EN 14607-8:2004

(Main)Space engineering - Mechanical - Part 8: Materials

Space engineering - Mechanical - Part 8: Materials

EN 14607 Part 8 of Space engineering - Mechanical defines the mechanical engineering requirements for materials.

This document also encompasses the effects of the natural and induced environments to which materials used for space applications can be subjected.

This document defines requirements for the establishment of the required mechanical and physical properties of the materials including the effects of the environmental conditions, material selection, procurement, production and verification. Verification includes destructive and nondestructive test methods. Material procurement and control is closely related to required quality assurance procedures and detailed references to EN 13291-3 are made.

When viewed from the perspective of a specific project context, the requirements defined in this document should be tailored to match the genuine requirements of a particular profile and circumstances of a project.

NOTE Tailoring is a process by which individual requirements of specifications, standards and related documents are evaluated, and made applicable to a specific project by selection, and in some exceptional cases, modification of existing or addition of new requirements.

Raumfahrttechnik - Mechanik - Teil 8: Werkstoffe

Ingénierie spatiale - Mécanique - Partie 8: Matériaux

Vesoljska tehnika – Mehanika - 8. del: Materiali

General Information

- Status

- Withdrawn

- Publication Date

- 03-Aug-2004

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/SS T02 - Aerospace

- Drafting Committee

- CEN/SS T02 - Aerospace

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 24-Aug-2016

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 31-Aug-2016

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 14607-8:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Space engineering - Mechanical - Part 8: Materials". This standard covers: EN 14607 Part 8 of Space engineering - Mechanical defines the mechanical engineering requirements for materials. This document also encompasses the effects of the natural and induced environments to which materials used for space applications can be subjected. This document defines requirements for the establishment of the required mechanical and physical properties of the materials including the effects of the environmental conditions, material selection, procurement, production and verification. Verification includes destructive and nondestructive test methods. Material procurement and control is closely related to required quality assurance procedures and detailed references to EN 13291-3 are made. When viewed from the perspective of a specific project context, the requirements defined in this document should be tailored to match the genuine requirements of a particular profile and circumstances of a project. NOTE Tailoring is a process by which individual requirements of specifications, standards and related documents are evaluated, and made applicable to a specific project by selection, and in some exceptional cases, modification of existing or addition of new requirements.

EN 14607 Part 8 of Space engineering - Mechanical defines the mechanical engineering requirements for materials. This document also encompasses the effects of the natural and induced environments to which materials used for space applications can be subjected. This document defines requirements for the establishment of the required mechanical and physical properties of the materials including the effects of the environmental conditions, material selection, procurement, production and verification. Verification includes destructive and nondestructive test methods. Material procurement and control is closely related to required quality assurance procedures and detailed references to EN 13291-3 are made. When viewed from the perspective of a specific project context, the requirements defined in this document should be tailored to match the genuine requirements of a particular profile and circumstances of a project. NOTE Tailoring is a process by which individual requirements of specifications, standards and related documents are evaluated, and made applicable to a specific project by selection, and in some exceptional cases, modification of existing or addition of new requirements.

EN 14607-8:2004 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14607-8:2004 has the following relationships with other standards: It is inter standard links to EN 16603-32-08:2016, EN 16603-32:2014, EN 16602-70:2016, EN 13701:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14607-8:2004 is associated with the following European legislation: Standardization Mandates: M/237. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14607-8:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Vesoljska tehnika – Mehanika - 8. del: MaterialiRaumfahrttechnik - Mechanik - Teil 8: WerkstoffeIngénierie spatiale - Mécanique - Partie 8: MatériauxSpace engineering - Mechanical - Part 8: Materials49.140Vesoljski sistemi in operacijeSpace systems and operationsICS:Ta slovenski standard je istoveten z:EN 14607-8:2004SIST EN 14607-8:2005en01-januar-2005SIST EN 14607-8:2005SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14607-8August 2004ICS 49.140English versionSpace engineering - Mechanical - Part 8: MaterialsIngénierie spatiale - Mécanique - Partie 8: MatériauxRaumfahrttechnik - Mechanik - Teil 8: WerkstoffeThis European Standard was approved by CEN on 27 June 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14607-8:2004: ESIST EN 14607-8:2005

