EN 15026:2023

(Main)Hygrothermal performance of building components and building elements - Assessment of moisture transfer by numerical simulation

Hygrothermal performance of building components and building elements - Assessment of moisture transfer by numerical simulation

This document specifies the model components to be used in a numerical hygrothermal simulation model for calculating the transient transfer of heat and moisture through building structures.

This document specifies a method to be used for validating a numeric hygrothermal simulation model claiming conformity with this document.

Wärme- und feuchtetechnisches Verhalten von Bauteilen und Bauelementen - Bewertung der Feuchteübertragung durch numerische Simulation

Dieses Dokument legt die in einem numerischen Modell der wärme- und feuchtetechnischen Simulation zur Berechnung der transienten Wärme- und Feuchteübertragung innerhalb von Bauwerken zu verwendenden Modellkomponenten fest.

Dieses Dokument legt ein Verfahren fest, das dazu dient, zu validieren, dass das betreffende numerische Modell der wärme- und feuchtetechnischen Simulation diesem Dokument entspricht.

Performance hygrothermique des composants et parois de bâtiments - Évaluation du transfert d’humidité par simulation numérique

Le présent document spécifie les composantes de modèle à utiliser dans le cadre d’un modèle de simulation hygrothermique numérique pour calculer le transfert transitoire de chaleur et d’humidité à travers les structures des bâtiments.

Le présent document spécifie une méthode à utiliser pour valider la conformité au présent document d’un modèle de simulation hygrothermique numérique.

Higrotermalno obnašanje sestavnih delov stavb in elementov stavb - Ocenjevanje prenosa vlage z numerično simulacijo

Ta dokument določa komponente modela, ki se uporabljajo v numeričnem higrotermalnem simulacijskem modelu za izračun prenosa toplote in vlage skozi stavbne konstrukcije.

Ta dokument določa metodo, ki se uporablja za potrjevanje numeričnega higrotermalnega simulacijskega modela kot dokaz skladnosti s tem dokumentom.

General Information

- Status

- Published

- Publication Date

- 25-Jul-2023

- Technical Committee

- CEN/TC 89 - Thermal performance of buildings and building components

- Drafting Committee

- CEN/TC 89/WG 10 - Moisture

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 26-Jul-2023

- Due Date

- 01-Jun-2023

- Completion Date

- 26-Jul-2023

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15026:2023 (CEN) defines how to assess the hygrothermal performance of building components and elements by numerical simulation of moisture transfer. The standard specifies the model components, material descriptions, boundary and initial conditions, numerical practices and a method to validate a hygrothermal simulation model claiming conformity. It supersedes EN 15026:2007 and is intended for transient heat-and-moisture modelling of multi-layer building structures.

Key topics and requirements

- Model components: Required hygrothermal balance equations, driving potentials and conserved quantities for coupled heat and moisture transport (including ice/freezing enthalpy in heat transport).

- Material properties: Detailed guidance on heat storage, heat transport, moisture storage and transport parameters; limitations and special phenomena (hysteresis, swelling, ageing) are addressed in Annex A.

- Boundary and initial conditions: Prescribed inside/outside climate parameters, interpolation of climatic data, wind-driven rain, vapour diffusion and convective latent flows; Annex D gives inside boundary conditions for residential and office buildings.

- Auxiliary models: Methods to include special effects such as component ventilation, rainwater penetration and air infiltration (Annex E).

- Numerical simulation practice: Geometry modelling, grid and time-step sensitivity studies, numerical accuracy control and documentation of simulation tool and numerical properties (Sections 6–7).

- Validation and benchmarking: A normative validation method and benchmark test suite (Annex B) allowing demonstrable conformity of a numerical hygrothermal model.

- Reporting: Requirements for documenting input data, simulated geometry, material parameters, boundary conditions, auxiliary models and display/interpretation of results.

Applications

- Performance assessment of walls, roofs, façades and layered building components for moisture safety and thermal behaviour.

- Design and optimization to prevent interstitial condensation, mould risk and material degradation.

- Evaluation of retrofit solutions, new building envelopes, and the impact of ventilation or rain penetration on moisture dynamics.

- Benchmarking and validating hygrothermal simulation software used in research, design and certification.

