EN 16479:2023

(Main)Water quality - Performance requirements and conformity test procedures for water monitoring equipment - Automatic sampling devices (samplers) for water and waste water

Water quality - Performance requirements and conformity test procedures for water monitoring equipment - Automatic sampling devices (samplers) for water and waste water

This document specifies general requirements, performance requirements and conformity test procedures for automatic sampling devices (samplers) for water and waste water that:

— sample water and waste water from non-pressurized (i.e. open to atmosphere) channels or vessels;

— sample over extended periods to collect discrete or composite samples based on time, event or flow proportional sampling.

It does not include sampling systems built into online and in-line analysers.

The general requirements include functional facilities that samplers need to meet users’ applications and information that needs to be included in associated documents.

The test procedures specify uniform methods to be used when determining key performance characteristics of samplers at one or more set sample volume. It is for the sampler manufacturer and/or user to decide on the required set sample volume(s). All of the test procedures are to be carried out under laboratory conditions. It is recognized that for some samplers, certain test procedures are not applicable.

Statistical procedures are specified for evaluation of the test data. Some example calculations are provided.

Specific sample integrity requirements are specified for samplers to be used for the collection of samples of final effluent or influent for the purpose of monitoring the performance of urban waste water treatment works. Samplers to be used for other industrial applications do not need to be assessed against these specific sample integrity requirements.

This document does not cover the installation and on-going use of samplers.

Wasserbeschaffenheit - Leistungsanforderungen und Konformitätsprüfungen für Geräte zum Wassermonitoring - Automatische Probenahmegeräte für Wasser und Abwasser

Dieses Dokument legt allgemeine Anforderungen, Leistungsanforderungen und Verfahrensweisen für die Konformitätsprüfung von automatischen Probenahmegeräten für Wasser und Abwasser fest, die:

für die Probenahme von Wasser und Abwasser aus nicht unter Druck stehenden (d. h. nach oben offen) Gerinnen oder Becken bestimmt sind;

für die Probenahme über einen längeren Zeitraum zum Sammeln von Einzelproben oder Mischproben beruhend auf der zeit-, ereignis- oder durchflussproportionalen Probenahme bestimmt sind.

Es berücksichtigt nicht die in Online- und Inline-Analysatoren eingebauten Probenahmesysteme.

Die allgemeinen Anforderungen umfassen funktionelle Einrichtungen, die Probennahmegeräte benötigen, um den Anwendungen der Benutzer zu entsprechen, sowie Informationen, die in den zugehörigen Dokumenten enthalten sein müssen.

Die Prüfverfahren legen einheitliche Methoden fest, die bei der Bestimmung der wichtigsten Leistungsmerkmale von Probennahmegeräten bei einem oder mehreren festgelegten Probenahmevolumen anzuwenden sind. Durch den Hersteller des Probennahmegeräts und/oder dem Anwender ist das Probenvolumen festzulegen. Es wird erwartet, dass alle Prüfverfahren unter Laborbedingungen durchgeführt werden. Es wird anerkannt, dass für einige Probennahmegeräte bestimmte Prüfverfahren nicht anwendbar sind.

Es werden statistische Verfahren für die Auswertung der Prüfdaten festgelegt. Es werden einige Beispielrechnungen angegeben.

Es werden spezifische Anforderungen zur Probenintegrität für Probenahmegeräte festgelegt, die zum Sammeln von Proben an der Ablauf- oder der Zulaufstelle verwendet werden, um die Leistung von kommunalen Abwasserbehandlungsanlagen zu überwachen. Probenahmegeräte die für andere industrielle Zwecke verwendet werden, brauchen nicht im Hinblick auf diese spezifischen Anforderungen zur Probenintegrität beurteilt werden.

Dieses Dokument beschreibt nicht den Installationsvorgang und den praktischen Umgang mit automatischen Probenahmegeräten.

Qualité de l'eau - Exigences de performance et modes opératoires d'essai de conformité pour les équipements de surveillance de l'eau - Dispositifs d'échantillonnage automatiques (échantillonneurs) pour l'eau et les eaux usées

Le présent document spécifie les exigences générales, les exigences de performance et les modes opératoires d'essai de conformité des dispositifs d'échantillonnage automatiques (échantillonneurs) pour l'eau et les eaux usées qui :

— échantillonnent l'eau et les eaux usées à partir de canaux ou de récipients non pressurisés (c'est à dire ouverts à l'atmosphère) ;

— effectuent des échantillonnages sur des périodes prolongées afin de prélever des échantillons discrets ou composites basés sur l'échantillonnage proportionnel au temps, à l'événement ou au débit.

Il n'inclut pas les systèmes d'échantillonnage intégrés aux analyseurs en ligne, avec ou sans boucle de prélèvement.

Les exigences générales comprennent les installations fonctionnelles dont les échantillonneurs ont besoin pour répondre aux besoins des utilisateurs pour leurs applications, ainsi que les informations qui doivent être incluses dans les documents associés.

Les modes opératoires d'essai spécifient les méthodes uniformes à utiliser pour déterminer les caractéristiques de performance clés des échantillonneurs, pour un ou plusieurs volume(s) unitaire(s) défini(s). C'est au fabricant de l'échantillonneur et/ou à l'utilisateur de décider du ou des volume(s) unitaire(s) défini(s) requis. Tous les modes opératoires d'essai doivent être réalisés en conditions de laboratoire. Il est reconnu que pour certains échantillonneurs, certains modes opératoires d'essai ne sont pas applicables.