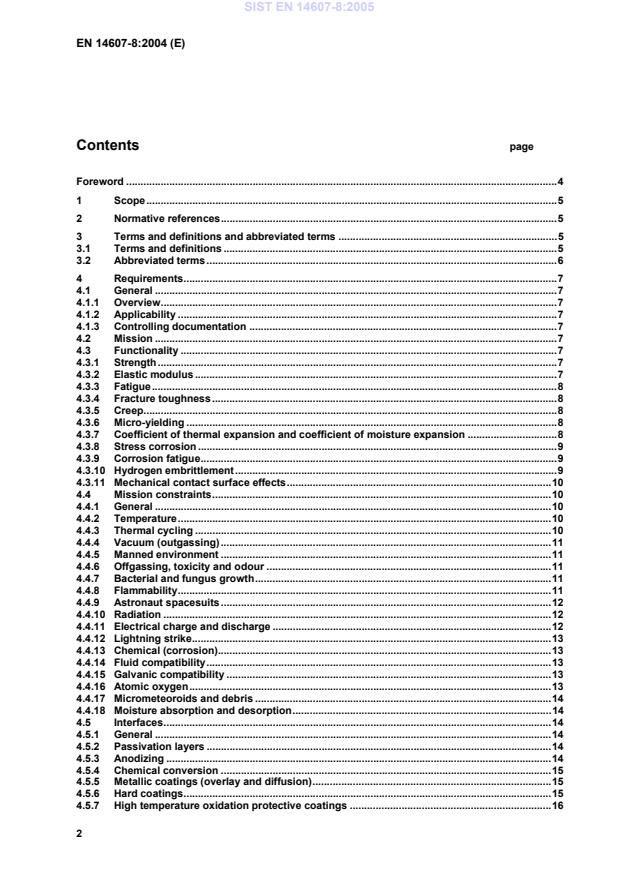

3 4.5.8 Thermal barriers.16 4.5.9 Moisture barriers.16 4.5.10 Diffusion barriers.16 4.5.11 Coatings on CFRP.16 4.6 Joining.17 4.6.1 General.17 4.6.2 Mechanical fastening.17 4.6.3 Adhesive bonding.17 4.6.4 Fusion.18 4.7 Design.19 4.7.1 General.19 4.7.2 Material design allowables.19 4.7.3 Metal design allowables.19 4.7.4 Composite design allowables.20 4.7.5 Composite sandwich constructions.20 4.7.6 Aluminium.21 4.7.7 Steel.21 4.7.8 Titanium.22 4.7.9 Magnesium alloys.22 4.7.10 Beryllium and beryllium alloys.22 4.7.11 Mercury.22 4.7.12 Refractory alloys.22 4.7.13 Superalloys.23 4.7.14 Other metals.23 4.7.15 Castings.23 4.7.16 Forgings.23 4.7.17 Glass and ceramics.23 4.7.18 Ceramic Matrix Composites — CMC (including carbon-carbon).23 4.7.19 Polymers (thermosets and thermoplastics).23 4.7.20 Rubbers (excluding adhesive rubbers).24 4.7.21 Lubricants.24 4.7.22 Thermal control insulants (including ablative materials).25 4.7.23 Optical materials.25 4.8 Verification.25 4.8.1 General.25 4.8.2 Metallic materials.25 4.8.3 Composite materials — laminates.26 4.8.4 Mechanical and physical test methods.26 4.8.5 Test methods on metals.26 4.8.6 Test methods on composites.27 4.8.7 Non-destructive inspection (NDI).28 4.8.8 Proof testing.29 4.9 Production and manufacture.29 4.9.1 General.29 4.9.2 Procurement.29 4.9.3 Manufacturer.29 4.9.4 Supplier.29 4.10 In-service.29 4.10.1 General.29 4.10.2 Maintenance.30 4.10.3 Inspection.30 4.10.4 Repair.30 4.11 Data exchange.30 4.12 Product assurance.31 4.13 Deliverables.32 Bibliography.33

