EN 16429:2021

(Main)Stationary source emissions - Reference method for the determination of the concentration of gaseous hydrogen chloride (HCl) in waste gases emitted by industrial installations into the atmosphere

Stationary source emissions - Reference method for the determination of the concentration of gaseous hydrogen chloride (HCl) in waste gases emitted by industrial installations into the atmosphere

This document specifies the standard reference method (SRM) based on an automatic method for determination of the mass concentration of hydrogen chloride (HCl) in ducts and stacks emitting to the atmosphere. It describes the sampling and gas conditioning system.

This document specifies the characteristics to be determined and the performance criteria to be fulfilled by portable automated measuring systems (P-AMS) using the infrared measurement method. It applies for periodic monitoring and for the calibration or control of automated measuring systems (AMS) permanently installed on a stack, for regulatory or other purposes.

The infrared measurement method described in this document can be used as a SRM, provided the expanded uncertainty of the method is less than 20 % relative at the daily Emission Limit Value (ELV), or 1 mg/m3 for ELV below 5 mg/m3, and the criteria associated to performance characteristics described in EN 15267-4 for portable automated measuring systems (P-AMS), are fulfilled.

This document specifies criteria for demonstration of equivalence of an alternative method (AM) to the SRM by application of EN 14793.

Emissionen aus stationären Quellen - Referenzverfahren zur Bestimmung der Konzentration von gasförmigem Chlorwasserstoff (HCl) in Abgasen, die von Industrieanlagen in die Atmosphäre emittiert werden

Dieses Dokument legt das auf einem automatischen Verfahren beruhende Standardreferenzverfahren (SRM) zur Bestimmung der Massenkonzentration von Chlorwasserstoff (HCl) in Abgasen, die aus Kanälen und Kaminen in die Atmosphäre emittiert werden, fest. Es legt die Einrichtungen zur Probenahme und Gaskonditionierung fest.

Dieses Dokument legt die zu bestimmenden Eigenschaften und Leistungskriterien fest, die von tragbaren automatischen Messeinrichtungen (en: portable automated measuring system, P-AMS) mit Infrarot-Messverfahren zu erfüllen sind. Es ist anwendbar für die regelmäßige Überwachung und für die Kalibrierung oder Steuerung von dauerhaft an einem Abgaskanal installierten automatischen Messeinrichtungen (en: automated measuring system, AMS) aufgrund regulatorischer oder anderer Gründe.

Das in diesem Dokument festgelegte Infrarot-Messverfahren kann als SRM verwendet werden, sofern die erweiterte Messunsicherheit des Verfahrens weniger als 20 % (relativ) beim 1-Tages-Emissionsgrenzwert (Emission Limit Value, ELV) oder 1 mg/m3 für einen ELV kleiner als 5 mg/m3 beträgt und die Kriterien, die den in EN 15267 4 für tragbare automatische Messeinrichtungen (P-AMS) genannten Leistungskenngrößen zugeordnet sind, erfüllt werden.

Dieses Dokument legt Kriterien für den Nachweis der Gleichwertigkeit eines Alternativverfahrens (en: Alternative Method; AM) mit dem SRM durch Anwendung der EN 14793 fest.

Émissions de sources fixes - Méthode de référence pour la détermination de la concentration de chlorure d’hydrogène gazeux (HCl) dans les effluents gazeux émis dans l’atmosphère par des installations industrielles

Le présent document spécifie la méthode de référence normalisée (SRM) basée sur une méthode automatique de détermination de la concentration massique de chlorure d’hydrogène (HCl) émis dans l’atmosphère par les conduits et les cheminées. Il décrit le système de prélèvement et de conditionnement du gaz.

Le présent document spécifie les caractéristiques devant être déterminées et les critères de performance devant être remplis par les systèmes de mesurage automatisés portables (P-AMS) utilisant la méthode de mesurage infrarouge. Il s’applique à la surveillance périodique ainsi qu’à l’étalonnage ou au contrôle des systèmes de mesurage automatisés (AMS) installés à demeure sur une cheminée, à des fins réglementaires ou autres.

La méthode de mesurage par infrarouge décrite dans le présent document peut servir de SRM, à condition que l’incertitude élargie de la méthode soit inférieure à la valeur relative de 20 % à la valeur limite d’émission (VLE) journalière, ou 1 mg/m3 pour une VLE inférieure à 5 mg/m3, et que les critères associés aux caractéristiques de performance décrites dans l’EN 15267-4 pour les systèmes de mesurage automatisés portables (P-AMS) soient satisfaits.

Le présent document spécifie des critères permettant de prouver l’équivalence d’une méthode alternative (AM) avec la méthode de référence normalisée en appliquant l’EN 14793.

Emisije nepremičnih virov - Referenčna metoda za določevanje koncentracije plinastega vodikovega klorida (HCl) v odpadnih plinih, ki se sproščajo v ozračje iz industrijskih naprav

General Information

- Status

- Published

- Publication Date

- 02-Mar-2021

- Withdrawal Date

- 29-Sep-2021

- Technical Committee

- CEN/TC 264 - Air quality

- Drafting Committee

- CEN/TC 264 - Air quality

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 03-Mar-2021

- Due Date

- 12-Jun-2021

- Completion Date

- 03-Mar-2021

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16429:2021 - Stationary source emissions: Reference method for the determination of gaseous hydrogen chloride (HCl) concentration in waste gases - defines a standard reference method (SRM) based on an automatic infrared measurement method. Published by CEN in 2021, the standard covers sampling, gas conditioning and performance criteria for portable automated measuring systems (P‑AMS) and supports periodic monitoring, calibration and control of permanently installed automated measuring systems (AMS/CEMS).

