EN 16214-4:2013

(Main)Sustainability criteria for the production of biofuels and bioliquids for energy applications - Principles, criteria, indicators and verifiers - Part 4: Calculation methods of the greenhouse gas emission balance using a life cycle analysis approach

Sustainability criteria for the production of biofuels and bioliquids for energy applications - Principles, criteria, indicators and verifiers - Part 4: Calculation methods of the greenhouse gas emission balance using a life cycle analysis approach

This European Standard specifies a detailed methodology that will allow any economic operator in a biofuel or bioliquid chain to calculate the actual GHG emissions associated with its operations in a standardised and transparent manner, taking all materially relevant aspects into account. It includes all steps of the chain from biomass production to the end transport and distribution operations.

The methodology strictly follows the principles and rules stipulated in the RED and particularly its Annex V, the EC decision dated 10 June 2010 "Guideline for calculation of land carbon stocks" for the purpose of Annex V to Directive 2009/28/EC (2010/335/EU) [5] as well as any additional interpretation of the legislative text published by the EU Commission. Where appropriate these rules are clarified, explained and further elaborated. In the context of accounting for heat and electricity consumption and surpluses reference is also made to Directive 2004/8/EC [6] on "the promotion of cogeneration based on a useful heat demand in the internal energy market" and the associated EU Commission decision of 21/12/2006 "establishing harmonised efficiency reference values for separate production of electricity and heat" [7].

The main purpose of this standard is to specify a methodology to estimate GHG emissions at each step of the biofuel/bioliquid production and transport chain. The specific way in which these emissions have to be combined to establish the overall GHG balance of a biofuel or bioliquid depends on the chain of custody system in use and is not per se within the scope of this part 4 of the EN 16214 standard. Part 2 of the standard, addresses these issues in detail also in accordance with the stipulations of the RED. Nevertheless, Clause 6 of this part of the standard includes general indications and guidelines on how to integrate the different parts of the chain.

Nachhaltigkeitskriterien für die Herstellung von Biokraftstoffen und flüssigen Biobrennstoffen für Energieanwendungen - Grundsätze, Kriterien, Indikatoren und Prüfer - Teil 4: Berechnungsmethoden der Treibhausgasemissionsbilanz unter Verwendung einer Ökobilanz

Diese Europäische Norm legt eine detaillierte Methodik fest, nach der jeder Wirtschaftsteilnehmer innerhalb einer Kette für Biokraftstoffe oder flüssige Biobrennstoffe die tatsächlichen, mit den jeweils durchgeführten Arbeitsgängen verbundenen Treibhausgasemissionen in einer genormten und transparenten Weise unter Berücksichtigung aller materiell relevanten Aspekte berechnen kann. Einbezogen sind alle Stufen der Kette von der Biomasseproduktion bis zum Endtransport und Vertrieb.

Die Methodik hält die in der EER und insbesondere in ihrem Anhang V festgelegten Grundsätze und Regeln, den Beschluss der Kommission vom 10. Juni 2010 über „Leitlinien für die Berechnung des Kohlenstoff-bestands im Boden für die Zwecke des Anhangs V der Richtlinie 2009/28/EG“ (2010/335/EU) [5] (2010/335/EU) ebenso wie alle zusätzlichen Auslegungen des von der EU-Kommission veröffentlichen legislativen Textes exakt ein. Diese Regeln werden, wenn angebracht, verdeutlicht, erläutert und weiter ausgearbeitet. Im Zusammenhang mit dem Wärme- und Stromverbrauch und den entsprechenden Überschüssen wird auch auf die Richtlinie 2004/8/EG [6] über die „Förderung einer am Nutzwärmebedarf orientierten Kraft-Wärme-Kopplung im Energiebinnenmarkt“ und die zugehörige Entscheidung der EU-Kommission vom 21.12.2006 zur „Festlegung harmonisierter Wirkungsgrad-Referenzwerte für die getrennte Erzeugung von Strom und Wärme“ [7] verwiesen.