Tables Table 1 —Document requirements for materials.32 SIST EN 14607-8:2005

Foreword This document (EN 14607-8:2004) has been prepared by CMC. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by February 2005, and conflicting national standards shall be withdrawn at the latest by February 2005. It is based on a previous version1)

originally prepared by the ECSS Mechanical Engineering Standard Working Group, reviewed by the ECSS Technical Panel and approved by the ECSS Steering Board. The European Cooperation for Space Standardization (ECSS) is a cooperative effort of the European Space Agency, National Space Agencies and European industry associations for the purpose of developing and maintaining common standards. This document is one of the series of space standards intended to be applied together for the management, engineering and product assurance in space projects and applications. Requirements in this document are defined in terms of what shall be accomplished, rather than in terms of how to organize and perform the necessary work. This allows existing organizational structures and methods to be applied where they are effective, and for the structures and methods to evolve as necessary without rewriting the standards. EN 14607 Space engineering - Mechanical is published in 8 Parts: • Part 1: Thermal control • Part 2: Structural • Part 3: Mechanisms • Part 4: ECLS • Part 5: Propulsion • Part 5.1: Liquid and electric propulsion for spacecraft • Part 5.2: Solid propulsion for spacecraft, solid and liquid propulsion for launchers • Part 6: Pyrotechnics • Part 7: Mechanical parts • Part 8: Materials According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

1) ECSS-E-30 Part 8A. SIST EN 14607-8:2005

reaction of the engineering material with its environment with a consequent deterioration in properties of the material 3.1.5 Elastic modulus the ratio between uniaxial stress and the strain 3.1.6 material design allowable material property that has been determined from test data on a probability basis and has been chosen to assure a high degree of confidence in the integrity of the completed structure 3.1.7 micro-yield applied force to produce a residual strain of 1 ×10-6 mm/m along the tensile or compression loading direction 3.1.8 polymer high molecular weight organic compound, natural or synthetic, with a structure that can be represented by a repeated small unit, the mer EXAMPLE Polyethylene, rubber, and cellulose. 3.2 Abbreviated terms The following abbreviated terms are defined and used within this document. Abbreviation Meaning ASTM American Society for Testing Materials CFRP carbon fibre reinforced plastic CMC ceramic matrix composites CME coefficient of moisture expansion CTE coefficient of thermal expansion DRD document requirements definition EB electron beam Kic plane strain critical stress intensity factor Kiscc plane strain critical stress intensity factor for a specific environment LEO low Earth orbit MIG metal inert gas MMC metal matrix composite MoS2 molybdenum disulphide NDE non-destructive evaluation NDI non-destructive inspection SIST EN 14607-8:2005

NOTE Fatigue fracture can form in components which are subjected to alternating stresses. These stresses can exist far below the allowed static strength of the material. 4.3.4 Fracture toughness a) For homogeneous materials the Kic or Kiscc shall be measured according to approved procedures. b) Metallic materials intended for use in corrosive surface environments shall be tested for fracture toughness under representative conditions. NOTE The fracture toughness is a measure of the damage tolerance of a material containing initial flaws or cracks. The fracture toughness in metallic materials is described by the plain strain value of the critical stress intensity factor. The fracture toughness depends on the environment. 4.3.5 Creep When creep is expected to occur, testing under representative service conditions shall be performed. NOTE Creep is a time-dependant deformation of a material under an applied load. It usually occurs at elevated temperature, although some materials creep at room temperature. If permitted to continue indefinitely, creep terminates in rupture. Extrapolations from simple to complex stress-temperature-time conditions are difficult. 4.3.6 Micro-yielding a) Where dimensional stability requirements shall be met, micro-yielding shall be assessed. b) When micro-yielding is expected to occur, testing and analysis in relation with the mechanical loading during the life cycle of the hardware shall be performed. NOTE

1 Some materials can exhibit residual strain after mechanical loading. NOTE

2 In general the most severe mechanical loading occurs during launch. 4.3.7 Coefficient of thermal expansion and coefficient of moisture expansion a) Thermal coefficient mismatch between structural members shall be minimized such that stresses generated in the specified temperature range for the item are acceptable. b) The coefficient of thermal expansion (CTE) of composite materials intended for high stability structural applications shall be systematically determined by means of dry test coupons under dry test conditions. c) For hygroscopic materials intended for high stability structural applications, the coefficient of moisture expansion (CME) shall be systematically determined. d) A sensitivity analysis which takes in consideration the inaccuracies inherent in the manufacturing process shall be performed for all composite materials. NOTE The difference in thermal or moisture expansion between members of a construction or between the constituents of a composite or a coated material can induce large stresses or strains and can finally lead to failures. SIST EN 14607-8:2005

