EN 12284:2003

(Main)Refrigerating systems and heat pumps - Valves - Requirements, testing and marking

Refrigerating systems and heat pumps - Valves - Requirements, testing and marking

This European Standard specifies safety requirements, safety factors, test methods, test pressures used and marking of refrigerating valves and other components with similar bodies, hereinafter called valves, for use in refrigerating systems.

It describes the procedure to be followed when designing (by calculation or by an experimental design method) valve parts subjected to pressure as well as the criteria to be used in the selection of materials.

The standard describes methods by which reduced impact values at low temperatures may be taken into account in a safe manner.

This standard applies to the design of bodies and bonnets for pressure relief devices, including bursting disc devices, with respect to pressure containment but it does not apply to any other aspects of the design or application of pressure relief devices.

Kälteanlagen und Wärmepumpen - Ventile - Anforderungen, Prüfung und Kennzeichnung

Diese Norm legt sicherheitstechnische Anforderungen, Sicherheitsbeiwerte, Prüfverfahren, anzuwendende Prüfdrücke und die Kennzeichnung von Kältemittelventilen und andere Bauteilen mit vergleichbaren Gehäusen, im Folgenden kurz Ventil genannt, für die Verwendung in Kälteanlagen fest.

Sie beschreibt das Verfahren, das bei der Konstruktion (durch Berechnung oder anhand von Prüfungen) von druckbeanspruchten Ventilen zugrunde zu legen ist sowie die bei der Auswahl von Werkstoffen für Ventilteile zu berücksichtigenden Kriterien.

Die Norm beschreibt Methoden, nach denen reduzierte Werte für die Kerbschlagarbeit bei niedriger Temperatur auf sichere Art und Weise berücksichtigt werden können.

Diese Norm gilt für die Konstruktion von Gehäusen und Oberteilen für Druckentlastungseinrichtungen, einschließlich Berstscheibeneinrichtungen, im Hinblick auf die Druckfestigkeit, sie gilt jedoch nicht für andere Aspekte der Konstruktion oder die Anwendung von Druckentlastungseinrichtungen.

Systèmes de réfrigération et pompes à chaleur - Robinetterie - Exigences, essais et marquage

La présente Norme européenne spécifie les exigences de sécurité, les coefficients de sécurité, les méthodes d'essai, les pressions d'essai utilisées ainsi que le marquage des robinets frigorifiques et des autres composants possédant un corps similaire, ci-après désignés par « robinets », destinés à être utilisés dans les systèmes de réfrigération.

La présente Norme décrit la procédure à suivre lors de la conception (par calcul ou par une méthode expérimentale de conception) des éléments de robinetterie soumis à une pression, ainsi que les critères à appliquer lors de la sélection des matériaux.

Elle décrit également les méthodes permettant de prendre en compte en toute sécurité des valeurs de résilience faibles à basse température.

La présente Norme s'applique à la conception des corps et des chapeaux des dispositifs limiteurs de pression, y compris les dispositifs à disque de rupture, eu égard au confinement de la pression, mais ne s'applique pas aux autres aspects de la conception ou de l'application des dispositifs limiteurs de pression.

Hladilni sistemi in toplotne črpalke - Ventili - Zahteve, preskušanje in označevanje

General Information

- Status

- Withdrawn

- Publication Date

- 16-Sep-2003

- Withdrawal Date

- 03-Feb-2026

- Technical Committee

- CEN/TC 182 - Refrigerating systems, safety and environmental requirements

- Drafting Committee

- CEN/TC 182/WG 2 - Design and testing

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 03-Nov-2021

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 11-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

CR ISO 15608:2000 - Welding - Guidelines for a metallic material grouping system (ISO/TR 15608:2000) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 12284:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Refrigerating systems and heat pumps - Valves - Requirements, testing and marking". This standard covers: This European Standard specifies safety requirements, safety factors, test methods, test pressures used and marking of refrigerating valves and other components with similar bodies, hereinafter called valves, for use in refrigerating systems. It describes the procedure to be followed when designing (by calculation or by an experimental design method) valve parts subjected to pressure as well as the criteria to be used in the selection of materials. The standard describes methods by which reduced impact values at low temperatures may be taken into account in a safe manner. This standard applies to the design of bodies and bonnets for pressure relief devices, including bursting disc devices, with respect to pressure containment but it does not apply to any other aspects of the design or application of pressure relief devices.

