EN 12897:2016+A1:2020

(Main)Water supply - Specification for indirectly heated unvented (closed) storage water heaters

Water supply - Specification for indirectly heated unvented (closed) storage water heaters

EN 12897:2016+A1 specifies the constructional and performance requirements and methods of test for indirectly heated, unvented (closed) storage water heaters of up to 2 000 l volume suitable for connection to a water supply at a pressure between 0,05 MPa and 1,0 MPa (0,5 bar and 10 bar), and fitted with control and safety devices designed to prevent the temperature of the stored drinking water from reaching 95 °C. Whilst storage water heaters intended primarily for direct heating are not covered by this document, it does allow the provision of electric heating elements for auxiliary use.

Wasserversorgung - Bestimmung für mittelbar beheizte, unbelüftete (geschlossene) Speicher-Wassererwärmer

Dieses Dokument legt die Anforderungen an die Konstruktionstechnik und die Leistung und Prüfverfahren für mittelbar (indirekte) beheizte, unbelüftete (geschlossene) Speicher Wassererwärmer bis zu 2 000 l Volumen fest, die für den Anschluss an ein Wasserversorgungssystem bei einem Druck zwischen 0,05 MPa und 1,0 MPa (0,5 bar und 10 bar) geeignet und mit Regel und Sicherheitseinrichtungen ausgerüstet sind, die so ausgelegt sind, dass die Temperatur des gespeicherten Trinkwassers 95 °C nicht übersteigt.

Obwohl dieses Dokument keine Speicher Wassererwärmer behandelt, die hauptsächlich für direkte Er-wärmung vorgesehen sind, lässt es die Bereitstellung von elektrischen Heizelementen zu Hilfszwecken zu.

Alimentation en eau - Prescriptions pour préparateurs d'eau chaude par accumulation à chauffage indirect non ouverts à l'air libre (fermés)

Oskrba z vodo - Specifikacija za posredno ogrevane neprezračevane (zaprte) akumulacijske grelnike vode

General Information

- Status

- Published

- Publication Date

- 04-Feb-2020

- Withdrawal Date

- 30-Aug-2020

- Technical Committee

- CEN/TC 164 - Water supply

- Drafting Committee

- CEN/TC 164/WG 10 - Hot water and cold water storage within dwellings

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 22-May-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 24-Mar-2020

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 13959:2004 - Anti-pollution check valves - DN 6 to DN 250 inclusive family E, type A, B, C and D - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12897:2016+A1:2020 is a European standard published by CEN that specifies constructional and performance requirements and test methods for indirectly heated unvented (closed) storage water heaters (hot water storage tanks). The amendment A1 (approved October 2019, published February 2020) updates the 2016 edition and aligns the standard with EU energy labelling and ecodesign requirements. It covers units up to 2 000 L and systems designed to limit stored drinking water temperature to 95 °C. The standard applies to heaters suitable for connection to mains water pressures between 0.05 MPa and 1.0 MPa and permits auxiliary electric elements for indirect systems.

Key Topics and Requirements

The standard addresses both design and verification aspects. Major technical topics include:

- Constructional requirements: inspection access, draining and hydraulic connections.

- Temperature control: control devices and limits to prevent excessive water temperature.

- Mechanical resistance and stability: pressure resistance of storage vessels and primary heaters, durability and leakage testing (including double-walled primary heaters).

- Safety equipment: requirements for energy cut-outs, temperature relief valves, pressure/expansion valves, pressure reducing devices, expansion provision and backflow prevention.

- Performance testing: hot water safety and performance (Annex A), measurement of standing heat loss for factory-insulated units (Annex B), standing heat loss methodology aligned with EU directives.

- Conformity and factory production control: initial type testing, production testing, and technical documentation requirements.

- Documentation: assembly, maintenance and operating instructions.

- Notable changes in A1: capacity extended to 2 000 L, maximum permitted temperature reduced to 95 °C, and revised durability and heat-loss testing methods.

Applications and Who Uses It

EN 12897:2016+A1:2020 is intended for:

- Manufacturers designing and certifying indirectly heated closed storage water heaters.

- Test laboratories performing type and production tests (standing heat loss, pressure and leakage tests, performance).

- Certification and conformity bodies assessing compliance with European regulations (energy labelling and ecodesign).

- Specifiers, consulting engineers and procurement teams writing product requirements for buildings and district heating systems.

- Installers and maintenance teams using the standard’s guidance for safe installation, expansion provisions and maintenance instructions.

Practical benefits include improved safety, harmonized test methods for market access across CEN member states, and clear data for energy labelling and ecodesign compliance.