Des procédures statistiques sont spécifiées pour l'évaluation des données d'essai. Des exemples de calculs sont fournis.

Les exigences spécifiques sur l'intégrité de l'échantillon sont spécifiées pour les échantillonneurs à utiliser pour prélever des échantillons d'effluent ou d'affluent final en vue de surveiller les performances des installations de traitement des eaux résiduaires urbaines. Il n'est pas nécessaire d'évaluer les échantillonneurs à utiliser pour d'autres applications industrielles par rapport à ces exigences spécifiques d'intégrité de l'échantillon.

Le présent document ne couvre pas l'installation et l'utilisation courante des échantillonneurs.

Kakovost vode - Zahteve za zmogljivost in postopki preskušanja skladnosti opreme za monitoring vode - Avtomatski vzorčevalniki za vodo in odpadno vodo

Evropski standard določa splošne zahteve, zahteve za zmogljivost in postopke skladnosti za avtomatske vzorčevalnike za vodo in odpadno vodo, ki:

– - zbirajo vodo in odpadno vodo iz kanalov ali vsebnikov, ki niso pod tlakom (tj. so v stiku z atmosfero);

– zbirajo v daljšem časovnem obdobju, da se zberejo ločeni ali sestavljeni vzorci, ki temeljijo na vzorčenju po času, dogodku ali sorazmernosti s pretokom.

Za vzorčevalnike, ki se uporabljajo za zbiranje vzorcev končnega odtoka ali vtoka za spremljanje delovanja čistilnih naprav za odpadno vodo, so določene zahteve glede stabilnosti vzorcev, kot zahteva Direktiva o čiščenju komunalne odpadne vode. Vzorčevalnikov, ki se uporabljajo za druge industrijske namene, ni treba oceniti glede na te določene zahteve glede stabilnosti vzorcev.

Ta evropski standard ne obravnava namestitve in stalne uporabe vzorčevalnikov.

General Information

- Status

- Published

- Publication Date

- 04-Apr-2023

- Technical Committee

- CEN/TC 230 - Water analysis

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 05-Apr-2023

- Due Date

- 10-Feb-2023

- Completion Date

- 05-Apr-2023

Relations

- Effective Date

- 18-Jan-2023

Overview

EN 16479:2023 (CEN) is the European product standard for automatic sampling devices (samplers) used in water quality and waste water monitoring. It specifies general and performance requirements plus laboratory conformity test procedures for samplers that:

- collect discrete or composite samples from non‑pressurized (open to atmosphere) channels or vessels, and

- operate over extended periods using time-, event- or flow‑proportional sampling.

The standard excludes sampling systems built into online or in‑line analysers. It replaces EN 16479:2014 and was prepared by CEN/TC 230 “Water analysis”.

Key topics and requirements

- General requirements: functional features samplers must provide and required information to be supplied with the device (documentation and user information).

- Performance requirements: capability to collect accurate, repeatable samples; the manufacturer/user selects the “set sample volume” for testing.

- Conformity test procedures (laboratory conditions): uniform methods to evaluate key characteristics, including:

- Collected sample volume (accuracy and repeatability)

- Sampling principles (time, flow, event proportional modes)

- Sample line velocity

- Power supply performance (mains, DC/battery conditions)

- Sample integrity (specific requirements for samplers used to monitor urban waste water treatment works influent/final effluent)

- Sampler timing error

- Effect of ambient air temperature (including samplers with and without temperature control)

- Statistical evaluation: defined statistical procedures (e.g., ANOVA and example calculations in annexes) for interpreting conformity test data and assessing compliance.

Applications and who uses it

EN 16479:2023 is used by:

- Sampler manufacturers - for design validation, type testing and technical documentation to demonstrate conformity and performance claims.

- Water and wastewater utilities - when procuring samplers for regulatory monitoring and plant performance assessment.

- Environmental laboratories and test houses - to perform standardized laboratory conformity testing and create reproducible reports.

- Regulators and consultants - to specify minimum performance and sampling integrity requirements in monitoring programs. Practical uses include procurement specifications, acceptance testing, routine verification, and assurance of sample representativity for compliance monitoring.

Related standards

- Supersedes EN 16479:2014.

- Prepared by CEN/TC 230; users should consult CEN national bodies for related water analysis and monitoring standards and for the full official text of EN 16479:2023.

For implementation, refer to the full EN 16479:2023 for test methods, annex examples, and reporting formats to ensure compliance and consistent, SEO-relevant alignment with terms like “automatic sampling devices”, “water quality”, “conformity test procedures”, and “sample integrity”.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 16479:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Water quality - Performance requirements and conformity test procedures for water monitoring equipment - Automatic sampling devices (samplers) for water and waste water". This standard covers: This document specifies general requirements, performance requirements and conformity test procedures for automatic sampling devices (samplers) for water and waste water that: — sample water and waste water from non-pressurized (i.e. open to atmosphere) channels or vessels; — sample over extended periods to collect discrete or composite samples based on time, event or flow proportional sampling. It does not include sampling systems built into online and in-line analysers. The general requirements include functional facilities that samplers need to meet users’ applications and information that needs to be included in associated documents. The test procedures specify uniform methods to be used when determining key performance characteristics of samplers at one or more set sample volume. It is for the sampler manufacturer and/or user to decide on the required set sample volume(s). All of the test procedures are to be carried out under laboratory conditions. It is recognized that for some samplers, certain test procedures are not applicable. Statistical procedures are specified for evaluation of the test data. Some example calculations are provided. Specific sample integrity requirements are specified for samplers to be used for the collection of samples of final effluent or influent for the purpose of monitoring the performance of urban waste water treatment works. Samplers to be used for other industrial applications do not need to be assessed against these specific sample integrity requirements. This document does not cover the installation and on-going use of samplers.