This European Standard specifies safety requirements, safety factors, test methods, test pressures used and marking of refrigerating valves and other components with similar bodies, hereinafter called valves, for use in refrigerating systems. It describes the procedure to be followed when designing (by calculation or by an experimental design method) valve parts subjected to pressure as well as the criteria to be used in the selection of materials. The standard describes methods by which reduced impact values at low temperatures may be taken into account in a safe manner. This standard applies to the design of bodies and bonnets for pressure relief devices, including bursting disc devices, with respect to pressure containment but it does not apply to any other aspects of the design or application of pressure relief devices.

EN 12284:2003 is classified under the following ICS (International Classification for Standards) categories: 23.060.20 - Ball and plug valves. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12284:2003 has the following relationships with other standards: It is inter standard links to EN ISO 21922:2021, EN 60534-2-1:1998, EN ISO 683-4:2018, EN 14276-1:2006, CR ISO 15608:2000, EN 13445-2:2002, EN ISO 6708:1995, EN 10204:2004, EN 378-2:2000, EN 1563:2018, EN ISO 5149-4:2025, EN 764-4:2014, EN 12728:1999, EN 12516-2:2014+A1:2021, EN 764-5:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12284:2003 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12284:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Refrigerating systems and heat pumps - Valves - Requirements, testing and markingSystemes de réfrigération et pompes a chaleur - Robinetterie - Exigences, essais et marquageKälteanlagen und Wärmepumpen - Ventile - Anforderungen, Prüfung und KennzeichnungTa slovenski standard je istoveten z:EN 12284:2003SIST EN 12284:2004en27.20027.08023.060.20ICS:SLOVENSKI

STANDARDSIST EN 12284:200401-september-2004

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12284September 2003ICS 23.060.20English versionRefrigerating systems and heat pumps - Valves - Requirements,testing and markingSystèmes de réfrigération et pompes à chaleur -Robinetterie - Exigences, essais et marquageKälteanlagen und Wärmepumpen - Ventile -Anforderungen, Prüfung und KennzeichnungThis European Standard was approved by CEN on 21 April 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12284:2003 E

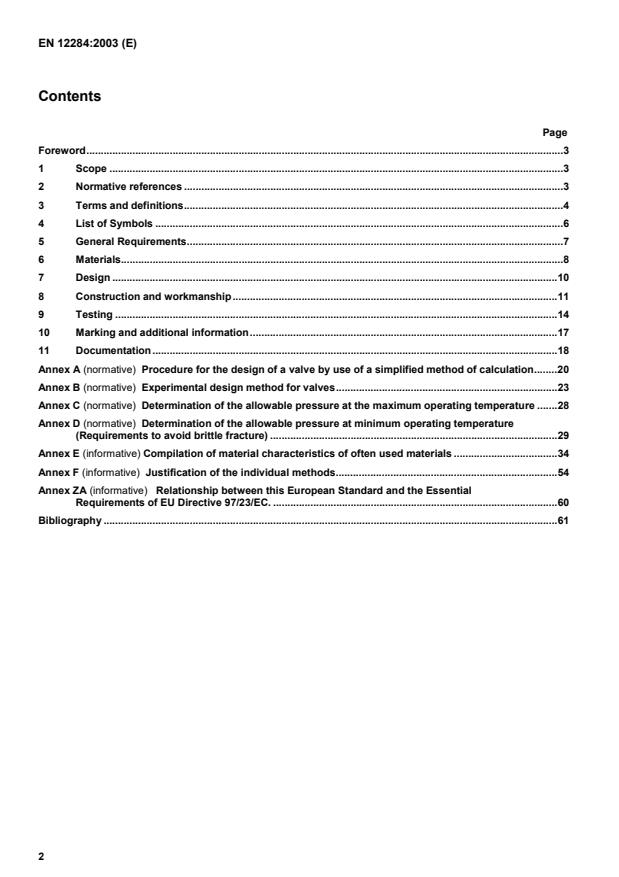

Procedure for the design of a valve by use of a simplified method of calculation.20Annex B (normative)

Experimental design method for valves.23Annex C (normative)

Determination of the allowable pressure at the maximum operating temperature.28Annex D (normative)