Key topics and technical requirements

- Measurement principle: Non‑dispersive infrared (NDIR) / infrared measurement method is specified as the SRM when performance criteria are met.

- Performance limits: The infrared method may be used as SRM provided the expanded uncertainty is less than 20% relative at the daily Emission Limit Value (ELV), or ≤ 1 mg/m3 when the ELV is below 5 mg/m3.

- Sampling and conditioning system: Detailed descriptions and requirements for probe, filters, sampling line, sample pump and conditioning configurations (e.g., permeation drier or heated line + heated analyser) are included.

- P‑AMS characteristics: Specifies which characteristics and performance criteria for portable automated measuring systems must be determined (references performance criteria in EN 15267‑4).

- Quality assurance: Requirements for on‑site setup, preliminary and end-of-measurement zero/span checks, ongoing quality control, uncertainty budget and expression of results.

- Equivalence of alternative methods: Criteria and procedure for demonstrating equivalence of an alternative method (AM) to the SRM via EN 14793.

- Validation: Field validation examples (Annex C) include tests on a bench, a waste incineration plant and a large combustion plant for 30‑min sampling periods and HCl ranges (~2.5–61 mg/m3).

Applications and users

EN 16429:2021 is intended for:

- Environmental and emissions monitoring teams conducting stack testing and regulatory compliance checks

- Operators of industrial installations subject to ELVs (waste incineration, large combustion, chemical plants)

- Laboratories and service providers that supply P‑AMS or perform calibration and validation of AMS/CEMS

- Regulators and auditors requiring a standardized SRM for HCl emissions reporting and enforcement

Practical benefits: consistent, traceable HCl concentration measurement; guidance for sampling system design; defined acceptance criteria for instruments and measurement uncertainty.

Related standards

- EN 15267‑4 (P‑AMS performance criteria)

- EN 14793 (demonstration of equivalence of an alternative method)

- EN 15259, EN 15267‑3, EN ISO 14956, ISO/IEC Guide 98‑3 and CEN/TS 17337 - referenced for uncertainty, certification and measurement planning

Keywords: EN 16429:2021, hydrogen chloride, HCl, stationary source emissions, reference method, infrared measurement, P‑AMS, ELV, EN 15267‑4, EN 14793.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 16429:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Stationary source emissions - Reference method for the determination of the concentration of gaseous hydrogen chloride (HCl) in waste gases emitted by industrial installations into the atmosphere". This standard covers: This document specifies the standard reference method (SRM) based on an automatic method for determination of the mass concentration of hydrogen chloride (HCl) in ducts and stacks emitting to the atmosphere. It describes the sampling and gas conditioning system. This document specifies the characteristics to be determined and the performance criteria to be fulfilled by portable automated measuring systems (P-AMS) using the infrared measurement method. It applies for periodic monitoring and for the calibration or control of automated measuring systems (AMS) permanently installed on a stack, for regulatory or other purposes. The infrared measurement method described in this document can be used as a SRM, provided the expanded uncertainty of the method is less than 20 % relative at the daily Emission Limit Value (ELV), or 1 mg/m3 for ELV below 5 mg/m3, and the criteria associated to performance characteristics described in EN 15267-4 for portable automated measuring systems (P-AMS), are fulfilled. This document specifies criteria for demonstration of equivalence of an alternative method (AM) to the SRM by application of EN 14793.

This document specifies the standard reference method (SRM) based on an automatic method for determination of the mass concentration of hydrogen chloride (HCl) in ducts and stacks emitting to the atmosphere. It describes the sampling and gas conditioning system. This document specifies the characteristics to be determined and the performance criteria to be fulfilled by portable automated measuring systems (P-AMS) using the infrared measurement method. It applies for periodic monitoring and for the calibration or control of automated measuring systems (AMS) permanently installed on a stack, for regulatory or other purposes. The infrared measurement method described in this document can be used as a SRM, provided the expanded uncertainty of the method is less than 20 % relative at the daily Emission Limit Value (ELV), or 1 mg/m3 for ELV below 5 mg/m3, and the criteria associated to performance characteristics described in EN 15267-4 for portable automated measuring systems (P-AMS), are fulfilled. This document specifies criteria for demonstration of equivalence of an alternative method (AM) to the SRM by application of EN 14793.