Der Hauptzweck dieser Norm ist die Festlegung einer Methodik zur Berechnung der Treibhausgasemissionen für jede Stufe der Produktions- und Transportkette für Biokraftstoff/flüssigen Biobrennstoff. Die spezifische Art, in der diese Emissionen kombiniert werden müssen, um die gesamte Treibhausgasbilanz eines Biokraftstoffs oder flüssigen Biobrennstoffs zu ermitteln, hängt von dem für die überwachte Lieferkette (en: chain of custody) verwendeten System ab und fällt nicht per se in den Anwendungsbereich dieses Teils 4 von EN 16214. In Teil 2 der Norm werden diese Punkte, auch in Übereinstimmung mit den Festlegungen der EER, ausführlich behandelt. Dennoch werden in Abschnitt 6 dieses Teils der Norm allgemeine Hinweise und Leitlinien für die Integration der einzelnen Teile der Kette angegeben.

Critères de durabilité pour la production de biocarburants et de bioliquides pour des applications énergétiques - Principes, critères, indicateurs et vérificateurs - Partie 4: Méthodes de calcul du bilan des émissions de GES utilisant une approche d'analyse du cycle de vie

La présente Norme européenne spécifie une méthodologie détaillée permettant, à tout opérateur économique

de la chaîne du biocarburant ou du bioliquide, de calculer des émissions de GES réelles associées à ses

activités d’une manière normalisée et transparente, prenant en compte tous les aspects matériellement

pertinents. Elle comprend toutes les étapes de la chaîne, depuis la production de biomasse jusqu’aux

opérations finales de transport et de distribution.

La méthodologie observe rigoureusement les principes et les règles stipulés dans la Directive ENR et

particulièrement dans son Annexe V, la décision CE en date du 10 juin 2010 « Lignes directrices pour le

calcul des stocks de carbone dans les sols aux fins de l'Annexe V de la Directive 2009/28/CE (2010/335/UE)

[5], ainsi que toute interprétation du texte législatif publié par la Commission de l’UE. Ces règles sont

clarifiées, expliquées et développées, le cas échéant. Dans le cadre de la prise en compte de la

consommation et du surplus de chaleur et d’électricité, il est également fait référence à la

Directive 2004/8/CE [6] sur « la promotion de la cogénération sur la base de la demande de chaleur utile dans

le marché intérieur de l’énergie » et à la décision associée de la Commission de l’UE du 21 décembre 2006

« définissant des valeurs de référence d’efficacité harmonisées pour la production séparée d’électricité et de

chaleur » [7].

La présente norme vise principalement à spécifier une méthodologie d'estimation des émissions de GES à

chaque étape de la chaîne de production et de transport du biocarburant/bioliquide. La manière spécifique de

combiner ces émissions pour établir le bilan global des GES d’un biocarburant ou d’un bioliquide dépend de la

chaîne du système de surveillance utilisée et n’est pas traitée en soi dans le domaine d'application de cette

partie 4 de la norme EN 16214. La Partie 2 de la norme aborde ces sujets en détail conformément aux

stipulations de la Directive ENR. Néanmoins, l’Article 6 de cette partie de la norme contient des indications et

des directives générales sur la manière d'intégrer les différentes parties de la chaîne.

Sonaravno proizvedena biomasa za energijsko uporabo - Načela, merila, kazalniki in preverjalniki biogoriv in biotekočin - 4. del: Računske metode za bilance emisij toplogrednih plinov z uporabo analize življenjskega cikla

