EN 14411:2006

(Main)Ceramic tiles - Definitions, classification, characteristics and marking

Ceramic tiles - Definitions, classification, characteristics and marking

This European Standard defines and gives terms, specifies requirements and marking criteria for ceramic tiles (produced by extrusion and dry-pressing techniques) of the best commercial quality (first quality).

Tiles not of first commercial quality are also covered following the provisions of Annex Q.

This European Standard does not cover tiles made by other than the normal processes of extrusion or dry-pressing nor decorative accessories or trim (such as edges, corners, skirting, capping, coves, beads, steps, curved tiles and other accessory pieces) or mosaics (i.e. any piece that can fit into a 7 cm 7 cm area, see custom nomenclature).

NOTE EN ISO 10545 describes the test procedures required to determine the product characteristics listed in

this European Standard. EN ISO 10545 is divided into parts, each describing a specific test procedure or related matter.

Keramische Fliesen und Platten - Begriffe, Klassifizierung, Gütemerkmale und Kennzeichnung

Diese Europäische Norm legt Begriffe für (durch Strangpress und Trockenpresstechniken hergestellte) keramische Fliesen und Platten der ersten handelsüblichen Güteklasse sowie die entsprechenden Anfor¬derungen und Kennzeichnungskriterien fest.

Fliesen und Platten, die nicht der ersten handelsüblichen Güteklasse entsprechen, sind nach den Vorgaben von Anhang Q ebenfalls einbezogen.

Diese Europäische Norm gilt weder für Fliesen und Platten, die durch andere als die üblichen Strang¬press oder Trockenpressprozesse hergestellt wurden, noch für dekoratives Zubehör und Verzierungen (wie zum Beispiel Kanten, Ecken, Sockel, Wölbungen, Kehlungen, Bördelränder, Stufen, gekrümmte Fliesen/ Platten und weiteres Zubehör) und Mosaiks (d. h. Teile, die in eine Fläche von 7 cm 7 cm hineinpassen, siehe Handelsnomenklatur).

ANMERKUNG EN ISO 10545 beschreibt die Prüfverfahren, die erforderlich sind, um die in dieser Europäischen Norm aufgeführten Produktmerkmale zu bestimmen. EN ISO 10545 besteht aus mehreren Teilen, von denen jeder Teil ein bestimmtes Prüfverfahren oder ein damit zusammenhängendes Phänomen beschreibt.

Carreaux céramiques - Définitions, classification, caractéristiques et marquage

La présente Norme européenne définit et fixe les termes, les exigences et les critères de marquage des carreaux céramiques (produits à l’aide de techniques d’étirage et de pressage à sec) de premier choix.

Les carreaux qui ne sont pas de premier choix d’un point de vue commercial sont également couverts par les dispositions de l’Annexe Q.

La présente Norme européenne couvre uniquement les carreaux fabriqués par étirage ou pressage à sec. Elle ne concerne ni les accessoires décoratifs (cabochons, frises), ni les pièces spéciales (telles que marches, nez de marche, plinthes, angles), ni les mosaïques (c’est-à-dire aucune pièce qui peut rentrer dans une surface de (7 7) cm, voir la nomenclature).

NOTE L'EN ISO 10545 décrit les modes opératoires d'essai permettant de déterminer les caractéristiques des produits figurant dans la présente Norme européenne. L'EN ISO 10545 est divisée en plusieurs parties, chacune décrivant un mode opératoire d'essai particulier ou un point en rapport avec un mode opératoire.

Keramične ploščice - Definicije, razvrstitev, lastnosti in označevanje

General Information

- Status

- Withdrawn

- Publication Date

- 19-Dec-2006

- Withdrawal Date

- 09-Oct-2012

- Technical Committee

- CEN/TC 67 - Ceramic tiles

- Drafting Committee

- CEN/TC 67 - Ceramic tiles

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Oct-2012

- Completion Date

- 10-Oct-2012

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 14411:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Ceramic tiles - Definitions, classification, characteristics and marking". This standard covers: This European Standard defines and gives terms, specifies requirements and marking criteria for ceramic tiles (produced by extrusion and dry-pressing techniques) of the best commercial quality (first quality). Tiles not of first commercial quality are also covered following the provisions of Annex Q. This European Standard does not cover tiles made by other than the normal processes of extrusion or dry-pressing nor decorative accessories or trim (such as edges, corners, skirting, capping, coves, beads, steps, curved tiles and other accessory pieces) or mosaics (i.e. any piece that can fit into a 7 cm 7 cm area, see custom nomenclature). NOTE EN ISO 10545 describes the test procedures required to determine the product characteristics listed in this European Standard. EN ISO 10545 is divided into parts, each describing a specific test procedure or related matter.