This document specifies general requirements, performance requirements and conformity test procedures for automatic sampling devices (samplers) for water and waste water that: — sample water and waste water from non-pressurized (i.e. open to atmosphere) channels or vessels; — sample over extended periods to collect discrete or composite samples based on time, event or flow proportional sampling. It does not include sampling systems built into online and in-line analysers. The general requirements include functional facilities that samplers need to meet users’ applications and information that needs to be included in associated documents. The test procedures specify uniform methods to be used when determining key performance characteristics of samplers at one or more set sample volume. It is for the sampler manufacturer and/or user to decide on the required set sample volume(s). All of the test procedures are to be carried out under laboratory conditions. It is recognized that for some samplers, certain test procedures are not applicable. Statistical procedures are specified for evaluation of the test data. Some example calculations are provided. Specific sample integrity requirements are specified for samplers to be used for the collection of samples of final effluent or influent for the purpose of monitoring the performance of urban waste water treatment works. Samplers to be used for other industrial applications do not need to be assessed against these specific sample integrity requirements. This document does not cover the installation and on-going use of samplers.

EN 16479:2023 is classified under the following ICS (International Classification for Standards) categories: 13.060.45 - Examination of water in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16479:2023 has the following relationships with other standards: It is inter standard links to EN 16479:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16479:2023 is associated with the following European legislation: EU Directives/Regulations: 2000/60/EC, 91/271/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16479:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2023

Nadomešča:

SIST EN 16479:2014

Kakovost vode - Zahteve za zmogljivost in postopki preskušanja skladnosti

opreme za monitoring vode - Avtomatski vzorčevalniki za vodo in odpadno vodo

Water quality - Performance requirements and conformity test procedures for water

monitoring equipment - Automated sampling devices (samplers) for water and waste

water

Wasserbeschaffenheit - Leistungsanforderungen und Konformitätsprüfungen für Geräte

zum Wassermonitoring - Automatische Probenahmegeräte für Wasser und Abwasser

Qualité de l'eau - Exigences de performance et modes opératoires d'essai de conformité

pour les équipements de surveillance de l'eau - Dispositifs d'échantillonnage

automatiques (échantillonneurs) pour l'eau et les eaux usées

Ta slovenski standard je istoveten z: EN 16479:2023

ICS:

13.060.45 Preiskava vode na splošno Examination of water in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16479

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2023

EUROPÄISCHE NORM

ICS 13.060.45 Supersedes EN 16479:2014

English Version

Water quality - Performance requirements and conformity

test procedures for water monitoring equipment -

Automatic sampling devices (samplers) for water and

waste water

Qualité de l'eau - Exigences de performance et modes Wasserbeschaffenheit - Leistungsanforderungen und

opératoires d'essai de conformité pour les Konformitätsprüfungen für Geräte zum

équipements de surveillance de l'eau - Dispositifs Wassermonitoring - Automatische Probenahmegeräte

d'échantillonnage automatiques (échantillonneurs) für Wasser und Abwasser

pour l'eau et les eaux usées

This European Standard was approved by CEN on 27 February 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16479:2023 E

worldwide for CEN national Members.