Ta evropski standard določa podrobno metodologijo, ki bo omogočala vsem gospodarskim subjektom v verigi biogoriv ali biotekočin izračun dejanske vrednosti emisij toplogrednih plinov (GHG), ki nastajajo med njihovimi operacijami, na standardiziran in pregleden način, pri čemer bodo upoštevani vsi bistveni vidiki. Vključuje vse točke v verigi od proizvodnje biomase do zaključnih operacij na področju prevoza in distribucije. V metodologiji so strogo upoštevana načela in pravila, navedena v direktivi o obnovljivih virih energije in zlasti v Prilogi V k navedeni direktivi, Sklep Komisije z dne 10. junija 2010 o smernicah za izračun zalog ogljika v zemljišču za namene Priloge V k Direktivi 2009/28/ES (2010/335/EU) [5] in dodatne razlage zakonodajnega besedila, ki ga je objavila Evropska komisija. Ta pravila so pojasnjena, razložena in dodatno opredeljena, kjer je to potrebno. V kontekstu vodenja evidence porabe toplote in električne energije ter presežnih vrednosti je prisotno tudi sklicevanje na Direktivo 2004/8/ES [6] o »spodbujanju soproizvodnje, ki temelji na rabi koristne toplote, na notranjem trgu z energijo«, in s tem povezano Odločbo Komisije z dne 21. decembra 2006 »o določitvi harmoniziranih vrednosti referenčnih izkoristkov za ločeno proizvodnjo električne energije in toplote« [7]. Glavni cilj tega standarda je določiti metodologijo za oceno emisij toplogrednih plinov na vsaki točki proizvodnje biogoriv/biotekočin in prevozne verige. Ta specifičen način, na katerega morajo biti te emisije združene za vzpostavitev celovitega ravnovesja toplogrednih plinov biogoriv oziroma biotekočin, je odvisen od verige sistema oskrbe v uporabi in ni samodejno del področja uporabe tega četrtega dela standarda EN 16214. Drugi del standarda podrobno obravnava ta vprašanja tudi v skladu z določbami direktive o obnovljivih virih energije. Kljub temu točka 6 tega dela standarda vključuje splošne navedbe in smernice glede načina vključitve različnih delov verige.

General Information

- Status

- Withdrawn

- Publication Date

- 15-Jan-2013

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 383 - Sustainably produced biomass for energy applications

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Nov-2019

- Completion Date

- 21-Jan-2026

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 11-Oct-2017

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

EN 16214-4:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Sustainability criteria for the production of biofuels and bioliquids for energy applications - Principles, criteria, indicators and verifiers - Part 4: Calculation methods of the greenhouse gas emission balance using a life cycle analysis approach". This standard covers: This European Standard specifies a detailed methodology that will allow any economic operator in a biofuel or bioliquid chain to calculate the actual GHG emissions associated with its operations in a standardised and transparent manner, taking all materially relevant aspects into account. It includes all steps of the chain from biomass production to the end transport and distribution operations. The methodology strictly follows the principles and rules stipulated in the RED and particularly its Annex V, the EC decision dated 10 June 2010 "Guideline for calculation of land carbon stocks" for the purpose of Annex V to Directive 2009/28/EC (2010/335/EU) [5] as well as any additional interpretation of the legislative text published by the EU Commission. Where appropriate these rules are clarified, explained and further elaborated. In the context of accounting for heat and electricity consumption and surpluses reference is also made to Directive 2004/8/EC [6] on "the promotion of cogeneration based on a useful heat demand in the internal energy market" and the associated EU Commission decision of 21/12/2006 "establishing harmonised efficiency reference values for separate production of electricity and heat" [7]. The main purpose of this standard is to specify a methodology to estimate GHG emissions at each step of the biofuel/bioliquid production and transport chain. The specific way in which these emissions have to be combined to establish the overall GHG balance of a biofuel or bioliquid depends on the chain of custody system in use and is not per se within the scope of this part 4 of the EN 16214 standard. Part 2 of the standard, addresses these issues in detail also in accordance with the stipulations of the RED. Nevertheless, Clause 6 of this part of the standard includes general indications and guidelines on how to integrate the different parts of the chain.

This European Standard specifies a detailed methodology that will allow any economic operator in a biofuel or bioliquid chain to calculate the actual GHG emissions associated with its operations in a standardised and transparent manner, taking all materially relevant aspects into account. It includes all steps of the chain from biomass production to the end transport and distribution operations. The methodology strictly follows the principles and rules stipulated in the RED and particularly its Annex V, the EC decision dated 10 June 2010 "Guideline for calculation of land carbon stocks" for the purpose of Annex V to Directive 2009/28/EC (2010/335/EU) [5] as well as any additional interpretation of the legislative text published by the EU Commission. Where appropriate these rules are clarified, explained and further elaborated. In the context of accounting for heat and electricity consumption and surpluses reference is also made to Directive 2004/8/EC [6] on "the promotion of cogeneration based on a useful heat demand in the internal energy market" and the associated EU Commission decision of 21/12/2006 "establishing harmonised efficiency reference values for separate production of electricity and heat" [7]. The main purpose of this standard is to specify a methodology to estimate GHG emissions at each step of the biofuel/bioliquid production and transport chain. The specific way in which these emissions have to be combined to establish the overall GHG balance of a biofuel or bioliquid depends on the chain of custody system in use and is not per se within the scope of this part 4 of the EN 16214 standard. Part 2 of the standard, addresses these issues in detail also in accordance with the stipulations of the RED. Nevertheless, Clause 6 of this part of the standard includes general indications and guidelines on how to integrate the different parts of the chain.

