EN 1656:2019

(Main)Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of bactericidal activity of chemical disinfectants and antiseptics used in the veterinary area - Test method and requirements (phase 2, step 1)

Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of bactericidal activity of chemical disinfectants and antiseptics used in the veterinary area - Test method and requirements (phase 2, step 1)

This document specifies a test method and the minimum requirements for bactericidal activity of chemical disinfectant and antiseptic products that form a homogeneous, physically stable preparation when diluted with hard water or - in the case of ready-to-use products - with water. Products can only be tested at a concentration of 80 % or less, as some dilution is always produced by adding the test organisms and interfering substance.

The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used. This document applies to products that are used for equipment disinfection by immersion, surface disinfection by wiping, spraying, flooding or other means and teat disinfection in the veterinary area - e.g. in the breeding, husbandry, production, veterinary care facilities, transport and disposal of all animals except when in the food chain following death and entry into processing industry. This document also applies to products used for teat disinfection in these veterinary areas.

This method is not applicable to evaluate the activity of hand hygiene products. For these products reference is made to EN 14885, which specifies in detail the relationship of the various tests to one another and to "use recommendations".

NOTE This method corresponds to a phase 2 step 1 test.

Chemische Desinfektionsmittel und Antiseptika - Quantitativer Suspensionsversuch zur Bestimmung der bakteriziden Wirkung chemischer Desinfektionsmittel und Antiseptika für den Veterinärbereich - Prüfverfahren und Anforderungen (Phase 2, Stufe 1)

Dieses Dokument legt ein Prüfverfahren für und die Mindestanforderungen an die bakterizide Wirkung von chemischen Desinfektionsmitteln und antiseptischen Produkten fest, die bei Verdünnung in Wasser standardisierter Härte oder - im Falle gebrauchsfertiger Produkte - in Wasser als homogenes und physikalisch stabiles Präparat vorliegen. Die Produkte können nur bei einer Konzentration von höchstens 80 % geprüft werden, da durch die Zugabe der Prüforganismen und der Belastungssubstanz immer eine bestimmte Verdünnung auftritt.

Das beschriebene Verfahren soll der Bestimmung der Wirkung handelsüblicher Zubereitungen oder von Wirkstoffen unter den Bedingungen dienen, unter denen sie in der Praxis angewendet werden. Dieses Dokument gilt für Produkte, die für die Instrumentendesinfektion durch Eintauchen und bei der Oberflächendesinfektion durch Abwischen, Besprühen, Überfluten oder auf sonstige Weise sowie bei der Zitzendesinfektion im Veterinärbereich verwendet werden - z. B. bei der Aufzucht, Haltung, Produktion, in veterinärischen Pflegeeinrichtungen, beim Transport von Tieren sowie bei der Tierkörperbeseitigung aller Tiere mit Ausnahme der Tiere, die nach der Tötung direkt als Nahrungsmittel verwendet oder der weiterverarbeitenden Industrie zugeführt werden. Dieses Dokument gilt auch für Produkte, die bei der Zitzendesinfektion in diesen Veterinärbereichen verwendet werden.

Dieses Verfahren kann nicht angewendet werden, um die Wirkung von Produkten der Handhygiene zu überprüfen. Für diese Produkte wird auf EN 14885 verwiesen, die im Einzelnen den Zusammenhang zwischen den verschiedenen Prüfungen sowie zu den "Anwendungsempfehlungen" festlegt.

ANMERKUNG Dieses Verfahren entspricht einer Prüfung der Phase 2, Stufe 1.

Antiseptiques et désinfectants chimiques - Essai quantitatif de suspension pour l’évaluation de l’activité bactéricide des antiseptiques et des désinfectants chimiques utilisés dans le domaine vétérinaire - Méthode d’essai et exigences (phase 2, étape 1)

Le présent document spécifie une méthode d’essai et les exigences minimales relatives à l’activité bactéricide des produits antiseptiques et désinfectants chimiques qui forment une préparation homogène, physiquement stable, lorsqu’ils sont dilués dans de l’eau dure ou, dans le cas de produits prêts à l’emploi, dans l’eau. Les produits ne peuvent être soumis à l’essai qu’à la concentration de 80 % ou à des concentrations inférieures, car l’ajout des microorganismes d’essai et de la substance interférente s’accompagne forcément d’une dilution.

La méthode décrite vise à déterminer l’activité des formulations commerciales ou des substances actives dans les conditions d’utilisation. Le présent document s’applique aux produits utilisés dans la désinfection des équipements par immersion, la désinfection de surfaces par essuyage, pulvérisation, inondation ou d’autres moyens, la désinfection des trayons dans le domaine vétérinaire, par exemple dans la reproduction, l’élevage, la production, les services vétérinaires, le transport et l’abattage de tous les animaux, à l’exception de la chaîne alimentaire qui suit l’abattage et l’entrée dans l’industrie de transformation. Le présent document s’applique également aux produits utilisés dans la désinfection des trayons dans ces domaines vétérinaires.

Cette méthode ne s’applique pas à l’évaluation de l’activité des produits d’hygiène des mains. Pour ces produits, se référer à l’EN 14885, qui spécifie de façon détaillée les relations des différents essais entre eux et avec les « recommandations d’emploi ».

NOTE Cette méthode correspond à un essai de phase 2, étape 1.

Kemična razkužila in antiseptiki - Kvantitativni suspenzijski preskus za vrednotenje baktericidnega delovanja kemičnih razkužil in antiseptikov v veterini - Preskusna metoda in zahteve (faza 2, stopnja 1)

Ta evropski standard določa preskusno metodo in minimalne zahteve za baktericidno delovanje kemičnih razkužil in antiseptikov, ki tvorijo homogen, fizikalno stabilen pripravek, če so razredčeni s trdo vodo oziroma z vodo pri izdelkih, ki so pripravljeni za uporabo. Izdelke je mogoče preskušati samo pri 80-odstotni ali nižji koncentraciji, ker dodajanje preskusnih organizmov in moteče snovi vedno povzroči razredčenje.

