

transition fitting

a fitting jointing different types of pipe and/or comprising different types of outlet

3.1.3

end-load bearing joint

a joint which can resist axial loads without additional external mechanical support

3.1.4

non-load bearing joint

a joint which cannot resist axial loads without additional external mechanical support

3.1.5

fitting size

the nominal size of the connecting steel pipe

NOTE For transition fittings the designation follows the type of the outlet.

3.1.6

fitting body

the main pressure-bearing part a fitting

3.1.7

outlet

end of a fitting which connects with a pipe

3.1.8

run

two principal axially aligned outlets of a tee

3.1.9

branch

side outlet of a tee.

3.1.10

compression end

an end of a fitting in which the joint is made by the compression of components onto the smooth wall pipe to provide

pressure integrity and leaktightness

3.1.11

grip ring

ring that holds the pipes in place and prevents pull out from the joint

3.1.12

minimum bore

smallest internal diameter measured at any cross-section of the assembled fitting

3.1.13

smooth walls

smooth pipe surfaces in the seal and clamping area which are unshaped, undamaged and untreated

NOTE Cleaning and deburring is not regarded as treatment.

3.1.14

dismountibility

ability of a fitting to disconnect and re-assemble the joint without destroying the fitting body and the pipe, except the

components of the jointing system, such as the sealing and compression rings

3.1.15

jointing thread

thread complying with EN 10226-1

3.1.16

fastening thread

thread complying with EN ISO 228-1

3.1.17

component test

test to verify the performance of a fitting carried out on the fitting with or without the internal parts

3.1.18

assembly test

test to verify the fitness for purpose of an assembled fitting with the connecting pipes

3.2

movability

3.2.1

angular deflection

maximum angle α subtended between the axes of the fitting and the connected pipe when the assembly still remains

leak-tight following 2 full deflections by ± α in relation to the starting position (α according to manufacturer's

specifications)

3.2.2

axial movability

axial path within which the fitting remains leak-tight following 2 full path changes by ± a in relation to the starting

position (a = according to manufacturer's specifications)

3.2.3

torsional angle

the maximum angle β within the piece can twist around its axis, when the assembly still remains leak-tight following 2

full twists by ± β in relation to the starting position (β is according to manufacturer's specifications)

3.3

resistance to pull-out

the ability of the joint to withstand axial mechanical forces or applied through internal pressure, while remaining leak-

tight

3.4

pressure and temperature

3.4.1

allowable operating pressure (PFA

the maximum operating pressure of the connected pipe joint(s) in continuous function

3.4.2

allowable operating temperature (TFA)

the maximum operating temperature of the connected pipe joint(s) in continuous function

4 Types of fittings

All types of fittings subject to this standard, provide dismountable joints

5 Materials

5.1 Material of the fitting

5.1.1 Malleable cast iron

The material used for the fitting body shall be malleable cast iron conforming to EN 1562. The grade of material used

shall be selected from the following grades :

grade EN-GJMW-400-5 or EN-GJMB-350-10 for fittings in white heart malleable iron ;

grade EN-GJMW-350-4 or EN-GJMB-300-6 for fittings in black heart malleable iron.

Fittings shall be identified by material symbols according to the selected material mentioned above and as given in

Table 1.

Table 1 — Material symbols

Material symbol Material grade

EN-GJMW-400-5 or

A

EN-GJMB-350-10

EN-GJMW-350-4 or

B

EN-GJMB-300-6

5.1.2 Other ferrous materials

Notwithstanding this requirement, any other ferrous materials which give mechanical properties at least equivalent to

those malleable cast irons specified above will be allowed.

5.2 Elastomers

The material of elastomeric sealing rings used in fittings shall be chosen for drinking water application from EN 681-

1 and for gas supply EN 682, respectively EN 549, depending on the specific application and shall conform to the

appropriate class respectively type. For applications in cold geographic areas the minimum design temperature is –

20 °C (see Table 3) and the test requirements specified in 9.3.5 and 9.3.6 are to be considered.

6 Corrosion protection

6.1 General

In applications where materials are susceptible to corrosion, the components shall be adequately protected.

6.2 Hot dip galvanizing

Where a protection by zinc coating is required, the zinc coating shall be applied by the hot dip galvanizing process

and shall meet the following requirements.

NOTE For fittings supplied in other ferrous materials (see 5.1.2) alternative zinc coating may be provided by agreement with

the purchaser.

6.2.1 Chemical composition of the hot dip galvanized coating

The content by mass of the accompanying elements in the finished zinc coating shall not exceed the following

maximum values :

antimony (Sb) 0,01 % ;

arsenic (As) 0,02 % ;

bismuth (Bi) 0,01 % ;

cadmium (Cd) 0,01 % ;

lead (Pb) 1,6 % in individual cases 1,8 %.