EN 16214-4:2013 is classified under the following ICS (International Classification for Standards) categories: 27.190 - Biological sources and alternative sources of energy; 75.160.20 - Liquid fuels; 75.160.40 - Biofuels. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16214-4:2013 has the following relationships with other standards: It is inter standard links to EN 16214-4:2013+A1:2019, EN 16214-1:2012, CEN/TS 16214-2:2020, EN 16214-4:2013/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16214-4:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Nachhaltig produzierte Biomasse für Energieanwendungen - Grundsätze, Kriterien, Indikatoren und Prüfer für Biokraftstoffe und flüssige Biobrennstoffe - Teil 4: Berechnungsmethoden der Treibhausgasemissionsbilanz unter Verwendung einer ÖkobilanzBiomasse produite de façon durable pour des utilisations énergétiques - Princips, critères, indicateurs et verificateurs pour bio-essences ét bioliquide - Partie 4 : Methode de calcul du bilan des emissions de GES utilisant une approche analyse du cycle de vieSustainably produced biomass for energy applications - Principles, criteria, indicators and verifiers for biofuels and bioliquids - Part 4: Calculation methods of the greenhouse gas emission balance using a life cycle analysis27.190Biološki viri in drugi alternativni viri energijeBiological sources and alternative sources of energy13.020.40Onesnaževanje, nadzor nad onesnaževanjem in ohranjanjePollution, pollution control and conservationICS:Ta slovenski standard je istoveten z:EN 16214-4:2013SIST EN 16214-4:2013en,fr,de01-junij-2013SIST EN 16214-4:2013SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16214-4

January 2013 ICS 75.160.20 English Version

Sustainability criteria for the production of biofuels and bioliquids for energy applications - Principles, criteria, indicators and verifiers - Part 4: Calculation methods of the greenhouse gas emission balance using a life cycle analysis approach

Critères de durabilité pour la production de biocarburants et de bioliquides pour des applications énergétiques - Principes, critères, indicateurs et vérificateurs - Partie 4: Méthodes de calcul du bilan des émissions de GES utilisant une approche d'analyse du cycle de vie

Nachhaltigkeitskriterien für die Herstellung von Biokraftstoffen und flüssigen Biobrennstoffen für Energieanwendungen - Grundsätze, Kriterien, Indikatoren und Prüfer - Teil 4: Berechnungsmethoden der Treibhausgasemissionsbilanz unter Verwendung einer Ökobilanz This European Standard was approved by CEN on 15 September 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 16214-4:2013: ESIST EN 16214-4:2013