Who should use this standard

- Building physicists, façade and envelope engineers

- Simulation software developers and QA teams

- Manufacturers of building materials and pre-fabricated elements

- Energy and moisture risk assessors, consultants and researchers

- National standards bodies implementing CEN standards

Related note

- EN 15026:2023 is a CEN European Standard; it supersedes EN 15026:2007 and must be adopted as a national standard by CEN members. For implementation and patent information, consult your national standards body.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 15026:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Hygrothermal performance of building components and building elements - Assessment of moisture transfer by numerical simulation". This standard covers: This document specifies the model components to be used in a numerical hygrothermal simulation model for calculating the transient transfer of heat and moisture through building structures. This document specifies a method to be used for validating a numeric hygrothermal simulation model claiming conformity with this document.

This document specifies the model components to be used in a numerical hygrothermal simulation model for calculating the transient transfer of heat and moisture through building structures. This document specifies a method to be used for validating a numeric hygrothermal simulation model claiming conformity with this document.

EN 15026:2023 is classified under the following ICS (International Classification for Standards) categories: 91.120.01 - Protection of and in buildings in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15026:2023 has the following relationships with other standards: It is inter standard links to EN 15026:2007, EN ISO 9346:2007, EN ISO 7345:2018, EN 15243:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15026:2023 is associated with the following European legislation: EU Directives/Regulations: 305/2011. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15026:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2023

Nadomešča:

SIST EN 15026:2007

Higrotermalno obnašanje sestavnih delov stavb in elementov stavb - Ocenjevanje

prenosa vlage z numerično simulacijo

Hygrothermal performance of building components and building elements - Assessment

of moisture transfer by numerical simulation

Wärme- und feuchtetechnisches Verhalten von Bauteilen und Bauelementen -

Bewertung der Feuchteübertragung durch numerische Simulation

Performance hygrothermique des composants et parois de bâtiments - Évaluation du

transfert d’humidité par simulation numérique

Ta slovenski standard je istoveten z: EN 15026:2023

ICS:

91.120.30 Zaščita pred vlago Waterproofing

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15026

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2023

EUROPÄISCHE NORM

ICS 91.120.01 Supersedes EN 15026:2007

English Version

Hygrothermal performance of building components and

building elements - Assessment of moisture transfer by

numerical simulation

Performance hygrothermique des composants et Wärme- und feuchtetechnisches Verhalten von

parois de bâtiments - Évaluation du transfert Bauteilen und Bauelementen - Bewertung der

d'humidité par simulation numérique Feuchteübertragung durch numerische Simulation

This European Standard was approved by CEN on 26 June 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15026:2023 E

worldwide for CEN national Members.