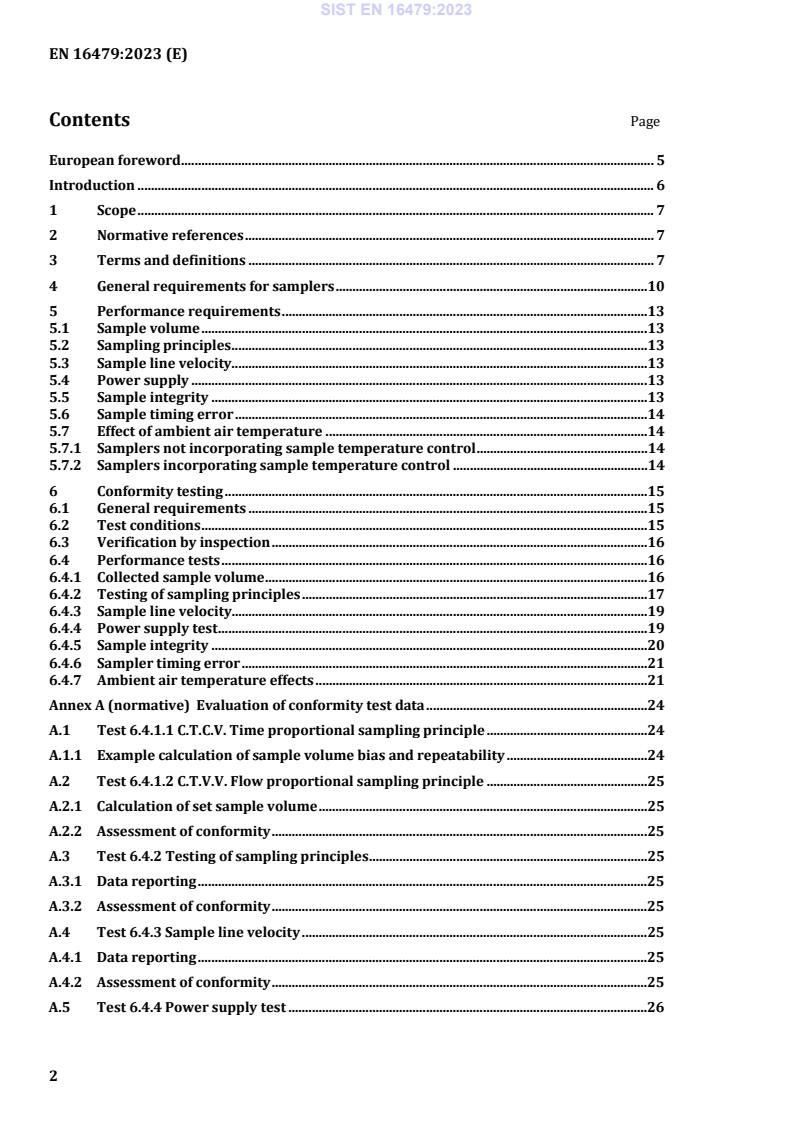

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 General requirements for samplers .10

5 Performance requirements .13

5.1 Sample volume .13

5.2 Sampling principles .13

5.3 Sample line velocity.13

5.4 Power supply .13

5.5 Sample integrity .13

5.6 Sample timing error .14

5.7 Effect of ambient air temperature .14

5.7.1 Samplers not incorporating sample temperature control .14

5.7.2 Samplers incorporating sample temperature control .14

6 Conformity testing .15

6.1 General requirements .15

6.2 Test conditions .15

6.3 Verification by inspection .16

6.4 Performance tests .16

6.4.1 Collected sample volume .16

6.4.2 Testing of sampling principles .17

6.4.3 Sample line velocity.19

6.4.4 Power supply test .19

6.4.5 Sample integrity .20

6.4.6 Sampler timing error .21

6.4.7 Ambient air temperature effects .21

Annex A (normative) Evaluation of conformity test data .24

A.1 Test 6.4.1.1 C.T.C.V. Time proportional sampling principle .24

A.1.1 Example calculation of sample volume bias and repeatability .24

A.2 Test 6.4.1.2 C.T.V.V. Flow proportional sampling principle .25

A.2.1 Calculation of set sample volume .25

A.2.2 Assessment of conformity .25

A.3 Test 6.4.2 Testing of sampling principles .25

A.3.1 Data reporting .25

A.3.2 Assessment of conformity .25

A.4 Test 6.4.3 Sample line velocity .25

A.4.1 Data reporting .25

A.4.2 Assessment of conformity .25

A.5 Test 6.4.4 Power supply test .26

A.5.1 Test 6.4.4.1 Data reporting . 26

A.5.2 Assessment of conformity . 26

A.5.3 Test 6.4.4.2 Data reporting . 26

A.5.4 Assessment of conformity . 26

A.6 Test 6.4.5 Sample integrity. 26

A.6.1 Calculation of results based on the analysis of variance . 26

A.6.2 Notation . 26

A.6.3 Calculations . 27

A.6.4 Interpretation of the results . 28

A.7 Test 6.4.6 Sampler timing error . 28

A.7.1 Calculation of elapsed time, timing error and normalization of timing error . 28

A.7.2 Assessment of conformity . 28

A.8 Test 6.4.7 Ambient air temperature effects . 29

A.8.1 Test 6.4.7.2 Volumetric test . 29

A.8.2 Assessment of conformity . 29

A.8.3 Test 6.4.7.3 Sample temperature control . 29

Annex B (informative) Example calculations . 30

B.1 General . 30

B.2 Test 6.4.1.1 C.T.C.V. Time proportional sampling principle. 30

B.2.1 Calculation of sample volume bias and repeatability . 30

B.2.2 Assessment of conformity . 32

B.3 Test 6.4.1.2 C.T.V.V. flow proportional sampling principle . 32

B.3.1 Calculation of sample volume bias and repeatability . 32

B.3.2 Assessment of conformity . 34

B.4 Tests 6.4.2 Sampling principles . 34

B.4.1 Test 6.4.2.2 C.T.C.V. sampling principle . 34

B.4.2 Test 6.4.2.3 C.V.V.T. sampling principle (impulse flow signal) . 35

B.4.3 Test 6.4.2.4 C.V.V.T. sampling principle (analogue flow signal) . 35

B.4.4 Test 6.4.2.5 event triggered sampling . 36

B.5 Test 6.4.3 Sample line velocity . 36

B.5.1 Data reporting . 36

B.5.2 Assessment of conformity . 37

B.6 Test 6.4.4 Power supply test . 37

B.6.1 Test 6.4.4.1 mains supply samplers . 37

B.6.2 Test 6.4.4.2 DC and battery powered samplers . 39

B.7 Test 6.4.5 Sample integrity. 40

B.7.1 Data reporting, intermediate calculations and an ANOVA calculation.40

B.7.2 Assessment of conformity .41

B.8 Test 6.4.6 Sampler timing error .42

B.8.1 Data reporting .42

B.8.2 Calculation of elapsed time, timing error and normalization of timing error .42

