EN 12750:2001+A1:2009

(Main)Safety of woodworking machines - Four-sided moulding machines

Safety of woodworking machines - Four-sided moulding machines

This document specifies all the significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to four sided moulding machines with a maximum working width of 350 mm hereafter referred to as "machines" designed to cut solid wood, chipboard, fibreboard, plywood and also these materials where these are covered with plastic laminate or edgings.

Controlled machines (CNC) this European Standard does not cover hazards related to Electro-Magnetic Compatibility (EMC).

This European Standard does not apply to:

a) hazards relating to infeed devices (magazines, hoppers, etc.);

b) machines designed for machining logs which have not previously been machined.

This European Standard is primarily applicable to machines which are manufactured after the date of issue of this European Standard.

Sicherheit von Holzbearbeitungsmaschinen - Fräsmaschinen für vierseitige Bearbeitung

!Dieses Dokument spezifiziert die in Abschnitt 4 aufgeführten signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die zutreffen auf Fräsmaschinen für vierseitige Bearbeitung mit einer größtmöglichen Arbeitsbreite von 350 mm, im Folgenden als "Maschinen" bezeichnet, die konstruiert sind zum Bearbeiten von Massivholz, Spanplatten, Faserplatten oder Sperrholz sowie diesen Werkstoffen, wenn sie kunststoffbeschichtet oder mit Kantenmaterial versehen sind."

!gestrichener Text"

Diese Europäische Norm behandelt bei CNC-Maschinen nicht die Gefährdungen im Zusammenhang mit der elektromagnetischen Verträglichkeit (EMV).

Diese Europäische Norm gilt nicht für:

a) Gefährdungen im Zusammenhang mit Beschickungseinrichtungen (Magazine, Vorratsbehälter usw.);

b) Maschinen zur Bearbeitung von Rundholz, welches nicht vorbearbeitet worden ist.

Diese Europäische Norm ist in erster Linie auf Maschinen anzuwenden, die nach dem Datum der Herausgabe dieser Europäischen Norm hergestellt werden.

Sécurité des machines pour le travail du bois - Machines à moulurer sur quatre faces

!Le présent document spécifie tous les phénomènes dangereux, situations dangereuses et événements dangereux énumérés dans l’Article 4 qui sont pertinents pour les machines à moulurer sur quatre faces d’une largeur maximale de 350 mm, ci-après désignées «machines», conçues pour usiner du bois massif, des panneaux de particules et de fibres, de contre-plaqué, ainsi que ces matériaux lorsque leurs surfaces ou leurs chants sont recouverts de matière plastique stratifiée."

!texte supprimé"

La présente norme européenne ne couvre pas, pour les machines de commande numérique (CNC), les risques liés à la compatibilité électromagnétique (CEM).

La présente norme européenne ne s'applique pas :

a) aux phénomènes dangereux relatifs aux dispositifs d'amenage (magasins, trémies, etc.) ;

b) aux machines conçues pour la découpe de grumes non précédemment usinés.

La présente norme européenne est applicable aux machines fabriquées après la date de publication.

Varnost lesnoobdelovalnih strojev - Rezkalnik za štiristransko obdelavo

General Information

- Status

- Withdrawn

- Publication Date

- 11-Aug-2009

- Withdrawal Date

- 19-Feb-2013

- Technical Committee

- CEN/TC 142 - Woodworking machines - Safety

- Drafting Committee

- CEN/TC 142/WG 9 - Four sided planing and moulding machines

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 20-Feb-2013

- Completion Date

- 20-Feb-2013

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 309, C 309, C 309, C 309, C 309, C 309, C 309, C OJ Date: 18-Dec-2009

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 12750:2001+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of woodworking machines - Four-sided moulding machines". This standard covers: This document specifies all the significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to four sided moulding machines with a maximum working width of 350 mm hereafter referred to as "machines" designed to cut solid wood, chipboard, fibreboard, plywood and also these materials where these are covered with plastic laminate or edgings. Controlled machines (CNC) this European Standard does not cover hazards related to Electro-Magnetic Compatibility (EMC). This European Standard does not apply to: a) hazards relating to infeed devices (magazines, hoppers, etc.); b) machines designed for machining logs which have not previously been machined. This European Standard is primarily applicable to machines which are manufactured after the date of issue of this European Standard.

This document specifies all the significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to four sided moulding machines with a maximum working width of 350 mm hereafter referred to as "machines" designed to cut solid wood, chipboard, fibreboard, plywood and also these materials where these are covered with plastic laminate or edgings. Controlled machines (CNC) this European Standard does not cover hazards related to Electro-Magnetic Compatibility (EMC). This European Standard does not apply to: a) hazards relating to infeed devices (magazines, hoppers, etc.); b) machines designed for machining logs which have not previously been machined. This European Standard is primarily applicable to machines which are manufactured after the date of issue of this European Standard.