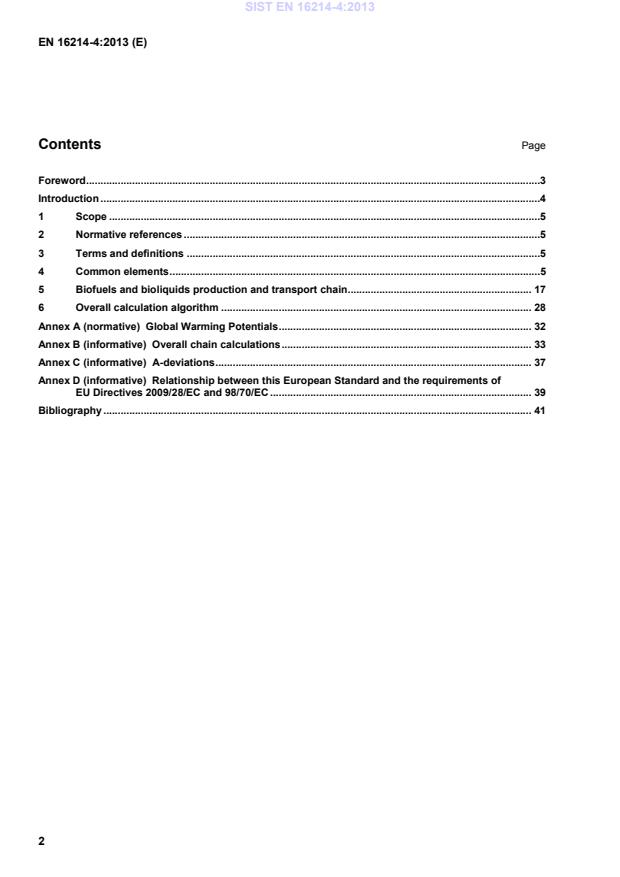

Global Warming Potentials . 32 Annex B (informative)

Overall chain calculations . 33 Annex C (informative)

A-deviations . 37 Annex D (informative)

Relationship between this European Standard and the requirements of EU Directives 2009/28/EC and 98/70/EC . 39 Bibliography . 41

the provision, by economic operators, of evidence that the production of raw material has not interfered with nature protection purposes, that the harvesting of raw material is necessary to preserve grassland's grassland status, and that the cultivation and harvesting of raw material does not involve drainage of previously undrained soil;

the auditing, by Member States and by voluntary schemes of information submitted by economic operators;

Both the EC and CEN agreed that these may play a role in the implementation of the EU biofuel and bioliquid sustainability scheme. In the Communication from the Commission on the practical implementation of the EU biofuels and bioliquids sustainability scheme and on counting rules for biofuels (2010/C 160/02, [4]), awareness of the CEN work is indicated. It is widely accepted that sustainability at large encompasses environmental, social and economic aspects. The European Directives make mandatory the compliance of several sustainability criteria for biofuels and bioliquids. This European Standard has been developed with the aim to assist EU Member States and economic operators with the implementation of EU biofuel and bioliquids sustainability requirements mandated by the European Directives. This European Standard is limited to certain aspects relevant for a sustainability assessment of biomass produced for energy applications. Therefore compliance with this standard or parts thereof alone does not substantiate claims of the biomass being produced sustainably. Where applicable, the parts of this standard contain at the end an annex that informs the user of the link between the requirements in the European Directive and the requirements in the CEN Standard. SIST EN 16214-4:2013

prEN 16214-2, Sustainably produced biomass for energy applications rs and 2: Conformity assessment including chain of custody and mass balance 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 16214-1:2012 apply. 4 Common elements 4.1 General A number of elements are relevant to several steps of the biofuel/bioliquid production and transport chain. They are described in this clause to which reference is made in subsequent clauses as appropriate. SIST EN 16214-4:2013

g/kg/t CO2eq / unit Lower heating value LHV Megajoule/ kilogram or Gigajoule/tonne MJ/kg, GJ/t Distance (land) D Kilometre km Distance (sea) D Nautical mile nM

4.5 Common basis for GHG emission terms In Annex V of the RED, the total GHG emissions from the use of a biofuel/bioliquid E, expressed per MJ of the biofuel/bioliquid, is expressed by the following formula: E = eec + el + ep + etd + eu – esca – eccs – eccr – eee (2) where eec

are the emissions from the extraction or cultivation of raw materials; el

are the annualised emissions from carbon stock changes caused by land-use change; ep

are the emissions from processing; etd

are the emissions from transport and distribution; eu

are the emissions from the fuel in use which shall be taken to be zero for biofuels and bioliquids esca

are the emission saving from soil carbon accumulation via improved agricultural management; eccs

are the emission saving from carbon capture and geological storage; eccr

are the emission saving from carbon capture and replacement; and eee

are the emission saving from excess electricity from cogeneration. "e"- terms are emissions incurred at various steps of the chain (see also Clause 5). This formulation implies that all “e” terms are expressed per unit of the biofuel/bioliquid (e.g. in g CO2eq / MJ). In practice the GHG emissions associated with each individual step of the biofuel/bioliquid production and transport chain cannot be immediately expressed per unit of the biofuel/bioliquid inasmuch as the exact fate of the product from this particular step is not known at the point of production. In this standard the GHG emissions associated with SIST EN 16214-4:2013