This European Standard defines and gives terms, specifies requirements and marking criteria for ceramic tiles (produced by extrusion and dry-pressing techniques) of the best commercial quality (first quality). Tiles not of first commercial quality are also covered following the provisions of Annex Q. This European Standard does not cover tiles made by other than the normal processes of extrusion or dry-pressing nor decorative accessories or trim (such as edges, corners, skirting, capping, coves, beads, steps, curved tiles and other accessory pieces) or mosaics (i.e. any piece that can fit into a 7 cm 7 cm area, see custom nomenclature). NOTE EN ISO 10545 describes the test procedures required to determine the product characteristics listed in this European Standard. EN ISO 10545 is divided into parts, each describing a specific test procedure or related matter.

EN 14411:2006 is classified under the following ICS (International Classification for Standards) categories: 91.100.25 - Terracotta building products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14411:2006 has the following relationships with other standards: It is inter standard links to EN 14411:2012, EN ISO 10644:2009, EN 14891:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14411:2006 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/119. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14411:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Ceramic tiles - Definitions, classification, characteristics and markingYDQMHCarreaux céramiques - Définitions, classification, caractéristiques et marquageKeramische Fliesen und Platten - Begriffe, Klassifizierung, Gütemerkmale und KennzeichnungTa slovenski standard je istoveten z:EN 14411:2006SIST EN 14411:2007en91.100.23Ceramic tilesICS:SIST EN 14411:20041DGRPHãþDSLOVENSKI

STANDARDSIST EN 14411:200701-marec-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14411December 2006ICS 91.100.25Supersedes EN 14411:2003

English VersionCeramic tiles - Definitions, classification, characteristics andmarkingCarreaux et dalles céramiques - Définitions, classification,caractéristiques et marquageKeramische Fliesen und Platten - Begriffe, Klassifizierung,Gütemerkmale und KennzeichnungThis European Standard was approved by CEN on 13 November 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14411:2006: E

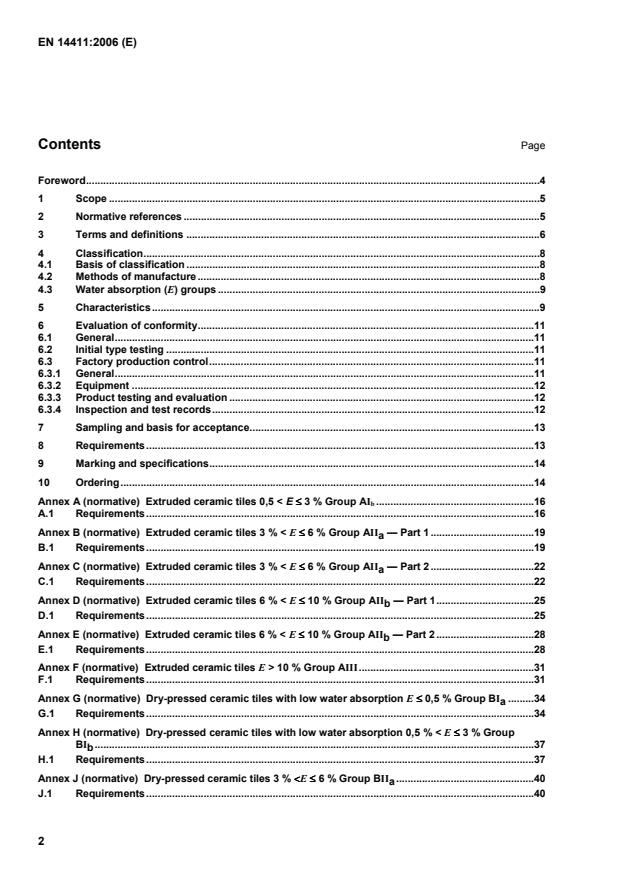

Extruded ceramic tiles 0,5 < E ≤≤≤≤ 3 % Group AIb.16 A.1 Requirements.16 Annex B (normative)