Ta evropski standard se uporablja za izdelke v veterini, tj. pri vzreji, živinoreji, prevozu in odstranjevanju vseh živali, razen če so v prehrambeni verigi po smrti in so del predelovalne industrije.

Standard EN 14885 podrobno določa razmerje med različnimi preizkusi in priporočili za uporabo.

OPOMBA 1: Opisana metoda je namenjena določevanju dejavnosti komercialnih oblik ali aktivnih snovi pod pogoji, v katerih se uporabljajo.

OPOMBA 2: Ta metoda ustreza preskusu stopnje 1 faze 2.

General Information

- Status

- Published

- Publication Date

- 17-Sep-2019

- Withdrawal Date

- 30-Mar-2020

- Technical Committee

- CEN/TC 216 - Chemical disinfectants and antiseptics

- Drafting Committee

- CEN/TC 216/WG 2 - Veterinary use

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 18-Sep-2019

- Due Date

- 16-Nov-2019

- Completion Date

- 18-Sep-2019

Relations

- Effective Date

- 25-Sep-2019

- Effective Date

- 04-May-2016

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-May-2024

Overview

EN 1656:2019 - "Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of bactericidal activity ... (phase 2, step 1)" is a CEN standard that defines a laboratory quantitative suspension test to assess the bactericidal activity of chemical disinfectants and antiseptics used in the veterinary area. The method evaluates commercial formulations or active substances under practical-use conditions (contact time, temperature, interfering substances). Products tested must form a homogeneous, physically stable preparation when diluted with hard water (or with water for ready-to-use products) and can be assessed only at concentrations of 80% or less.

Key topics and requirements

- Scope: Equipment disinfection (immersion), surface disinfection (wiping, spraying, flooding), and teat disinfection in breeding, husbandry, veterinary care, transport and disposal of animals (excluding carcass processing in food chain).

- Minimum efficacy: Demonstration of at least a 5 log10 (decimal) reduction of target bacteria under specified conditions.

- Test organisms:

- General disinfection: Enterococcus hirae, Proteus hauseri, Pseudomonas aeruginosa, Staphylococcus aureus.

- Teat disinfectants: Escherichia coli, Staphylococcus aureus, Streptococcus uberis.

- Test conditions:

- Temperature ranges and contact times are specified (e.g., surfaces: 5 °C to 40 °C; teat products: narrower temperature and contact-time regimes for pre- and post-milking).

- Interfering substances simulate soiling: low level (3 g/L bovine albumin), high level (10 g/L yeast extract + 10 g/L bovine albumin), and milk/skimmed milk variants for teat products.

- Methods:

- Preferred neutralization: dilution-neutralization (validated neutralizers).

- Alternative: membrane filtration if neutralizers are not feasible.

- Validation & controls: Procedures for verification of methods, control counts, and expression/interpretation of results are included.

Applications and users

EN 1656:2019 is used by:

- Manufacturers developing veterinary disinfectants and teat dips (for product development and label claims).

- Independent testing laboratories performing standardized bactericidal efficacy tests.

- Regulatory authorities and certification bodies assessing product performance.

- Veterinary professionals, farm biosecurity managers and QA teams seeking validated disinfection products for livestock facilities, transport vehicles, equipment and teat hygiene.

Keywords: EN 1656:2019, quantitative suspension test, bactericidal activity, veterinary disinfectants, teat disinfectants, dilution-neutralization, membrane filtration, hard water, CEN.

Related standards

- EN 14885 - Application of European standards for chemical disinfectants and antiseptics (relationship of tests and use recommendations).

- EN 12353 - Preservation of test organisms used in efficacy testing.

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

Intertek Bangladesh

Intertek certification and testing services in Bangladesh.

Sponsored listings

Frequently Asked Questions

EN 1656:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of bactericidal activity of chemical disinfectants and antiseptics used in the veterinary area - Test method and requirements (phase 2, step 1)". This standard covers: This document specifies a test method and the minimum requirements for bactericidal activity of chemical disinfectant and antiseptic products that form a homogeneous, physically stable preparation when diluted with hard water or - in the case of ready-to-use products - with water. Products can only be tested at a concentration of 80 % or less, as some dilution is always produced by adding the test organisms and interfering substance. The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used. This document applies to products that are used for equipment disinfection by immersion, surface disinfection by wiping, spraying, flooding or other means and teat disinfection in the veterinary area - e.g. in the breeding, husbandry, production, veterinary care facilities, transport and disposal of all animals except when in the food chain following death and entry into processing industry. This document also applies to products used for teat disinfection in these veterinary areas. This method is not applicable to evaluate the activity of hand hygiene products. For these products reference is made to EN 14885, which specifies in detail the relationship of the various tests to one another and to "use recommendations". NOTE This method corresponds to a phase 2 step 1 test.

This document specifies a test method and the minimum requirements for bactericidal activity of chemical disinfectant and antiseptic products that form a homogeneous, physically stable preparation when diluted with hard water or - in the case of ready-to-use products - with water. Products can only be tested at a concentration of 80 % or less, as some dilution is always produced by adding the test organisms and interfering substance. The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used. This document applies to products that are used for equipment disinfection by immersion, surface disinfection by wiping, spraying, flooding or other means and teat disinfection in the veterinary area - e.g. in the breeding, husbandry, production, veterinary care facilities, transport and disposal of all animals except when in the food chain following death and entry into processing industry. This document also applies to products used for teat disinfection in these veterinary areas. This method is not applicable to evaluate the activity of hand hygiene products. For these products reference is made to EN 14885, which specifies in detail the relationship of the various tests to one another and to "use recommendations". NOTE This method corresponds to a phase 2 step 1 test.