4.6 Completeness and system boundaries In order to determine which data is required for the estimation of the GHG associated with a certain activity, the economic operator shall define the boundaries of the system under consideration. A number of material and energy streams will enter the system directly controlled by the economic operator. Each of these streams will itself have a production and transport chain involving other streams and so on. In all cases the principle of completeness shall be followed, i.e. all emissions associated with all inputs into the economic operator’s core system shall be taken into account. This may be done by using overall figures from other sources in which case the boundaries are set narrowly around the economic operator’s system. Alternatively all or part of the production and transport chain of some of the input streams may be included thereby expanding the boundaries of the economic operator’s system. To account for the inherent variability of agricultural yields and inputs (fertilisers, agrochemicals etc.), multiannual averages may be used. The extent to which such production and transport chain are included within the boundary is a matter of judgement by the economic operator. A guiding element shall be the materiality of the contribution of a certain input to the overall GHG balance of the desired product and the completeness and quality of the overall figures from the other sources. Where such contribution is small, additional specific calculations are unlikely to be justified and use of a generic literature data may be appropriate.

Some processes involve use of very small amounts of input material such as process chemicals (e.g. anti-foam agents, corrosion inhibitors, water treatment chemicals etc.). The impact of such inputs on the total GHG footprint of the product is generally negligible and, in agreement with the verifiers, may be ignored. As guidance in this respect it is recommended that the contribution of such inputs be ignored if their combined value is unlikely to affect the GHG savings value of the biofuel/bioliquid rounded to the nearest percentage point. In line with the RED, GHG emissions generated during manufacturing or maintenance of equipment such as farm machinery, process plants and transport vectors or by the people operating them shall not be taken into account. 4.7 GHG emissions from energy use 4.7.1 General Each step of the chain will consume energy, either imported or internally generated from a portion of the feedstock or as a result of the conversion process. Energy may be imported in the form of: Fuel e.g. coal, oil, diesel, gasoline, natural gas, biomass (including in some cases the biofuel feedstock), biofuel or bioliquids; SIST EN 16214-4:2013

Where other forms of biomass or biomass-derived products are used as fuel, their emission factor shall be based on an analysis of their production and transport chain. For the purpose of this calculation CO2 emissions from the combustion of biomass-based fuels shall be taken as zero. Relevant emission factors will normally be available from the fuel supplier. For the calculation of the GHG emission factor of the fuel, CO2 emissions associated with end use of the fuel shall be those that would be produced by its complete combustion. For fuels that are fully or partly of biomass origin, combustion emissions from the fraction of carbon from biomass origin shall be deemed to be zero. Any significant emission of nitrous oxide or methane during the combustion process shall be taken into account. SIST EN 16214-4:2013

Although it is not per se required for the GHG calculation, the related energy consumption 0x may be calculated separately as: εx = LHVx x Qx (6) Typical LHVs of various fuels are listed in Annex III of the RED while emissions associated with biofuels as fuel to a process can be derived from the typical values in Annex V of the RED. Emission factors and LHVs for other fuels may be obtained from the applicable Member State guidance for calculating the Greenhouse Gas balance of biofuels. Where no Member State guidance is available this data shall be obtained from a verifiable source. In most cases, the fuel supplier should be able to supply this data. Values of εx or Qx can be obtained from either plant or accounting/invoicing records. 4.7.2.3 Imported heat Heat may be imported in the form of steam or via a hot fluid system. The emission factor shall be based on an analysis of the heat production facility. This will normally be provided by the heat supplier. 4.7.2.4 Imported electricity If the biofuel/bioliquid facility is connected to the local grid or imports electricity from a plant connected to the grid, then imported electricity (usually expressed in energy terms εel) shall be deemed to have been provided by the grid. The associated emission factor Feel shall represent a national or regional (e.g. EU-wide) supply average as published by authoritative bodies such as national statistics agencies. Where a biofuel/bioliquid facility imports electricity from a plant that is not connected to the grid the actual emission factor of that plant shall be used. 4.7.3 Combined heat and power supply (Cogeneration) In many cases both heat and electricity will be supplied to a facility from a cogeneration scheme. The following rules are applicable whether or not the cogeneration scheme and the biofuel/bioliquid facility have a common ownership and/or operation.