EN 16429:2021 is classified under the following ICS (International Classification for Standards) categories: 13.040.40 - Stationary source emissions. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16429:2021 has the following relationships with other standards: It is inter standard links to CEN/TS 16429:2013, ISO/IEC Guide 98-3:2008, EN 15267-4:2017, CEN/TS 17337:2019, EN ISO 14956:2002, EN 14793:2017, EN 15259:2007, EN 15267-3:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16429:2021 is associated with the following European legislation: Standardization Mandates: M/513. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16429:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2021

Nadomešča:

SIST-TS CEN/TS 16429:2013

Emisije nepremičnih virov - Referenčna metoda za določevanje koncentracije

plinastega vodikovega klorida (HCl) v odpadnih plinih, ki se sproščajo v ozračje iz

industrijskih naprav

Stationary source emissions - Reference method for the determination of the

concentration of gaseous hydrogen chloride (HCl) in waste gases emitted by industrial

installations into the atmosphere

Emissionen aus stationären Quellen - Referenzverfahren zur Bestimmung der

Konzentration von gasförmigem Chlorwasserstoff (HCl) in Abgasen, die von

Industrieanlagen in die Atmosphäre emittiert werden

Émissions de sources fixes - Méthode de référence pour la détermination de la

concentration de chlorure d’hydrogène gazeux (HCl) dans les effluents gazeux émis

dans l’atmosphère par des installations industrielles

Ta slovenski standard je istoveten z: EN 16429:2021

ICS:

13.040.40 Emisije nepremičnih virov Stationary source emissions

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16429

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2021

EUROPÄISCHE NORM

ICS 13.040.40 Supersedes CEN/TS 16429:2013

English Version

Stationary source emissions - Reference method for the

determination of the concentration of gaseous hydrogen

chloride (HCl) in waste gases emitted by industrial

installations into the atmosphere

Émissions de sources fixes - Méthode de référence Emissionen aus stationären Quellen -

pour la détermination de la concentration de chlorure Referenzverfahren zur Bestimmung der Konzentration

d'hydrogène gazeux (HCl) dans les effluents gazeux von gasförmigem Chlorwasserstoff (HCl) in Abgasen,

émis dans l'atmosphère par des installations die von Industrieanlagen in die Atmosphäre emittiert

industrielles werden

This European Standard was approved by CEN on 1 February 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16429:2021 E

worldwide for CEN national Members.

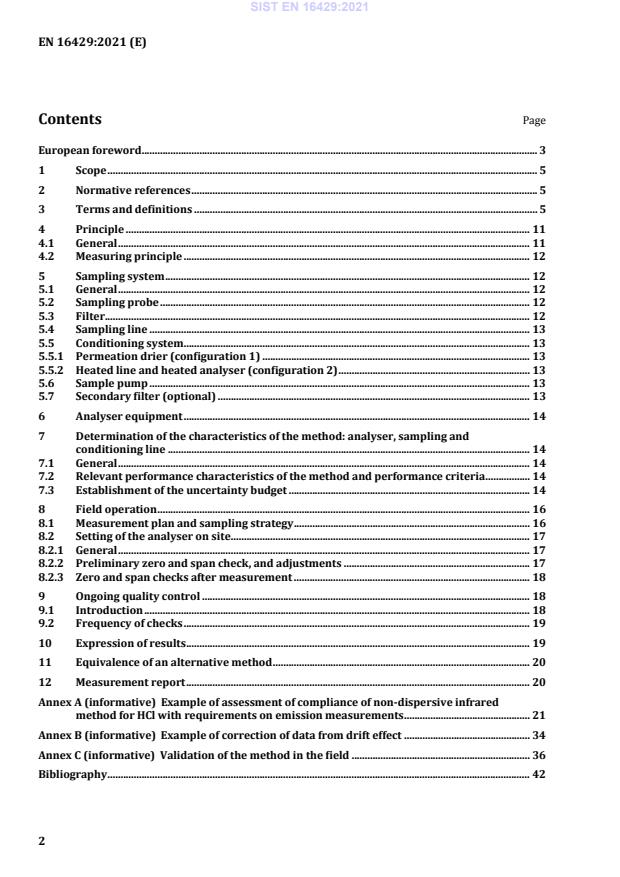

Contents Page

European foreword . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Principle . 11

4.1 General . 11

4.2 Measuring principle . 12

5 Sampling system . 12

5.1 General . 12

5.2 Sampling probe . 12

5.3 Filter . 12

5.4 Sampling line . 13

5.5 Conditioning system . 13

5.5.1 Permeation drier (configuration 1) . 13

5.5.2 Heated line and heated analyser (configuration 2) . 13

5.6 Sample pump . 13

5.7 Secondary filter (optional) . 13

6 Analyser equipment . 14

7 Determination of the characteristics of the method: analyser, sampling and

conditioning line . 14

7.1 General . 14

7.2 Relevant performance characteristics of the method and performance criteria . 14

7.3 Establishment of the uncertainty budget . 14

8 Field operation . 16

8.1 Measurement plan and sampling strategy . 16

8.2 Setting of the analyser on site . 17

8.2.1 General . 17

8.2.2 Preliminary zero and span check, and adjustments . 17

8.2.3 Zero and span checks after measurement . 18

9 Ongoing quality control . 18

9.1 Introduction . 18

9.2 Frequency of checks . 19

10 Expression of results . 19

11 Equivalence of an alternative method . 20

12 Measurement report . 20

Annex A (informative) Example of assessment of compliance of non-dispersive infrared

method for HCl with requirements on emission measurements . 21

Annex B (informative) Example of correction of data from drift effect . 34

Annex C (informative) Validation of the method in the field . 36

Bibliography . 42

European foreword

This document (EN 16429:2021) has been prepared by Technical Committee CEN/TC 264 “Air quality”,

the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2021, and conflicting national standards shall

be withdrawn at the latest by September 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes CEN/TS 16429:2013.

