EN 13477-2:2010

(Main)Non-destructive testing - Acoustic emission - Equipment characterisation - Part 2: Verification of operating characteristic

Non-destructive testing - Acoustic emission - Equipment characterisation - Part 2: Verification of operating characteristic

This part of the standard specifies methods for routine verification of the performance of AE equipment comprising one or more sensing channels. It is intended for use by operators of the equipment under laboratory conditions. Verification of the measurement characteristics is recommended after purchase of equipment, modifications, use under extraordinary conditions, or if one suspects a malfunction. The procedures described in this European Standard do not exclude other qualified methods, e.g. verification in the frequency domain.

Zerstörungsfreie Prüfung - Schallemissionsprüfung - Charakterisierung der Prüfausrüstung - Teil 2: Überprüfung der Betriebskenngrößen

In diesem Teil der Norm werden Verfahren für die routinemäßige Prüfung der Funktion von AE-(en: acoustic emission) Messinstrumenten festgelegt, die mit einem Aufnehmerkanal oder mehreren Aufnehmerkanälen ausgestattet sind. Dieser Teil wurde für die Bediener der Messinstrumente für Prüfungen im Laboratorium konzipiert. Eine Überprüfung der Messcharakteristika wird empfohlen nach dem Kauf einer Ausrüstung, nach der Durchführung von Änderungen, nach einem Einsatz unter außergewöhnlichen Bedingungen oder wenn eine fehlerhafte Funktion befürchtet wird. Die in dieser Norm beschriebenen Verfahren schließen andere qualifizierte Verfahren, z. B. Überprüfungen im Frequenzbereich, nicht aus.

Essais non destructifs - Émission acoustique - Caractérisation de l'équipement - Partie 2: Vérifications des caractéristiques de fonctionnement

La présente partie de la norme spécifie des méthodes appliquées pour les vérifications de routine des

performances d'un équipement d'émission acoustique comprenant une ou plusieurs voies de détection. Elle

est destinée aux utilisateurs du matériel en conditions de laboratoire. La vérification des caractéristiques de

mesure est recommandée après l'achat de l'équipement, après toute modification ou toute utilisation dans des

conditions extraordinaires ou si l'on soupçonne un dysfonctionnement. Les modes opératoires décrits dans la

présente Norme européenne n'excluent pas toute autre méthode qualifiée, par exemple une vérification dans

le domaine de fréquences.

Neporušitveno preskušanje - Akustična emisija - Določevanje značilnosti opreme - 2. del: Preverjanje lastnosti delovanja

Ta del standarda določa metode za rutinsko preverjanje delovanja opreme AE, ki je sestavljena iz enega ali več senzorskih kanalov. Njegov namen je, da ga uporabljajo operaterji opreme pod laboratorijskimi pogoji. Preverjanje merilnih lastnosti se priporoča po nakupu opreme, spremembah, uporabi pod posebnimi pogoji ali če obstaja sum okvare. Postopki, opisani v tem evropskem standardu, ne izključujejo drugih kvalificiranih metod, npr. preverjanja v frekvenčni domeni.

General Information

- Status

- Withdrawn

- Publication Date

- 14-Sep-2010

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 138 - Non-destructive testing

- Drafting Committee

- CEN/TC 138/WG 7 - Acoustic emission testing

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Oct-2021

- Completion Date

- 14-Apr-2025

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 06-Dec-2017

Frequently Asked Questions

EN 13477-2:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Non-destructive testing - Acoustic emission - Equipment characterisation - Part 2: Verification of operating characteristic". This standard covers: This part of the standard specifies methods for routine verification of the performance of AE equipment comprising one or more sensing channels. It is intended for use by operators of the equipment under laboratory conditions. Verification of the measurement characteristics is recommended after purchase of equipment, modifications, use under extraordinary conditions, or if one suspects a malfunction. The procedures described in this European Standard do not exclude other qualified methods, e.g. verification in the frequency domain.