• classified as fracture critical items, or • parts associated with the fabrication of launch vehicles. e) The technical criteria, for the selection of materials, of EN 13291-3 shall apply. 4.3.9 Corrosion fatigue For all materials in contact with chemicals and experiencing an alternating loading it shall be demonstrated that the degradation of properties over the complete mission is acceptable. NOTE Corrosion fatigue indicates crack formation and propagation caused by the effect of alternating loading in the presence of a corrosion process. Because of the time dependence of corrosion, the number of cycles before failure depends on the frequency of the loading. Since chemical attack takes time to take effect, its influence is greater as the frequency is reduced. No metals or alloys demonstrate complete resistance to corrosion fatigue.

4.3.10 Hydrogen embrittlement The possibility of hydrogen embrittlement occurring during component manufacture or use shall be assessed. An appropriate material evaluation shall be undertaken including the assessment of adequate protection and control. NOTE Metals can be embrittled by absorbed hydrogen to such a degree that the application of the smallest tensile stress can cause the formation of cracking.

The following are possible sources of hydrogen:

• thermal dissociation of water in metallurgical processes (e.g. casting and welding), • decomposition of gases, • pickling, • corrosion, • galvanic processes (e.g. plating), and • ion bombardment. SIST EN 14607-8:2005

1 The friction behaviour of polymers differs from that of metals. The surfaces left in contact under load can creep and high local temperatures can be generated by frictional heating at regions of real contact. NOTE

2 When clean surfaces are placed in contact they do not touch over the whole of their apparent area. The load is supported by surface irregularities and the following interactions can occur: • elastic deformation, • adhesion, • plastic deformation, • material transfer and removal, • heat transfer chemical reaction, • transformation of kinetic energy into heat energy, and • diffusion or localized melting. b) Structural applications shall be designed to avoid wear. NOTE Wear is the progressive loss of material from the operating surface of a body occurring as a result of relative motion at the surface. Wear is generally considered to be detrimental, but in mild form it can be beneficial, e.g. during the running-in period of engineering surfaces.

The major types of wear are abrasive wear, adhesive wear, erosive wear, rolling wear and fretting. c) For all solid surfaces in static contact with other solid surfaces and intended to be separated it shall be demonstrated that the increase in separation force during this physical contact conforms to the required performance. NOTE For very clean surfaces strong adhesion occurs at the regions of real contact, a part of which can result in cold-welding. 4.4 Mission constraints 4.4.1 General Product assurance requirements on mission constraints shall be in accordance with EN 13291-3. 4.4.2 Temperature a) Material properties shall be compatible with the thermal environment to which they are exposed. b) The passage through transition temperatures (e.g. brittle-ductile transitions or glass transition temperatures including the effects of moisture or other phase transitions) shall be taken into account. NOTE Cryogenic tanks and thermal protection systems for re-entry applications are examples of the extremes of the temperature range. Temperatures below room temperature generally cause an increase in strength properties, with a reduction in the ductility. Ductility and strength can however either increase or decrease at temperatures above room temperature. This change depends on many factors, such as temperature and time of exposure. 4.4.3 Thermal cycling Materials subject to thermal cycling shall be selected to ensure they are capable of withstanding the induced thermal stresses and shall be tested according to approved procedures. SIST EN 14607-8:2005

4.4.4 Vacuum (outgassing) All materials intended for use in space systems shall be evaluated by thermal vacuum tests according to approved procedures to determine their outgassing characteristics. NOTE

1 Vacuum exposure can lead to outgassing. In some cases it can degrade the properties of the material and can raise corona problems or contamination on other parts due to evolved products. NOTE

2 The screening process applied to materials depends on their intended application, e.g. near optics the requirements are more stringent, while materials used in a hermetically sealed container are not necessarily subjected to an outgassing test.