List of significant technical changes compared to CEN/TS 16429:2013:

— Clause 6 "Analyser equipment": The description of the analyser equipment has been replaced by the

reference to performance criteria given in EN 15267-4.

— The informative Annex "Examples of schematics of non-dispersive infrared spectrometer" was

deleted.

— The informative Annex "Validation of the method in the field" was added. EN 16429 has been

validated during field tests on a test bench, on a waste incineration plant and a large combustion

plant for HCl concentrations with sampling periods of 30 min in the range of 2,5 mg/m3 to 61 mg/m3.

The characteristics of installations, the conditions during field tests and the values of repeatability

and reproducibility in the field are given in Annex C.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

The European Commission (EC) has charged the European Committee for Standardization (CEN) to

elaborate this new standard (with Mandate M/513 of January 2013). The work was allocated to

CEN/TC 264 “Air quality”/WG 3, who has prepared this document.

This document has been validated during field tests on a test bench, on a waste incineration plant and a

large combustion plant for HCl concentrations with sampling periods of 30 min in the range of 2,5 mg/m

3 3

to 61 mg/m . Directive 2010/75/EU lays down emission values which are expressed in mg/m , on dry

basis at a specified value of oxygen and at standard conditions (273 K and 101,3 kPa).

NOTE The characteristics of installations, the conditions during field tests and the values of repeatability and

reproducibility in the field are given in Annex C.

1 Scope

This document specifies the standard reference method (SRM) based on an automatic method for

determination of the mass concentration of hydrogen chloride (HCl) in ducts and stacks emitting to the

atmosphere. It describes the sampling and gas conditioning system.

This document specifies the characteristics to be determined and the performance criteria to be fulfilled

by portable automated measuring systems (P-AMS) using the infrared measurement method. It applies

for periodic monitoring and for the calibration or control of automated measuring systems (AMS)

permanently installed on a stack, for regulatory or other purposes.

The infrared measurement method described in this document can be used as a SRM, provided the

expanded uncertainty of the method is less than 20 % relative at the daily Emission Limit Value (ELV), or

3 3

1 mg/m for ELV below 5 mg/m , and the criteria associated to performance characteristics described in

EN 15267-4 for portable automated measuring systems (P-AMS), are fulfilled.

This document specifies criteria for demonstration of equivalence of an alternative method (AM) to the

SRM by application of EN 14793.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 14793, Stationary source emissions — Demonstration of equivalence of an alternative method with a

reference method

EN 15259:2007, Air quality — Measurement of stationary source emissions — Requirements for

measurement sections and sites and for the measurement objective, plan and report

EN 15267-3:2007, Air quality — Certification of automated measuring systems — Part 3: Performance

criteria and test procedures for automated measuring systems for monitoring emissions from stationary

sources

EN 15267-4:2017, Air quality — Certification of automated measuring systems — Part 4: Performance

criteria and test procedures for automated measuring systems for periodic measurements of emissions from

stationary sources

EN ISO 14956:2002, Air quality — Evaluation of the suitability of a measurement procedure by comparison

with a required measurement uncertainty (ISO 14956:2002)

CEN/TS 17337, Stationary source emissions — Determination of mass concentration of multiple gaseous

species — Fourier transform infrared spectroscopy

ISO/IEC Guide 98-3:2008, Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in

measurement (GUM:1995)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

adjustment of a measuring system

set of operations carried out on a measuring system so that it provides prescribed indications

corresponding to given values of a quantity to be measured

[SOURCE: JCGM 200:2012]

3.2

alternative method

AM

measurement method which complies with the criteria given by this document with respect to the

reference method

Note 1 to entry: An alternative method can consist of a simplification of the reference method.

[SOURCE: EN 14793:2017]

3.3

ambient temperature

temperature of the air around the measuring system

3.4

automated measuring system

AMS

entirety of all measuring instruments and additional devices for obtaining a result of measurement

Note 1 to entry: Apart from the actual measuring device (the analyser), an AMS includes facilities for taking

samples (e.g. probe, sample gas lines, flow meters and regulator, delivery pump) and for sample conditioning (e.g.

dust filter, pre-separator for interferents, cooler, converter). This definition also includes testing and adjusting

devices that are required for functional checks and, if applicable, for commissioning.

Note 2 to entry: The term “automated measuring system” (AMS) is typically used in Europe. The term

“continuous emission monitoring system” (CEMS) is also typically used in the UK and USA.

[SOURCE: EN 15267-4:2017]

3.5

calibration

set of operations that establish, under specified conditions, the relationship between values of quantities

indicated by a measuring method or measuring system, and the corresponding values given by the

applicable reference

Note 1 to entry: In case of automated measuring system (AMS) permanently installed on a stack, the applicable

reference is the standard reference method (SRM) used to establish the calibration function of the AMS.

Note 2 to entry: Calibration should not be confused with adjustment of a measuring system.

3.6

drift

difference between two zero (zero drift) or span readings (span drift) at the beginning and at the end of

a measuring period

3.7

emission limit value

ELV

emission limit value laid out in EU Directives on the basis of a specified period (e.g. 10 min, 30 min, one

hour, one day…)

3.8

influence quantity

quantity that, in a direct measurement, does not affect the quantity that is actually measured, but affects

the relation between the indication and the measurement result

EXAMPLES

— ambient temperature;

— atmospheric pressure;

— presence of interfering gases in the flue gas matrix;

— pressure of the gas sample.