Extruded ceramic tiles 3 % < E ≤≤≤≤ 6 % Group AIIa — Part 1.19 B.1 Requirements.19 Annex C (normative)

Extruded ceramic tiles 3 % < E ≤≤≤≤ 6 % Group AIIa — Part 2.22 C.1 Requirements.22 Annex D (normative)

Extruded ceramic tiles 6 % < E ≤≤≤≤ 10 % Group AIIb — Part 1.25 D.1 Requirements.25 Annex E (normative)

Extruded ceramic tiles 6 % < E ≤≤≤≤ 10 % Group AIIb — Part 2.28 E.1 Requirements.28 Annex F (normative)

Extruded ceramic tiles E > 10 % Group AIII.31 F.1 Requirements.31 Annex G (normative)

Dry-pressed ceramic tiles with low water absorption E ≤≤≤≤ 0,5 % Group BIa.34 G.1 Requirements.34 Annex H (normative)

Dry-pressed ceramic tiles with low water absorption 0,5 % < E ≤≤≤≤ 3 % Group BIb.37 H.1 Requirements.37 Annex J (normative)

Dry-pressed ceramic tiles 3 % <<<

Dry-pressed ceramic tiles 6 % < E ≤≤≤≤ 10 % Group BIIb.43 K.1 Requirements.43 Annex L (normative)

Dry-pressed ceramic tiles E > 10 % Group BIII.46 L.1 Requirements.46 Annex M (normative)

Extruded ceramic tiles with low water absorption E ≤≤≤≤

0,5 % Group AIa.49 M.1 Requirements.49 Annex N (informative)

Classification of glazed tiles for floors according to their abrasion resistance.52 Annex P (informative)

Test methods.53 Annex Q (normative)

Additional European requirements on tiles.54 Q.1 General.54 Q.2 Release of cadmium.54 Q.3 Release of lead.54 Annex R (informative)

Symbols for intended use.55 ZA.1 Scope and general.57 ZA.2 Procedures for the attestation of conformity of products.61 ZA.2.1 Procedures for the attestation of conformity of flooring.61 ZA.2.2 Procedures for the attestation of conformity of wall and ceiling finishes.61 ZA.3 CE marking and labelling.62 ZA.3.1 CE marking.62 ZA.3.2 Examples of reference model for the marking and labelling.63 ZA.4 EC Declaration of conformity.66 Bibliography.67

this European Standard. EN ISO 10545 is divided into parts, each describing a specific test procedure or related matter. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 12004, Adhesives for tiles — Definitions and specifications EN ISO 10545-1, Ceramic tiles — Part 1: Sampling and basis for acceptance (ISO 10545-1:1995) EN ISO 10545-2, Ceramic tiles — Part 2: Determination of dimensions and surface quality (ISO 10545-2:1995, including Technical Corrigendum 1:1997) EN ISO 10545-3, Ceramic tiles — Part 3: Determination of water absorption, apparent porosity, apparent relative density and bulk density (ISO 10545-3:1995, including Technical Corrigendum 1:1997) EN ISO 10545-4, Ceramic tiles — Part 4: Determination of modulus of rupture and breaking strength (ISO 10545-4:1995) EN ISO 10545-5, Ceramic tiles — Part 5: Determination of impact resistance by measurement of coefficient of restitution (ISO 10545-5:1996, including Technical Corrigendum 1:1996) EN ISO 10545-6, Ceramic tiles — Part 6: Determination of resistance to deep abrasion for unglazed tiles (ISO 10545-6:1995) EN ISO 10545-7, Ceramic tiles — Part 7: Determination of resistance to surface abrasion for glazed tiles (ISO 10545-7:1996) EN ISO 10545-8, Ceramic tiles — Part 8: Determination of linear thermal expansion (ISO 10545-8:1994) EN ISO 10545-9, Ceramic tiles — Part 9: Determination of resistance to thermal shock (ISO 10545-9:1994) EN ISO 10545-10, Ceramic tiles — Part 10: Determination of moisture expansion (ISO 10545-10:1995) EN ISO 10545-11, Ceramic tiles — Part 11: Determination of crazing resistance for glazed tiles (ISO 10545-11:1994) EN ISO 10545-12, Ceramic tiles — Part 12: Determination of frost resistance (ISO 10545-12:1995, including Technical Corrigendum 1:1997) EN ISO 10545-13, Ceramic tiles — Part 13: Determination of chemical resistance (ISO 10545-13:1995)