Related Standards

EN 12897 references several normative standards relevant to valves, controls and safety devices, for example:

- EN 1487, EN 1488, EN 1489, EN 1490, EN 1491 (building valves)

- EN 1567 (pressure reducing valves)

- EN 1717 (backflow prevention)

- EN 60379, EN 13203 (performance of storage and gas-fired hot water appliances)

- EN 60730-2-9 (temperature sensing controls)

- EN 15332 (energy assessment of hot water storage systems)

Keywords: EN 12897:2016+A1:2020, indirectly heated unvented storage water heaters, closed storage water heaters, standing heat loss, pressure resistance, durability testing, energy labelling, ecodesign.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 12897:2016+A1:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Water supply - Specification for indirectly heated unvented (closed) storage water heaters". This standard covers: EN 12897:2016+A1 specifies the constructional and performance requirements and methods of test for indirectly heated, unvented (closed) storage water heaters of up to 2 000 l volume suitable for connection to a water supply at a pressure between 0,05 MPa and 1,0 MPa (0,5 bar and 10 bar), and fitted with control and safety devices designed to prevent the temperature of the stored drinking water from reaching 95 °C. Whilst storage water heaters intended primarily for direct heating are not covered by this document, it does allow the provision of electric heating elements for auxiliary use.

EN 12897:2016+A1 specifies the constructional and performance requirements and methods of test for indirectly heated, unvented (closed) storage water heaters of up to 2 000 l volume suitable for connection to a water supply at a pressure between 0,05 MPa and 1,0 MPa (0,5 bar and 10 bar), and fitted with control and safety devices designed to prevent the temperature of the stored drinking water from reaching 95 °C. Whilst storage water heaters intended primarily for direct heating are not covered by this document, it does allow the provision of electric heating elements for auxiliary use.

EN 12897:2016+A1:2020 is classified under the following ICS (International Classification for Standards) categories: 91.140.65 - Water heating equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12897:2016+A1:2020 has the following relationships with other standards: It is inter standard links to EN 12897:2016, EN IEC 60730-2-9:2019, EN 60379:2004, EN 1488:2021, EN 1491:2022, EN 13203-3:2022, EN 13203-7:2022, EN 13959:2004, EN 15332:2007, EN 1567:1999, EN 13203-2:2022, EN 13203-4:2022, EN 1717:2025, EN 13203-6:2022, EN 13203-1:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12897:2016+A1:2020 is associated with the following European legislation: EU Directives/Regulations: 812/2013, 814/2013; Standardization Mandates: M/534. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12897:2016+A1:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2020

Nadomešča:

SIST EN 12897:2016

Oskrba z vodo - Specifikacija za posredno ogrevane neprezračevane (zaprte)

akumulacijske grelnike vode

Water supply - Specification for indirectly heated unvented (closed) storage water

heaters

Wasserversorgung - Bestimmung für mittelbar beheizte, unbelüftete (geschlossene)

Speicher-Wassererwärmer

Alimentation en eau - Prescriptions pour préparateurs d'eau chaude par accumulation à

chauffage indirect non ouverts à l'air libre (fermés)

Ta slovenski standard je istoveten z: EN 12897:2016+A1:2020

ICS:

91.140.65 Oprema za ogrevanje vode Water heating equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12897:2016+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2020

EUROPÄISCHE NORM

ICS 91.140.65

English Version

Water supply - Specification for indirectly heated

unvented (closed) storage water heaters

Alimentation en eau - Prescriptions pour préparateurs Wasserversorgung - Bestimmung für mittelbar

d'eau chaude par accumulation à chauffage indirect beheizte, unbelüftete (geschlossene) Speicher-

non ouverts à l'air libre (fermés) Wassererwärmer

This amendment A1 modifies the European Standard EN 12897:2016; it was approved by CEN on 9 October 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for inclusion of

this amendment into the relevant national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This amendment exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the

same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12897:2016+A1:2020 E

worldwide for CEN national Members.