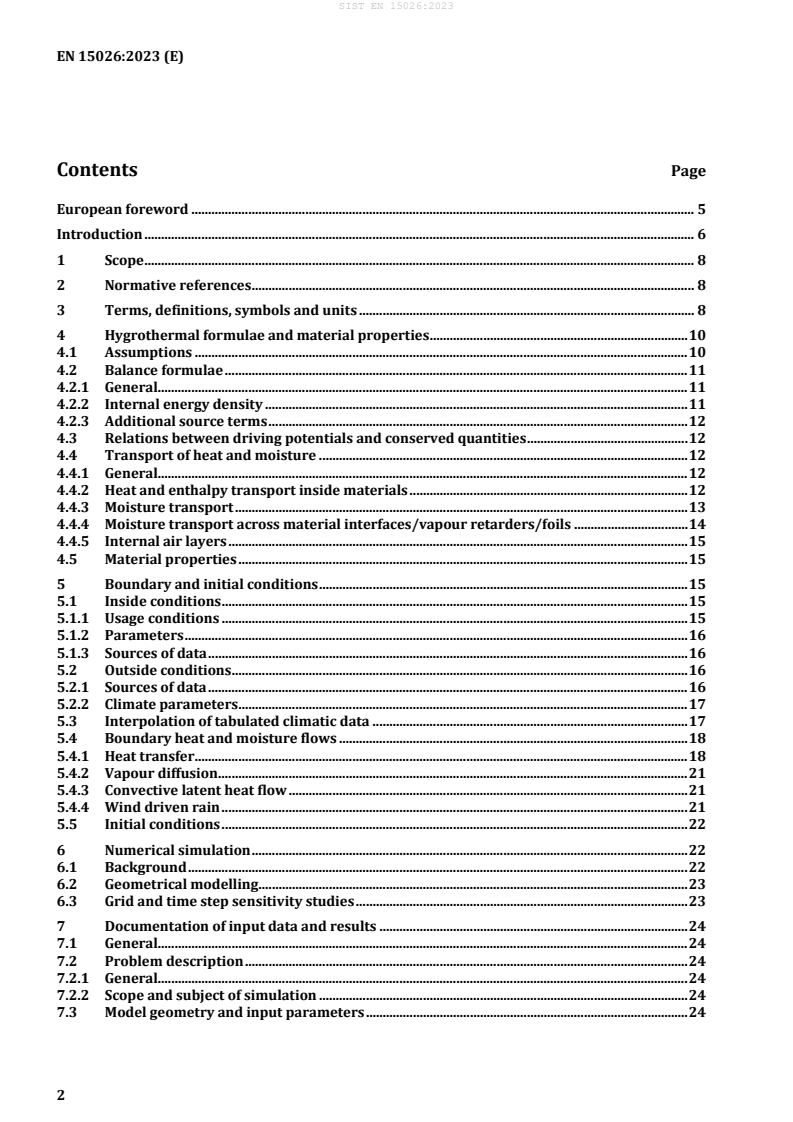

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 8

2 Normative references . 8

3 Terms, definitions, symbols and units . 8

4 Hygrothermal formulae and material properties . 10

4.1 Assumptions . 10

4.2 Balance formulae . 11

4.2.1 General. 11

4.2.2 Internal energy density . 11

4.2.3 Additional source terms . 12

4.3 Relations between driving potentials and conserved quantities . 12

4.4 Transport of heat and moisture . 12

4.4.1 General. 12

4.4.2 Heat and enthalpy transport inside materials . 12

4.4.3 Moisture transport . 13

4.4.4 Moisture transport across material interfaces/vapour retarders/foils . 14

4.4.5 Internal air layers . 15

4.5 Material properties . 15

5 Boundary and initial conditions . 15

5.1 Inside conditions . 15

5.1.1 Usage conditions . 15

5.1.2 Parameters . 16

5.1.3 Sources of data . 16

5.2 Outside conditions . 16

5.2.1 Sources of data . 16

5.2.2 Climate parameters . 17

5.3 Interpolation of tabulated climatic data . 17

5.4 Boundary heat and moisture flows . 18

5.4.1 Heat transfer . 18

5.4.2 Vapour diffusion . 21

5.4.3 Convective latent heat flow . 21

5.4.4 Wind driven rain . 21

5.5 Initial conditions . 22

6 Numerical simulation . 22

6.1 Background . 22

6.2 Geometrical modelling . 23

6.3 Grid and time step sensitivity studies . 23

7 Documentation of input data and results . 24

7.1 General. 24

7.2 Problem description . 24

7.2.1 General. 24

7.2.2 Scope and subject of simulation . 24

7.3 Model geometry and input parameters . 24

7.3.1 Simulated geometry . 24

7.3.2 Initial conditions . 24

7.3.3 Boundary conditions . 24

7.3.4 Material parameters . 25

7.3.5 Auxiliary models . 25

7.3.6 Output specifications . 25

7.4 Simulation method and numerical properties . 25

7.4.1 General . 25

7.4.2 Simulation tool . 25

7.4.3 Numerical simulation properties . 25

7.4.4 Numerical accuracy control . 26

7.5 Calculation report . 26

7.5.1 General . 26

7.5.2 Display of results . 26

7.5.3 Interpretation of the results . 26

Annex A (informative) Material parameters . 28

A.1 General . 28

A.2 Heat storage . 28

A.3 Heat transport . 28

A.4 Moisture storage . 30

A.5 Moisture transport properties . 31

A.5.1 General . 31

A.5.2 Water vapour diffusion resistance . 31

A.5.3 Liquid transport properties . 33

A.6 Material-related model limitations. 34

A.6.1 General . 34

A.6.2 Influence of material boundaries on liquid moisture transport . 34

A.6.3 Hysteresis phenomena . 34

A.6.4 Swelling . 35

A.6.5 Weathering and ageing . 35

Annex B (normative) Benchmark tests . 36

B.1 General . 36

B.1.1 General background . 36

B.1.2 Reference implementation . 36

B.2 Problem description . 36

B.3 Results . 38

B.4 Other benchmark cases and validation suites . 40

Annex C (informative) Moisture design years . 41

Annex D (normative) Inside boundary conditions for residential and office buildings . 42

Annex E (normative) Auxiliary models for the simplified inclusion of special effects . 43

E.1 General . 43

E.2 Rear ventilation and venting of building components . 43

E.3 Condensation caused by air flow through building components . 44

E.4 Wind driven rain penetration . 45

Bibliography . 47

European foreword

This document (EN 15026:2023) has been prepared by Technical Committee CEN/TC 89 “Thermal

performance of buildings and building components”, the secretariat of which is held by SIS.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2024, and conflicting national standards shall

be withdrawn at the latest by January 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 15026:2007.