Determination of the allowable pressure at minimum operating temperature(Requirements to avoid brittle fracture).29Annex E (informative) Compilation of material characteristics of often used materials.34Annex F (informative)

Justification of the individual methods.54Annex ZA (informative)

Relationship between this European Standard and the EssentialRequirements of EU Directive 97/23/EC.60Bibliography.61

diameter of the rodmmA5Elongation after fracture where the measured length is equal 5 times ofdiameter of the rod%aLifetime in years; for valves 20 yearsannoCQFactor to compensate for the quality of a casting—deNegative wall thickness tolerancemmeactActual wall thickness at given measuring points of the valve to be testedmmecReduction in wall thickness caused by occurance of corrosionmmeconComponent wall thickness as specified in the design drawingmmKVImpact rupture energyJKV0Threshold value of impact rupture energy, where the impact rupture energy isdefined as independent of the temperatureJKV0tStandard value of impact rupture energy at standard temperature of the materialJKVTS minImpact rupture energy at minimum operating temperature TS minJKVSis the rate of flow of water in cubic metres per hour for a differential pressure Dp of1 bar (0,1 MPa) at the rated full opening m3/hLthe leakage in percent of KVS%N6is 31,6 according to Table 1 of EN 60534-2-1—PDDesign pressureMPaPFMaximum allowable design test pressureMPaPSMaximum allowable pressure in common sense, without regarding any influenceof temperatureMPaPS0Maximum allowable pressure at ambient temperature (- 10 °C to + 50 °C)according to strength design (without temperature correction)MPaPSTS maxMaximum allowable pressure at maximum operating temperatureMPaPSTS minMaximum allowable pressure at minimum operating temperatureMPaPTestMinimum burst test pressure (greater than PF)MPap1Upstream pressureMPaDpDifferential pressureMPap'Testing pressure of each valve after productionMPaQMMass flow ratekg/hQVupstream flow ratem3/hRe 1,0Yield strength, 1,0% offsetMPa, N/mm2Re 1,0 TS maxYield strength, 1,0% offset at highest operating temperatureMPa, N/mm2Re 0,2Yield strength, 0,2% offset at ambient temperatureMPa, N/mm2Rp 0,2Proof strength, 0,2% offset at ambient temperatureMPa, N/mm2Rp 0,2 TS minProof strength, 0,2% offset at minimum operating temperatureMPa, N/mm2Rp 0,2/tProof strength, 0,2% offset at temperature tMPa, N/mm2Rp 0,2 TS maxProof strength, 0,2% offset at highest operating temperatureMPa, N/mm2Rp 1,0Proof strength, 1,0% offset at ambient temperatureMPa, N/mm2ReHUpper yield strengthMPa, N/mm2ReH TS maxUpper yield strength at

highest operating temperatureMPa, N/mm2RmTensile strengthMPa, N/mm2

highest operating temperatureMPa, N/mm2Rm actActual tensile strength of the material of the valve to be testedMPa, N/mm2Rm conTensile strength used for the designMPa, N/mm2rDensity of the actual fluidkg/m3r0Density of water at 15,5 °Ckg/m3r1Upstream densitykg/m3SCFactor to compensate effects of corrosion—SconFactor for the calculation of the burst test pressure taking into account the tensilestrength according to Table A.2 (see footnoted of Table A.2)SFFactor to allow for forming—STS minFactor taking into consideration the impact strength reduction due to minimumoperating temperature—STS maxFactor to allow for the reduction in strength due to the highest operatingtemperature—SsFactor to allow for the test pressure—s conInitial design stressMPa, N/mm2s corrAllowable stress values derived from s conMPa, N/mm2TSOperating temperature°CTSminLowest operating temperature°CTSmaxHighest operating temperature°CVInner volume of a valvelXCorrection of the actual wall thickness relative to the wall thickness of the design—kassignes the value 1PpD—YCorrection on the basis of current strength values of the test sample relative tothe strength parameters for the design of valves—ZFactor to allow for the quality of a joint (e.g. welded joint)—¶Wall thickness reduction per yearmmNOTE