EN 12750:2001+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 79.120.10 - Woodworking machines. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12750:2001+A1:2009 has the following relationships with other standards: It is inter standard links to EN 12750:2001, EN 12750:2001/prA1, EN 12750:2013, EN 60439-1:1999, EN 61310-1:2008, HD 22.1 S4:2002, EN 60529:1991, HD 21.1 S4:2002, EN 60947-4-1:2001, EN 60947-5-1:2004, EN 50370-1:2005, EN 1005-4:2005, EN ISO 4871:1996, EN 894-1:1997, EN 894-2:1997. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12750:2001+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12750:2001+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Varnost lesnoobdelovalnih strojev - Rezkalnik za štiristransko obdelavoSicherheit von Holzbearbeitungsmaschinen - Fräsmaschinen für vierseitige BearbeitungSécurité des machines pour le travail du bois - Machines à moulurer sur quatre facesSafety of woodworking machines - Four-sided moulding machines79.120.10Lesnoobdelovalni strojiWoodworking machinesICS:Ta slovenski standard je istoveten z:EN 12750:2001+A1:2009SIST EN 12750:2002+A1:2009en01-oktober-2009SIST EN 12750:2002+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12750:2001+A1

August 2009 ICS 79.120.10 Supersedes EN 12750:2001English Version

Safety of woodworking machines - Four-sided moulding machines

Sécurité des machines pour le travail du bois - Machines à moulurer sur quatre faces

Sicherheit von Holzbearbeitungsmaschinen - Fräsmaschinen für vierseitige Bearbeitung This European Standard was approved by CEN on 4 June 2001 and includes Amendment 1 approved by CEN on 16 July 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12750:2001+A1:2009: ESIST EN 12750:2002+A1:2009

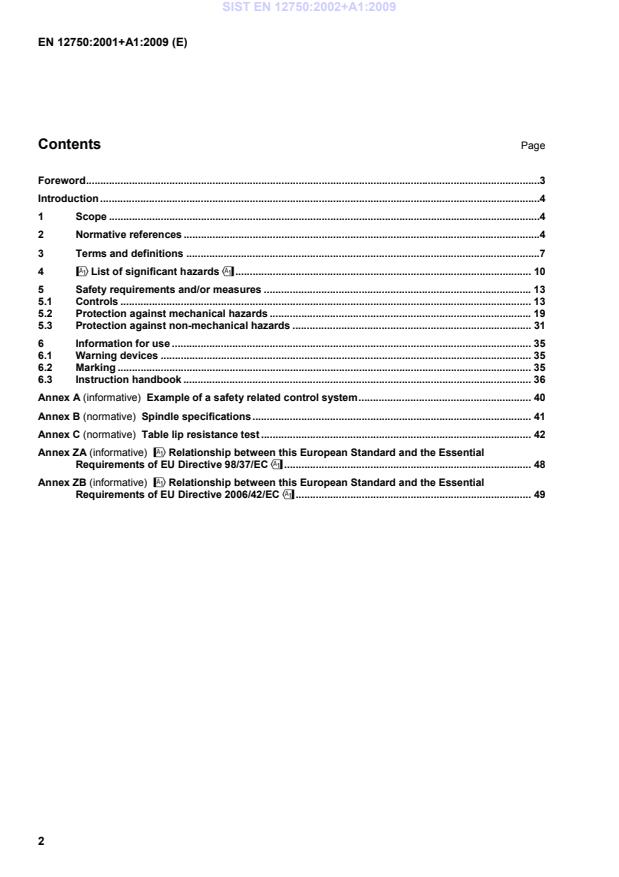

Example of a safety related control system . 40Annex B (normative)

Spindle specifications . 41Annex C (normative)

Table lip resistance test . 42Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC" . 48Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 49 SIST EN 12750:2002+A1:2009

!EN ISO 12100-1:2003" for a description of A, B and C standards). According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Part 1: Emission EN 50370-2:2003, Electromagnetic compatibility (EMC) — Product family standard for machine-tools —

Part 2: Immunity" !EN 60204-1:2006", Safety of machinery — Electrical equipment of machines — Part 1: General requirements !(IEC 60204-1:2005, modified)" !EN 60439-1:1999, Low-voltage switchgear and controlgear assemblies — Part 1: Type-tested and partially type-tested assemblies (IEC 60439-1:1999)" EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989) !EN 60947-4-1:2001", Low voltage switchgear and control gear — Part 4: Contactors and motor starters — Section 1: Electromechanical contactors and motor starters !(IEC 60947-4-1:2000)" !EN 60947-5-1:2004", Low voltage switchgear and control gear — Part 5-1: Control circuit devices and switching elements — Electro-mechanical control circuit devices !(IEC 60947-5-1:2003)" !EN 61310-1:2008, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual, auditory and tactile signals (IEC 61310-1:2007)" SIST EN 12750:2002+A1:2009