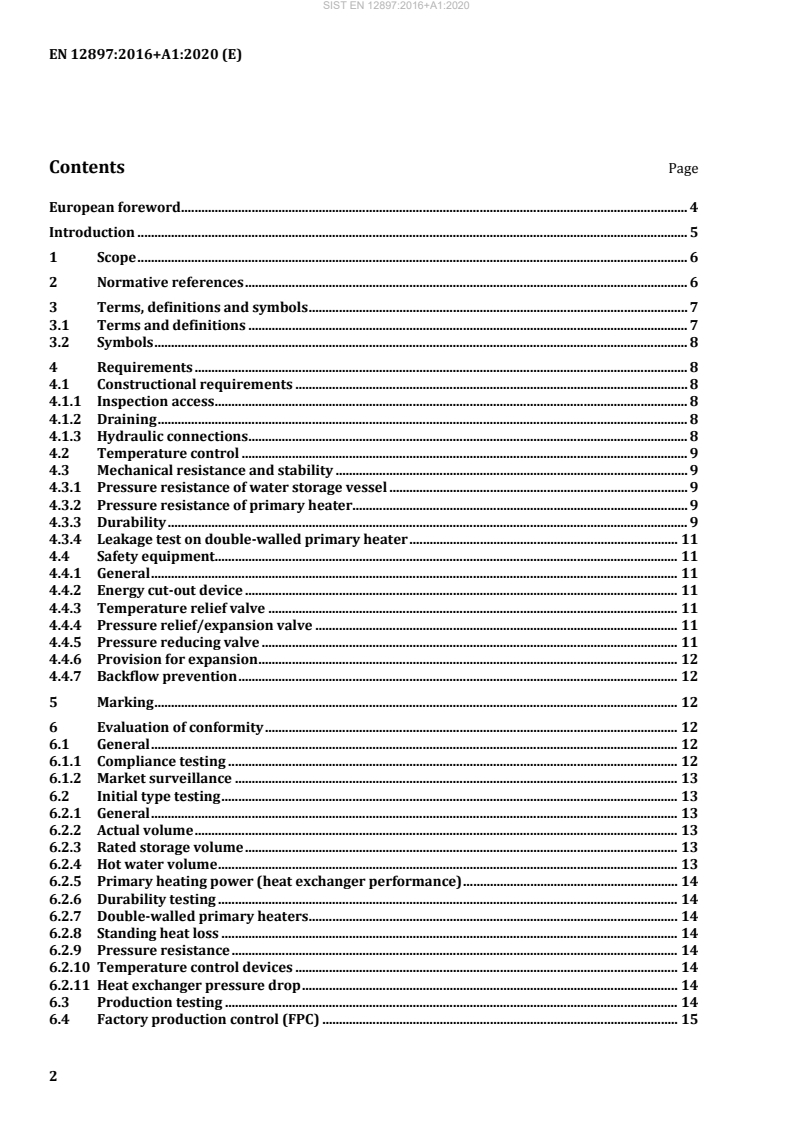

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and symbols . 7

3.1 Terms and definitions . 7

3.2 Symbols . 8

4 Requirements . 8

4.1 Constructional requirements . 8

4.1.1 Inspection access . 8

4.1.2 Draining . 8

4.1.3 Hydraulic connections . 8

4.2 Temperature control . 9

4.3 Mechanical resistance and stability . 9

4.3.1 Pressure resistance of water storage vessel . 9

4.3.2 Pressure resistance of primary heater. 9

4.3.3 Durability . 9

4.3.4 Leakage test on double-walled primary heater . 11

4.4 Safety equipment. 11

4.4.1 General . 11

4.4.2 Energy cut-out device . 11

4.4.3 Temperature relief valve . 11

4.4.4 Pressure relief/expansion valve . 11

4.4.5 Pressure reducing valve . 11

4.4.6 Provision for expansion . 12

4.4.7 Backflow prevention . 12

5 Marking . 12

6 Evaluation of conformity . 12

6.1 General . 12

6.1.1 Compliance testing . 12

6.1.2 Market surveillance . 13

6.2 Initial type testing . 13

6.2.1 General . 13

6.2.2 Actual volume . 13

6.2.3 Rated storage volume . 13

6.2.4 Hot water volume . 13

6.2.5 Primary heating power (heat exchanger performance) . 14

6.2.6 Durability testing . 14

6.2.7 Double-walled primary heaters . 14

6.2.8 Standing heat loss . 14

6.2.9 Pressure resistance . 14

6.2.10 Temperature control devices . 14

6.2.11 Heat exchanger pressure drop . 14

6.3 Production testing . 14

6.4 Factory production control (FPC) . 15

7 Technical documents . 15

7.1 General . 15

7.2 Assembly and maintenance instructions . 15

7.3 Operating instructions . 16

Annex A (normative) Hot water safety and performance testing . 17

A.1 Tests required . 17

A.2 Test apparatus and tolerances . 17

A.3 Performance tests . 19

A.4 Interpretation and calculation of hot water performance results . 21

A.5 Function of safety devices. 22

Annex B (normative) Measurement of standing heat loss for factory insulated storage

water heaters . 23

B.1 General . 23

B.2 Apparatus . 23

B.3 Test Procedure . 25

B.4 Calculation of Results . 26

Annex C (informative) Inspection access . 28

Annex ZA (informative) !Relationship between this European Standard and the

requirements of Commission Delegated Regulation (EU) No 812/2013 of 18

February 2013 supplementing Directive 2010/30/EU regarding energy labelling of

water heaters, hot water storage tanks and packages of water heater and solar

device . 30

Annex ZB (informative) !Relationship between this European Standard and the

requirements of Commission Regulation (EU) No 814/2013 of 2 August 2013

implementing Directive 2009/125/EC with regard to ecodesign requirements for

water heaters and hot water storage tanks . 32

Bibliography . 34

European foreword

This document (EN 12897:2016+A1:2020) has been prepared by Technical Committee CEN/TC 164

“Water supply”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of

an identical text or by endorsement, at the latest by August 2020, and conflicting national standards

shall be withdrawn at the latest by August 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent

rights.