The significant technical changes compared to the previous edition EN 15026:2007 of the standard are:

— the scope has been shortened;

— all the transport formulae are given for two-dimensional calculations and source terms for auxiliary

models accounting for special effects have been added;

— approaches to calculate the sources and sinks in the transport formulae to account for these special

effects, i.e. component ventilation, rainwater penetration and air infiltration, are documented in

Annex E;

— ice formation and freezing enthalpy have been added to the heat transport formula;

— the section on material properties has been expanded with more detailed information given in

Annex A;

— the sections on internal and external boundary conditions and the corresponding annexes have been

modified to account for new research results.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document defines the practical application of hygrothermal simulation software used to predict

transient heat and moisture transfer in multi-layer building envelope components subjected to dynamic

climate conditions on either side.

In contrast to the steady-state assessment of interstitial condensation by the Glaser method (as described

in EN ISO 13788), transient hygrothermal simulation provides more detailed and accurate information

on the risk of moisture problems within building components and on the design of remedial treatment.

While the Glaser method considers only steady-state conduction of heat and vapour diffusion, the

transient hygrothermal simulation models which are composed of the formulae defined in this document

also take account of heat and moisture storage, latent heat effects and liquid and convective transport

under realistic boundary and initial conditions. The application of such models has become widely used

in building practice in recent years, resulting in a significant improvement in the accuracy and

reproducibility of hygrothermal simulation.

The following examples of transient heat and moisture phenomena in building components can be

simulated by the models covered in this document:

— drying of initial construction moisture;

— moisture accumulation by interstitial condensation due to diffusion in winter;

— moisture penetration due to driving rain exposure;

— summer condensation due to migration of moisture from outside to inside;

— outside surface condensation due to cooling by long-wave radiation exchange;

— moisture-related heat losses by transmission and moisture evaporation.

The factors relevant to hygrothermal simulation of building components are summarized below. The

document starts with the description of the physical model on which hygrothermal simulation tools are

based. Then the necessary input parameters and their procurement are dealt with. The evaluation,

interpretation and documentation of the output form the last part. Benchmark cases for the assessment

of numerical simulation tools are discussed in Annex B.

Input parameters include:

— assembly, orientation and inclination of building components;

— hygrothermal material parameters and functions;

— boundary conditions, surface transfer for inside and outside climate;

— initial condition, calculation period, numerical control parameters.

Output parameters include:

— temperature and heat flux distributions and temporal variations;

— water content, relative humidity and moisture flux distributions and temporal variations.

Based on the output parameters, experimentally validated post-processing tools can help to evaluate:

— Moisture dependent thermal performance;

— biological growth, rot and corrosion;

— moisture-related damage and degradation.

Outputs from the calculations are useful for various purposes, but applications are not covered by the

standard and are made at the user's own risk.

1 Scope

This document specifies the model components to be used in a numerical hygrothermal simulation model

for calculating the transient transfer of heat and moisture through building structures.

This document specifies a method to be used for validating a numeric hygrothermal simulation model

claiming conformity with this document.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN ISO 7345, Thermal performance of buildings and building components — Physical quantities and

definitions (ISO 7345:2018)

EN ISO 9346, Hygrothermal performance of buildings and building materials — Physical quantities for

mass transfer — Vocabulary (ISO 9346:2007)

3 Terms, definitions, symbols and units

For the purposes of this document, the terms and definitions given in EN ISO 9346 and EN ISO 7345 apply.

The following symbols and units apply.