Tiles are generally used as coverings for floors and walls. They are usually shaped by extruding (Method A) or dry-pressing (Method B) at room temperature followed by drying and firing at temperatures sufficient to develop the required properties, but can be formed by other processes. Tiles can be glazed (GL) or unglazed (UGL) and are incombustible and unaffected by light NOTE 2 A fully vitrified (or porcelain) tile is a tile with water absorption lower than 0,5 %. 3.2 glaze vitrified covering 3.3 engobed surface clay-based covering with a matt finish which can be permeable or impermeable NOTE A tile with an engobed surface is regarded as an unglazed tile. 3.4 polished surface surface of a glazed or unglazed tile which has been given a glossy finish by mechanical polishing carried out after firing 3.5 extruded tile tile whose body is shaped in the plastic state in an extruder, the column obtained being cut into tiles of pre-determined dimension NOTE 1 This European Standard classifies extruded tiles as “precision” or “natural”. The classification is dependent upon the different technical characteristics as listed in the normative Annexes A to F and R. NOTE 2 Traditional terms used for extruded products are “split tiles” and “quarry tiles”. They commonly indicate double-extruded and single-extruded tiles respectively. The term “quarry tiles” only refers to extruded tiles with a water absorption not exceeding 6 %. NOTE 3 Extruded tiles include the letter ‘A’ in their designation (see Table 1). 3.6 dry-pressed tile tile formed from a finely milled body mixture and shaped by pressing

The use of spacer lugs are illustrated in Figure 2. 3.8 water absorption (symbol E) percentage of water by mass, measured in accordance with EN ISO 10545-3 3.9 description of sizes see Figures 1 and 2 NOTE These are only defined for rectangular tiles. If the sizes of non-rectangular tiles are required, they are defined by the smallest rectangle into which they will fit. 3.9.1 nominal size size used to describe the product 3.9.2 work size (symbol W) size of a tile specified for manufacturing to which the actual size has to conform within specified permissible deviations NOTE This is specified by the dimensions length, width and thickness. 3.9.3 actual size size obtained by measuring the face of the tile in accordance with EN ISO 10545-2 3.9.4 coordinating size (symbol C) work size plus the joint width 3.9.5 modular size dimensions based on the modules M, and also their multiples or subdivisions, except for tiles with a surface area of less than 9 000 mm2 NOTE See ISO 1006 where 1 M = 100 mm. 3.9.6 non-modular size size not based on module M NOTE See ISO 1006 where 1 M = 100 mm. 3.9.7 tolerance difference between the permissible limits

NOTE Families can be defined in terms of body characteristics (same size and thickness) or surface finish characteristics (same glaze and/or decoration composition and properties). 4 Classification 4.1 Basis of classification Ceramic tiles are divided into groups according to their method of manufacture and their water absorption (see 3.8 and Table 1). The groups do not presuppose the usage of the products. Table 1 — Classification of ceramic tiles with respect to water absorption and shaping Shaping Group I E ≤≤≤≤ 3 % Group IIa 3 % <<<< E ≤ 6 % Group IIb 6 % <<<< E ≤ 10 % Group III E > 10 % A Extruded Group AIa E ≤ 0,5 % (see Annex M) Group AIb 0,5 % < E ≤ 3 % (see Annex A) Group AIIa-1 a (see Annex B) Group AIIa-2 a (see Annex C) Group AIIb-1 a (see Annex D) Group AIIb-2 a (see Annex E) Group AIII (see Annex F) B Dry pressed Group BIa E ≤ 0,5 % (see Annex G) Group BIb 0,5 % < E ≤ 3 % (see Annex H) Group BIIa (see Annex J) Group BIIb (see Annex K) Group BIII b (see Annex L) a

Groups AIIa and AIIb are divided into two parts (Parts 1 and 2) with different product specifications. b

Group BIII covers glazed tiles only. There is a low quantity of dry-pressed unglazed tiles produced with water absorption greater than 10 % that is not covered by this product group.