[SOURCE: JCGM 200:2012, examples have been adapted]

3.9

interference

negative or positive effect that a substance has upon the output of the P-AMS, when that substance is not

the measured component

[SOURCE: EN 15267-4:2017]

3.10

cross-sensitivity

response of the P-AMS to interferents

Note 1 to entry: See interference.

[SOURCE: EN 15267-4:2017]

3.11

lack of fit

systematic deviation, within the measurement range, between the accepted value of a reference material

applied to the measuring system and the corresponding result of measurement produced by the

calibrated measuring system

Note 1 to entry: In common language lack of fit is often called “linearity” or “deviation from linearity”. Lack of fit

test is often called “linearity test”.

[SOURCE: EN 15267-4:2017]

3.12

measurand

particular quantity subject to measurement

Note 1 to entry: The measurand is a quantifiable property of the stack gas under test, for example mass

concentration of a measured component, temperature, velocity, mass flow, oxygen content and water vapour

content.

[SOURCE: EN 15259:2007]

3.13

measurement method

method described in a written procedure containing all the means and procedures required to sample

and analyse, namely field of application, principle and/or reactions, definitions, equipment, procedures,

presentation of results, other requirements and measurement report

[SOURCE: EN 14793:2017]

3.14

measurement plane

plane normal to the centreline of the duct at the sampling position

Note 1 to entry: Measurement plane is also known as sampling plane.

[SOURCE: EN 15259:2007]

3.15

measurement point

position in the measurement plane at which the sample stream is extracted or the measurement data are

obtained directly

Note 1 to entry: Measurement point is also known as sampling point.

[SOURCE: EN 15259:2007]

3.16

measuring system

set of one or more measuring instruments and often other devices, including any reagent and supply,

assembled and adapted to give information used to generate measured quantity values within specified

intervals for quantities of specified kinds

[SOURCE: JCGM 200:2012]

3.17

performance characteristic

quantity assigned to the P-AMS in order to define its performance

Note 1 to entry: The values of relevant performance characteristics are determined in the performance testing

and compared to the applicable performance criteria.

[SOURCE: EN 15267-4:2017]

3.18

portable automated measuring system

P-AMS

automated measuring system which is in a condition or application to be moved from one to another

measurement site to obtain measurement results for a short measurement period

Note 1 to entry: The measurement period is typically 8 h for a day.

Note 2 to entry: The P-AMS can be configured at the measurement site for the special application but can be also

set-up in a van or mobile container. The probe and the sample gas lines are installed often just before the

measurement task is started.

[SOURCE: EN 15267-4:2017]

3.19

reference method

RM

measurement method taken as a reference by convention, which gives the accepted reference value of

the measurand

Note 1 to entry: A reference method is fully described.

Note 2 to entry: A reference method can be a manual or an automated method.

Note 3 to entry: Alternative methods may be used if equivalence to the reference method has been demonstrated.

[SOURCE: EN 15259:2007]

3.20

repeatability

condition of measurement, out of a set of conditions that includes the same measurement procedure,

same operators, same measuring system, same operating conditions and same location, and replicable

measurements on the same or similar objects over a short period of time

3.21

repeatability in the field

closeness of the agreement between the results of simultaneous measurements of the same measurand

carried out with two sets of equipment under the same conditions of measurement

Note 1 to entry: These conditions include:

— same measurement method;

— two sets of equipment, the performance of which fulfils the requirements of the measurement method,

used under the same conditions;

— same location;

— implemented by the same laboratory;

— typically calculated on short periods of time in order to avoid the effect of changes of influence

parameters (e.g. 30 min).

Note 2 to entry: Repeatability may be expressed quantitatively in terms of the dispersion characteristics of the

results.

Note 3 to entry: In this document, the repeatability under field conditions is expressed as a value with a level of

confidence of 95 %.

3.22

reproducibility in the field

closeness of the agreement between the results of simultaneous measurements of the same measurand

carried out using several sets of equipment under the same conditions of measurement

Note 1 to entry: These conditions are called field reproducibility conditions and include:

— same measurement method;

— several sets of equipment, the performance of which are fulfilling the requirements of the measurement

method, used under the same conditions;

— same location;

— implemented by several laboratories.

Note 2 to entry: Reproducibility may be expressed quantitatively in terms of the dispersion characteristics of the

results.

Note 3 to entry: In this document, the reproducibility under field conditions is expressed as a value with a level

of confidence of 95 %.

3.23

residence time in the measuring system

time period for the sampled gas to be transported from the inlet of the probe to the inlet of the

measurement cell

3.24

response time

t

time interval between the instant of a sudden change in the value of the input quantity to an AMS and the

time as from which the value of the output quantity is reliably maintained above 90 % of the correct value

of the input quantity

Note 1 to entry: The response time is also referred to as the 90 % time.

[SOURCE: EN 15267-3:2007]

3.25

span gas

test gas used to adjust and check a specific point on the response line of the measuring system

Note 1 to entry: This concentration is often chosen around 80 % of the upper limit of the range or around the

emission limit value.

