EN 14382:2005+A1:2009

(Main)Safety devices for gas pressure regulating stations and installations - Gas safety shut-off devices for inlet pressures up to 100 bar

Safety devices for gas pressure regulating stations and installations - Gas safety shut-off devices for inlet pressures up to 100 bar

This document specifies constructional, functional, testing and marking requirements, sizing and documentation of gas safety shut-off devices used in the pressure regulating stations in accordance with EN 12186 or EN 12279:

- for inlet pressures up to 100 bar and nominal diameters up to DN 400;

- for an operating temperature range from -20 °C to +60 °C,

which operate with fuel gases of the 1st and 2nd family in accordance with EN 437 in transmission and distribution networks and also in commercial and industrial installations.

"Gas safety shut-off devices" will hereafter be called "SSDs" except in titles.

For standard safety shut-off devices when used in pressure regulating stations complying with EN 12186 or EN 12279, Annex ZA lists all applicable Essential Requirements except the external corrosion resistance in case of environmental conditions where corrosion is likely to occur.

This document considers the following classes/types of SSDs:

temperature classes:

- class 1: operating temperature range from -10 °C to 60 °C;

- class 2: operating temperature range from -20 °C to 60 °C;

functional classes:

- class A: SSDs that close when damage to the pressure detector element occurs (applicable to overpressure SSDs only) or when external power fails and whose re-opening, after an intervention for overpressure, is possible only manually;

- class B: SSDs that do not close when damage to the pressure detector element occurs and whose re-opening, after an intervention for overpressure, is possible only manually;

SSDs types:

- type IS: (integral strength type);

- type DS: (differential strength type).

SSDs complying with the requirements of this document may be declared as "in conformity with EN 14382" and bear the mark "EN 14382".

The material and functional requirements specified in this document may be applied to SSDs which use thermal energy or the effects of electrical energy to trip the operation of the closing member. For these SSDs the operat

Sicherheitseinrichtungen für Gas-Druckregelanlagen und –einrichtungen - Gas-Sicherheitsabsperreinrichtungen für Eingangsdrücke bis 100 bar

!Dieses Dokument legt Anforderungen an Konstruktion, Funktion, Prüfung und Kennzeichnung,

Dimensionierung und Dokumentation von Gas-Sicherheitsabsperreinrichtungen fest, die in Druckregelanlagen

nach EN 12186 und EN 12279 eingesetzt werden:"

⎯ für Eingangsdrücke bis 100 bar und Nennweiten bis DN 400;

⎯ für einen Betriebstemperaturbereich von −20 °C bis +60 °C,

die mit Gasen der 1. und 2. Gasfamilie nach EN 437 in Gastransport- und Gasverteilungsnetzen und auch in

gewerblichen und industriellen Anlagen eingesetzt werden.

„Gas-Sicherheitsabsperreinrichtung“ wird im Weiteren, außer in Überschriften, mit „SAE“ abgekürzt.

!Für Standard-Sicherheitsabsperreinrichtungen, die in den Druckregelanlagen nach EN 12186 oder

EN 12279 verwendet werden, sind in Anhang ZA alle relevanten grundlegenden Anforderungen erfasst, mit

Ausnahme der äußeren Korrosionsbeständigkeit unter Umgebungsbedingungen, in denen das Auftreten von

Korrosion wahrscheinlich ist."

!Dieses Dokument behandelt folgende Klassen und Ausführungen von SAE:"

Temperaturklassen:

⎯ Klasse 1: Betriebstemperaturbereich von −10 °C bis 60 °C;

⎯ Klasse 2: Betriebstemperaturbereich von −20 °C bis 60 °C.

Funktionsklassen:

⎯ !Klasse A: SAE, die bei Schaden an der Vergleichermembran (nur bei SAE mit oberem Ansprechdruck)

oder beim Ausfall der externen Hilfsenergie schließen und bei denen die erneute Öffnung nach

einem Auslösen beim oberen Ansprechdruck nur manuell möglich ist;

⎯ Klasse B: SAE, die bei einem Schaden an der Vergleichermembran nicht schließen, und bei denen die

erneute Öffnung nach einem Auslösen beim oberen Ansprechdruck nur manuell möglich ist.

SAE-Ausführungen:

⎯ Ausführung IS (einheitlicher Festigkeitsbereich);

⎯ Ausführung DS (verschiedene Festigkeitsbereiche);"

SAE, die den Anforderungen dieser Norm entsprechen, dürfen als „in Übereinstimmung mit EN 14382“

deklariert und mit der Kennzeichnung „EN 14382“ versehen werden.