EN 1656:2019 is classified under the following ICS (International Classification for Standards) categories: 71.100.35 - Chemicals for industrial and domestic disinfection purposes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1656:2019 has the following relationships with other standards: It is inter standard links to EN 1656:2009/AC:2010, EN 1656:2009, EN 14885:2022, EN 12353:2021, EN 14885:2015, EN 14885:2018, EN 14885:2006, EN ISO 23903:2021, EN 17422:2022, prEN 1656. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1656:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2019

Nadomešča:

SIST EN 1656:2010

SIST EN 1656:2010/AC:2010

Kemična razkužila in antiseptiki - Kvantitativni suspenzijski preskus za

vrednotenje baktericidnega delovanja kemičnih razkužil in antiseptikov v veterini -

Preskusna metoda in zahteve (faza 2, stopnja 1)

Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation

of bactericidal activity of chemical disinfectants and antiseptics used in the veterinary

area - Test method and requirements (phase 2, step 1)

Chemische Desinfektionsmittel und Antiseptika - Quantitativer Suspensionsversuch zur

Bestimmung der bakteriziden Wirkung chemischer Desinfektionsmittel und Antiseptika

für den Veterinärbereich - Prüfverfahren und Anforderungen (Phase 2, Stufe 1)

Antiseptiques et désinfectants chimiques - Essai quantitatif de suspension pour

l'évaluation de l'activité bactéricide des antiseptiques et des désinfectants chimiques

utilisés dans le domaine vétérinaire - Méthode d'essai et prescriptions (phase 2, étape 1)

Ta slovenski standard je istoveten z: EN 1656:2019

ICS:

11.080.20 Dezinfektanti in antiseptiki Disinfectants and antiseptics

11.220 Veterinarstvo Veterinary medicine

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1656

EUROPEAN STANDARD

NORME EUROPÉENNE

September 2019

EUROPÄISCHE NORM

ICS 71.100.35 Supersedes EN 1656:2009

English Version

Chemical disinfectants and antiseptics - Quantitative

suspension test for the evaluation of bactericidal activity of

chemical disinfectants and antiseptics used in the

veterinary area - Test method and requirements (phase 2,

step 1)

Antiseptiques et désinfectants chimiques - Essai Chemische Desinfektionsmittel und Antiseptika -

quantitatif de suspension pour l'évaluation de l'activité Quantitativer Suspensionsversuch zur Bestimmung der

bactéricide des antiseptiques et des désinfectants bakteriziden Wirkung chemischer Desinfektionsmittel

chimiques utilisés dans le domaine vétérinaire - und Antiseptika für den Veterinärbereich -

Méthode d'essai et exigences (phase 2, étape 1) Prüfverfahren und Anforderungen (Phase 2, Stufe 1)

This European Standard was approved by CEN on 28 July 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1656:2019 E

worldwide for CEN national Members.

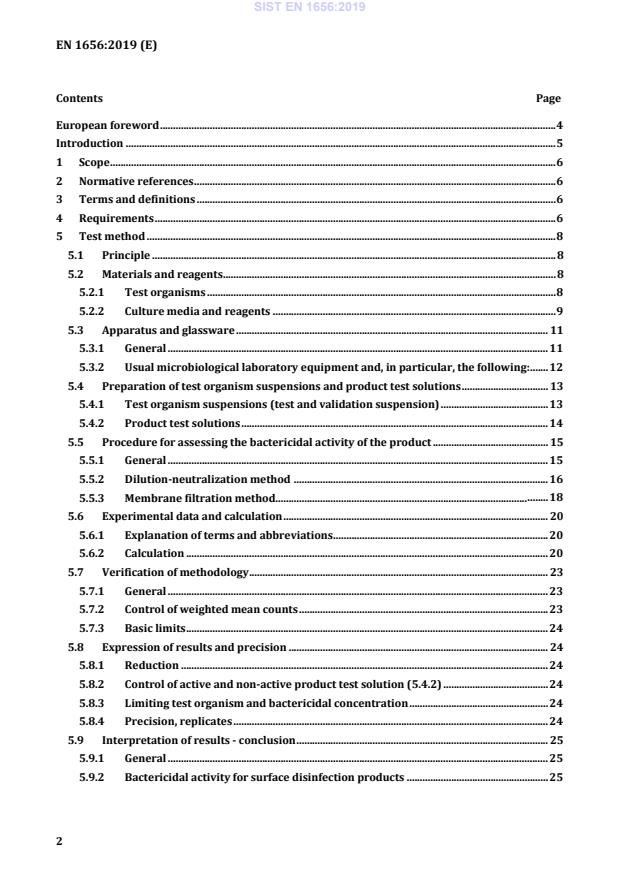

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Requirements . 6

5 Test method . 8

5.1 Principle . 8

5.2 Materials and reagents . 8

5.2.1 Test organisms . 8

5.2.2 Culture media and reagents . 9

5.3 Apparatus and glassware . 11

5.3.1 General . 11

5.3.2 Usual microbiological laboratory equipment and, in particular, the following: . 12

5.4 Preparation of test organism suspensions and product test solutions . 13

5.4.1 Test organism suspensions (test and validation suspension) . 13

5.4.2 Product test solutions . 14

5.5 Procedure for assessing the bactericidal activity of the product . 15

5.5.1 General . 15

5.5.2 Dilution-neutralization method . 16

5.5.3 Membrane filtration method. 18

5.6 Experimental data and calculation . 20

5.6.1 Explanation of terms and abbreviations . 20

5.6.2 Calculation . 20

5.7 Verification of methodology . 23

5.7.1 General . 23

5.7.2 Control of weighted mean counts . 23

5.7.3 Basic limits . 24

5.8 Expression of results and precision . 24

5.8.1 Reduction . 24

5.8.2 Control of active and non-active product test solution (5.4.2) . 24

5.8.3 Limiting test organism and bactericidal concentration . 24

5.8.4 Precision, replicates . 24

5.9 Interpretation of results - conclusion . 25

5.9.1 General . 25

5.9.2 Bactericidal activity for surface disinfection products . 25

5.9.3 Bactericidal activity for teat disinfection products . 25

5.10 Test report . 25

Annex A (informative) Referenced strains in national collections . 27

Annex B (informative) Examples of neutralizers of the residual antimicrobial activity of chemical

disinfectants and antiseptics and rinsing liquids . 29

Annex C (informative) Dilution-neutralization method . 31

Annex D (informative) Example of a typical test report . 36

Bibliography . 40

European foreword

This document (EN 1656:2019) has been prepared by Technical Committee CEN/TC 216 “Chemical

disinfectants and antiseptics”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by March 2020, and conflicting national standards shall be

withdrawn at the latest by March 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This European Standard supersedes EN 1656:2009 and was revised to harmonize the structure and

wording with other quantitative suspension tests of CEN/TC 216 (existing or in preparation).