Symbol Quantity Unit

a

rain water retention factor of a surface – (0 … 1)

r

c

specific heat capacity of liquid water J/(kg⋅K)

c

specific heat capacity of water vapour J/(kg⋅K)

v

c

specific heat capacity of ice J/(kg⋅K)

ice

c

specific heat capacity of air J/(kg⋅K)

a

c

specific heat capacity of dry material (solid) J/(kg⋅K)

s

D

liquid conductivity

m /s

E 2

total flux density of incident solar radiation

W/m

sol

gg,

density of moisture flow rate

kg/(m ⋅s)

w

g 2

density of liquid water flow rate

kg/(m ⋅s)

l

density of water flow rate which can be absorbed at

g 2

kg/(m ⋅s)

l,max

the surface of a material

density of moisture flow rate of available water from

g 2

kg/(m ⋅s)

p

precipitation

g 2

density of water vapour flow rate

kg/(m ⋅s)

v

h surface heat transfer coefficient

W/(m ⋅K)

Symbol Quantity Unit

h

convective heat transfer coefficient

W/(m ⋅K)

c

specific latent enthalpy of evaporation or

h

J/kg

e

condensation

h

specific enthalpy of liquid water J/kg

l

h

radiative heat transfer coefficient

W/(m ⋅K)

r

h specific enthalpy of water vapour J/kg

v

K

liquid conductivity s/m

l

n

air change rate 1/s

p

ambient atmospheric pressure Pa

a

p

capillary pressure Pa

c

p

partial water vapour pressure Pa

v

partial water vapour pressure in the

p

Pa

v,e

environment/ambient air

p

partial water vapour pressure at a surface Pa

v,s

p

saturated water vapour pressure Pa

v,sat

q density of heat flow rate

W/m

q 2

density of sensible heat flow rate

W/m

sens

r

liquid moisture flow resistance of interface m/s

l

R

normal (i.e. vertical) rain rate mm/s

N

r

rain exposure factor of a surface –

s

r

water vapour diffusion resistance of interface m/s

v

R

gas constant of water vapour J/(kg⋅K)

v

water vapour diffusion equivalent air layer thickness

S

m

d,s

of a surface layer

S 3

source term for internal energy

J/(m ⋅s)

u

S

source term for moisture

kg/(m ⋅s)

w

T thermodynamic temperature K

T

ambient air temperature K

a

T

temperature of a surface K

s

Symbol Quantity Unit

t time s

u internal energy density of the material

J/m

v wind speed m/s

w moisture content

kg/m

w 3

liquid water content

kg/m

l

w

saturation moisture content

kg/m

sat

w 3

ice content

kg/m

ice

X distance m

α

solar absorptance – (0 … 1)

sol

δ vapour permeability of still air kg/(m⋅s⋅Pa)

δ

vapour permeability of a material kg/(m⋅s⋅Pa)

v

ε

long-wave emissivity of the outside surface – (0 … 1)

ϑ

Celsius temperature °C

λ

thermal conductivity W/(m⋅K)

ϕ

relative humidity – (0 . 1)

µ

water vapour diffusion resistance factor –

ρ density of air

kg/m

a

ρ

density of solid material matrix

kg/m

s

ρ 3

density of liquid water

kg/m

l

4 Hygrothermal formulae and material properties

4.1 Assumptions

Formulae (1) to (16) contain the following assumptions:

— geometry remains constant with no swelling or shrinkage;

— no chemical reactions are occurring;

— local equilibrium exists between liquid and vapour, without hysteresis;

— moisture storage function is not dependent on temperature.

4.2 Balance formulae

4.2.1 General

The development of the formulae is based on the conservation of energy and moisture mass. The

mathematical expressions of the conservation laws are the balance formulae. Heat conservation shall be

expressed by the change of internal energy u over time in accordance with Formula (1).

∂+q hg + h g

( )

∂u vv l l

k

=−+ S (1)

u

∂∂tx

k

The moisture mass conservation shall be expressed in accordance with Formula (2)

∂+g g

( )

vl

∂w

k

=−+ S (2)

w

∂∂t x

k

The subscript k denotes the directions x, y, z, both for the coordinates and the corresponding flux

quantities q and g. Removing the index k from the formulae yields the formulation for one-dimensional

problems. q and g are vectors and the derivative of vector q, for example, expands for two-dimensional

problems to Formula (3).

∂q

∂∂qq

y

kx

(3)

+

∂∂xx ∂

ky

4.2.2 Internal energy density

A reference state shall be selected when defining the internal energy density and associated enthalpies.