Dispositifs de sécurité pour postes et installations de détente-régulation de pression de gaz - Clapets de sécurité pour pressions amont jusqu'à 100 bar

Varnostne naprave za plinske regulacijske postaje in napeljave - Plinske varnostne zaporne naprave za vstopne tlake do 100 bar (vključno z dopolnilom A1)

General Information

- Status

- Withdrawn

- Publication Date

- 17-Mar-2009

- Withdrawal Date

- 10-Feb-2026

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-Aug-2019

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2014/68/EU - Directive 2014/68/EU of the European Parliament and of the Council of 15 May 2014 on the harmonisation of the laws of the Member States relating to the making available on the market of pressure equipmentOJ Ref: C 293/01, C 293/01, C 293/01, C 293/01, C 293/01,, OJ Date: 12-Aug-2016

Not Harmonized97/23/EC - Pressure equipmentOJ Ref: C 226, C 226, C 226, C 226, C 226, C 226, C 226, C OJ Date: 19-Sep-2009

Relations

- Effective Date

- 09-Dec-2015

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 06-Sep-2010

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

prEN 15116 - Ventilation in buildings - Chilled beams - Testing and rating of active chilled beams - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 14382:2005+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety devices for gas pressure regulating stations and installations - Gas safety shut-off devices for inlet pressures up to 100 bar". This standard covers: This document specifies constructional, functional, testing and marking requirements, sizing and documentation of gas safety shut-off devices used in the pressure regulating stations in accordance with EN 12186 or EN 12279: - for inlet pressures up to 100 bar and nominal diameters up to DN 400; - for an operating temperature range from -20 °C to +60 °C, which operate with fuel gases of the 1st and 2nd family in accordance with EN 437 in transmission and distribution networks and also in commercial and industrial installations. "Gas safety shut-off devices" will hereafter be called "SSDs" except in titles. For standard safety shut-off devices when used in pressure regulating stations complying with EN 12186 or EN 12279, Annex ZA lists all applicable Essential Requirements except the external corrosion resistance in case of environmental conditions where corrosion is likely to occur. This document considers the following classes/types of SSDs: temperature classes: - class 1: operating temperature range from -10 °C to 60 °C; - class 2: operating temperature range from -20 °C to 60 °C; functional classes: - class A: SSDs that close when damage to the pressure detector element occurs (applicable to overpressure SSDs only) or when external power fails and whose re-opening, after an intervention for overpressure, is possible only manually; - class B: SSDs that do not close when damage to the pressure detector element occurs and whose re-opening, after an intervention for overpressure, is possible only manually; SSDs types: - type IS: (integral strength type); - type DS: (differential strength type). SSDs complying with the requirements of this document may be declared as "in conformity with EN 14382" and bear the mark "EN 14382". The material and functional requirements specified in this document may be applied to SSDs which use thermal energy or the effects of electrical energy to trip the operation of the closing member. For these SSDs the operat

This document specifies constructional, functional, testing and marking requirements, sizing and documentation of gas safety shut-off devices used in the pressure regulating stations in accordance with EN 12186 or EN 12279: - for inlet pressures up to 100 bar and nominal diameters up to DN 400; - for an operating temperature range from -20 °C to +60 °C, which operate with fuel gases of the 1st and 2nd family in accordance with EN 437 in transmission and distribution networks and also in commercial and industrial installations. "Gas safety shut-off devices" will hereafter be called "SSDs" except in titles. For standard safety shut-off devices when used in pressure regulating stations complying with EN 12186 or EN 12279, Annex ZA lists all applicable Essential Requirements except the external corrosion resistance in case of environmental conditions where corrosion is likely to occur. This document considers the following classes/types of SSDs: temperature classes: - class 1: operating temperature range from -10 °C to 60 °C; - class 2: operating temperature range from -20 °C to 60 °C; functional classes: - class A: SSDs that close when damage to the pressure detector element occurs (applicable to overpressure SSDs only) or when external power fails and whose re-opening, after an intervention for overpressure, is possible only manually; - class B: SSDs that do not close when damage to the pressure detector element occurs and whose re-opening, after an intervention for overpressure, is possible only manually; SSDs types: - type IS: (integral strength type); - type DS: (differential strength type). SSDs complying with the requirements of this document may be declared as "in conformity with EN 14382" and bear the mark "EN 14382". The material and functional requirements specified in this document may be applied to SSDs which use thermal energy or the effects of electrical energy to trip the operation of the closing member. For these SSDs the operat