Results obtained using the previous version of this standard are still valid.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document specifies a suspension test for establishing whether a chemical disinfectant or antiseptic

has a bactericidal activity in the fields described in the scope.

This laboratory test takes into account practical conditions of application of the product, including

contact time, temperature, test organisms and interfering substances, i.e. conditions which may influence

its action in practical situations.

The conditions are intended to cover general purposes and to allow reference between laboratories and

product types. Each utilization concentration of the chemical disinfectant or antiseptic found by this test

corresponds to defined experimental conditions. However, for some applications the recommendations

of use of a product may differ and therefore additional test conditions need to be used.

1 Scope

This document specifies a test method and the minimum requirements for bactericidal activity of

chemical disinfectant and antiseptic products that form a homogeneous, physically stable preparation

when diluted with hard water or - in the case of ready-to-use products - with water. Products can only be

tested at a concentration of 80 % or less, as some dilution is always produced by adding the test

organisms and interfering substance.

The method described is intended to determine the activity of commercial formulations or active

substances under the conditions in which they are used. This document applies to products that are used

for equipment disinfection by immersion, surface disinfection by wiping, spraying, flooding or other

means and teat disinfection in the veterinary area – e.g. in the breeding, husbandry, production,

veterinary care facilities, transport and disposal of all animals except when in the food chain following

death and entry into processing industry. This document also applies to products used for teat

disinfection in these veterinary areas.

This method is not applicable to evaluate the activity of hand hygiene products. For these products

reference is made to EN 14885, which specifies in detail the relationship of the various tests to one

another and to “use recommendations”.

NOTE This method corresponds to a phase 2 step 1 test.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12353, Chemical disinfectants and antiseptics — Preservation of test organisms used for the

determination of bactericidal (including Legionella), mycobactericidal, sporicidal, fungicidal and virucidal

(including bacteriophages) activity

EN 14885, Chemical disinfectants and antiseptics — Application of European Standards for chemical

disinfectants and antiseptics

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 14885 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

4 Requirements

The product shall demonstrate at least a 5 decimal log (lg) reduction when diluted with hard water

(5.2.2.7) or – in the case of ready-to-use products – with water (5.2.2.2) and tested in accordance with

Table 1 and Clause 5 under simulated low level soiling (3 g/l bovine albumin) or high level soiling (10 g/l

yeast extract and 10 g/l bovine albumin) or 10 g/l skimmed milk for post-milking teat disinfectants or

3 g/l bovine albumin for pre-milking teat disinfectants or in additional test conditions.

Table 1 — Test conditions

Bactericidal

Bactericidal activity for teat

Test conditions activity on

disinfectants

surfaces

Minimum spectrum of Enterococcus hirae Escherichia coli

test organisms

Proteus hauseri ) Staphylococcus aureus

Pseudomonas Streptococcus uberis

aeruginosa

Staphylococcus

aureus

additional any relevant test any relevant test organism

organism

Test temperature at intervals of 5 °C

minimum 5 °C ± 1 °C 20 °C ± 1 °C

maximum 40 °C ± 1 °C 30 °C ± 1 °C

Contact time at intervals of 30 s from 30 s to 5 min and at intervals

of 5 min from 5 min to 120 min

minimum 1 min ± 5 s

1 min ± 5 s for post-milking teat

disinfectants

30 s ± 5 s for pre-milking teat

disinfectants

maximum 120 min ± 10 s

30 min ± 10 s for post-milking teat

disinfectants

3 min ± 10 s for pre-milking teat

disinfectants

Interfering substance Interfering substance

low level soiling 3,0 g/l bovine albumin Post milking: 10,0 g/l of milk

powder

high level soiling 10 g/l yeast extract

plus 10 g/l bovine Pre-milking: 3,0 g/l bovine

albumin albumin

additional any relevant any relevant substance

substance

)

Was known as Proteus vulgaris.

Any additional specific bactericidal activity shall be determined in accordance with 5.2.1 and 5.5.1.1 in

order to take into account intended specific use conditions.

5 Test method

5.1 Principle

5.1.1 A sample of the product as delivered and/or diluted with hard water (or water for ready-to-use

products) is added to a test suspension of bacteria in a solution of an interfering substance. The mixture

is maintained at the test temperature θ for the test contact time t. At the end of this contact time, an

aliquot is taken, and the bactericidal and/or the bacteriostatic activity in this portion is immediately

neutralized or suppressed by a validated method. The method of choice is dilution-neutralization. If a

suitable neutralizer cannot be found, membrane filtration is used. The numbers of surviving bacteria in

each sample are determined and the reduction is calculated.

5.1.2 For general disinfectant products, the test is performed using Enterococcus hirae, Proteus hauseri,

Pseudomonas aeruginosa and Staphylococcus aureus as test organisms. For teat disinfectants the test is

performed using Escherichia coli, Staphylococcus aureus and Streptococcus uberis as test organisms.

5.1.3 Additional and optional contact times and temperatures are specified. Additional test organisms

can be used.

5.2 Materials and reagents

5.2.1 Test organisms

The bactericidal activity shall be evaluated using the following strains as test organisms: )

a) General disinfection products

- Enterococcus hirae ATCC 10541

- Proteus hauseri ATCC 13315

- Pseudomonas aeruginosa ATCC 15442

- Staphylococcus aureus ATCC 6538

b) Teat disinfectants

- Escherichia coli ATCC 10536

- Staphylococcus aureus ATCC 6538

- Streptococcus uberis ATCC 19436

NOTE Refer to Annex A for strain references in some other culture collections.