B.8.3 Assessment of conformity .42

B.9 Ambient air temperature effects .42

B.9.1 Volumetric test 6.4.7.2 .42

B.9.2 Sample temperature control test 6.4.7.3 .44

Annex C (informative) Example procedure for demonstrating sample integrity for samplers

to be used for monitoring the performance of urban waste water treatment works 45

C.1 General .45

C.2 Waste water .45

C.3 Sample collection .46

C.4 Sample volume .46

C.5 Sample integrity .46

C.6 Determination of conformance .46

Annex D (informative) Example format for the report .47

Bibliography .49

European foreword

This document (EN 16479:2023) has been prepared by Technical Committee CEN/TC 230 “Water

analysis”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2023, and conflicting national standards shall

be withdrawn at the latest by October 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 16479:2014.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is a product standard for automatic sampling devices (samplers) for water and waste

water. It specifies general requirements, performance requirements, and procedures for the conformity

testing of samplers.

The general requirements include functional facilities that samplers need to meet users’ applications and

information that needs to be included in associated documents. Conformity with these requirements is

verified by inspection. The performance requirements define the capability of a sampler to collect

samples of water reliably. Conformity with these requirements is determined by testing carried out in a

laboratory under controlled conditions. Statistical procedures are defined for evaluation of the

conformity test data and some example calculations are provided.

The sample volume over which the test procedures will be applied, the “set sample volume”, is not

specified. It is for the sampler manufacturer and/or the user to decide on the required set sample volume

taking into account varying national commercial markets and regulatory requirements.

These requirements and statistical procedures take into account those specified in ISO 5667-10:2020 [1]

for automatic samplers. Samplers that are shown, by means of the tests, to conform to the requirements

specified in this document are considered to be fit for purpose. However, this document does not cover

the installation and on-going use of samplers.

This document is associated with EN 17075 [2] which covers measuring devices for water and waste

water.

Automatic sampling devices are widely used for compliance monitoring purposes under national and

European regulations.

The use of an automatic sampling device, for example in a hazardous environment, can also be subject to

national, European and international rules and legislation governing the safety of products.

1 Scope

This document specifies general requirements, performance requirements and conformity test

procedures for automatic sampling devices (samplers) for water and waste water that:

— sample water and waste water from non-pressurized (i.e. open to atmosphere) channels or vessels;

— sample over extended periods to collect discrete or composite samples based on time, event or flow

proportional sampling.

It does not include sampling systems built into online and in-line analysers.

The general requirements include functional facilities that samplers need to meet users’ applications and

information that needs to be included in associated documents.

The test procedures specify uniform methods to be used when determining key performance

characteristics of samplers at one or more set sample volume. It is for the sampler manufacturer and/or

user to decide on the required set sample volume(s). All of the test procedures are to be carried out under

laboratory conditions. It is recognized that for some samplers, certain test procedures are not applicable.

Statistical procedures are specified for evaluation of the test data. Some example calculations are

provided.

Specific sample integrity requirements are specified for samplers to be used for the collection of samples

of final effluent or influent for the purpose of monitoring the performance of urban waste water

treatment works. Samplers to be used for other industrial applications do not need to be assessed against

these specific sample integrity requirements.

This document does not cover the installation and on-going use of samplers.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

automatic sampling device for water and waste water

automatic sampler

equipment for collecting and storing samples of water or waste water for subsequent laboratory analysis

3.2

bias

estimate of a systematic measurement error

Note 1 to entry: The systematic measurement error is a component of measurement error that in replicate

measurements remains constant or varies in a predictable manner.

[SOURCE: ISO/IEC Guide 99:2007, 2.18, modified — Note 1 to entry has been added.] [4]

3.3

composite sample

two or more samples or sub-samples, mixed together in appropriate known proportions (either

discretely or continuously), from which the average value of a desired characteristic may be obtained

Note 1 to entry: The proportions are usually based on time or flow measurements.

[SOURCE: ISO 6107:2021, 3.126] [5]

3.4

constant volume variable time sampling

C.V.V.T

flow proportional sampling based on collecting equal volumes of sample at frequencies proportional to

flow

3.5

constant time variable volume sampling

C.T.V.V

flow proportional sampling based on collecting samples at fixed time intervals but where the volume of

sample is varied in proportion to the flow

3.6

constant time constant volume sampling

C.T.C.V

equal volumes of sample or sub-sample collected at equal increments of time

3.7

determinand

property/substance that is required to be measured and to be reflected by/present in a calibration

solution

[SOURCE: EN ISO 15839:2006, 3.13] [6]

3.8

discrete sample

single sample taken from a body of water

[SOURCE: ISO 6107:2021, 3.183, modified — “process, whereby” deleted] [5]

3.9

measurement error

error of measurement

error

measured quantity value minus a reference quantity value

Note 1 to entry: The concept of “measurement error” can be used both:

a) when there is a single reference quantity value to refer to, which occurs if a calibration is made by means of

a measurement standard with a measured quantity value having a negligible measurement uncertainty or if a

conventional quantity value is given, in which case the measurement error is known; and

b) if a measurand is supposed to be represented by a unique true quantity value or a set of true quantity values

of negligible range, in which case the measurement error is not known.