3.26

standard reference method

SRM

reference method prescribed by European or national legislation

[SOURCE: EN 15259:2007]

3.27

uncertainty

parameter associated with the result of a measurement, that characterises the dispersion of the values

that could reasonably be attributed to the measurand

[SOURCE: ISO/IEC Guide 98-3:2008]

3.28

standard uncertainty

uncertainty of the result of a measurement expressed as a standard deviation u

[SOURCE: ISO/IEC Guide 98-3:2008]

3.29

combined standard uncertainty

standard uncertainty of the result of a measurement when that result is obtained from the values of a

number of other quantities, equal to the positive square root of a sum of terms, the terms being the

variances or covariances of these other quantities weighted according to how the measurement result

varies with changes in these quantities

[SOURCE: ISO/IEC Guide 98-3:2008]

3.30

expanded uncertainty

quantity defining a level of confidence about the result of a measurement that could be expected to

encompass a specific fraction of the distribution of values that could reasonably be attributed to a

measurand

[SOURCE: ISO/IEC Guide 98-3:2008]

Note 1 to entry: The interval about the result of measurement is established for a level of confidence of 95 %.

3.31

uncertainty budget

statement of a measurement uncertainty, of the components of that measurement uncertainty, and of

their calculation and combination

[SOURCE: JCGM 200:2012; Note 1 added]

Note 1 to entry: Calculation table combining all the sources of uncertainty according to EN ISO 14956 or

ISO/IEC Guide 98-3:2008.

4 Principle

4.1 General

This document specifies a method for the determination of the mass concentration of hydrogen chloride

(HCl) in ducts and stacks emitting to atmosphere by means of an automatic analyser using the infrared

absorption principle. The specific components and requirements for the sampling system and the

infrared analyser are described in Clause 5 and 6. A number of performance characteristics with

associated minimum performance criteria and an expanded uncertainty of the method are given.

Requirements and recommendations for quality assurance and quality control are given for

measurements in the field (see Table 1 in 7.3).

4.2 Measuring principle

The HCl concentration is measured with an infrared absorption method. The attenuation of infrared light

passing through a sample cell is a measure of the concentration of HCl in the cell, according to the

Lambert-Beer law. Not only HCl but also most hetero-atomic molecules absorb infrared light, in particular

water and CO have broad bands that can interfere with the measurement of HCl. Different technical

solutions have been developed to suppress cross-sensitivity, instability and drift in order to design

automatic monitoring systems with acceptable properties. For instance: Gas Filter Correlation, Tunable

Diode Laser (TDL) and Fourier Transform Infrared Spectroscopy (FTIR).

The P-AMS will be used only in the field of gas matrices tested during its characterization according to

EN 15267-4.

Infrared analysers are part of extractive or in situ systems. Most of them are combined with an extractive

sampling system and a gas conditioning system. A representative sample of gas is taken from the stack

with a sampling probe and conveyed to the analyser through the sampling line and gas conditioning

system. The values from the analyser are recorded and/or stored by means of electronic data processing.

The concentration of HCl is typically measured in parts per million by volume (ppmv). The final results

for reporting are expressed in milligrams per cubic meter using standard conversion factors (see

Clause 10).

5 Sampling system

5.1 General

A volume is extracted (see 8.2.1) from the flue gas for a fixed period of time at a controlled flow rate. A

filter removes the dust in the sampled volume before the sample is conditioned and passes to the

analyser. Two different sampling and conditioning configurations can be used in order to avoid

uncontrolled water vapour condensation in the measuring system. These configurations are:

— configuration 1: removal of water vapour through elimination using a permeation drier;

— configuration 2: maintaining the temperature of the sampling line at a minimum value (see 5.5.2) up

to the heated analyser.

Conditions and layout of the sampling equipment contribute to the expanded uncertainty. In order to

minimize this contribution to the expanded uncertainty of the method, sampling conditions are given in

5.2 and performance criteria for the sampling equipment in 7.2.

5.2 Sampling probe

In order to access the representative measurement point(s) of the measurement plane, probes of

different lengths and inner diameters may be used. The design and configuration of the probe used shall

ensure the residence time of the sample gas within the probe is minimized in order to reduce the response

time of the measuring system. The probes shall be heated if they are not fully inserted into the duct or

stack.

The procedure described in 8.1 shall be used when a lack of homogeneity in the flue gas is suspected.

5.3 Filter

The filter shall be made of an inert material with an appropriate pore size. Use a heated filter appropriate

to the dust loading that shall be changed or cleaned periodically depending on the dust loading at the

sampling site.

Overloading of the particle filter could increase the pressure drop in the sampling line.

5.4 Sampling line

The sampling line shall be heated up to the conditioning system. It shall be made of a suitable corrosion

resistant material (e.g. borosilicate glass or titanium could be used; PTFE is suitable for flue gas

temperatures lower than 200 °C).

5.5 Conditioning system

5.5.1 Permeation drier (configuration 1)

It is important that all parts of the sampling equipment upstream of the analyser are made of materials

that do not react with or absorb HCl.

In presence of few mg/m of ammonia, risk occurs to have salt deposition in the sampling line, potentially

clogging and damaging the permeation drier. This risk can be avoided using a scrubber specific to remove

NH installed at the outlet of the sampling probe. The remaining ammonia concentration shall not exceed

1 mg/m .