This part of the standard specifies methods for routine verification of the performance of AE equipment comprising one or more sensing channels. It is intended for use by operators of the equipment under laboratory conditions. Verification of the measurement characteristics is recommended after purchase of equipment, modifications, use under extraordinary conditions, or if one suspects a malfunction. The procedures described in this European Standard do not exclude other qualified methods, e.g. verification in the frequency domain.

EN 13477-2:2010 is classified under the following ICS (International Classification for Standards) categories: 19.100 - Non-destructive testing. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13477-2:2010 has the following relationships with other standards: It is inter standard links to EN 13477-2:2001, EN 13477-2:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase EN 13477-2:2010 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Zerstörungsfreie Prüfung - Schallemissionsprüfung - Gerätecharakterisierung - Teil 2: Überprüfung der BetriebskenngrößenEssais non destructifs, émission acoustique - Caractérisation de l’équipement - Partie 2: Vérifications des caractéristiques de fonctionnementNon destructive testing acoustic emission - Equipment Characterisation - Part 2: Verification of operating characteristic19.100Neporušitveno preskušanjeNon-destructive testingICS:Ta slovenski standard je istoveten z:EN 13477-2:2010SIST EN 13477-2:2011en,fr,de01-februar-2011SIST EN 13477-2:2011SLOVENSKI

STANDARDSIST EN 13477-2:20011DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13477-2

September 2010 ICS 19.100 Supersedes EN 13477-2:2001English Version

Non-destructive testing - Acoustic emission - Equipment characterisation - Part 2: Verification of operating characteristic Essais non destructifs, émission acoustique - Caractérisation de l'équipement - Partie 2: Vérifications des caractéristiques de fonctionnement

Zerstörungsfreie Prüfung - Schallemissionsprüfung - Gerätecharakterisierung - Teil 2: Überprüfung der Betriebskenngrößen This European Standard was approved by CEN on 30 July 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13477-2:2010: ESIST EN 13477-2:2011

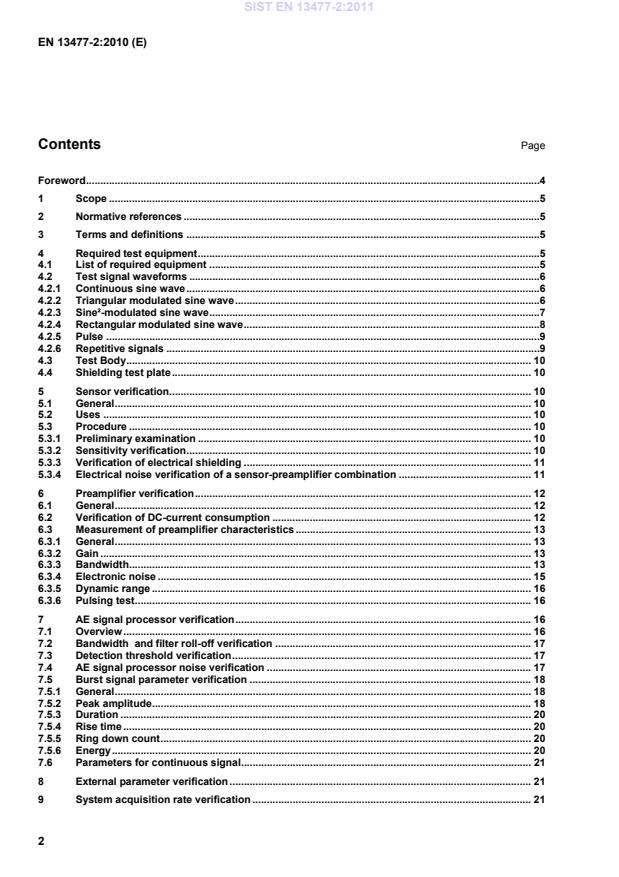

and filter roll-off verification . 177.3 Detection threshold verification . 177.4 AE signal processor noise verification . 177.5 Burst signal parameter verification . 187.5.1 General . 187.5.2 Peak amplitude . 187.5.3 Duration . 207.5.4 Rise time . 207.5.5 Ring down count . 207.5.6 Energy . 207.6 Parameters for continuous signal . 218 External parameter verification . 219 System acquisition rate verification . 21SIST EN 13477-2:2011