Note 2 to entry: “Measurement error” is not to be confused with production error or mistake.

[SOURCE: ISO/IEC Guide 99:2007, 2.16] [4]

3.10

rated operating conditions

minimum to maximum values of any environmental, fluid or electrical parameter within which the

sampler is designed to operate without adjustment and with errors within performance limits

3.11

lift height

vertical distance between the surface of the water being sampled and the highest point to which the

sample is lifted

Note 1 to entry: Sometimes called “sampling head” or “suction height”.

Note 2 to entry: The maximum lift height for samplers using vacuum pumps (e.g. pneumatic samplers and

peristaltic samplers) is set to an atmospheric pressure of 1 000 mbar. At low atmospheric pressure the maximum

lift height will be consequentially lower.

3.12

measurement repeatability

repeatability

measurement precision under a set of repeatability conditions of measurement

[SOURCE: ISO/IEC Guide 99:2007, 2.21] [4]

3.13

repeatability condition of measurement

repeatability condition

condition of measurement, out of a set of conditions that includes the same measurement procedure,

same operators, same measuring system, same operating conditions and same location, and replicate

measurements on the same or similar objects over a short period of time

Note 1 to entry: A condition of measurement is a repeatability condition only with respect to a specified set of

repeatability conditions.

Note 2 to entry: In chemistry, the term “intra-serial precision condition of measurement” is sometimes used to

designate this concept.

[SOURCE: ISO/IEC Guide 99:2007, 2.20] [4]

3.14

precision

closeness of agreement between indications or measured quantity values obtained by replicate

measurements on the same or similar objects under specified conditions

Note 1 to entry: Measurement precision is usually expressed numerically by measures of imprecision, such as

standard deviation, variance, or coefficient of variation under specified conditions of measurement.

Note 2 to entry: The “specified conditions” can be, for example, repeatability conditions of measurement,

intermediate precision conditions of measurement, or reproducibility conditions of measurement (see

ISO 5725-3:1994).

Note 3 to entry: Measurement precision is used to define measurement repeatability, intermediate measurement

precision, and measurement reproducibility.

Note 4 to entry: Sometimes “measurement precision” is erroneously used to mean measurement accuracy.

[SOURCE: ISO/IEC Guide 99:2007 [4], 2.15] [4]

3.15

sampling interval

time between successive sampling events

3.16

sampling line

conduit from intake point to inlet of dosing system

[SOURCE: ISO 6107:2021, 3.494, modified — “sampling probe” was replaced by “intake point” and

delivery point was replaced by “inlet of dosing system”] [5]

4 General requirements for samplers

See 6.3 for details on verification by inspection.

A sampler shall:

a) have a unique designation that unambiguously identifies it (e.g. model, serial number);

b) be designed (including its operating methodology) and constructed to ensure that the composition

of the sample is, as far as is practicable, not altered by the sampling procedure;

It can be impracticable to prevent the loss of volatile substances during sampling with vacuum and

peristaltic samplers.

c) have a rated maximum lift height at which all of the performance requirements of this document are

fulfilled. The rated maximum lift height shall be inscribed on the sampler or declared in the operating

manual published by the manufacturer;

Conformity testing of the sampler shall be based on a range of lift heights up to and including the

sampler’s rated maximum lift height.

d) have provision for the user to set the volume of a discrete sample;

e) have rated minimum and maximum set sample volumes of a discrete sample inscribed on the

sampler or declared in the operating manual published by the manufacturer;

f) have the stated capacities, for any integrated sample storage, both by number(s) and volume(s) of

individual bottles and of a composite container, inscribed on the sampler or declared in the operating

manual published by the manufacturer;

g) be capable of collecting a series of samples, on a timed, event and/or a flow proportional basis.

Samples can be collected and stored in individual bottles or a single composite sample bottle;

h) have its possible sampling intervals inscribed on the sampler or declared in the operating manual

published by the manufacturer;

i) have provision for the user to set the sample interval as a minimum in the range 5 min to 1 h with

increments of 1 min, for time proportional samplers;

j) have provision for the sample interval (in the case of C.V.V.T. sampling) or the sample volume (in the

case of C.T.V.V. sampling) to be set on the basis of a flow signal (e.g. pulse or analogue) from a flow

meter. For pulse inputs, the relationship between pulse input and sample interval or volume should

be adjustable as a minimum over the range 1 pulse to 999 pulses in increments of 1 pulse;

k) have a control unit capable of recording sample collection failures;

l) have a control unit capable of recording any low battery alarm during sample collection;

m) be designed to minimize the possibility of clogging of the sample line by suspended solids in waste

water. The nominal internal diameter of the sample line shall be not less than 9 mm and the average

sample line velocity shall not be less than 0,5 m/s. The sampler shall be capable of achieving this

average sample line velocity at all lift heights up to and including its maximum rated lift height at all

rated operating voltages.

The requirement on sample line diameter excludes pipe restriction caused by the normal operation of

pinch valves and peristaltic pumps.