The temperature of the components coming into contact with the gas shall be maintained, upstream the

permeation system, at a sufficiently high temperature to prevent condensation.

This configuration is not recommended for water vapour content higher than 30 %.

The permeation drier is used before the gas enters the analyser in order to separate water vapour from

the flue gas. A water dew-point temperature below 4 °C is required at the outlet of the permeation drier.

The concentrations, provided by this sampling configuration, are considered to be given on dry basis.

However, the results may be corrected for the remaining water vapour (refer to the table of Annex B in

EN 14790:2017).

5.5.2 Heated line and heated analyser (configuration 2)

It is important that all parts of the sampling equipment upstream of the analyser are made of materials

that do not react with or absorb HCl.

In presence of few mg/m NH , risk occurs to have salts formation. The temperature of its components

coming into contact with the gas shall be maintained at a sufficiently high temperature to prevent salt

formation (typically between 175 °C and 200 °C) and higher than the water dew point to prevent

condensation in the sampling equipment.

If the concentrations are given on wet basis, they shall be corrected so that they are expressed on dry

basis. The correction shall be made from the water vapour concentration measured in the flue gas. The

uncertainty attached to this correction shall be part of the uncertainty budget.

5.6 Sample pump

The sample pump shall be capable of operating to the specified flow requirements of the manufacturer

of the analyser and pressure conditions required for the sample cell. The pump shall be resistant to

corrosion. If an external pump is used it shall be compatible with the requirements of the analyser to

which it is connected.

5.7 Secondary filter (optional)

The secondary filter is used to separate fine dust, with a pore size less than 5 µm. For example, it may be

made of glass-fibre, sintered ceramic, stainless steel or PTFE-fibre.

6 Analyser equipment

This document does not prescribe the technique. Instead, this document specifies performance criteria

(see EN 15267-4:2017, Table 1), regardless of the technique used to measure HCl. Additional

requirements described in method specific standards shall be observed, when they exist (e.g.

CEN/TS 17337 for P-AMS based on FTIR technique).

7 Determination of the characteristics of the method: analyser, sampling and

conditioning line

7.1 General

The user of this document shall demonstrate that:

— the performance characteristics of the P-AMS shall be equal or better than the associated

performance criteria given in EN 15267-4:2017, Table 1; and

— the expanded uncertainty of the method calculated by combining values of standard uncertainties

associated with the performance characteristics is less than 20 % at the daily emission limit value or

3 3

1 mg/m below 5 mg/m , in the measurement conditions, before correction to the specified value of

O and humidity.

The values of the performance characteristics shall be evaluated by an experienced and independent

laboratory recognized by the competent authority. Laboratory tests and a field test will be implemented

according to EN 15267-4. The P-AMS will be used only in the field of gas matrices tested during its

characterization according to EN 15267-4.

It is the responsibility of the user to check the performance characteristics with a periodicity given in

Table 2 (Clause 9).

7.2 Relevant performance characteristics of the method and performance criteria

The uncertainty of the measured values by the method is not only influenced by the performance

characteristics of the analyser itself but also by:

— the sampling line and conditioning system;

— the site-specific conditions;

— the reference material used (e.g. compressed gas in cylinders or gas provided by a gas generator).

The performance characteristics of the method shall be evaluated in accordance with EN 15267-4.

EN 15267-4:2017, Table 1 gives an overview of the relevant performance characteristics and

performance criteria, which shall be determined during laboratory and field tests according to the

relevant CEN procedures, and indicates values included in the calculation of the expanded uncertainty of

the method.

7.3 Establishment of the uncertainty budget

An uncertainty budget shall be established to determine if the analyser and its associated sampling

system fulfil the requirements for a maximum allowable expanded uncertainty of the method.

The method shall have an expanded uncertainty lower than 20 % at the daily emission limit value, or

3 3

1 mg/m for daily emissions limit values below 5 mg/m . This expanded uncertainty of the method is

calculated on a dry basis and before correction to the O reference concentration. If the concentrations of

the automated method are given on a wet basis, a correction to dry basis shall be carried out. The

uncertainty attached to the correction of water vapour content shall be added to the uncertainty budget.

An example of calculation is given in Annex A.

The principle of calculation of the expanded uncertainty of the method is based on the law on propagation

of uncertainty laid down in EN ISO 14956:

— determine the standard uncertainties for each value included in the calculation of the budget

uncertainty by means of laboratory and field tests, and according to EN ISO 14956;

— calculate the uncertainty budget by combining all the standard uncertainties according to

EN ISO 14956. This shall include the uncertainty of the certified reference material. It shall also take

variations in the range of influence quantities and interferents of the specific site conditions into

account. If these conditions are unknown, default values defined in Table 1 shall be applied. When

corrections for residual water content in the flue gas are applied, the uncertainty attached to this

correction shall be added to the uncertainty budget;

— values of standard uncertainty that are less than 5 % of the maximum standard uncertainty can be

neglected; and

— calculate the expanded uncertainty of the method at the daily emission limit value, on a dry basis.