∆∆∆∆t measurement verification . 2211 Documentation . 22Annex A (informative)

Sensor performance check form . 25Annex B (informative)

Preamplifier performance check form . 27Annex C (informative)

AE signal processor - bandwidth & noise verification form (one per channel) . 29 SIST EN 13477-2:2011

Key [mV] amplitude Figure 1 — Triangular modulated sine wave in time (left) and frequency (right) domain The measured rise time may be shorter than the visible rise time of the test signal because rise time measurement starts at the time of the first threshold crossing. Table 1 shows the dependency of this threshold crossing delay on the difference between maximum amplitude and threshold setting in an AE channel. 4.2.3 Sine²-modulated sine wave A sine²-modulated signal (see Figure 2) can be used as an alternative to a triangular modulated sine wave. Due to its smooth begin, peak and end, its spectrum is very pure and the influence of filter overshoot and filter ring down behaviour is reduced. This signal can be used to obtain the frequency response of the bandpass of a preamplifier or AE signal processor by burst peak amplitude measurement.

Key [mV] amplitude Figure 2 — Sine²-modulated sine wave in time (left) and frequency domain (right) NOTE The shown signal corresponds to the following function: ))/(²(sin)/2sin(][SWpBSpSWNSpSWNUNUP××××××=ππ (1) 0=N to )SWpB(SpSW×, in integer steps (2) where N = number of each sample in time order; SpSW = Samples per sine wave (48 in Figure 2); SWpB = Sine waves per burst (41 in Figure 2); U[N] = Voltage of sample N; SIST EN 13477-2:2011

()SpSWft×=cs1 (4) Example in Figure 2: ts = 1/(200 kHz x 48) = 104.167 ns Similar to the triangular modulated sine wave, the rise time measured by an AE signal processor is shorter than the visible rise time of the test signal, because rise time measurement starts at the time of the first threshold crossing. This so-called “first threshold crossing delay” depends on the difference of maximum amplitude and detection threshold in dB and is listed for the two modulated test signals in Table 1. Table 1 First threshold crossing delay versus amplitude to threshold ratio

for a sin2 and triangular modulated test signal Threshold Sin² modulated first threshold crossing delay % of signal rise time Triangular modulated

first threshold crossing delay % of signal rise time A – 20 dB 19,7 11,0 A – 25 dB 15,0 6,0 A – 30 dB 12,3 3,5 A – 35 dB 8,3 3,0 A – 40 dB 7,6 1,0

4.2.4 Rectangular modulated sine wave This type of signal is defined by the characteristics A, D and f, see

4.2.2 and Figure 3.

Key [mV] amplitude Figure 3 — Rectangular modulated sine wave in time (left) and frequency domain (right) SIST EN 13477-2:2011

Figure 4 — Pulse 4.2.6 Repetitive signals This signal is used to verify the signal processing rate. It is a series of pulses as described in 4.2.5. It is defined by A (amplitude), D (pulse duration) and f (repetition frequency), typically 1 Hz – 10 kHz. Figure 5 shows an example with 1/f = 160 µs, taken after the band pass filter of an AE signal processor. The maximum reasonable repetition frequency is limited by the ring down effect of the band pass filter, if a pulse causes multiple threshold crossings.

Key [mV] amplitude Figure 5 — A series of transient signals (pulses) 160 µs apart behind the band pass SIST EN 13477-2:2011

Figure 6 — Shielding verification set-up 5.3.4 Electrical noise verification of a sensor-preamplifier combination The electrical noise level of a sensor and preamplifier combination shall be measured in acoustically quiet environment with the sensor dismounted from a structure. The measurement set-up is according to 6.3.4. The noise level is measured in specified units and shall not exceed the noise specification of the manufacturer. The measured value shall be reported on the test record (see Annex A). SIST EN 13477-2:2011

With no input from the sine wave generator measure and record the stand by current,ISB

in mA.