Then u is defined as energy density relative to some reference energy density u at the reference

ref

temperature, T

ref.

u=ρ⋅ c⋅ TT−+ w⋅ c⋅ TT−+ w ⋅ c TT−− h (4)

( ) ( ) ( )

( )

s s ref l l ref ice ref ice

ice

NOTE 1 The internal energy density, u, of a dry building material depends on its temperature. It is possible to

use a linear relation for this purpose within temperature ranges that can occur in buildings. The internal energy of

water as liquid and/or ice is additionally present in moist materials. The internal energy stored in the gas phase, i.e.

dry air and water vapour, can be neglected.

In the time scales relevant to application of this document, freezing and thawing processes are considered

to be fast enough to treat freezing and thawing of ice inside the porous material as equilibrium processes.

Macroscopically, still a time delay in thawing/freezing can be observed, which is then mainly governed

by the ability of the material to transport heat to or from the freezing zone.

Depending on the choice of the reference temperature, T ( or 273,15 K) the corresponding freezing

0K

ref

enthalpy h shall be inserted into Formula (4) (see Table 1).

ice

NOTE 2 A consistent model can ensure that in the presence of ice the sum of the volumetric contents of liquid

water and ice will not exceed the available porosity of the material.

=

4.2.3 Additional source terms

When additional source terms are used they shall be integrated by using the Auxiliary models in Annex E.

NOTE Additional heat sources, S , and moisture sources, S , allow the consideration of special effects, for

u w

instance building component ventilation or additional moisture sources due to rain water penetration. The use of

source terms makes it possible to integrate auxiliary models into the balance formulae which can be tailored to the

effects to be factored in.

4.3 Relations between driving potentials and conserved quantities

The primary state variables or conserved quantities are the internal energy density u and the water

content (moisture mass density) w, defined through the balance formulae for energy and moisture mass.

The calculation of the energy and mass flows of the individual transport processes requires additional

state variables or driving potentials: capillary pressure, p , partial pressure of water vapour, p and

c v

temperature, T.

The relative humidity shall be calculated in accordance with Formula (5):

Ρ

v

ϕ= (5)

Ρ ()T

v,sat

The capillary pressure of the pore water is related to the relative humidity of the surrounding air by the

Kelvin Formula (6):

Ρρ= RT lnϕ (6)

( )

c lv

The consideration of moisture transfer in capillary active materials requires a sufficiently well defined

sorption isotherm in the humidity range 92 %%≤≤ϕ 100 .

4.4 Transport of heat and moisture

4.4.1 General

In Formulae (7) to (9) one-dimensional flux density expressions are used. 2D and 3D formulations are

obtained through use of directional indexes, k, for the vector flux quantities (see 7.2).

4.4.2 Heat and enthalpy transport inside materials

Heat transport shall be composed of sensible and latent components. Heat transport by thermal

conduction q shall be calculated with Fourier’s law (Formula (7)) with a thermal conductivity which

depends on moisture content. If ice is considered in the calculation, the thermal conductivity λ ww,

( )

ice

also depends on the ice content w (see A.3).

ice

∂T

qwλ()⋅ (7)

∂x

The condensation of water vapour into liquid water is a phase change releasing heat. Evaporation is a

phase change absorbing heat. Mathematically this is incorporated in the model by associating liquid and

vapour mass fluxes with different levels of enthalpy. These fluxes are associated with convectively

transported sensible and latent energy.

=

Convective heat transport by water vapour shall be calculated in accordance with Formula (8):

hg= c⋅−T T ⋅ g (8)

( ) )

(

vv v ref v

Convective heat transport by liquid water shall be calculated in accordance with Formula (9):

h g= c⋅−TT ⋅ g (9)

( )

l lll ref

NOTE The convective transfer of sensible heat, i.e. the terms with thermal capacities cv and cl, can be ignored

in applications where moisture fluxes are small. In other cases, for example, when considering driving rain

penetration or liquid water uptake, these terms can be important. In the case of rainwater penetration, care has to

be taken to distinguish rain temperature from ambient air temperature.

The latent heat of evaporation h shall to be defined in agreement with the selected reference

e

temperature T in the internal energy density Formula (4). The constants for heat capacities and latent

ref

heat of evaporation listed in Table 1 shall be used. Similarly, the freezing enthalpy (heat of fusion) shall

to be chosen based on the selected reference temperature.