EN 14382:2005+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 23.060.40 - Pressure regulators. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14382:2005+A1:2009 has the following relationships with other standards: It is inter standard links to EN 13787:2001, EN 14382:2005/prA1, EN 14382:2005, EN 14382:2019, EN 60534-1:1993, EN ISO 15613:2004, EN 12516-2:2004, EN ISO 9606-3:1999, EN 13906-2:2013, EN 1349:2009, EN ISO/IEC 17025:2000, prEN 15116, EN ISO 15607:2003, EN 12186:2025, EN ISO 15610:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14382:2005+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14382:2005+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheitseinrichtungen für Gas-Druckregelanlagen und –einrichtungen - Gas-Sicherheitsabsperreinrichtungen für Eingangsdrücke bis 100 barDispositifs de sécurité pour postes et installations de détente-régulation de pression de gaz - Clapets de sécurité pour pressions amont jusqu'à 100 barSafety devices for gas pressure regulating stations and installations - Gas safety shut-off devices for inlet pressures up to 100 bar23.060.40Pressure regulatorsICS:Ta slovenski standard je istoveten z:EN 14382:2005+A1:2009SIST EN 14382:2005+A1:2009en,fr,de01-junij-2009SIST EN 14382:2005+A1:2009SLOVENSKI

STANDARDSIST EN 14382:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14382:2005+A1

March 2009 ICS 23.060.40 Supersedes EN 14382:2005English Version

Safety devices for gas pressure regulating stations and installations - Gas safety shut-off devices for inlet pressures up to 100 bar

Dispositifs de sécurité pour postes et installations de détente-régulation de pression de gaz - Clapets de sécurité pour pressions amont jusqu'à 100 bar

Sicherheitseinrichtungen für Gas-Druckregelanlagen und -einrichtungen - Gas-Sicherheitsabsperreinrichtungen für Eingangsdrücke bis 100 bar This European Standard was approved by CEN on 30 December 2004 and includes Amendment 1 approved by CEN on 12 January 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14382:2005+A1:2009: ESIST EN 14382:2005+A1:2009

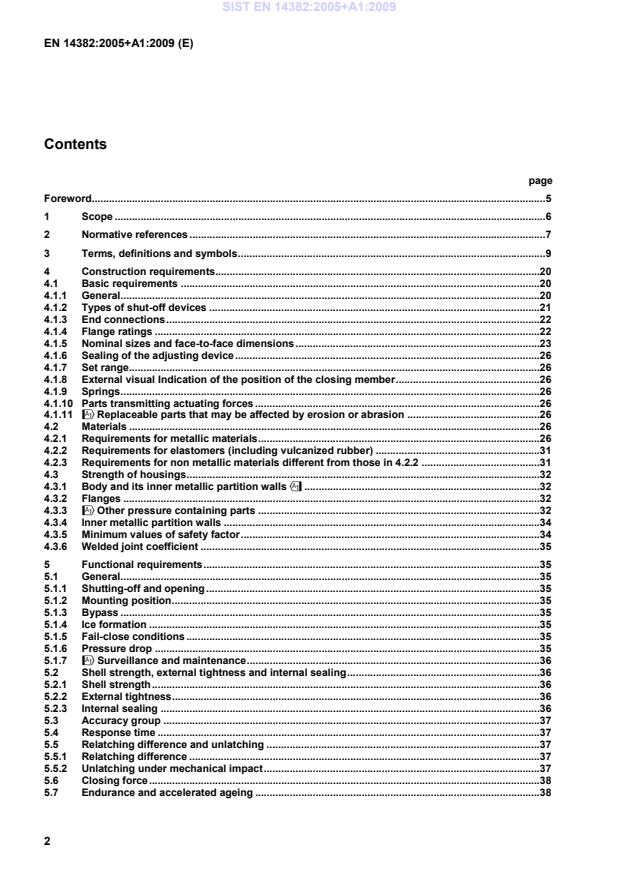

Ice formation . 58A.1General . 58A.2Requirements . 58A.3Tests . 58Annex B (informative)

Compliance evaluation . 59B.1General . 59B.2Introduction . 59B.3Procedure . 59B.4Manufacturer’s compliance evaluation . 60B.5Issue of the certificate of compliance . 60Annex C (informative)

Pressure drop and flow coefficient . 61C.1Calculation method for pressure drop throughout the SSD . 61C.2Test method for the determination of the flow coefficient Cv . 61Annex D (informative)

Alternative test method for verification of the strength of the trip mechanism, valve seat and closing member. 63D.1Test method. 63D.2Test method for the determination of the dynamic factor Cr . 63D.3Test method for a series of SSDs . 64Annex E (informative)