Use a sine wave of a frequency within the pass band of the preamplifier and set the preamplifier AC output to full scale. Measure and record the full scale current IFS

in mA. Standby current ISB and full scale current IFS shall not exceed the manufacturer’s specifications.

Figure 7 — Set-up for measurement of DC current consumption SIST EN 13477-2:2011

Figure 8 — Test set-up for the verification of preamplifier gain and bandwidth 6.3.3 Bandwidth Figure 8 shows the test set-up for the verification of preamplifier bandwid

...

La norme EN 13477-2:2010, intitulée « Essai non destructif - Émission acoustique - Caractérisation des équipements - Partie 2 : Vérification des caractéristiques de fonctionnement », établit des méthodes essentielles pour la vérification routinière des performances des équipements d'émission acoustique (AE) comportant un ou plusieurs canaux de détection. Ce document est d'une grande importance pour les opérateurs utilisant ces dispositifs dans des conditions de laboratoire, assurant ainsi que les équipements fonctionnent selon les spécifications nécessaires. Un des points forts de cette norme réside dans sa capacité à recommander des vérifications des caractéristiques de mesure après l'achat de l'équipement, suite à des modifications, lors d'une utilisation dans des conditions extraordinaires, ou en cas de doute quant à un éventuel dysfonctionnement. Cela garantit que les opérateurs disposent d'un guide solide pour maintenir la fiabilité et la précision des résultats fournis par leurs équipements. De plus, la norme EN 13477-2:2010 reconnaît la possibilité d'autres méthodes qualifiées, comme la vérification dans le domaine de la fréquence, renforçant ainsi sa pertinence dans un contexte où les technologies évoluent rapidement. Cette flexibilité dans les procédures proposées permet aux utilisateurs d'adapter les vérifications à leurs besoins spécifiques tout en maintenant une conformité aux exigences normatives. En considérant son ampleur, sa robustesse et sa pertinence dans le domaine des essais non destructifs, cette norme s'avère être un outil indispensable pour tout opérateur souhaitant garantir la performance optimale de ses équipements d'émission acoustique.

SIST EN 13477-2:2011 표준은 비파괴 검사에서의 음향 방출 장비의 성능 검증을 위한 중요한 방법론을 제시하고 있습니다. 이 표준의 주요 초점은 AE(음향 방출) 장비의 검증으로, 여러 감지 채널을 포함하는 장비의 일상적인 성능 검증을 다루고 있습니다. 이 문서는 장비 운영자들이 실험실 조건 하에서 사용할 수 있는 검증 절차를 명시하고 있어 신뢰성을 높이고 있습니다. 표준의 강점 중 하나는 장비 구매 후, 수정 사항 발생 시, 비정상적 조건에서 사용한 경우, 또는 기능 장애가 의심될 경우 측정 특성을 검증하는 것을 권장하는 점입니다. 이를 통해 사용자는 장비의 정확성과 신뢰성을 지속적으로 유지할 수 있습니다. 또한, 이 표준은 주파수 영역에서의 검증과 같은 다른 자격 있는 방법들을 배제하지 않기 때문에, 다양한 검증 기법을 수용할 수 있는 유연성을 제공합니다. SIST EN 13477-2:2011의 범위와 특징은 비파괴 검사 분야에서의 음향 방출 기술의 발전에 기여하며, 장비 운영자들이 보다 효과적으로 AE 장비의 성능을 관리할 수 있도록 지원합니다. 이 표준은 비파괴 검사 분야에서의 관련성과 실용성을 높이며, 사용자의 요구에 부응하는 강력한 도구로 자리잡고 있습니다.