This document includes Amendment 1 approved by CEN on 2019-10-09.

This document supersedes !EN 12897:2016".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of Commission Delegated

Regulation (EU) No 812/2013 and Commission Regulation (EU) No 814/2013.

For relationship with EU Directives, see informative Annexes ZA and ZB which are an integral part of

this document.

In comparison with EN 12897:2006, the following significant changes have been made:

— the capacity range extended from 1 000 l to 2 000 l;

— the maximum temperature reduced from 100 °C to 95 °C;

— revisions in durability testing for cylinders using expansion vessels or internal expansion space;

— provision is made in Annex A for the calculation of the V hot water capacity;

— Annex B has been revised to improve the test methodology and bring the standing heat loss test

requirements in line with those required by the EU directives for the Ecodesign and labelling of hot

water storage tanks.

!According to the CEN/CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom."

Introduction

In respect of potential adverse effects on the quality of water intended for human consumption caused

by the product covered by this standard:

a) This standard provides no information as to whether the product may be used without restriction

in any of the Member States of the EU or EFTA.

b) It should be noted that, while awaiting the adoption of the verifiable European criteria, existing

national regulations concerning the use and/or the characteristics of this product remain in force.

1 Scope

This document specifies the constructional and performance requirements and methods of test for

indirectly heated, unvented (closed) storage water heaters of up to 2 000 l volume suitable for

connection to a water supply at a pressure between 0,05 MPa and 1,0 MPa (0,5 bar and 10 bar), and

fitted with control and safety devices designed to prevent the temperature of the stored drinking water

from reaching 95 °C.

Whilst storage water heaters intended primarily for direct heating are not covered by this document, it

does allow the provision of electric heating elements for auxiliary use.

2 Normative references

!The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments)

applies."

EN 1487, Building valves — Hydraulic safety groups — Tests and requirements

EN 1488, Building valves — Expansion groups — Tests and requirements

EN 1489, Building valves — Pressure safety valves — Tests and requirements

EN 1490, Building valves — Combined temperature and pressure relief valves — Tests and requirements

EN 1491, Building valves — Expansion valves — Tests and requirements

EN 1567, Building valves — Water pressure reducing valves and combination water pressure reducing

valves — Requirements and tests

EN 1717, Protection against pollution of potable water in water installations and general requirements of

devices to prevent pollution by backflow

EN 13203 (all parts), Gas-fired domestic appliances producing hot water

EN 13959, Anti-pollution check valves — DN 6 to DN 250 inclusive family E, type A, B, C and D

EN 15332:2007, Heating boilers — Energy assessment of hot water storage systems

EN 60379:2004, Methods for measuring the performance of electric storage water-heaters for household

purposes (IEC 60379:1987)

EN 60730-2-9, Automatic electrical controls for household and similar use — Part 2-9: Particular

requirements for temperature sensing controls (IEC 60730-2-9)

3 Terms, definitions and symbols

For the purposes of this document, the following terms, definitions and symbols apply.

!ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp"

3.1 Terms and definitions

3.1.1

indirectly heated unvented (closed) storage water heater

vessel complete with heat exchanger (primary heater) for heating and storage of drinking water where

the contents are not vented to atmosphere

3.1.2

rated volume

rated storage volume

V

volume of the water storage vessel in litres as specified in the manual

3.1.3

actual volume

measured volume of the drinking water storage vessel in litres

3.1.4

water side

part of the storage water heater directly in contact with the drinking water

3.1.5

heating side

parts of the storage water heater which contain the heating medium

3.1.6

maximum design pressure

rated pressure

maximum pressure to which the unvented storage water heater is designed to be subjected in use

3.1.7

maximum inlet pressure

specified maximum cold water inlet pressure for the water heater

3.1.8

maximum safety temperature

maximum temperature that the stored water can reach under a fault condition

3.1.9

maximum operating temperature

maximum temperature that can be set for normal operation

3.1.10

primary heater

heat exchanger system fitted to the hot water storage vessel through which a heating medium (such as

water from a boiler) flows to heat the stored drinking water

3.1.11

double-walled primary heater

primary heater with concentric walls such that any leak through one wall will not allow the heating

fluid to contaminate the drinking water

3.2 Symbols

Symbol Unit Description

θ´p [ °C ] Average temperature of the water drawn off at ≥ (θc + 30) °C

V [l] Mixed water quantity delivered at 40 °C.