4.2 Methods of manufacture There are two methods of manufacture as follows: method A, extruded tiles (see 3.5), method B, dry-pressed tiles (see 3.6).

for extruded tiles: 1) E ≤ 0,5 % (Group AIa,,), 2) 0,5 % < E ≤ 3 % (Group AIb,). a2) for dry-pressed tiles: 3) E ≤ 0,5 % ( Group BIa,), 4) 0,5 % < E ≤ 3 % ( Group BIb,). b) Tiles of medium water absorption (Group II), 3 % <<<< E ≤≤≤≤ 10 % Group II is further divided as follows: b1) for extruded tiles: 1) 3 % < E ≤ 6 % (Group AIIa, Parts 1 and 2), 2) 6 % < E ≤ 10 % (Group AIIb, Parts 1 and 2); b2) for dry-pressed tiles: 3) 3 % < E ≤ 6 % Group BIIa, 4) 6 % < E ≤ 10% Group BIIb. c) Tiles of high water absorption (Group III), E >>>> 10 % 5 Characteristics The characteristics for different applications of ceramic tiles are given in Table 2.

EN ISO 10545-6 Resistance to surface abrasion – glazed tiles X X

EN ISO 10545-7 Linear thermal expansion a X X X X EN ISO 10545-8 Resistance to thermal shock a X X X X EN ISO 10545-9 Resistance to crazing – glazed tiles X X X X EN ISO 10545-11 Frost resistance b

X

X EN ISO 10545-12 Coefficient of friction X X

Declare test method used Moisture expansion a X X X X EN ISO 10545-10 Small colour differences a X X X X EN ISO 10545-16 Impact resistance a X X

EN ISO 10545-5 Chemical properties Interior Exterior Interior Exterior Reference Resistance to staining

EN ISO 10545-14 — glazed tiles X X X X EN ISO 10545-14 — unglazed tiles a X X X X EN ISO 10545-14 Resistance to acids and alkalis of low concentration X X X X EN ISO 10545-13 Resistance to acids and alkalis of high concentration a X X X X EN ISO 10545-13 Resistance to household cleaning agents and swimming pool chemicals X X X X EN ISO 10545-13 Lead and cadmium release – glazed tiles a X X X X EN ISO 10545-15 a

Test method available, but this standard does not specify values. b

For tiles intended to be used in situations where frost conditions apply.

strength b EN ISO 10545-4 See Tables A.1 to L.1 and R.1 7 Once a year Slipperiness c

Declared value As required by test method used Once a year Skid resistance c

Declared value As required by test method used Once a year Thermal shock resistance a EN ISO 10545-9 See Tables A.1 to L.1 and R.1 5 Once a year Frost resistance, freeze/thaw a EN ISO 10545-12 See Tables A.1 to L.1 and R.1 10 Once a year Bond strength/

adhesion a

a) For cementitious adhesives, EN 12004 b) For dispersion adhesives, EN 12004 c) For reaction resin adhesives, EN 12004

See EN 12004

Once per product group Release of dangerous substances c EN ISO 10545-15 See Annex Q

Once a year a

Testing for a product group. b

Testing for a family in a group of products (group of absorption, dimensions and thickness). c

Testing for a family in a group of products (finish surface characteristics, same composition and properties).

7 Sampling and basis for acceptance The sampling and basis for acceptance shall be in accordance with that presented in EN ISO 10545-1. The control frequencies for the evaluation of conformity as regard the characteristics shall be stated and declared by the manufacturer, taking into account the production organisation. 8 Requirements Dimensional and surface quality requirements and physical and chemical properties shall be as given in the specific annex (Annexes A through L and R) for each tile group (see contents).

9 Marking and specifications Tiles and/or their packaging shall bear the following marking: 1) manufacturer's mark and/or trademark and the country of origin; 2) mark to indicate first quality; 3) reference to the appropriate annex of this European Standard, i.e. EN 14411:2006 and classification ("Precision" or "Natural"), where applicable; 4) nominal and work sizes; 5) nature of the surface, i.e. glazed (GL) or unglazed (UGL). EXAMPLES Ceramic tile 1ST quality EN 14411, Annex A, Precision 25 cm x 12,5 cm (W 240 mm x 115 mm x 10 mm) GL Ceramic tile 1ST quality EN 14411, Annex A, Natural 15 cm x 15 cm (W 150 mm x 150 mm x 12 mm) UGL 10 Ordering When an order is placed, items such as size, thickness, type of surface, colour, profile, abrasion class for glazed tiles and other properties shall be agreed by the parties concerned.