Die Norm EN 13477-2:2010 befasst sich mit der Charakterisierung von akustischen Emissionen und legt spezifische Methoden zur routinemäßigen Überprüfung der Leistungsfähigkeit von Prüfgeräten fest, die aus einem oder mehreren Sensorkanälen bestehen. Diese Norm ist besonders relevant für Betreiber von akustischen Emissionstestgeräten im Laborumfeld. Die Stärken dieser Norm liegen in ihrer klaren Struktur und den detaillierten Verfahren zur Verifizierung der Betriebsmerkmale. Durch die Festlegung verlässlicher Methoden zur Überprüfung der Messcharakteristika wird sichergestellt, dass die Geräte die erforderliche Leistung unter regulären und außergewöhnlichen Bedingungen erbringen. Dies ist besonders wichtig, um die Integrität der Testergebnisse zu gewährleisten und mögliche Fehlfunktionen frühzeitig zu identifizieren. Ein weiterer Vorteil der EN 13477-2:2010 liegt in ihrer flexiblen Anwendbarkeit. Die Norm empfiehlt die Verifizierung nach dem Kauf von Geräten, nach Modifikationen oder bei Verdacht auf Fehlfunktionen, sodass Betreiber jederzeit sicherstellen können, dass ihre Geräte korrekt arbeiten. Die Möglichkeit, auch andere qualifizierte Methoden, wie z.B. die Verifizierung im Frequenzbereich, zu verwenden, ergänzt die Norm sinnvoll und bietet zusätzliche Optionen zur Qualitätssicherung. Insgesamt ist die EN 13477-2:2010 von hoher Relevanz für Fachleute im Bereich der zerstörungsfreien Prüfungen, da sie neben klaren Verfahrensweisen auch ein hohes Maß an Zuverlässigkeit und Flexibilität bietet, um die Leistungsfähigkeit von akustischen Emissionstestgeräten zu garantieren.

この標準文書「EN 13477-2:2010」は、非破壊試験における音響放出の機器特性の検証に関するものであり、特にAE(Acoustic Emission)機器の性能の定期的な確認を目的としています。標準の範囲は、1つまたは複数のセンシングチャネルを持つAE機器の性能評価に特化しており、研究所条件下での設備運用者による利用が推奨されています。 この標準の強みは、装置購入後、改造後、異常な条件下での使用時、または故障の疑いがある場合における計測特性の確認を推奨している点です。これにより、オペレーターは常に機器の信頼性を確保することができ、非破壊試験の結果の信頼性を向上させることが可能となります。 「EN 13477-2:2010」の定義した手順は、測定の特性を定期的に評価することにより、音響放出技術の精度と一貫性を保つために非常に重要です。このプロセスは、科学的および工業的なアプリケーションにおいて音響放出の利用がますます広がる中で、機器性能の信頼性を確保するための基盤を提供します。また、この標準は周波数ドメインでの検証など、他の適切な方法を排除するものではなく、あくまでAE機器の性能確認のための補完的な役割を果たしています。 全体として、標準「EN 13477-2:2010」は非破壊試験分野における音響放出機器の性能管理にとって極めて関連性があり、信頼性の高い計測結果を得るための指針を提供します。

The EN 13477-2:2010 standard is a crucial document in the field of non-destructive testing, specifically focusing on acoustic emission (AE) equipment characterization. This part of the standard details methods for the routine verification of the performance of AE equipment, which includes one or more sensing channels. Its primary scope is to provide guidelines for operators to ensure the reliability and accuracy of their AE testing equipment under laboratory conditions. One of the significant strengths of this standard is its comprehensive approach to verifying the measurement characteristics of AE equipment. It specifically recommends carrying out these verifications post-purchase, following any equipment modifications, after usage under extraordinary conditions, or when there is a suspicion of malfunction. This proactive verification process is essential for maintaining high standards in non-destructive testing and ensuring the integrity of the results obtained from AE techniques. Additionally, the standard acknowledges the existence of other qualified verification methods, such as those involving frequency domain analysis. This flexibility allows operators to choose the best-suited verification methods for their specific circumstances, thereby enhancing the robustness of their testing procedures. The relevance of EN 13477-2:2010 cannot be overstated, as it directly addresses the critical need for maintaining the operational reliability of AE equipment. With the growing emphasis on precision and accuracy in non-destructive testing, the standard serves as an essential reference for ensuring that acoustic emission equipment operates effectively and produces valid results. Its intrinsic focus on verification aligns perfectly with the industry's demand for high-quality testing standards, making it a vital resource for professionals in the field.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...