θc [ °C ] Average temperature of inlet cold water during the test

θ [ °C ] Target hot water temperature for hot water performance testing = θ

set c

+ 50 K

θpri [ °C ] Primary flow temperature = θc + 70 K

θ [ °C ] Target temperature of stored water for heat loss testing

w

e [ °C ] Mean of all the differentials between θ and measured ambient air

w

temperature

θa [ °C ] Measured ambient temperature at a given position

V [ l ] Volume of water drawn off at ≥ (θ + 30)°C

hot c

Qc [ kWh/24h ] Corrected 24 h heat loss

Q [ kWh/24h Declared standing heat loss

st

or W ]

Qm [ kWh ] Power consumption meter reading

t [ minutes ] Time taken to reheat the storage water heater from θc to θset

P [ kW ] Calculated heat exchanger performance

4 Requirements

4.1 Constructional requirements

4.1.1 Inspection access

Unvented storage water heaters shall be provided with means for internal inspection (see Annex C).

This can also be achieved by using a connection intended and dimensioned for another purpose where

the use of a suitable inspection instrument such as an endoscope is acceptable.

4.1.2 Draining

Unvented storage water heaters shall permit in situ draining. The method of draining shall be given in

the manufacturer's instructions.

4.1.3 Hydraulic connections

Hydraulic connections shall be of a type that allows the storage water heater to be disconnected from

the pipework.

4.2 Temperature control

The temperature of the stored drinking water shall be regulated either by control of the heat source or

sources or by control of the water heater.

4.3 Mechanical resistance and stability

4.3.1 Pressure resistance of water storage vessel

When tested in accordance with 6.2, the water heater shall withstand a pressure of 2,0 times the

maximum design pressure (as specified by the manufacturer) for a period of not less than 10 min

without showing any leakage or cracking.

4.3.2 Pressure resistance of primary heater

When tested in accordance with 6.2, the primary heater or heaters shall withstand a pressure of 2,0

times the maximum design pressure, as specified by the manufacturer, for a period of not less than

10 min without showing any leakage or cracking.

4.3.3 Durability

4.3.3.1 General

Water heaters shall be tested for durability by pressure cycle testing to either 4.3.3.2 or 4.3.3.3 as

appropriate. See Figure 2 for details. The storage water heater shall show no signs of leakage or

cracking after testing.

For water heaters without inlet pressure and system expansion control and where the internal pressure

is likely to reach maximum design pressure due to water expansion after heat input, the test in 4.3.3.2

shall be applied.

For water heaters designed for use with expansion vessels or internal expansion space such that the

rise in internal pressure due to expansion is controlled to below maximum design pressure, then the

alternative 4.3.3.3 shall be used.

If 4.3.3.3 is used then the installation manual supplied with the water heater shall specify the pressure

reduction and expansion control devices required.

4.3.3.2 Water heaters without inlet pressure and system expansion control

The water heater shall be subjected to either 20 000 periodic cycles at 1,2 × maximum design pressure

or 100 000 periodic cycles at 1,0 × maximum design pressure.

4.3.3.3 Water heaters designed for use with expansion vessels or internal expansion space

For water heaters supplied for use with inlet pressure controls and expansion control systems and

these control systems are supplied with the water heater then the water heater shall be subjected to

either 20 000 periodic cycles at 1,5 × maximum inlet pressure or 100 000 periodic cycles at

1,3 × maximum inlet pressure. This procedure is illustrated by Figure 1.

Key

Y pressure

X time

Figure 1 — Diagram of test pressure cycle variations

T ≥ 15 s ≤ 30 s

T ≥ 15 s ≤ 20 s

T ≥ 45 s ≤ 60 s

P = Minimum inlet pressure as defined in the technical documents or 0,1 MPa (1 bar) whichever is the

lower value.

P = Test pressure as defined in 4.3.3.2 or 4.3.3.3 as appropriate.

Key

1 optional inlet pressure control with expansion valve (4.3.3.2)

2 mandatory inlet pressure control with external expansion vessel (4.3.3.3)

3 mandatory inlet pressure control with internal expansion space (4.3.3.3)

Figure 2 — Pressure control options

4.3.4 Leakage test on double-walled primary heater

When a water heater is provided with a double-walled primary heater, it shall be constructed such that

any leakage from the heating side shall be routed to outside the heat exchanger without coming into

contact with the stored drinking water.

4.4 Safety equipment

4.4.1 General

Control and safety devices shall operate in the following sequence:

1) thermostatic control device;

2) energy cut out device;

3) where required, temperature pressure relief valve or safety relief valve.

Water heaters shall, where required, either be factory fitted, supplied with or fitted in accordance with

the manufacturer's instructions with all devices necessary for the operation of the water heater and the

prevention of contamination of the drinking water supply.

All tests, unless specified within the test method, shall be carried out with all devices necessary to

control the temperature of the water and all devices necessary for the operation of the water heater and

the prevention of contamination of the drinking water supply, fitted.