Table 1 — Heat capacities and latent heat of evaporation

Property Symbol Value

4 180 J/(kg⋅K)

c

Specific heat capacity of liquid water

c 2 050 J/(kg⋅K)

Specific heat capacity of water vapour

v

c 2 108 J/(kg⋅K)

Specific heat capacity of ice

ice

Latent heat of evaporation, T = 273,15K h 2 503 000 J/kg

ref e

Latent heat of freezing, T = 273,15 K h 333 550 J/kg

ref ice

NOTE The constant c does not have a large influence on the simulation results, since the latent heat of

v

evaporation dominates the energy transport in the gas phase. Hence, use of different values for this constant will

not affect simulation results much.

The heat of sorption as well as condensation is considered in the model through Formulae (3) and (7).

Moisture entering a porous system as vapour with associated latent heat (7) and condensing into the

liquid phase will cause the temperature to increase (3). Moisture evaporating from the liquid phase will

leave the porous system with associated latent heat, thus reducing the temperature (3).

4.4.3 Moisture transport

In porous building materials, moisture transfer occurs through capillary liquid transport and diffusion of

water vapour as specified in Formula (10):

g g+ g (10)

w vl

Various physical transport mechanisms are behind these processes. Vapour diffusion is the result of a

partial pressure gradient of water vapour in the pore air, thus including the effect of differences in water

vapour concentration in the pore air and temperature as defined in Formula (11).

δ ∂p

0 v

g =− (11)

v

µχ∂

=

The water vapour permeability δ of still air is divided by the material-dependent water vapour diffusion

resistance factor to take account of the reduced cross-section available for vapour transport and the

µ

longer diffusion path along the winding pores if diffusion occurs in a pore system rather than a bulk

volume of air. This material property is typically moisture-dependent, usually expressed by µ w or

( )

µϕ . The water vapour permeability δ of a material is defined by Formula (12):

( )

v

δ T

( )

δ Tw, = (12)

( )

v

µ w

( )

The transport function is then defined by Formula (13)

∂p

v

g =−δ Tw, (13)

( )

vv

∂χ

The vapour permeability of air δ is a temperature-dependent quantity. For practical purpose it can be

taken as constant or as function of temperature and ambient pressure.

Liquid transport, the result of capillary forces is related to the capillary pressure gradient by

Formula (14):

∂p

c

g =−K (14)

wl

∂χ

The liquid water conductivity K is a function of moisture content, typically expressed as Kw or

( )

l l

Kp . Secondary transport mechanisms, such as surface diffusion, shall be included in the liquid water

( )

lc

conductivity function (measurement of such effects alone is generally not possible).

The temperature dependence of the water vapour diffusion resistance factor and the liquid water

conductivity may be neglected. In cases where such dependency is critical, for example in polymers, the

temperature dependence shall be incorporated into the water vapour permeability function.

NOTE Temperature increase reduces the viscosity and the surface tension of the pore liquid. Within the

application scope of this document, the impact is expected to be low. It is therefore sufficient to use parametrization

obtained in laboratory conditions for other temperatures as well.

For liquid transport, alternative potentials such as relative humidity and moisture content can be used if

the transport coefficients are transformed accordingly and the interfaces between two materials are

handled in such a way that the suction pressure and partial vapour pressure are still continuous functions

across the interface.

4.4.4 Moisture transport across material interfaces/vapour retarders/foils

The details of the contact between two layers of building materials can have a large influence on the

moisture transport. Additional coatings, such as adhesives, can modify the diffusive moisture transport

and the liquid transport.

Small air gaps between the materials and the modification of the pore structures at the material interfaces

because of chemical reaction products, or by substances absorbed during application, reduce the

capillary water transport across the interface. The influence of the interface on the liquid moisture flow

can be described by a moisture resistance r and calculated in accordance with Formula (15) by:

l

∆p

c

g = (15)

l

r

l

Similarly, an additional resistance defined by Formula (16) can be introduced for vapour flow:

∆p

v

g = (16)

v

r

v

NOTE In case of humidity-dependent vapour retarders, the diffusion resistance r can be a function of the

v

moisture content.

4.4.5 Internal air layers

In the case of a material boundary to an internal air layer, i.e. for cavities, the vapour flow from the

material to the air shall be expressed in terms of heat and vapour diffusion boundary conditions, using

transfer coefficients for heat transfer (conduction and long-wave radiation) and vapour diffusion.

4.5 Material properties

The following material properties are required for each material used in the simulation model:

— moisture retention function wp or sorption isotherm w ϕ ;

( ) ( )

c

— specific heat capacity c and density ρ of the dry material;

s s

— thermal conductivity of the dry material λ , or as moisture-dependent function λ w ;

( )

dry

— water vapour diffusion resistance factor µϕ , µ w or vapour permeability δ ;

( ) ( )

v

— liquid water conductivity Kw or liquid diffusivity D w .