Key coordinating size (C) = work size (W) + joint (J) work size (W)

dimension of the visible face (a), (b) and thickness (d) Figure 1 — Tile

Key 1 spacer lugs coordinating size (C) = work size (W) + joint (J) work size (W)

dimension of the visible face (a), (b) and thickness (d) Figure 2 — Tile with spacer lug

Extruded ceramic tiles 0,5 < E ≤≤≤≤ 3 % Group AIb A.1 Requirements Dimensional and surface quality requirements and physical and chemical properties shall be in accordance with Table A.1. Table A.1 — Requirements for extruded ceramic tiles, Group AIb, 0,5 < E ≤≤≤≤ 3 % Dimensions and surface quality Precision Natural Test Length and width

The manufacturer shall choose the work size as follows: a) for modular tiles in order to allow a nominal joint width of between 3 mm and 11 mm a; b) for non-modular tiles so that the difference between the work size and the nominal size is not more than ± 3 mm.

The deviation, in percent, of the average size for each tile (2 or 4 sides) from the work size (W). ± 1,0 % to a maximum of ± 2 mm ± 2,0 % to a maximum of ± 4 mm EN ISO 10545-2 The deviation, in percent, of the average size for each tile (2 or 4 sides) from the average size of the

10 test specimens (20 or 40 sides). ± 1,0 % ± 1,5 %

EN ISO 10545-2 Thickness

a) The thickness shall be specified by the manufacturer.

b) The deviation, in percent, of the average thickness of each tile from the work size thickness. ± 10 % ± 10 % EN ISO 10545-2 Straightness of sides b (facial sides)

The maximum deviation from straightness, in percent, related to the corresponding work sizes. ± 0,5 % ± 0,6 % EN ISO 10545-2

The maximum deviation from rectangularity, in percent, related to the corresponding work sizes. ± 1,0 % ± 1,0 % EN ISO 10545-2 Surface flatness

The maximum deviation from flatness, in percent:

a) centre curvature, related to diagonal calculated from the work sizes; ± 0,5 % ± 1,5 % EN ISO 10545-2 b) edge curvature, related to the corresponding work sizes; ± 0,5 % ± 1,5 % EN ISO 10545-2 c) warpage, related to diagonal calculated from the work sizes. ± 0,8 % ± 1,5 % EN ISO 10545-2 Surface quality c A minimum of 95 % of the tiles shall be free

from visible defects that would impair the appearance of a major area of tiles EN ISO 10545-2 Physical properties Precision Natural Test Water absorption Percent by mass 0,5 < E ≤≤≤≤ 3,0 %

Individual maximum 3,3 % 0,5 < E ≤≤≤≤ 3,0 %

Individual maximum 3,3 % EN ISO 10545-3 Breaking strength, in N

a) Thickness ≥ 7,5 mm. Not less than 1 100 Not less than 1 100 EN ISO 10545-4 b) Thickness < 7,5 mm. Not less than 600 Not less than 600 EN ISO 10545-4 Modulus of rupture, in N/mm2 Not applicable to tiles with breaking strength ≥ 3 000 N. Minimum 23 Individual minimum 18 Minimum 23 Individual minimum 18 EN ISO 10545-4 Abrasion resistance

a) Resistance to deep abrasion of unglazed tiles: removed volume, in cubic millimetres. Maximum 275 Maximum 275 EN ISO 10545-6 b) Resistance to surface abrasion of glazed tiles intended for use on floors d. Report abrasion class and cycles passed Report abrasion class and cycles passed EN ISO 10545-7 Coefficient of linear thermal expansion

From ambient temperature to 100 °C. Test method available Test method available EN ISO 10545-8 Thermal shock resistance Test method available Test method available EN ISO 10545-9 Crazing resistance: glazed tiles f Required Required EN ISO 10545-11Frost resistance Required Required EN ISO 10545-12Coefficient of friction