4.4.2 Energy cut-out device

Where required, water heaters shall be fitted with one or more non-self-resetting energy cut-outs

conforming to EN 60730-2-9 connected to the heat source to ensure that the heat input is interrupted in

the event of failure of the control thermostat and before the temperature of the stored water reaches

95 °C.

4.4.3 Temperature relief valve

Where required, a temperature relief or a temperature and pressure relief valve shall conform to

EN 1490 and be positioned in the water heater so that it prevents the temperature of the stored water

from exceeding 100 °C.

4.4.4 Pressure relief/expansion valve

Where required, water heaters shall be fitted, on the cold-water inlet, with either:

a) an expansion valve conforming to EN 1491,

b) an expansion group conforming to EN 1488,

c) a pressure safety valve conforming to EN 1489, or

d) a hydraulic safety group conforming to EN 1487.

4.4.5 Pressure reducing valve

Where required, a pressure reducing valve conforming to EN 1567 shall be used.

4.4.6 Provision for expansion

Where it is a local requirement that expansion water is contained within the hot water system, water

heaters shall either:

a) have an expansion capability within the storage vessel, or

b) be supplied with, or fitted in accordance with the manufacturer's instructions with an expansion

vessel.

4.4.7 Backflow prevention

Where required, a protective device against backflow conforming to EN 1717 shall be used. If non-

return valves are used, they shall comply with EN 13959.

5 Marking

Water heaters shall be permanently marked, by means of a plate or label to be visible after installation,

with, as a minimum, the following information:

a) number and year of this standard, EN 12897:2016;

b) manufacturer's name, trademark or identification mark;

c) manufacturing number or serial number, indicating year of manufacture;

d) maximum design pressure on the drinking water side;

e) maximum design pressure on the heating side;

f) rated storage volume;

g) rated volume of the heat exchanger(s);

h) standing heat loss in kWh/24h or W.

In the case of water heaters that are incorporated into heating boilers, the characteristics of the storage

water heater and the heating boiler may be shown on a common rating plate or label.

6 Evaluation of conformity

6.1 General

6.1.1 Compliance testing

The compliance of the product with the requirements of this European Standard and with the stated

values (including classes) shall be demonstrated by:

— initial type testing; and

— factory production control by the manufacturer, including product assessment.

For the purposes of testing, products may be grouped into families, where it is considered that the

selected property is common to all products within that family.

6.1.2 Market surveillance

Storage water heaters are type tested for compliance purposes by means of a specially manufactured

unit without the heat exchanger and with an electric immersion heater fitted as specified in B.1 of this

standard.

For surveillance check testing of production storage water heaters fitted with heat exchangers, the test

may be carried out using either an existing immersion heater or one fitted in an existing connection

provided that it meets the positional conditions specified in B.1 and heats at least 85 % of the storage

water heater's contents.

In the event of any doubt then the results from the special type test unit shall take precedence.

6.2 Initial type testing

6.2.1 General

Initial type testing shall be performed to show conformity with this European Standard. Tests

previously performed in accordance with the provisions of this European Standard (same product,

same characteristic(s), test method, sampling procedure, system of attestation of conformity, etc.) may

be taken into account. In addition, initial type testing shall be performed at the beginning of the

production of a new product type (unless a member of the same family) or at the beginning of a new

method of production (where this may affect the stated properties).

Whenever a change occurs in the product design, the raw material or supplier of the components, or the

production process (subject to the definition of a family), which would change significantly one or more

of the characteristics, the type tests shall be performed for the appropriate characteristic(s).

6.2.2 Actual volume

The actual volume shall be determined for each model in a manufacturer’s product range using a

suitable measuring or calculation technique with an accuracy of ± 1 %. This may be done by weighing

the heater empty and full of water and calculating the volume of the water. Where a water heater has an

internal air space, this test shall be done with the storage water heater at normal maximum inlet

pressure, i.e. the set pressure of the pressure-reducing valve.

6.2.3 Rated storage volume

The rated storage volume shall be within the percentage of the actual volume given in Table 1.

Table 1 — Tolerance on storage volume

Storage volume Tolerance

l

V ≤ 100 −2 % +5 %

100 < V ≤ 500 −5 % +5 %

500 < V ≤ 2 000 −5 % +10 %

6.2.4 Hot water volume

The hot water volume shall be determined according to the procedure described in A.4.2 to A.5.1 for

each model in a manufacturers product range. At least 75 % of the cylinder's actual capacity shall be

drawn off as hot water at (θ + 30) °C or above and the mixed water volume at 40 °C (V ) shall be

c 40

declared.