The required incubation temperature for these test organisms is 36 °C ± 1 °C or 37 °C ± 1 °C (5.3.2.3). The

same temperature (either 36 °C or 37 °C) shall be used for all incubations performed during a test and its

control and validation.

2)

The ATCC numbers are the collection numbers of strains supplied by the American Type Culture Collection (ATCC) This

.

information is given for the convenience of users of this standard and does not constitute an endorsement by CEN of the product

named.

If additional test organisms are used, they shall be incubated under optimum growth conditions

(temperature, time, atmosphere, media) noted in the test report. If the additional test organisms selected

do not correspond to the specified strains, their suitability for supplying the required inocula shall be

verified. If these additional test organisms are not classified at a reference centre, their identification

characteristics shall be stated. In addition, they shall be held by the testing laboratory or national culture

collection under a reference for five years.

5.2.2 Culture media and reagents

5.2.2.1 General

All weights of chemical substances given in this standard refer to the anhydrous salts. Hydrated forms

may be used as an alternative, but the weights required shall be adjusted to allow for consequent

molecular weight differences.

The reagents shall be of analytical grade and/or appropriate for microbiological purposes. They shall be

free from substances that are toxic or inhibitory to the test organisms.

To improve reproducibility, it is recommended that commercially available dehydrated material is used

for the preparation of culture media. The manufacturer's instructions relating to the preparation of these

products should be rigorously followed.

For each culture medium and reagent, a shelf life should be fixed (see ISO/IEC 17025:2017).

5.2.2.2 Water

The water shall be freshly glass-distilled water and not demineralized water.

Sterilize in the autoclave [5.3.2.1 a)].

Refer to 5.2.2.7 for the procedure to prepare hard water.

NOTE 1 Sterilization is not necessary if the water is used e.g. for preparation of culture media and subsequently

sterilized.

NOTE 2 If distilled water of adequate quality is not available, water for injections (see bibliographic reference

[1]) can be used.

5.2.2.3 Tryptone Soya Agar (TSA)

Tryptone soya agar, consisting of:

— Tryptone, pancreatic digest of casein 15,0 g;

— Soya peptone, papaic digest of soybean meal 5,0 g;

— Sodium chloride (NaCl) 5,0 g;

— Agar 15,0 g;

— Water (5.2.2.2) to 1 000,0 ml.

Sterilize in the autoclave [5.3.2.1 a)]. After sterilization the pH of the medium shall be equivalent to

7,2 ± 0,2 when measured at (20 ± 1) °C.

In case of encountering problems with neutralization (5.5.1.2 and 5.5.1.3) it may be necessary to add

neutralizer to the TSA. Annex B gives guidance on the neutralizers that may be used.

5.2.2.4 Diluent

Tryptone sodium chloride solution, consisting of:

— Tryptone, pancreatic digest of casein 1,0 g;

— Sodium chloride (NaCl) 8,5 g;

— Water (5.2.2.2) to 1 000,0 ml.

— Sterilize in the autoclave [5.3.2.1 a)].

— After sterilization, the pH of the diluent shall be equivalent to 7,0 ± 0,2 when measured at (20 ± 1) °C.

5.2.2.5 Neutralizer

The neutralizer shall be validated for the product being tested in accordance with 5.5.1.2, 5.5.1.3 and

5.5.2. It shall be sterile.

Information on neutralizers that have been found to be suitable for some categories of products is given

in Annex B.

5.2.2.6 Rinsing liquid (for membrane filtration)

The rinsing liquid shall be validated for the product being tested in accordance with 5.5.1.2, 5.5.1.3 and

5.5.3. It shall be sterile, compatible with the filter membrane and capable of filtration through the filter

membrane under the test conditions described in 5.5.3.

Information on rinsing liquids that have been found to be suitable for some categories of products is given

in Annex B.

5.2.2.7 Hard water for dilution of products

For the preparation of 1 000 ml of hard water, the procedure is as follows:

— prepare solution A: dissolve 19,84 g magnesium chloride (MgCl ) and 46,24 g calcium chloride

(CaCl ) in water (5.2.2.2) and dilute to 1 000 ml. Sterilize by membrane filtration (5.3.2.7) or in the

autoclave [5.3.2.1 a)]. Autoclaving – if used - may cause a loss of liquid. In this case make up to

1 000 ml with water (5.2.2.2) under aseptic conditions. Store the solution in the refrigerator (5.3.2.8)

for no longer than one month;

— prepare solution B: dissolve 35,02 g sodium bicarbonate (NaHCO ) in water (5.2.2.2) and dilute to

1 000 ml. Sterilize by membrane filtration (5.3.2.7). Store the solution in the refrigerator (5.3.2.8) for

no longer than one week;

— place 600 ml to 700 ml of water (5.2.2.2) in a 1 000 ml volumetric flask (5.3.2.12) and add 6,0 ml

(5.3.2.9) of solution A, then 8,0 ml of solution B. Mix and dilute to 1 000 ml with water (5.2.2.2). The

pH of the hard water shall be 7,0 ± 0,2 (5.3.2.4) when measured at (20 ± 1) °C. If necessary, adjust

the pH by using a solution of approximately 40 g/l (about 1 mol/l) of sodium hydroxide (NaOH) or

approximately 36,5 g/l (about 1 mol/l) of hydrochloric acid (HCl).

The hard water shall be freshly prepared under aseptic conditions and used within 12 h.

NOTE When preparing the product test solutions (5.4.2), the addition of the product to the hard water

produces a different final water hardness in each test tube. In any case the final hardness is lower than 300 mg/l of

calcium carbonate (CaCO ) in the test tube.

5.2.2.8 Interfering substance

5.2.2.8.1 General

The interfering substance shall be chosen according to the conditions of use laid down for the product.

The interfering substance shall be sterile and prepared at 10 times its final concentration in the test. The

ionic composition (e.g. pH, calcium and/or magnesium hardness) and chemical composition (e.g. mineral

substances, protein, carbohydrates, lipids and detergents) shall be defined.