1 MPa = 10 bar5 General Requirements5.1 Installation and operationValves shall be designed to be installed and operated in accordance with the requirements of EN 378 Parts 1, 2and 4.5.2 Components under pressureAll parts of the valve shall be designed and manufactured to remain leak proof and to withstand the pressureswhich may occur during operation, standstill and transportation, taking into account the thermal, physical andchemical stresses to be expected.5.3 Excessive mechanical stressAfter installation, valves, especially valves for hot gas defrosting, shall not be under excessive mechanical stressfrom fitting of the pipe or from temperature variations during operation.NOTEHot gas defrosting can produce hydraulic shocks resulting in transient pressures in excess of PS. Furtherinformation see subclause 6.3.2 in EN 378-2:2000.

atambient temperature, provided that the bodies and bonnets have been designed in accordance with 7.4. Tests of seriesproduction may be carried out on a statistical basis.9.3.2Under the test pressure, maintained for sufficient time to give reliable results, the specimen shall show novisible defects.9.3.3If the strength pressure test is carried out using gas (e.g. air or nitrogen) then it shall be conducted either ina special chamber strong enough to contain the effect of valve bursting or under-water in a tank equipped withmeans to prevent the ejection of fragments or using other suitable protection devices.9.3.4If the strength pressure test is carried out using a liquid, the valve shall be thoroughly dried after completionof the test or at least drained if this adequately satisfies the requirements given in 8.14.

1161003,162pkLKNQ´´´´´´=VSMwhereQMis the mass flow rate in kilograms per hour,N6is 31,6 according to Table 1 of EN 60534-2-1:1998;KVSis the rate of flow of water in cubic metres per hour for a differential pressure Dp of 1 bar at the rated fullopening;Lis the leakage, in percent of KVS;kis assigned the value 1ppDto introduce a dimensionless term for computational reasons;p1is the upstream pressure in MPa;r1is the upstream density in kilograms per cubic metre.NOTEA simplification is made by omitting the piping geometry factor in both cases. A further simplification is made byignoring the Reynolds number factor in 9.6.7. This means that the true leakage rates in some cases will be somewhat lowerthan calculated. Leaving out the expansion factor in 9.6.8 will give a small deviation towards smaller true leakage rates at smallDp. With rising Dp the true leakage rate can decrease to 50 % of the calculated leakage rate.9.6.9Valves with back seat shall be checked to ascertain that the back seat is sufficiently tight to allow change ofvalve packing without danger to the operator.9.7 CapsCaps acting as seals shall be checked for adequate strength, for a clean sealing face and for the presence of apressure relieving arrangement.

or:

DN 150 – 40PS

2,8 MPa

PS 2810.3 Hand-operated regulating valvesHand-operated regulating valves shall additionally be marked with either:a) letter ‘R' (denoting regulating valve) on upper body flange, orb) a plate or label with the inscription ‘regulating valve' under the handwheel nut.10.4 CapsCaps with a free net internal volume of 1 litre or greater which act as a seal shall be marked with the allowablemaximum pressure PS.10.5 Valves of nominal size DN 25 and smallerMarking of valves of nominal size DN 25 and smaller except valves with safety function shall include at least:a), b) and f) according to 10.2.

1)in MPa or bar

supply the following documentation containing information relevant to safety:a) assembly and installation instructions;b) adequate instruction for use;c) intended use of the device;d) maintenance and user inspection instructions;e) information requested in clause 10;f) drawings and diagrams necessary to understand the instructions;g) warnings against possible dangers caused by misuse of the valve assembly;h) reference to this standard;i) refrigerants for which the device is suitable;j) KVS value where appropriate (see 9.6);k) material designation in respect of body parts subject to pressure;l) pressure and temperature service ranges for actuator-operated control valves;m) maximum allowable pressure (PS) as a function of the minimum and maximum allowable temperature (TS2) ).NOTEThe following Table 3 provides an example of how to give the pressure as a function of the temperature.Table 3 — Pressure as a functionof temperature within the documentationof a valve (example)PSMPaaTS°C2,250,1 to 1502,8–10,0 to 50,02,1- 10,1 to – 60,00,7- 60,1 to – 85a1 MPa = 10 bar

2)If the valve is marked with "bar" in the documentation shall also be used the unit "bar“.

or the finite element method. Further reaction forces ormoments which are relevant to the strength, as well as the weakening of the valve due to other influences (e.g.corrosion) shall also be taken into consideration.NOTEMaterials with the mechanical properties according to the specifications of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...