4.4.5 Manned environment a) All materials intended for use in manned space flight systems shall be subject to product assurance, safety policy and basic specifications whose application shall be mandatory. b) All materials intended for use in manned space flight systems shall be analysed for hazard and risk potential, both structural and physiological. c) Safety of human life shall be the overriding consideration during design and operation of space systems, including all facilities and ground support systems. 4.4.6 Offgassing, toxicity and odour a) Spacecraft and associated equipment shall be manufactured from materials, and by processes, that shall not cause an unacceptable hazard to personnel or hardware, either on the ground or in space.

b) For materials intended for use in manned compartments of spacecrafts, offgassing and toxicity analysis shall be performed and the levels agreed with the customer.

NOTE In a closed environment of a manned spacecraft, contaminants in the atmosphere are potentially dangerous with respect to toxicity. 4.4.7 Bacterial and fungus growth a) Materials shall not support bacterial or fungus growth and shall be sterilizable without any deterioration of their properties. b) The level of bacterial and fungus contamination shall be determined on the finally assembled hardware. 4.4.8 Flammability a) Evaluation of materials flammability resistance, for the most hazardous environment envisaged for their use, shall be performed for: • unmanned spacecraft launched by Space Transportation System (STS) when powered on during launch, • manned spacecrafts, • stored equipment, and • payload or experiments. b) Materials shall be screened according to approved procedures.

b) Maximum potential differences shall be in accordance with approved values and procedures. NOTE If two or more dissimilar materials are in direct electrical contact in a corrosive solution or atmosphere, galvanic corrosion can occur. The least resistant material becomes the anode and the most resistant material becomes the cathode. The cathodic material corrodes very little or not at all, while the corrosion of the anodic material is greatly enhanced. 4.4.16 Atomic oxygen a) All materials considered for use on the external surfaces of the spacecraft intended for use at low Earth orbit altitudes (between 200 km and 700 km) shall be evaluated for their resistance to atomic oxygen. NOTE Spacecraft in low Earth orbit (LEO) altitudes are exposed to a flux of atomic oxygen. The flux level varies with altitude, velocity vector and solar activity. The fluence levels vary with the duration of exposure. b) Test procedures shall be subject to approval by the customer. SIST EN 14607-8:2005

1 Low energy impact occurs when a part impacts

the material with a velocity in a range of 1 m/s to 100 m/s. The effects of the impact is dependant upon the velocity, angle of impact and mass. NOTE

2 Low energy debris can cause plastic deformation on metals surfaces as the primary effects and can lead to delamination within composites. NOTE

3 High energy impact occurs at very high velocities in the range of several km/s. The effect of the impact depends among others on its mass of the debris. For impacts with low mass the primary effect is surface pitting and erosion. For impact with high mass significant impact damage can occur which can be catastrophic for the material. 4.4.18 Moisture absorption and desorption a) Precautions shall be taken to avoid moisture absorption during manufacture and storage. The relative humidity and temperature of the manufacture and storage environments shall be controlled and monitored. NOTE The properties of composite materials are susceptible to changes induced by the absorption of moisture. Moisture absorption occurs during production of components and up to the launch of the spacecraft, desorption occurs in the space vacuum. b) Induced stresses by moisture absorption and desorption of structural polymer-based materials occurring during the life cycle of the hardware shall be assessed and agreed with the customer. c) Where dimensional stability requirements are specified, hygro strains shall be assessed and agreed with the customer. 4.5 Interfaces 4.5.1 General The following covers the requirements for the interfaces (surface finishes) and methods of interfacing. NOTE The surface finish of a component can influence its mechanical and environmental durability. a) The surface finish shall be specified (e.g. composition and thickness). b) The surface finish shall be free from clearly visible coating defects and shall not be stained or discoloured. c) Materials applied to a substrate shall not cause the substrate to suffer degradation which can lead to an unacceptable loss of performance or integrity. d) Coatings and substrates shall be evaluated in combination and not separately (e.g. CTE mismatches). 4.5.2 Passivation layers When using passivation layers above their bakeout temperature water release can occur. The design shall take this into consideration. 4.5.3 Anodizing a) When anodizing is used as the final surface treatment, the anodized layers shall be sealed and shall be continuous. When anodizing as a bonding pre-treatment, sealing need not be done.

b) Very thin products such as foils shall be anodized with caution. SIST EN 14607-8:2005

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...