For drinking water applications the lead content shall be less than stated above, in order not to exceed the limit

specified in the Drinking Water Directive 98/83/EC.

6.2.2 Coating mass per surface unit

The areic mass of the zinc coating shall be not less than 500 g/m , as an average of 5 fittings. This corresponds to a

medium layer thickness of 70 µm.

It shall be not less than 450 g/m (63 µm) when it is measured on an individual sample.

The medium layer thickness s of the zinc coating in µm may be calculated by using the approximation formula :

m

A

s=

7.2

where

m is the surface related mass of the zinc coating in g/m .

A

6.2.3 Surface conditions of the zinc coating

The zinc coating on the internal surface of the fitting shall be continuous with the exception of machined black

surfaces. In the special case of larger material cross-sections the iron-zinc alloy phases may grow through. The

internal zinc coating shall be free from zinc blisters, zinc burrs, non-metallic remainders.

6.3 Non-metallic coating

Depending on external and internal conditions of use, also non-metallic coatings may be used, for example plastic

coatings, if they are accepted by the purchaser.

6.4 Dispatch conditions of finished fittings

The surface of the fitting shall be free of polycyclic aromatic hydrocarbons.

7 Design

7.1 General

The steel pipes to which the fitting is connectable, shall be defined by the manufacturer, but shall be in accordance

with minimum one of the following standards.

EN 10255 ;

EN 10208-1 ;

EN 10216-1 outside diameters series 1 ;

EN 10217-1 outside diameters series 1 ;

EN 10305-1 ;

EN 10305-2 ;

EN 10305-3.

If special mechanical assembly tools are required, they shall be made available and they shall have sufficiently large

bearing surfaces to avoid causing visible deformation during assembly.

7.2 Geometrical characteristics

Fittings according to this standard shall be designed for steel pipe diameters and jointing threads as specified in

Table 2

Table 2 — Pipe diameters, corresponding thread sizes and nominal diameters

Specified outside Nominal Diameter Size of jointing thread

diameter of pipe

mm DN

10,2 6 1/8

13,5 8 1/4

17,2 10 3/8

21,3 15 1/2

26,9 20 3/4

33,7 25 1

42,4 32 1 1/4

48,3 40 1 1/2

60,3 50 2

76,1 65 2 1/2

88,9 80 3

114,3 100 4

The dimensions and tolerances of the fitting and its possible components shall be designed for the connecting pipe in

such a way that the joint remains permanently tight when stresses arise under service load.

7.3 Minimum bore

The minimum bore is given by the manufacturer.

7.4 Pipe threads

Jointing threads on transition fittings shall be in accordance EN 10226-1 or EN 10226-2.

Fastening threads of outlets shall be in accordance with EN ISO 228-1.

NOTE Mating threads on pre-assembled components are left to the discretion of the manufacturers.

7.5 Sealing surfaces

The sealing surfaces shall be free of all scratches, blisters or cracks that might affect the leaktightness of the

assembled joint.

Those contact surfaces that are rendered tight by means of an elastomeric seal shall be smooth.

No component of the fitting shall show any signs of damage, scratches, pitting, bubbles, blisters, inclusions or cracks

to an extent that would prevent compliance with this standard. They shall not be impregnated to cover such defects.

7.6 Transition fittings

7.6.1 Transition with jointing thread

Jointing threads on transition fittings shall be in accordance with EN 10226-1 or EN 10226-2.

7.6.2 Transition for polyethylene pipe

Compression ends for the connection of polyethylene pipes shall be in conformance with EN 10284.

7.6.3 Transition for other pipes

Compression ends for the connection of pipes in other materials shall be in conformance with the relevant standard.

7.7 Load transmission

Compression ends fittings need to be end-load-bearing, however they can be also of non-end-load-bearing type for

certain applications. In this case they need additional mechanical fixations to transmit axial forces.

8 Performance requirements

8.1 Crushing strength

The crushing strength of the fittings is deemed to be satisfied if the malleable iron of the fitting body fulfil the test

requirements of 9.1.1.

8.2 Internal pressure strength

The internal pressure strength of the fittings shall be declared by the manufacturer as allowable operating pressure

PFA in bar following 8.3. The fittings shall be designed for the declared PFA and tested according to 9.3.

8.3 Pressure and temperature limits

The fittings shall be designed for the pressure and temperature limits in continuous service as specified in Table 3

and shall be tight under these operating conditions when they are joint to pipes.

Table 3 — Performance requirements

Application field Gas Pressurised Aqueous

Air liquids

Allowable operating

pressure PFA

5, 10 or 16 6 or 10 6, 10 or 16

bar

Allowable operating

temperature TFA

- 5* - 70 - 5* - 70 5 - 80

Min./max. °C

* -20 °C for application in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...