Where the entirety of the heat produced by the cogeneration plant is consumed by the biofuel/bioliquid facility, the GHG emission calculation shall be based on the total fuel consumption of the cogeneration plant. Where the cogeneration plant also supplies heat to other customers, the fuel consumption of the cogeneration plant shall be apportioned according to the relative heat consumption of each customer. SIST EN 16214-4:2013

4.7.5 Exported heat or electricity (no cogeneration cases) A step of the biofuel/bioliquid chain may produce excess heat that is exported and used by a third party. No credit shall be allocated to this excess heat. However where the surplus heat is clearly produced for meeting the demand of other parties by combusting a fuel in excess of the requirement of the biofuel/bioliquid facility, the portion of the fuel used for generating the surplus heat shall not be considered as an input into the chain. Unless the surplus heat is produced from a demonstrably separate facility that amount of fuel shall be deemed to have the quality of the average fuel used in all heat generation facilities used in the facility. A step of the biofuel/bioliquid chain may produce excess electricity that is exported either to the local grid or to a third party. SIST EN 16214-4:2013

4.7.6 Overall GHG balance from energy use and export The net GHG emissions associated with energy usage and export shall be calculated as follows: Cn = Cif + Cih + Cieg + Cint – Cex (8) where Cif is the emissions from fuel import (4.7.2.2), including cogeneration fuel (4.7.3); Cih is the emissions from heat import (4.7.2.3); Cieg is the emissions from grid electricity import (4.7.2.4); Cint is the emissions from combustion of own feedstock or internal stream (4.7.4); Cex is the emissions from exported cogeneration electricity (4.7.3). 4.8 Allocation rules The products from a step in the production and transport chain are classified into the biofuel/bioliquid itself or an intermediate product, co-products, residues and wastes (see definitions in EN 16214-1).

The total GHG emissions incurred in all upstream steps of the chain and up to the point where co-products are separated, are allocated between the biofuel/bioliquid or intermediate and the co-products. Wastes and residues do not share the burden of allocation i.e. none of the GHG emissions incurred up to the point at which they are collected are allocated to them. The conditions under which excess electricity produced on site and exported is deemed to be a co-product are set out in 4.7.5. The emission inventory for the allocation shall include all operations that need to be carried out in order to dispose of all wastes and residues which, therefore, leave the system without a GHG burden. Accordingly when a waste or residue is used for the production of biofuels or bioliquids the GHG emissions are deemed to be zero up to the point of collection as defined in EN 16214-1. If the waste or residue is subsequently used as feedstock for biofuels/bioliquid production all emissions incurred past that point shall be allocated to that waste or residue. As a result the identification of the biofuel/bioliquid or intermediate product related to the chain and the classification of an output product as a co-product, a residue or a waste is crucial to the outcome and shall be done in strict accordance with the definitions given in EN 16214-1. GHG emissions are allocated between the biofuel/bioliquid or intermediate and the co-products on the basis of their respective energy content as measured by their Lower Heating Value (LHV). The GHG emissions burden allocated to co-product i is therefore: ()∑×××=LHVjQjLHViQiCtCi/ (9) where Ct is the total GHG emissions incurred through the chain up to the point where the co-products are separated; Qi is the quantity of product i produced; SIST EN 16214-4:2013

Total GHG emissions associated with all inputs into processing A:

CtA = Cf + CmA + CeA GHG emissions allocation to Biofuel/Bioliquid:

C1 = CtA * Q1 * LHV1 / (Q1 * LHV1 + Q2 * LHV2) GHG emissions allocation to Co-product:

C2A = CtA * Q2 * LHV2 / (Q1 * LHV1 + Q2 * LHV2) Total GHG emissions associated with all inputs into processing B: Ctb = Cmb + CeB Total GHG emissions charged to the Co-product: C2 = C2A + CtB Where LHV1 is the lower heating value of the Biofuel/Bioliquid and LHV2 that of the Co-product. CtB = C2 + CmB + CeB Where LHVi is the lower heating value of product i. Figure 1 — Allocation between biofuel/bioliquid or intermediate and co-products without feedback loops SIST EN 16214-4:2013