Sizing equation . 66Annex F (informative)

Inspection certificate . 67Annex G (informative)

Order specification . 69G.1General . 69G.2Minimum specifications . 69G.2.1Details of construction . 69G.2.2Dimensions. 69G.2.3Performance . 69G.3Optional specifications . 70Annex H (informative)

Acceptance test . 71Annex I (informative)

!Seat leakage (alternative requirement)" . 72Annex J (normative)

Materials . 73J.1Steel materials for pressure containing parts and inner metallic partition walls . 73J.2Metallic materials different from steel materials for pressure containing parts and inner metallic partition walls . 79J.3Materials for fixtures, integral process and sensing lines, connectors and fasteners . 84Annex K (informative)

!Suitability of safety shut-off device for damp operating conditions . 87Annex L (informative)

Glossary . 88Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 97/23/EC . 90Bibliography . 92 SIST EN 14382:2005+A1:2009

≤ 200 m3/h at normal conditions and inlet pressure ≤ 5 bar." SIST EN 14382:2005+A1:2009

(ISO 9606-3:1999) EN ISO 9606-4:1999, Qualification test of welders – Fusion welding – Part 4: Nickel and nickel alloys

(ISO 9606-4:1999) EN ISO 15607:2003, Specification and qualification of welding procedures for metallic materials – General rules (ISO 15607:2003) EN ISO 15609-1:2004, Specification and qualification of welding procedures for metallic materials – Welding procedure specification – Part 1: Arc welding (ISO 15609-1:2004) EN ISO 15610:2003, Specification and qualification of welding procedures for metallic materials – Qualification based on tested welding consumables (ISO 15610:2003) EN ISO 15611:2003, Specification and qualification of welding procedures for metallic materials – Qualification based on previous welding experience (ISO 15611:2003) EN ISO 15612:2004, Specification and qualification of welding procedures for metallic materials – Qualification by adoption of a standard welding procedure (ISO 15612:2004) EN ISO 15613:2004, Specification and qualification of welding procedures for metallic materials – Qualification based on pre-production welding test (ISO 15613:2004) SIST EN 14382:2005+A1:2009

!

" Key 1 Bypass 6

Controller 2

Relatching device 7

Sensing line 3

Trip mechanism 8

Actuator 4

Breather line 9

Sensing point 5

Setting element 10

Closing member

!11 Scheme 1a" Figure 1 — Example of a direct acting safety shut-off device SIST EN 14382:2005+A1:2009

Key 1

Bypass 7

Sensing line 2

Actuator 8

External loading pressure line 3

Relatching device 9

Internal loading pressure line 4

Exhaust line 10

Breather/exhaust line 5

Trip mechanism 11

Sensing point 6

Controller 12

Closing member Figure 2 — Example of an indirect acting shut-off device

Key 1

Bypass 7

Sensing line 2

Actuator 8

External loading pressure line 3

Relatching device 9

Internal loading pressure line 4

Exhaust line 10

Breather/exhaust line 5

Trip mechanism 11

Sensing point 6

Controller 12

Closing member

13 Pressure reducer (is applicable) Figure 3 — Example of an indirect acting shut-off device

!deleted text" 3.2.3 loading pressure line line connecting the controller and/or actuator to the internal or external power source 3.2.4 pressure containing parts parts whose failure to function would result in a release of the retained fuel gas to the atmosphere NOTE These include bodies, closing member, controllers, bonnets, blind flanges and pipes for process and sensing lines but exclude compression fittings, diaphragms, bolts and other fasteners. 3.2.5 inner metallic partition wall metallic wall that separates a chamber into two individual pressure-containing chambers at different pressures under normal operating conditions 3.2.6 sensing line line connecting the sensing point and the controller 3.2.7 exhaust line !line connecting the controller and/or actuator of the SSD to atmosphere for the safe exhausting of fuel gas in the event of failure of any part" SIST EN 14382:2005+A1:2009

1) 1 bar = 105 Pascal = 1 000 mbar = 10-1 MPa = 105 N/m2. SIST EN 14382:2005+A1:2009

" Key 1

Set value of trip pressure (pdso) 2

Actual value of trip pressure (dio) 3

Trip pressure deviation 4

Accuracy group (AG) 5

Relatching difference (∆pw) Figure 4 — Monitored pressure and trip pressure !3.3.6.6 pressure drop drop in pressure, at specified operating conditions, of gas passing through the SSD body" 3.4 !Terms, symbols and definitions related to the design and tests" !deleted text" !3.4.1 component operating pressure p gas pressure occurring in any part of a SSD during operation" SIST EN 14382:2005+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...