National legal requirements can specify different minimum values for internal sample line diameter and

average sample line velocity. These can need to be taken into account.

n) be capable of purging the contents of the sampling line between each sampling event;

o) have stated ingress protection (IP) rating inscribed on the sampler or stated in the operating manual;

Requirements for ingress protection are detailed in EN 60529:1991 [7].

p) have a rated sample water and/or waste water temperature range of at least +1 °C to +25 °C at which

all of the performance requirements of this document are met. The rated temperature range shall be

inscribed on the sampler or declared in the operating manual published by the manufacturer;

q) have rated minimum and maximum voltages at which all of the performance requirements of this

document that are relevant to the sampler are met. The rated minimum and maximum operating

voltages shall be inscribed on the sampler or declared in the operating manual published by the

manufacturer.

The possible sampling options are illustrated in Figure 1.

Key

Q discharge

t time

a) flow rate curve

b) C.T.C.V. time proportional sampling

c) C.V.V.T. flow proportional sampling

d) C.T.V.V. flow proportional sampling

Figure 1 — Sampling options

5 Performance requirements

5.1 Sample volume

The bias of the collected sample volume shall not be greater than 5 % of the set volume over the tested

range for lift height.

The repeatability of the collected sample volume for set volumes greater than 100 ml shall not be greater

than 2,5 %, expressed as the repeatability variation coefficient, for the set volume over the tested range

for lift height.

The repeatability of the collected sample volume for set volumes less than or equal to 100 ml shall not be

greater than 4,0 %, expressed as the repeatability variation coefficient, for the set volume over the tested

range for lift height.

NOTE 1 The repeatability variation coefficient is expressed as the relative standard deviation.

NOTE 2 Details of how to calculate bias and repeatability are given in Annex A. Example calculations are detailed

in Annex B.

5.2 Sampling principles

See conformity tests 6.4.2.2, 6.4.2.3, 6.4.2.4 and 6.4.2.5.

The performance of the sampling principle shall be tested and the results reported. The timing error for

each operating principle shall not be greater than 1 %.

Event triggered timing error

The sampler shall start sample extraction, unless it is already doing so, within 10 s of a trigger signal

being received from an external input.

5.3 Sample line velocity

See conformity test 6.4.3.

The mean velocity of the sample water as it passes through the sample line during the sampling event

shall not be less than 0,5 m/s at each tested lift height and at the rated voltage for the power supply.

NOTE An example calculation of sample line velocity is given in Annex B.

National legal requirements can specify different minimum values for internal sample line diameter and

mean sample line velocity and these possibly need to be taken into account.

5.4 Power supply

See conformity test 6.4.4.

The mean velocity of the sample water as it passes through the sample line during the sampling event

shall not be less than 0,5 m/s between the minimum and maximum rated voltages for the power supply.

NOTE An example calculation of sample line velocity is given in Annex B.

5.5 Sample integrity

See conformity test 6.4.5 and the example procedure in Annex C.

Analyses for BOD (biochemical oxygen demand), COD (chemical oxygen demand), total nitrogen, and

total phosphorus in samples taken by the sampler and in samples taken manually from a test water

representative of a waste water from an urban waste water treatment plant in accordance with the

conformity test detailed in 6.4.5 shall show no significant statistical difference based on an analysis of

variance.

NOTE Details of how to calculate sample integrity using analysis of variance are given in Annex A. An example

calculation is detailed in Annex B.

The design of a sample integrity test for other applications shall be based on the procedure at 6.4.5 and

the example given in Annex C. The guidance given in EN ISO 5667-3 [8], for sample handling and

preservation of samples should also be taken into account. This guidance covers samples for both

physical and chemical examination, and for biological examination. The same pass criteria should be

applied when using a test water representative of a waste water from an application other than an urban

waste water treatment plant and for which relevant determinands have been identified.

5.6 Sample timing error

See conformity test 6.4.6.

The error of the sampler interval timing mechanism shall not be greater than ± 10 s per 24 h.

NOTE An example calculation of sample timing error is given in Annex B.

5.7 Effect of ambient air temperature

5.7.1 Samplers not incorporating sample temperature control

See conformity test 6.4.7.

Samplers which do not incorporate a means for maintaining the temperature of the sample within pre-

set limits shall conform to the sample volume performance requirements in 5.1 when operated within

one of the following sets of rated operating conditions with regards to ambient temperature:

a) from +5 °C to +40 °C; or

b) from −10 °C to +40 °C; or

c) from 0 °C to +40 °C.

Temperature range a) should be used for samplers designed without integral frost protection and for use

only indoors where the building provides protection from frost.

Temperature range b) should be used for samplers designed for use outdoors and which have integral

frost protection.

Temperature range c) should be used for samplers designed for use outdoors and which have no integral

frost protection.

NOTE Details of how to calculate bias and repeatability are given in Annex A. An example calculation is detailed

in Annex B.

5.7.2 Samplers incorporating sample temperature control

See conformity test 6.4.7.

Samplers which incorporate a means for maintaining the temperature of the collected sample within pre-

set limits shall conform to the sample volume performance requirements in 5.1 when operated within an

ambient temperature range from −10 °C to +40 °C.

The mean temperature of the collected sample shall be maintained within the range 0 °C to 5 °C during

the sampling period, when the sampler is operated within the rated operating conditions for ambient

temperature and process water or waste water temperature. The design of the sample temperature

control shall ensure that ice does not form in the collected sample.