Total GHG emissions associated with all inputs:

Ct = Cf + Cm + Ce GHG emissions allocation to Biofuel/Bioliquid:

C1 = Ct * Q1 * LHV1 / (Q1 * LHV1 + Q2 * LHV2) GHG emissions allocation to Co-product:

C2 = Ct * Q2 * LHV2 / (Q1 * LHV1 + Q2 * LHV2) Figure 2 — Allocation between biofuel/bioliquid or intermediate and co-products with feedback loops In Figure 1, the inputs to processing steps A and B are clearly separated and allocation occurs at the point at which the co-product is physically separated. Where different co-products are produced and separated at different stages of the process, a separate calculation and allocation shall be carried out for each sub-step leading to the production of a new co-product. In Figure 2, there are energy and material feedbacks between processing step A and B so that the energy inputs into each processing step are not clearly identifiable. The allocation boundary is extended to include processing step B. The LHV value shall be that pertaining to the actual product at the point at which it is separated from the other products and in the physical state in which it is produced taking into account its water content (see definition of LHV in EN 16214-1).

Products with high water content may have a very low or even negative heating value (i.e. the amount of heat required to dry them is higher than the heat that can be released by burning the dry matter). Negative heating values shall be considered to be zero i.e. no negative allocation is permitted. When a product is assigned a zero LHV, it effectively does not attract any GHG emissions allocation. Exported electricity produced in a scheme without cogeneration or from a co-product is considered as a co-product. In this case the term (Qi * LHVi) in Formula (9) shall be replaced by the actual electrical energy. Any material that would have been a co-product and is used directly to generate energy for the process or for export, shall be excluded from the allocation. Emission associated with the use of this material shall however be taken into account in the GHG balance. SIST EN 16214-4:2013

(13) where Qmmf is the fuel consumption of the machinery, expressed in mass, volume or energy terms per unit of land area and per year, Ff is the GHG emission factor for production transport and use of the fuel in mass of CO2eq per unit of fuel (mass, volume or energy). For reporting purposes the corresponding emission factor expressed in mass of CO2eq per unit of net biomass produced may also be calculated as Fmm = Clmm / Ybp (14) where Ybp is the net biomass yield expressed as the quantity of biomass (mass or volume), net of any losses or retained seeding material, per unit of land area and per year. 4.10.3 Other mobile or stationary machinery Emissions from other mobile or stationary machinery may be related to handling or preparation of biomass or other intermediate material (cranes, forklift trucks, elevators, etc.). The emissions from machinery in mass of CO2eq per unit of product handled are calculated as Cm = Qmf x Ff (15) where Qmf is the quantity of fuel consumed by the machinery over a period of time, expressed in mass, volume or energy terms, Ff is the GHG emission factor for production transport and use of the fuel in mass of CO2eq per unit of fuel (mass, volume or energy), The emission factor for the machinery is therefore: Fm = Qmf x Ff / Qp (16) where Qp is the quantity of product handled over the same period of time expressed in mass or volume. 4.11 GHG emissions from chemicals Chemicals may be used in various steps of the biofuel/bioliquid production and transport chain, process chemicals (additives, catalysts, etc.), reagents in conversion processes, etc. NOTE Fertilisers and agrochemicals are dealt with separately in 5.3.3 as their use is expressed per unit of land area. SIST EN 16214-4:2013

BIOMASS PRODUCTION covers all activities related to biomass cultivation, in either an agricultural, forestry or other environment, from plant seeding to harvesting. It includes the impact of all inputs such as seeding material, fertilisers, agrochemicals, energy etc. It also includes the GHG impact of nitrous oxide and methane emitted during biomass production. In addition to crops and forestry products, waste and residues from various sources may be used as feedstock for biofuel / bioliquid manufacture. For these alternative feedstocks the land use and biomass production steps do not apply. BIOMASS PREPARATION covers all activities related to the treatment of the biomass such as drying, chipping etc. In some cases wastes and residues may require such treatment beyond their point of collection for the specific purpose of using them as a feedstock for biofuel / bioliquid manufacture. SIST EN 16214-4:2013

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...