6.2.5 Primary heating power (heat exchanger performance)

The primary heating power (heat exchanger performance) shall be determined according to the

procedure given in A.4.2 to A.5.2 for each model in a manufacturer’s product range. If the vessel is to be

integrated into another appliance which is to be tested to any part of the EN 13203 series, this test is

not required.

This shall be performed following the procedure given in A.4.2 to A.5.2.

6.2.6 Durability testing

The mechanical resistance and stability of the vessel shall be tested in accordance with 4.3.3.

6.2.7 Double-walled primary heaters

When a water heater is provided with a double-walled primary heater, drill a (2 ± 0,1) mm hole through

the partition wall in contact with the heating side at the most critical location in the primary heater

(normally the furthest point from the connections). Fill the primary heater and subject it to a water-

pressure of (50 ± 5) kPa. Maintain that pressure for (300 ± 5) s. Water shall emerge to atmosphere from

the water heater.

6.2.8 Standing heat loss

The standing heat loss shall be determined in accordance with the procedure given in either:

— Annex B;

— EN 60379:2004, Clause 14;

— EN 15332:2007, 5.4.

6.2.9 Pressure resistance

This test shall be performed on a sample taken from production after lining (where applicable) but

before insulation. Connections may be fitted with temporary sealing arrangements. For tank-in-tank

water heaters the water side shall be filled to the heat source side maximum inlet pressure before

conducting the test on the heat source side.

Raise the internal pressure to 2,0 times the maximum design pressure specified by the manufacturer

and maintain the pressure for (600 ± 5) s. There shall be no leakage or cracking of the shell.

6.2.10 Temperature control devices

If the water heater is supplied with a temperature control device it shall be tested in accordance with

the procedure in Annex A.

6.2.11 Heat exchanger pressure drop

The heat exchanger pressure drop shall be tested in accordance with the procedure in Annex A.

6.3 Production testing

Following complete fabrication, but before lining for corrosion protection and application of insulation,

each water heater shall meet one of the following test requirements.

a) Raise the internal pressure to 1,3 times the maximum design pressure specified by the

manufacturer using water or another liquid. Hold at this pressure while checking for leakage. Any

leakage or cracking shall be deemed a failure and requires remedial action or rejection.

b) Pressurize with air or an inert gas (e.g. helium) using an appropriate method to detect leakage. Any

leakage or cracking shall be deemed a failure and requires remedial action or rejection. In addition,

at intervals appropriate to the factory production control a water heater from production shall be

tested with liquid as described above.

WARNING The pneumatic testing of unvented storage water heaters is potentially dangerous,

therefore, such test equipment requires careful consideration.

6.4 Factory production control (FPC)

The manufacturer shall establish, document and maintain an FPC system to ensure that the products

placed on the market conform to the stated performance characteristics. The FPC system shall consist of

procedures, regular inspections and tests and/or assessments and the use of the results to control raw

and other incoming materials or components, equipment, the production process and the product.

NOTE An FPC system conforming to the requirements of EN ISO 9001 (see [2]), and made specific to the

requirements of this document, is considered to satisfy the above requirements.

The results of inspections, tests or assessments requiring action shall be recorded, as shall any action

taken. The action to be taken when control values or criteria are not met shall be recorded.

7 Technical documents

7.1 General

Each water heater shall be supplied with a set of assembly instructions along with operating and service

recommendations, including maintenance instructions.

7.2 Assembly and maintenance instructions

The assembly instructions shall include, as a minimum, the following information:

a) technical data, including:

1) maximum inlet pressure (rated pressure) of the primary and the secondary system in Pa or

bar;

2) maximum operating temperature of the heating fluid in °C;

3) type of corrosion protection and maintenance;

4) rated storage volume of the water heater;

5) location and nominal diameter of all connections;

6) accommodation of expansion water;

7) pressure drop through the primary heater;

8) primary flow rate information;

9) diagram showing position of devices, drain tap, etc.;

10) V hot water volume in litres.

b) installation instructions with recommendations on mounting surfaces, distance from walls and

protection with regard to frost;

c) method for external pipework connection;

d) type and size of safety devices and drain tap;

e) necessary temperature control devices, including the wiring diagram;

f) type of inspection access if provided.

7.3 Operating instructions

The operating instructions shall include, as a minimum, the following information:

a) name and address of the manufacturer;

b) marking information given in Clause 5;

c) information on recommended maintenance;

d) information on the disassembly, recycling and disposal of the product.

Annex A(normative)

Hot water safety and performance testing

A.1 Tests required

The following table shows the performance testing requirements.

Table A.1 — Performance testing requirements

Test clause Test description

A.3.1.9 and A.4.1 Hot Water Capacity

A.3.1.9 and A.4.3 Hot Water Capacity V40 equivalent

Reheat Performance (primary

A.3.1.8 and A.4.2

heating power)

A.3.1.7 Primary Heater Pressure Drop

A.5 Temperature Control

A.2 Test apparatus and tolerances

A.2.1 General

The apparatus shall be constructed in accordance with the schematic diagram shown in Figure A.1. The

water heater shall either be supported on a flat base of 20 mm thick medium density fibreboard or wall

mounted using the manufacturer's instructions.