In the case of mains powered samplers, after completion of the sampling period, the sample temperature

shall remain within the range 0 °C to 5 °C for a minimum period of 24 h. The design of the sample

temperature control shall ensure that ice does not form in the collected sample.

In the case of portable samplers which are not powered directly from a mains electricity supply, the

minimum period of time, from the end of the sampling period, over which the temperature of the collected

sample remains within the range 0 °C to 5 °C with no formation of ice shall be 12 h.

NOTE Details of how to calculate bias and repeatability are given in Annex A. Example calculations are detailed

in Annex B.

6 Conformity testing

6.1 General requirements

The sampler shall be installed in accordance with any instructions provided by the manufacturer.

Each performance requirement for the sampler shall be considered on its own when performing the

conformity tests, except where otherwise indicated.

The test water used for each test shall be tap water, except for 6.4.5 when the test water shall be

representative of a waste water from an urban waste water treatment plant. This can be prepared using

tap water by following the guidance given at C.2.

Conformity testing of the sampler should be carried out in accordance with the requirements given in

EN ISO/IEC 17025 or other equivalent standards accepted at international level.

Sampler conformance shall be determined by evaluating the data from the tests in accordance with the

calculation methods given in Annex A.

Results from the conformity testing should be reported using the proposed format for the report given in

Annex D.

6.2 Test conditions

The sample line shall be arranged so that no part of the test water being sampled is retained within the

sample line.

Prior to carrying out any series of consecutive tests, the sampler shall be operated, for a total operating

period of 2 000 sampling cycles, under the following conditions:

— the rated maximum lift height;

— a sampling interval of 5 min;

— the set sample volume;

— collected samples can be re-used to save water consumption.

During tests that require the sampler to collect a sample of test water, the vessel containing the test water

to be sampled shall be open to the atmosphere.

Where a test requires repeat samples to be collected the lift height shall not change by more than 5 %

during the test.

In the case of a battery powered sampler, the battery shall be fully charged at the start of each conformity

test unless stated otherwise in the test conditions.

The sampler should be maintained, cleaned or recalibrated in accordance with the manufacturer's

instructions prior to any test, but adjustments shall not be carried out during the course of the test.

Table 1 gives the reference conditions for possible influence quantities. The sampler shall be tested with

all influence quantities at their reference values, including tolerances, unless where specifically varied in

any one test.

Table 1 — Test reference conditions

Influence quantity Reference value Tolerance

Ambient temperature 18 °C to 25 °C ±2,5 °C

Ambient humidity at 20 °C < 60 % —

Sample temperature 20 °C ±2,5 °C

a

Supply voltage (AC) 230 V (or 110 V) ±6 %

Supply voltage (DC) Rated voltage Rated voltage

a

see EN 60038:2011 [9].

6.3 Verification by inspection

The sampler shall be set up, calibrated and adjusted in accordance with the manufacturer’s instructions.

The sampler (or statements in the manufacturer’s operating manual) shall be inspected to verify

conformance to the general requirements listed at Clause 4, as appropriate to the sampler under test. The

means by which each requirement is fulfilled shall be reported.

6.4 Performance tests

6.4.1 Collected sample volume

6.4.1.1 C.T.C.V. Time proportional sampling principle

Determine the bias and repeatability of the collected sample volumes in accordance with the following

procedure.

1) Programme the sampler to collect the required set sample.

2) Set the sampler to operate on time proportional sampling.

3) Programme the sampler to collect 24 samples of the test water with a fixed 10 min interval at the set

sample volume.

4) Operate the sampler at a lift height of 1 m.

5) Measure and record the volume of each collected sample.

6) Repeat steps 3 to 7 at the rated maximum lift height and at half the rated maximum lift height. In each

case, measure and record the volume of each collected sample.

7) Calculate and report in accordance with Annex A. Example calculations are detailed at Annex B.

Where the sampler is to be tested at more than one set sample volume then steps 1 to 7 of the procedure

specified above shall be followed at each set sample volume.

These tests may be combined with the tests specified at 6.4.2.2 by recording the time at which the first

six samples are taken at a lift height of 1 m.

6.4.1.2 C.T.V.V. flow proportional sampling principle

Determine the bias and repeatability of the collected sample volumes in accordance with the following

procedure.

For samplers capable of operating with different input signals (analogue, pulse, digital) each input should

be tested separately.

1) Programme the sampler for the collection of C.T.V.V. flow proportional samples at a rate of 4 samples

per hour and a sample volume of 25 ml/m .

The procedure below assumes that the input to range has been programmed such that 100 % equals

3 3

100 m /h. The set sample volumes at 25 %, 50 %, 75 %, and 100 % of a programmed flow of 0 m /h to

100 m /h will be 156 ml, 313 ml, 469 ml and 625 ml respectively as detailed at Annex A.

2) Operate the sampler at a lift height of 1 m.

3) Apply a simulated flow signal representing 25 % of the maximum input signal until 6 individual

samples of the test water have been collected.

4) Sequentially increase the flow signal to represent flow rates of 50 %, 75 % and 100 % and in each

case collect six individual samples.

5) Calculate the set volume at each simulated flow rate in accordance with Annex A. Determine the

volume of each collected sample.

6) Repeat steps 1 to 5 for lift heights at the rated maximum lift height and at half the rated maximum

l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...