NOTE The term “interfering substance” is used even if it contains more than one substance.

5.2.2.8.2 Low-level soiling and Pre-milking teat disinfection (bovine albumin solution)

Dissolve 3,0 g of bovine albumin fraction V (suitable for microbiological purposes) in 100 ml of water

(5.2.2.2).

Sterilize by membrane filtration (5.3.2.7), keep in the refrigerator (5.3.2.8) and use within one month.

The final concentration of bovine albumin in the test procedure (5.5) is 3,0 g/l.

5.2.2.8.3 High-level soiling (mixture of bovine albumin solution with yeast extract)

Dissolve 50,0 g yeast extract powder in 150 ml of water (5.2.2.2) in a 250 ml volumetric flask (5.3.2.12)

and allow foam to collapse. Make up to the mark with water (5.2.2.2). Transfer to a clean dry bottle and

sterilize in an autoclave [5.3.2.1 a)]. Allow to cool to (20 ± 1) °C.

Pipette 25 ml of this solution into a 50 ml volumetric flask (5.3.2.12) and add 10 ml of water (5.2.2.2).

Dissolve 5,0 g of bovine albumin fraction V (suitable for microbiological purposes) in the solution with

shaking and allow foam to collapse. Make up to the mark with water (5.2.2.2), sterilize by membrane

filtration (5.3.2.7), keep in the refrigerator (5.3.2.8) and use within one month.

The final concentration in the test procedure (5.5) is 10,0 g/l yeast extract and 10,0 g/l bovine albumin.

5.2.2.8.4 Milk for post milking teat disinfection

Skimmed milk, guaranteed free of antibiotics and additives and reconstituted at a rate of 100 g powder

per litre of water (5.2.2.2), shall be prepared as follows:

+3

— prepare a solution of 100 g milk-powder in 1 000 ml water (5.2.2.2). Heat for 30 min at (105 ) °C

+3

or 5 min at (121 ) °C.

The final concentration in the test procedure (5.5) is 10,0 g/l milk powder.

5.3 Apparatus and glassware

5.3.1 General

Sterilize all glassware and parts of the apparatus that will come into contact with the culture media and

reagents or the sample, except those which are supplied sterile, by one of the following methods:

a) by moist heat, in the autoclave [5.3.2.1 a)];

b) by dry heat, in the hot air oven [5.3.2.1 b)].

5.3.2 Usual microbiological laboratory equipment and, in particular, the following:

5.3.2.1 Apparatus for sterilization:

+3

a) for moist heat sterilization, an autoclave capable of being maintained at (121 ) °C for a minimum

holding time of 15 min;

+5

b) for dry heat sterilization, a hot air oven capable of being maintained at (180 ) °C for a minimum

+5 +5

holding time of 30 min, at (170 ) °C for a minimum holding time of 1 h or at (160 ) °C for a

0 0

minimum holding time of 2 h.

5.3.2.2 Water baths, capable of being controlled between 5 and 40 °C ± 1 °C as required by the test

conditions, and at 45 °C ± 1 °C (to maintain melted TSA in case of pour plate technique).

5.3.2.3 Incubator, capable of being controlled either at 36 °C ± 1 °C or 37 °C ± 1 °C.

5.3.2.4 pH-meter, having an inaccuracy of calibration of no more than ± 0,1 pH units at 20 °C ± 1 °C.

A puncture electrode or a flat membrane electrode should be used for measuring the pH of the agar media

(5.2.2.3).

5.3.2.5 Stopwatch.

5.3.2.6 Shaker

a) Electromechanical agitator e.g. Vortex® mixer );

b) mechanical shaker.

5.3.2.7 Membrane filtration apparatus, constructed of a material compatible with the substances

to be filtered.

The apparatus shall have a filter holder of at least 50 ml volume. It shall be suitable for use with filters of

diameter 47 mm to 50 mm and 0,45 µm pore size for sterilization of hard water (5.2.2.7), bovine albumin

(5.2.2.8.2 and 5.2.2.8.3) and if the membrane filtration method (5.5.3) is used.

The vacuum source used shall give an even filtration flow rate. In order to obtain a uniform distribution

of the microorganisms over the membrane and to prevent overlong filtration, the device shall be set so

as to obtain the filtration of 100 ml of rinsing liquid in 20 s to 40 s.

5.3.2.8 Refrigerator, capable of being controlled at 2 °C to 8 °C.

5.3.2.9 Graduated pipettes, of nominal capacities 10 ml and 1 ml and 0,1 ml, or calibrated automatic

pipettes.

5.3.2.10 Petri dishes (plates) of size 90 mm to 100 mm.

5.3.2.11 Glass beads, 3 mm to 4 mm in diameter.

3)

Disposable sterile equipment is an acceptable alternative to reusable glassware.

4)

Vortex® is an example of a suitable product available commercially. This information is given for the convenience of users of

this standard and does not constitute an endorsement by CEN of this product.

5.3.2.12 Volumetric flasks.

5.4 Preparation of test organism suspensions and product test solutions

5.4.1 Test organism suspensions (test and validation suspension)

5.4.1.1 General

For each test organism, two different suspensions have to be prepared: the “test suspension” to perform

the test and the “validation suspension” to perform the controls and method validation.

5.4.1.2 Preservation and stock cultures of test organisms

The test organisms and their stock cultures shall be prepared and kept in accordance with EN 12353.

5.4.1.3 Working culture of test organisms

In order to prepare the working culture of the test organisms (5.2.1), prepare a subculture from the stock

culture (5.4.1.2) by streaking onto TSA slopes or plates (5.2.2.3) and incubate (5.3.2.3). After 18 h to 24

h prepare a second subculture from the first subculture in the same way and incubate for 18 h to 24 h.

From this second subculture, a third subculture may be produced in the same way. The second and (if

produced) third subcultures are the working cultures.

If it is not possible to prepare the second subculture on a particular day, a 48 h subculture may be used

for subsequent subculturing, provided that the subculture has been kept in the incubator (5.3.2.3) during

the 48 h period.