Table 1 — Default variations ranges of influence quantities and interferents to be applied for the

determination of the uncertainty budget

Performance characteristic or component Default variations range on site

Atmospheric pressure ±3 kPa

In accordance with the manufacturer's

Sample volume flow variation

recommendations

a

Ambient temperature

between 5 °C and 40 °C

at −15 % below and at +10 % above nominal supply

Influence of voltage

voltage

O 3 % to 21 %

H O 1 % to 30 %

3 3

CO 0 mg/m to 300 mg/m

CO 0 % to 15 %

3 3

CH 0 mg/m to 50 mg/m

3 3

N O 0 mg/m to 20 mg/m

N O

3 3

0 mg/m to 100 mg/m

fluidised bed combustion

3 3

NO 0 mg/m to 300 mg/m

3 3

NO 0 mg/m to 30 mg/m

3 3

NH 0 mg/m to 20 mg/m

3 3

SO 0 mg/m to 200 mg/m

SO

3 3

0 mg/m to 1 000 mg/m

coal fired power plants (without

desulphurisation)

a

Bigger ranges can be specified by the manufacturer.

8 Field operation

8.1 Measurement plan and sampling strategy

The measurement plan and the sampling strategy shall be carried out in accordance with EN 15259

requirements.

The homogeneity can be demonstrated according to EN 15259.

To avoid long response times, the sample line shall be as short as possible. If necessary, a bypass pump

shall be used.

Typically, the following characteristics of flue gases should be considered before a field campaign:

— temperature of exhaust gases;

— flue gas moisture content and acid dew point;

— dust loading;

— presence of NH ;

— expected concentration range of HCl and emission limit values;

— expected concentration of potentially interfering substances, including at least the components listed

in Table 1; and

— flue gas cleaning system.

The measuring range shall be chosen to be adapted to the measuring task.

8.2 Setting of the analyser on site

8.2.1 General

The complete measuring system, the sampling line including the conditioning unit, where required and

the analyser, shall be connected according to the manufacturer’s instructions. The probe is inserted so

that its open end is at the representative measurement point(s) in the duct (see 8.1).

After pre-heating, the flow passing through the sampling system and the analyser shall be adjusted to the

chosen flow rate to be used during measurement. This flow should be maintained at a constant level.

The conditioning unit, where required, sampling probe, filter, connection tube and analyser shall be

stabilized with respect to temperature before adjustment of the analyser.

Time resolution of the data recording system shall be adapted to the measuring task and to the response

time of the measuring system.

8.2.2 Preliminary zero and span check, and adjustments

8.2.2.1 Test gases

The relative expanded uncertainty on the certified reference material used for the span check shall be no

more than 2,5 %.

The zero gas shall be a gas containing no significant amount of hydrogen chloride (for example, nitrogen

or purified air). For reasons given in C.3, the gas shall be wet.

When the analyser is used for regulatory purposes, the wet span gas shall have a known concentration of

approximately 50 % to 90 % of the chosen measuring range or at the concentration level of the site.

8.2.2.2 Adjustment of the analyser

At the beginning of the measuring period, the zero and span gases are supplied to the measurement port

of the analyser. Adjustments are made until the correct zero and span gas values are given by the data

sampling system.

8.2.2.3 Check of the sampling system, for leaks and losses

The sampling line shall be checked for leakage and losses according to the following procedure.

Zero and span gases are supplied to the analyser through the sampling system, as close as possible to the

inlet of the line (in front of the filter if possible). Differences between the readings obtained during the

adjustment of the analyser and during the check shall be lower than 2 % of P-AMS chosen measuring

range.

NOTE 1 A passivation time of several minutes could be required to reach a stable HCl reading.

If the leakage and losses test failed, follow manufacturer’s instructions.

NOTE 2 The cause being leakage can be eliminated by sealing off the end of the probe and switching on the pump

and checking that the flow rate does not exceed more than 2 % of the flow rate expected to be used during

measurement.

NOTE 3 Measuring oxygen at the entrance and at the exit of the sample gas line is a possible method to determine

if the failure is due to a leak (greater oxygen at the exit of the line) or losses (oxygen remains unchanged).

During the validation of this document, it has been noticed that some material might adsorb or desorb

HCl. With some P-AMS using stainless steel (probe, filter, connections) it has been observed desorption

phenomena when the probe is inserted into the duct that could affect the signal during more than 30 min.

The user should evaluate the importance of these phenomena to reduce their impact of this induced effect

and remove data corresponding to this affected period or reducing their importance by extending the

measurement time.

8.2.3 Zero and span checks after measurement

At the end of the measuring period and at least once a day, zero and span checks shall be performed at

the inlet of the sampling probe by supplying test gases. The results of these checks (i.e. deviations

between checks before and after measurement) shall be documented and included in the measurement

report.

If the span or zero drifts are greater than 2,0 % of the span value, it is necessary to correct both for zero

and span drifts.

The drift of zero and span shall be lower than 5,0 % of the span value; otherwise, the results shall be

rejected.

The concentration Ccorr corrected according to time t for the concentration C given by the analyser shall

be calculated according to Formula (1):

C− Bt + Drift B × t

( ( ) ( ) )

C = (1)

corr

At +×Drift A t

( ) ( )

( )

where

result after adjustment at tt at span – result after adjustment at at zero

A(t ) = ;

span gas concentration – zero gas concentration

result during the drift check at tt at span – result during the drift check at at zero

end end

Drift A − At

( ) ( )

span gas concentration – zero gas concentration

tt –

( )

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...