(ISO 13850:2006)" !EN ISO 13857:2008, Safety of machinery — Safety distances to prevent hazard zones being reached by upper and lower limbs (ISO 13857:2008)" !ISO 230-1:1996", Test code for machine tools — Part 1: Geometric accuracy of machines operating under no-load or finishing conditions !deleted text" ISO 7960:1995, Airborne noise emitted by machine tools — Operating conditions for woodworking machines SIST EN 12750:2002+A1:2009

Key

1 Glass bead sawblade 2 Riving knife 3 Guiding channel for bead ledge 4 Bead ledge 5 Anti-kickback finger 6 Feed roller 7 Workpiece 8 Feed direction Figure 1 — Example of a glass bead saw unit 3.4 hydraulic tool fixing device device for clamping the tool to the spindle using hydraulic pressure 3.5 integrated feed feed mechanism for the workpiece or tool which is integrated with the machine and where the workpiece or machine element with incorporated tool are held and controlled mechanically during the machining operation 3.6 loading the machine operation where the workpiece is manually or automatically placed on to a carriage, magazine, lift, hopper, movable bed, conveyor or the presentation of the workpiece to an integrated feed device 3.7 cutting against the feed when the relative rotational direction of the tool cutting point is opposite to the direction of the feed 3.8 climb cutting when the relative rotational direction of the tool cutting point is in the same direction as the feed 3.9 cutting area of the tool area of the tool involved in the cutting process SIST EN 12750:2002+A1:2009

The words in brackets are not applicable to this machine. 3.15 catching finger device device designed to prevent the ejection of divided workpieces (see Figure 2)

Key 1 Catching finger 2 Workpiece 3 Feed direction Figure 2 — Example of catching fingers SIST EN 12750:2002+A1:2009

No

Hazards, hazardous situations and hazardous events

EN ISO 12100

Relevant clause(s) of this document

Part 1: 2003 Part 2: 2003

1 Mechanical hazards due to machine parts or work pieces due to

a) shape; 4.2 4.2.1, 4.2.2, 5 5.2.2, 5.2.3, 5.2.5, 5.2.6, 5.3.2

b) relative location; 5.1.2, 5.1.5, 5.2.5, 5.2.6, 5.2.7

c) mass and stability (potential energy of elements which may move under the effect of gravity); 5.3.5

d) mass and velocity (kinetic energy of elements in controlled or uncontrolled motion); 5.2.5

e) mechanical strength. 5.2.2, 5.2.3, 5.2.5, 5.2.6

- accumulation of energy inside the machinery by:

g) liquids and gases under pressure; 4.2 4.10, 5.5.4 5.3.7, 5.3.8 1.1 Crushing hazard 4.2.1

5.2.1 ; 5.2.7 1.2 Shearing hazard

5.2.7 1.3 Cutting or severing hazard

5.2.2 ; 5.2.3 ; 5.2.4 ; 5.2.7 ; 1.4 Entanglement hazard

5.2.3 ; 5.2.4 ; 5.2.6 ; 5.2.7 1.5 Drawing-in or trapping hazard

5.2.7 1.6 Impact hazard

5.2.7.2 1.9 High pressure fluid injection or ejection hazard 4.2.1 4.10 5.3.8 to be continued

No

Hazards, hazardous situations and hazardous events

EN ISO 12100

Relevant clause(s) of this document

Part 1: 2003 Part 2: 2003

2 Electrical hazards due to: 2.1 Contact of persons with live parts (direct contact) 4.3 4.9, 5.5.4 5.3.4 ; 5.3.15 ; 5.3.16 2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) 4.3 4.9 5.3.4 ; 5.3.15 ; 5.3.16 3 Thermal hazards resulting in: 3.1 Burns, scalds and other injuries by a possible contact of persons with objects or materials with an extreme high temperature and also by the radiation of heat sources 4.4

5.3.1 ; 5.3.9

4 Hazards generated by noise, resulting in: 4.1 Hearing loss (deafness), other physiological disorders (loss of balance, loss or awareness) 4.5 4.2.2, 5 5.3.2 7 Hazards generated by materials and substances (and their constituent elements) processed or used by the machinery 7.1 Hazards from contact with or inhalation of harmful fluids and dusts 4.8 4.3 b), 4.4 5.3.3 7.2 Fire 4.8 4.4 5.3.1 8 Hazards generated by neglecting ergonomic principles in machinery design related to 8.1 Unhealthy postures or excessive effort 4.9 4.7, 4.8.2, 4.11.12, 5.5.5, 5.5.6