Never produce and use a fourth subculture.

For additional test organisms, any departure from this method of culturing the test organisms or

preparing the suspensions shall be noted, giving the reasons in the test report.

5.4.1.4 Test suspension (N)

a) Take 10 ml of diluent (5.2.2.4) and place in a 100 ml vessel with 5 g of glass beads (5.3.2.11). Take

the working culture (5.4.1.3) and transfer loopfuls of the cells into the diluent (5.2.2.4). The cells

should be suspended in the diluent by rubbing the loop against the wet wall of the flask to dislodge

the cells before immersing in the diluent. Shake the flask for 3 min using a mechanical shaker [5.3.2.6

b)]. Aspirate the suspension from the glass beads and transfer to another tube.

8 5 8

Adjust the number of cells in the suspension to 1,5 × 10 cfu/ml ) to 5 × 10 cfu/ml using diluent

(5.2.2.4), estimating the number of cfu by any suitable means. The use of a spectrophotometer for

adjusting the number of cells is highly recommended (approximately 620 nm wavelength - cuvette

10 mm path length). Each laboratory should therefore produce calibration data for each test

organism knowing that suitable values of optical density are generally found between 0,150 and

0,460. A colourimeter is a suitable alternative.

Maintain this test suspension in the water bath at the test temperature θ [5.5.1.1 a)] and use within

2 h.

−6 −7

b) For counting, prepare 10 and 10 dilutions of the test suspension using diluent (5.2.2.4). Mix

[5.3.2.6 a)].

5)

cfu/ml = colony forming unit(s) per milliliter.

Take a sample of 1,0 ml of each dilution in duplicate and inoculate using the pour plate or the spread

plate technique.

1) When using the pour plate technique, transfer each 1,0 ml sample into separate Petri dishes and add

15 ml to 20 ml melted TSA (5.2.2.3), cooled to 45 °C ± 1 °C.

2) When using the spread plate technique, spread each 1,0 ml sample – divided into portions of

approximately equal size – on an appropriate number (at least two) of surface dried plates containing

TSA (5.2.2.3).

For incubation and counting see 5.4.1.6.

5.4.1.5 Validation suspension (Nv)

a) To prepare the validation suspension, dilute the test suspension (5.4.1.4) with the diluent (5.2.2.4)

2 3 −5

to obtain 3,0 × 10 cfu/ml to 1,6 × 10 cfu/ml [about one fourth (1+3) of the 10 dilution].

−1

b) For counting prepare a 10 dilution with diluent (5.2.2.4). Mix [5.3.2.6 a)]. Take a sample of 1,0 ml

in duplicate and inoculate using the pour plate or the spread plate technique [5.4.1.4 b)].

For incubation and counting see 5.4.1.6.

5.4.1.6 Incubation and counting of the test and the validation suspensions

a) Incubate (5.3.2.3) the plates for 20 h to 24 h. Discard any plates that are not countable for any reason.

Count the cfu on the plates to determine the total number of cfu. Incubate the plates for a further 20

h to 24 h. Do not recount plates that no longer show well-separated colonies. Recount the remaining

plates. If the number has increased, use only the higher number for further evaluation.

b) Note for each plate the exact number of colonies but record > 330 for any counts higher than 330 and

determine the Vc values according to 5.6.2.2.

c) Calculate the numbers of cfu/ml in the test suspension N and in the validation suspension Nv using

the methods given in 5.6.2.3 and 5.6.2.5. Verify according to 5.7.

5.4.2 Product test solutions

The concentration of a product test solution shall be 1,25 times the desired test concentration because it

is diluted to 80 % during the test and the method validation (5.5.2 or 5.5.3). Product test solutions shall

be prepared in hard water (5.2.2.7) at minimum three different concentrations to include one

concentration in the active range and one concentration in the non-active range (5.8.2). The product as

received may be used as one of the product test solutions, in this case the highest tested concentration is

80 %.

Dilutions of ready-to-use products, i.e. products that are not diluted when applied, shall be prepared in

water (5.2.2.2).

For solid products, dissolve the product as received by weighing at least 1,0 g ± 10 mg of the product in a

volumetric flask and filling up with hard water (5.2.2.7). Subsequent dilutions (lower concentrations)

shall be prepared in volumetric flasks (5.3.2.12) on a volume/volume basis in hard water (5.2.2.7).

For liquid products, dilutions of the product shall be prepared with hard water on a volume/volume basis

using volumetric flasks (5.3.2.12).

The product test solutions shall be prepared freshly and used in the test within 2 h. They shall give a

physically homogeneous preparation that is stable during the whole procedure. If during the procedure

a visible inhomogeneity appears due to the formation of a precipitate or flocculent (for example, through

the addition of the interfering substance), it shall be recorded in the test report.

NOTE Counting microorganisms embedded in a precipitate or flocculent is difficult and unreliable.

The concentration of the product stated in the test report shall be the desired test concentration. Record

the test concentration in terms of mass per volume or volume per volume and details of the product

sample as received.

5.5 Procedure for assessing the bactericidal activity of the product

5.5.1 General

5.5.1.1 Experimental conditions

The experimental conditions may be selected according to the practical use considered for the product

(Clause 4):

a) temperature θ (in °C):

The temperatures to be tested are specified in Clause 4, Table 1; the allowed deviation for each

chosen temperature is ± 1 °C;

b) contact time t (in min and s):

the contact times to be tested are specified in Clause 4, Table 1; the allowed deviation for each contact

time is ± 10 s, except for 1 min or less where it is ± 5 s;

c) interfering substance:

the interfering substances to be tested are specified in Clause 4, Table 1.

Additional interfering substances may be tested according to specific fields of application;

d) test organisms (5.2.1):

the test organisms are as specified in Clause 4, Table 1 and 5.2.1. Additional test organisms may be

tested.

5.5.1.2 Choice of test method (dilution-neutralization or membrane filtration)

The method of choice is the dilution-neutralization method (5.5.2). To determine a suitable neutralizer,

carry out the validation of the dilution neutralization method (5.5.2.3, 5.5.2.4 and 5.5.2.5 in connection

with 5.5.2.6) using a neutralizer, chosen according to laboratory experience and published data.