The length of any interconnecting pipework shall be kept to the minimum practicable and the primary

and draw off pipework insulated. If desired additional valves may be fitted for servicing and set up

purposes. The tests should be carried out with any safety devices such as temperature and or pressure

relief valves required to meet local requirements fitted.

All temperature measuring devices shall have an accuracy of ± 1 °C.

In order to facilitate testing the reference incoming water temperature θ is 10 °C. If the incoming water

c

temperature is higher or lower, the other test temperatures shall be adjusted by the same amount to

maintain the temperature differences. The incoming water temperature shall be in the range

(8 to 18) °C.

NOTE For testing to Commission Delegated Regulation (EU) No 812/2013, a temperature of (10 ± 1) °C is

required.

All flow measurement devices shall have an accuracy of ± 1 %.

All mass measurement devices shall have an accuracy of ± 1 %.

All pressure measurement devices shall have an accuracy of ± 2 %.

Key

FL , FL flowmeters

1 2

E energy source

C circulator

V1, V2, V5 quarter turn valves

V V flow control valves

3, 4

P , P pressure gauges

1 2

W weighing device

T1, T2, T3, T4 temperature sensors

1 water heater under test

2 water supply

Figure A.1 — Apparatus

A.2.2 Description of components

A.2.2.1 Heat Source - A thermostatically controlled heat source (E) capable of providing a primary

water flow temperature of (θ ± 2) °C

pri

where

θ = θ + 70.

pri c

Where test A.5.5 is required, a flow temperature θ of 110 °C will also be required (for test A.5.5 only).

pri

The primary flow rate will in practice depend on the specification and design of the boiler and heating

system to which the water heater will finally be fitted. Typically the system will be designed for

temperature drops between primary flow and return temperatures of between 10 K and 20 K.

In order to provide a basis for comparison, the default flow rate used in these tests is 0,25 l/s but this

may be changed to suit the recommendations of the manufacturer and/or intended conditions of use

but shall remain constant throughout the test procedure. The actual flow-rate used for the testing shall

be indicated in 7.2 a) 8).

A.2.2.2 Circulator - A circulator (C) capable of maintaining a primary flow of 0,25 l/s ± 1 % unless

otherwise specified by the manufacturer.

A.2.2.3 Flow Meter - A flowmeter (FL ) calibrated for water at 80 °C at the specified flow rate. The

second flow meter (FL ) is optional and is used to speed up calibration of the test rig.

A.2.2.4 By-Pass Arrangement - A primary by-pass arrangement (V1 and V2) employing two full

flow lever operated, quarter turn spherical valves.

A.2.2.5 Outlet Valve - A full flow lever operated, quarter turn spherical valve (V5).

A.2.2.6 Flow Control Valves – Two needle valves (V3 and V4) or similar devices for regulating the

primary and secondary flows respectively.

A.2.2.7 Pressure Gauges – Two pressure gauges (P1 and P2) or similar device/s such as a

differential manometer capable of measuring the pressure drop across the primary heat exchanger.

A.2.2.8 Temperature Sensors – Four thermometers or thermocouple type devices. The devices

shall be positioned as follows:

— (T ) positioned in the primary flow pipe from the circulator to sense the primary water

temperature immediately prior to the tee off to the by-pass arrangement;

— (T ) positioned inside or on the storage water heater to sense the stored water temperature at a

point 25 mm below the hot water outlet;

— (T ) positioned in the outlet pipe to sense the temperature of hot water leaving the storage water

heater, this shall be sited no more than 150 mm from the storage water heater outlet;

— (T ) positioned in the cold water inlet to sense the temperature of cold water entering the storage

water heater, this shall be sited no more than 150 mm from the storage water heater inlet.

A.3 Performance tests

A.3.1 Hot water performance

A.3.1.1 The storage water heater, including insulation if fitted, shall be set up for testing as shown in

Figure A.1 and the following procedure followed:

A.3.1.2 The water heater and its primary circuit shall be filled and all excess air expelled,

(additional air separation devices may be fitted in order to facilitate this operation). The primary circuit

shall now be allowed to heat up to a flow temperature of θ °C with valves V , V and V open and any

pri 1 2 3

excess air allowed to escape.

A.3.1.3 Valve V shall be closed, valves V and V shall be opened and valve V adjusted to give the

2 1 3 3

required primary flow rate (normally 0,25 l/s) . Once this is achieved then valve V shall be opened and

V closed.

A.3.1.4 With the water heater connected to a suitable cold water supply, valves V and V shall be

4 5

opened and any excess air expe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...