5.1.2 ; 5.3.5 8.3 Neglected use of personal protection equipment

4.8.7 6.3 8.4 Local lighting

4.8.6 5.3.6 to be continued

No

Hazards, hazardous situations and hazardous events

EN ISO 12100

Relevant clause(s) of this document

Part 1: 2003 Part 2: 2003

10 Unexpected start-up, unexpected overrun/overspeed (or any similar malfunction) from: 10.1 Failure/disorder of the control system

4.11, 5.5.4 5.1.1 10.2 Restoration of energy supply after an interruption

4.11.4 5.1.1 ; 5.1.12 ; 5.1.13 10.3 External influences on electrical equipment

4.11.11 5.3.12 11 Impossibility of stopping the machine in the best possible conditions

4.11.1, 4.11.3, 5.5.2

5.1.2 ; 5.1.4 ; 5.1.5 12 Variations in the rotational speed of tools

4.2.2, 4.3 5.1.7 13 Failure of the power supply

4.11.4 5.3.15 14 Failure of the control circuit

4.11, 5.5.4 5.1.1

15 Errors of fitting

4.7, 6.5 5.2.7.1, 6.3 16 Break-up during operation 4.2.2 4.3 5.2.2 17 Falling or ejected objects or fluids

4.3, 4.10 5.2.2 ; 5.2.3 ; 5.2.5 ; 5.2.6 ; 5.2.7; 5.3.15 18 Loss of stability / overturning of machinery

5.2.6 5.2.1 " 5 Safety requirements and/or measures For guidance in connection with risk reduction by design see !4.1 of EN ISO 12100-2:2003" and in addition: 5.1 Controls 5.1.1 Safety and reliability of control systems For the purpose of this European Standard safety related parts of control systems means the system from and including the initial manual control or position detector or other sensor to the point of input to the final actuator or element, e.g. motor. The safety related control systems of this machine are those for: starting (see 5.1.3); normal (manual) stopping (see 5.1.4); emergency stop (see 5.1.5); spindle speed (see 5.1.7); interlocking (see 5.2.7.1 and 5.2.7.4); SIST EN 12750:2002+A1:2009

EN ISO 12100-2:2003". For the positioning of the emergency stops see 5.1.5. Verification: By checking relevant drawings, measurement and inspection of the machine. 5.1.3 Starting See 9.2.5.2, first and second sentence of !EN 60204-1:2006" and in addition: For the purposes of this European Standard "safeguards in place and functional" is achieved by the interlocking arrangements described in 5.2.7. "Correct sequential starting" shall be achieved by the interlocking arrangements required by 5.1.9. The requirements shall be satisfied at the level of the control circuits (see also 5.1.6 and 5.1.9). It shall be possible to start each spindle motor separately. Verification: By checking relevant drawings and/or circuit diagrams, inspection and relevant functional testing on the machine. 5.1.4 Normal stopping A normal stop function shall be fitted which stops all machine actuators and cuts power to them once the stopping sequence is complete. If the machine is fitted with a mechanical brake, this stop function shall be of category 0 according to 9.2.2 of !EN 60204-1:2006". If the machine is fitted with an electrical brake, this stop function shall be of category 1 according to 9.2.2 of !EN 60204-1:2006" and the stopping sequence shall be: a) cut power to all machine actuators and actuate the brake; b) cut power to brake after braking sequence is complete. The stopping sequence shall be satisfied at the level of the control circuits. If a time delay device is used the time delay shall be at least equal to the maximum run-down time. Either the time delay shall be fixed or the time delay adjustment device shall be sealed. An emergency stop in accordance with 5.1.5 can also be used as a normal stop control, when it fulfils the requirement of this clause. SIST EN 12750:2002+A1:2009

b) polycarbonate with a wall thickness of at least 3 mm or other plastic material with such a wall thickness that the impact strength is equal to or better than that of polycarbonate of 3 mm thickness; c) cast iron with a minimum ultimate tensile strength of 350 N⋅mm-2 and minimum thickness of 5 mm. Verification: By checking the relevant drawings, measurement !and" inspection of the machine !deleted text". !NOTE For the ultimate tensile strength a confirmation from the manufacturer of the material can be useful." 5.2.3 Tool holder and tool design See 6.3, annex B and !EN 847-1:2005" and in addition: 5.2.3.1 Spindle strength and performance The spindles shall be manufactured from steel with an ultimate tensile strength of at least 580 N⋅mm-2. The tool holding part of the spindle shall have geometrical performance in accordance with the specifications given in annex B and shall have a tolerance of g6. Verification: By checking the relevant drawings !and" measurement !deleted text". !NOTE For the ultimate tensile strength a confirmation from the manufacturer of the material can be useful." SIST EN 12750:2002+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...