If this neutralizer is not valid, repeat the validation test using an alternative neutralizer taking into

account the information given in Annex B.

In special circumstances it may be necessary to add neutralizer to TSA (5.2.2.3).

5.5.1.3 General instructions for validation and control procedures

The neutralization and/or removal of the bactericidal and/or bacteriostatic activity of the product shall

be controlled and validated - only for the highest product test concentration - for each of the used test

organisms and for each experimental condition (interfering substance, temperature, contact time). These

procedures (experimental condition control, neutralizer or filtration control and method validation) shall

be performed at the same time as the test and with the same neutralizer – or rinsing liquid – used in the

test.

In the case of ready-to-use-products, use water (5.2.2.2) instead of hard water.

If because of problems with neutralization, a neutralizer has been added to TSA (5.5.1.2) used for the

validation and control procedures the TSA used for the test shall contain the same amount of this

neutralizer as well.

5.5.1.4 Equilibration of temperature

Prior to testing, equilibrate all reagents (product test solutions (5.4.2), test suspension (5.4.1.4),

validation suspension (5.4.1.5), diluent used in method validation C (5.2.2.4), hard water (5.2.2.7) and

interfering substance (5.2.2.8) to the test temperature [5.5.1.1 a)] using the water bath (5.3.2.2)

controlled at θ.

Check that the temperature of the reagents is stabilized at θ.

The neutralizer (5.2.2.5) or the rinsing liquid (5.2.2.6) and water (5.2.2.2) shall be equilibrated at a

temperature of (20 ± 1) °C.

In the case of ready-to-use-products, water (5.2.2.2) shall be additionally equilibrated to θ.

5.5.1.5 Precautions for manipulation of test organisms

Do not touch the upper part of the test tube sides when adding the test or the validation suspensions

(5.4.1).

5.5.2 Dilution-neutralization method

5.5.2.1 General

The test and the control and validation procedures (5.5.2.2 through 5.5.2.6) shall be carried out in parallel

and separately for each experimental condition (5.5.1.1).

5.5.2.2 Test “Na” – determination of bactericidal concentrations

The procedure for determining bactericidal concentrations is as follows:

a) pipette 1,0 ml of the interfering substance (5.2.2.8) into a tube. Add 1,0 ml of the test suspension

(5.4.1.4). Start the stopwatch (5.3.2.5) immediately, mix [5.3.2.6 a)] and place the tube in a water

bath controlled at the chosen test temperature θ [5.5.1.1 a)] for 2 min ± 10 s. At the end of this time,

add 8,0 ml of one of the product test solutions (5.4.2). Restart the stopwatch at the beginning of the

addition. Mix [(5.3.2.6 a)] and place the tube in a water bath controlled at temperature θ for the

chosen contact time t [5.5.1.1 b)]. Just before the end of t, mix [5.3.2.6 a)] again;

b) at the end of t, take a 1,0 ml sample of the test mixture Na and transfer into a tube containing 8,0 ml

neutralizer (5.2.2.5) and 1,0 ml water (5.2.2.2). Mix [5.3.2.6 a)] and place in a water bath controlled

at 20 °C ± 1 °C. After a neutralization time of 5 min ± 10 s (in case of contact times of 10 min or

shorter, after a neutralization time of 10 s ± 1 s), immediately take a sample of 1,0 ml of the

neutralized test mixture Na (containing neutralizer, product test solution, interfering substance and

test suspension) in duplicate and inoculate using the pour plate or spread plate technique.

1) When using the pour plate technique, pipette each 1,0 ml sample into separate Petri dishes and add

15 ml to 20 ml of melted TSA (5.2.2.3), cooled to 45 °C ± 1 °C.

6)

For a graphical representation of this method, see Annex C.

2) When using the spread plate technique, spread each 1,0 ml sample – divided into portions of

approximately equal size – on an appropriate number (at least two) of surface dried plates containing

TSA (5.2.2.3).

For incubation and counting, see 5.5.2.6.

c) Perform the procedures a) and b) using the other product test solutions at the same time.

d) Perform the procedures a) to c) applying other test conditions and – if appropriate – other additional

experimental conditions (5.5.1.1).

5.5.2.3 Experimental conditions control A – validation of the selected experimental conditions

and/or verification of the absence of any lethal effect in the test conditions

To validate the selected experimental conditions and/or verify the absence of any lethal effect in the test

conditions, the procedure is as follows:

a) pipette 1,0 ml of the interfering substance used in the test (5.5.2.2) into a tube. Add 1,0 ml of the

validation suspension (5.4.1.5). Start the stopwatch immediately, mix [5.3.2.6 a)] and place the tube

in a water bath controlled at θ for 2 min ± 10 s.

At the end of this time, add 8,0 ml of hard water (5.2.2.7). [In the case of ready-to-use products: water

(5.2.2.2) instead of hard water.] Restart the stopwatch at the beginning of the addition. Mix [5.3.2.6

a)] and place the tube in a water bath controlled at θ for t. Just before the end of t, mix [5.3.2.6 a)]

again;

b) at the end of t, take a sample of 1,0 ml of this mixture A in duplicate and inoculate using the pour

plate or the spread plate technique [5.5.2.2 b)].

For incubation and counting, see 5.5.2.6.

5.5.2.4 Neutralizer control B – verification of the absence of toxicity of the neutralize

To verify the absence of toxicity of the neutralizer, the procedure is as follows:

a) pipette 8,0 ml of the neutralizer – used in the test (5.5.2.2) — and 1,0 ml of water (5.2.2.2) into a tube.

Add 1,0 ml of the validation suspension (5.4.1.5). Start the stopwatch at the beginning of the addition,

mix [5.3.2.6 a)], and place the tube in a water bath controlled at 20 °C ± 1 °C for 5 min ± 10 s (in case

of contact times of 10 min or shorter, after 10 s ± 1 s). Just b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...