Tiles intended for use on floors. Where required Where required Declare test method(s)

a) Glazed tiles. Minimum Class 3 Minimum Class 3 EN ISO 10545-14b) Unglazed tiles. Test method available Test method available EN ISO 10545-14Resistance to chemicals

Resistance to low concentrations of acids and alkalis: a) glazed tiles; b) unglazed tiles g. Manufacturer to state classification Manufacturer to state classification EN ISO 10545-13Resistance to high concentrations of acids and alkalis e Test method available Test method available EN ISO 10545-13Resistance to household chemicals and swimming pool salts: a) glazed tiles; b) unglazed tiles g. Minimum GB Minimum UB Minimum GB Minimum UB EN ISO 10545-13Lead and cadmium release Test method available Test method available EN ISO 10545-15a

Similar joint widths may be used to apply to traditional systems based on non-metric sizes. b

Not applicable for tiles having curved shapes. c

Because of firing, slight variations from the standard colour are unavoidable. This does not apply to intentional irregularities of colour variation of the face of tiles (which can be unglazed, glazed or partly glazed) or to the colour variation over a tile area which is characteristic for this type of tile and desirable. Spots or coloured dots which are introduced for decorative purposes are not considered a defect. d

Reference may be made to Annex N of this European Standard for the abrasion resistance classification for all glazed tiles intended for use on floors. e

Reference may be made to Annex P of this European Standard for information regarding requirements which are non-compulsory but which are listed "test method available". f

Certain decorative effects may have a tendency to craze. They shall be identified by the manufacturer, in which case the crazing test given in EN ISO 10545-11 is not applicable. g

If the hue becomes slightly different, this is not considered to be chemical attack.

Extruded ceramic tiles 3 % < E ≤≤≤≤ 6 % Group AIIa — Part 1 B.1 Requirements Dimensional and surface quality requirements and physical and chemical properties shall be in accordance with Table B.1. Table B.1 — Requirements for extruded ceramic tiles, Group AIIa-1, 3 % < E ≤≤≤≤ 6 % Dimensions and surface quality Precision Natural Test Length and width

The manufacturer shall choose the work size as follows: a) for modular tiles in order to allow a nominal joint width of between 3 mm and 11 mm a; b) for non-modular tiles so that the difference between the work size and the nominal size is not more than ± 3 mm.

The deviation, in percent, of the average size for each tile (2 or 4 sides) from the work size (W). ± 1,25 % to a maximum of ± 2 mm ± 2,0 % to a maximum of ± 4 mm EN ISO 10545-2 The deviation, in percent, of the average size for each tile (2 or 4 sides) from the average size of the

10 test specimens (20 or 40 sides). ± 1,0 % ± 1,5 %

EN ISO 10545-2 Thickness

a) The thickness shall be specified by the manufacturer.

b) The deviation, in percent, of the average thickness of each tile from the work size thickness. ± 10 % ± 10 % EN ISO 10545-2 Straightness of sides b (facial sides)

The maximum deviation from straightness, in percent, related to the corresponding work sizes. ± 0,5 % ± 0,6 % EN ISO 10545-2

The maximum deviation from rectangularity, in percent, related to the corresponding work sizes. ± 1,0 % ± 1,0 % EN ISO 10545-2 Surface flatness

The maximum deviation from flatness, in percent:

a) centre curvature, related to diagonal calculated from the work sizes; ± 0,5 % ± 1,5 % EN ISO 10545-2 b) edge curvature, related to the corresponding work sizes; ± 0,5 % ± 1,5 % EN ISO 10545-2 c) warpage, related to diagonal calculated from the work sizes. ± 0,8 % ± 1,5 % EN ISO 10545-2 Surface quality c A minimum of 95 % of the tiles shall be free

from visible defects that would impair the appearance of a major area of tiles EN ISO 10545-2 Physical properties Precision Natural Test Water absorption Percent by mass 3,0 %< E ≤≤≤≤ 6,0 % Individual maximum 6,5 % 3,0 %< E ≤≤≤≤ 6,0 % Individual maximum 6,5 % EN ISO 10545-3 Breaking strength, in N