( ) ( )

l w

NOTE All the above-mentioned transport properties can depend on temperature, moisture and other state

variables.

See Annex A for background information on material properties and a description of measurement

techniques and calibration procedures for obtaining these parameters.

5 Boundary and initial conditions

5.1 Inside conditions

5.1.1 Usage conditions

If the design of a new building is being assessed, inside conditions appropriate to the most severe likely

use of the building shall be used. This can be achieved by selecting a slightly higher humidity load on the

inside for a conservative analysis.

5.1.2 Parameters

The following parameters shall be used to specify the inside climate:

— inside air temperature; and

— inside vapour pressure, or some other humidity parameter (typically relative humidity) that enables

the vapour pressure to be calculated.

5.1.3 Sources of data

Available data shall be chosen from the three options below:

— measured values for a similar building in a similar climate (should be justified by planning engineer)

or set values specified by air-conditioning systems;

— national standards; or

— approximations for residential or office buildings in accordance with Annex D.

Hygrothermal building simulation may also be used to obtain meaningful estimates for interior climate.

Due to the complexity of performing such simulations, the results shall be verified and documented and

calibrated with some reference measurement data.

5.2 Outside conditions

5.2.1 Sources of data

If the design of a new building is being assessed, at least one year of outside conditions, appropriate to

the most severe likely location of the building, shall be used. The following sources of data for these

conditions are available, arranged from the most to least appropriate:

a) reference Years (or moisture design years), applied repeatedly over 8 years to 10 years of simulation

time to assess the overall behaviour of the construction;

b) at least ten years, preferably more, of measured data;

c) in the absence of reference years, an annual temperature shift of ±2 K may be applied to a mean year

depending on whether summer or winter condensation is likely to be the problem, keeping the

relative humidity unchanged. Hereby, a change of 2 K yields data for a critical year that is likely to

occur once in ten years.

Annex C contains a detailed description on the generation of moisture design years, hereby utilizing

different data sources, e.g. data from weather stations.

If a problem in an existing building is being investigated, any data measured at the site of the building

shall be used, otherwise the data from a location similar to that of the building shall be used.

In cases where precipitation moisture affects the building component the meteorological data set shall

contain at least hourly values for precipitation and wind (velocity and direction).

For constructions below ground level, the ground temperature depends on the ground conditions and

the depth observed (EN ISO 13370). The relative humidity in the ground is assumed to be at least 99 %

unless more precise data for the specific location is available.

Measured data or simulation results can be necessary to define the outside boundary conditions for

components adjacent to crawl spaces, attics, vented cavities and green roofs.

NOTE To analyse the behaviour of a construction with respect to critical conditions (extreme winter or

summer), a critical year can be simulated to complement the general analysis. This can help to identify possible

problems resulting from constructions particularly sensible to critical conditions. Climatic data for a critical year

can be obtained by selecting measurement data of a year with very cold winter or very wet and cold summer.

5.2.2 Climate parameters

The outside climate data set shall include the climate parameters necessary for the analysis to be

undertaken. A complete set shall contain:

— dry bulb temperature;

— relative humidity (or any other humidity parameter that can be used to calculate vapour pressure);

— global (or direct) and diffuse solar radiation;

— sky temperature or long-wave atmospheric radiation;

— wind speed and direction; and

— precipitation (rain, snow, drizzle) or driving rain load for walls, if available.

Solar radiation, long-wave radiation, wind speed and precipitation are directional quantities. That is,

their effect on the simulated surface depends on the angle between the surface and the climatic quantity.

Usually, radiation and precipitation are measured on horizontal receiving surfaces. For a simulation

involving components with non-horizontal surfaces (in particular, vertical façades), the relevant

components of these quantities hitting the surface shall be determined with appropriate radiation

models. Conversion model limitations are avoided if the quantities in question can be directly measured

as incident on the simulated surface.

NOTE Methods for calculating the moisture load from precipitation are available in EN ISO 15927-3.

5.3 Interpolation of tabulated climatic data

Climate parameters may be provided as hourly data, or in irregular intervals, for example in the case of

measured climate. Hygrothermal simulation models can compute solutions at higher frequency and

require climate parameters between measured data points. In this case, linear interpolation shall be used

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...