a) Thickness ≥ 7,5 mm. Not less than 950 Not less than 950 EN ISO 10545-4 b) Thickness < 7,5 mm. Not less than 600 Not less than 600 EN ISO 10545-4 Modulus of rupture, in N/mm2 Not applicable to tiles with breaking strength ≥ 3 000 N. Minimum 20 Individual minimum 18 Minimum 20 Individual minimum 18 EN ISO 10545-4 Abrasion resistance

a) Resistance to deep abrasion of unglazed tiles: removed volume, in cubic millimetres. Maximum 393 Maximum 393 EN ISO 10545-6 b) Resistance to surface abrasion of glazed tiles intended for use on floors d. Report abrasion class and cycles passed Report abrasion class and cycles passed EN ISO 10545-7 Coefficient of linear thermal expansion e

From ambient temperature to 100 °C. Test method available Test method available EN ISO 10545-8 Thermal shock resistance e Test method available Test method available EN ISO 10545-9 Crazing resistance: glazed tiles f Required Required EN ISO 10545-11Frost resistance e Test method available Test method available EN ISO 10545-12Coefficient of friction

Tiles intended for use on floors. Where required Where required Declare test method(s)

a) Glazed tiles. Minimum Class 3 Minimum Class 3 EN ISO 10545-14 b) Unglazed tiles e. Test method available Test method available EN ISO 10545-14 Resistance to chemicals

Resistance to low concentrations of acids and alkalis: a) glazed tiles; b) unglazed tiles g. Manufacturer to state classification Manufacturer to state classification EN ISO 10545-13 Resistance to high concentrations of acids and alkalis e. Test method available Test method available EN ISO 10545-13 Resistance to household chemicals and swimming pool salts: a) glazed tiles; b) unglazed tiles g. Minimum GB Minimum UB Minimum GB Minimum UB EN ISO 10545-13 Lead and cadmium release e Test method available Test method available EN ISO 10545-15 a

Similar joint widths may be used to apply to traditional systems based on non-metric sizes. b

Not applicable for tiles having curved shapes. c

Because of firing, slight variations from the standard colour are unavoidable. This does not apply to intentional irregularities of colour variation of the face of tiles (which can be unglazed, glazed or partly glazed) or to the colour variation over a tile area which is characteristic for this type of tile and desirable. Spots or coloured dots which are introduced for decorative purposes are not considered a defect. d

Reference may be made to Annex N of this European Standard for the abrasion resistance classification for all glazed tiles intended for use on floors. e

Reference may be made to Annex P of this European Standard for information regarding requirements which are non-compulsory but which are listed "test method available". f

Certain decorative effects may have a tendency to craze. They shall be identified by the manufacturer, in which case the crazing test given in EN ISO 10545-11 is not applicable. g

If the hue becomes slightly different, this is not considered to be chemical attack.

Extruded ceramic tiles 3 % < E ≤≤≤≤ 6 % Group AIIa — Part 2 C.1 Requirements Dimensional and surface quality requirements and physical and chemical properties shall be in accordance with Table C.1. Table C.1 — Requirements for extruded ceramic tiles, Group AIIa-2, 3 % < E ≤≤≤≤ 6 % Dimensions and surface quality Precision Natural Test Length and width

The manufacturer shall choose the work size as follows: a) for modular tiles in order to allow a nominal joint width of between 3 mm and 11 mm a; b) for non-modular tiles so that the difference between the work size and the nominal size is not more than ± 3 mm.

The deviation, in percent, of the average size for each tile (2 or 4 sides) from the work size (W). ± 1,5 % to a maximum of ± 2 mm ± 2,0 % to a maximum of ± 4 mm EN ISO 10545-2 The deviation, in percent, of the average size for each tile (2 or 4 sides) from the average size of the

10 test specimens (20 or 40 sides). ± 1,5 % ± 1,5 % EN ISO 10545-2 Thickness

a) The thickness shall be specified by the manufacturer.

b) The deviation, in percent, of the average thickness of each tile from the work size thickness. ± 10 % ± 10 % EN ISO 10545-2 Straightness of sides b (facial sides)

The maximum deviation from straightness, in percent, related to the corresponding work sizes. ± 1,0 % ± 1,0 % EN ISO 10545-2

The maximum deviation from rectangularity, in percent, related to the corresponding work

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...