EN 1366-3:2009

(Main)Fire resistance tests for service installations - Part 3: Penetration seals

Fire resistance tests for service installations - Part 3: Penetration seals

This Part of EN 1366 specifies a method of test and criteria for the evaluation (including field of application rules) of the ability of a penetration seal to maintain the fire resistance of a separating element at the position at which it has been penetrated by a service. Penetration seals used to seal gaps around chimneys, air ventilation systems, fire rated ventilation ducts, fire rated service ducts, shafts and smoke extraction ducts are excluded from this standard except for mixed penetration seals. The fire resistance of those services itself cannot be assessed with the methods described in this standard.

Supporting constructions are used in this standard to represent separating elements such as walls or floors. These simulate the interaction between the test specimen and the separating element into which the sealing system is to be installed in practice.

This European Standard is used in conjunction with EN 1363-1.

The purpose of this test described in this standard is to assess:

a) the effect of such penetrations on the integrity and insulation performance of the separating element concerned;

b) the integrity and insulation performance of the penetration seal;

c) the insulation performance of the penetrating service or services, and where necessary, the integrity failure of a service.

No information can be implied by the test concerning the influence of the inclusion of such penetrations and sealing systems on the loadbearing capacity of the separating element.

It is not the intention of this test to provide quantitative information on the rate of leakage of smoke and/or hot gases or on the transmission or generation of fumes. Such phenomena are only to be noted in describing the general behaviour of test specimens during the test.

This test is not intended to supply any information on the ability of the penetration seal to withstand stress caused by movements or displacements of the penetrating services.

Feuerwiderstandsprüfungen für Installationen - Teil 3: Abschottungen

Dieser Teil von EN 1366 spezifiziert eine Prüfmethode und Kriterien zur Beurteilung (inklusive Regeln zum Anwendungsbereich) der Fähigkeit einer Abschottung, den Feuerwiderstand eines raumabschließenden Bauteils an der Stelle, wo durch dieses eine oder mehrere Leitungen durchgeführt werden, aufrecht¬zuerhalten. Abschottungen für Zwischenräume und Öffnungen um Kamine, Lüftungssysteme, Lüftungs¬leitungen, Installationskanäle und -schächte sowie Entrauchungsleitungen mit definierter Feuerwider¬stands¬dauer sind von dieser Norm ausgenommen, mit der Ausnahme von Kombischotts. Der Feuerwiderstand derartiger Installationen kann nicht mit den in dieser Norm beschriebenen Methoden ermittelt werden.

In dieser Norm werden Tragkonstruktionen stellvertretend für raumabschließende Bauteile, wie zum Beispiel Wände und Decken, verwendet. Diese stellen die Wechselwirkungen zwischen Prüfkörper und dem raumab-schließenden Bauteil, in welchen die Abschottung in der Praxis eingebaut werden soll, nach.

Diese Norm gilt zusammen mit EN 1363 1.

Die in dieser Norm beschriebene Prüfung dient der Beurteilung:

a) der Auswirkung derartiger Durchführungen auf das raumabschließende und wärmedämmende Verhalten des betreffenden raumabschließenden Bauteils;

b) des Raumabschlusses und Wärmedämmverhaltens der Abschottung;

c) des Wärmedämmverhaltens der durchlaufenden Leitung(en) und erforderlichenfalls des Verlustes der raumabschließenden Wirkung einer Leitung.

Die Prüfung ermöglicht keine Aussagen darüber, inwieweit das Vorhandensein derartiger Durchführungen und Abschottungen einen Einfluss auf die Tragfähigkeit des raumabschließenden Bauteils ausübt.

Der Zweck dieser Prüfung besteht nicht darin, quantitative Angaben über die Leckrate von Rauch und/oder heißen Gasen oder die Übertragung bzw. Erzeugung von Rauchgasen zu ermitteln. Derartige Beobachtungen sollten nur bei der Beschreibung des allgemeinen Verhaltens der Probekörper während der Prüfung fest-gehalten werden.

[...]

Essais de résistance au feu des installations techniques - Partie 3 : Calfeutrements de trémies

La présente partie de l'EN 1366 spécifie une méthode d'essai et des critères pour l'évaluation (ainsi que des règles de domaine d'application) de l'aptitude d'un calfeutrement à maintenir la résistance au feu d'un élément séparatif à l'endroit auquel il est traversé par un traversant. Les calfeutrements de trémie utilisés pour combler les espaces autour des cheminées, les systèmes de ventilation, les conduits de ventilation classés au feu, les gaines pour traversants classées au feu et les conduits d'extraction de fumée sont exclus de la présente norme, sauf les calfeutrements de trémie mixtes. La résistance au feu intrinsèque de ces traversants ne peut pas être évaluée selon les méthodes de la présente norme.

Les constructions support sont utilisées dans la présente norme pour représenter les éléments séparatifs comme les parois ou les planchers. Elles simulent l'interaction entre l'éprouvette et l'élément séparatif dans lequel le système de calfeutrement sera installé dans les conditions réelles.

La présente norme est utilisée en association avec l'EN 1363-1.

L'objet de cet essai décrit dans la norme est d'évaluer :

a) l’effet de ces trémies sur l’étanchéité au feu et l’isolation de l’élément séparatif concerné ;

b) l’étanchéité au feu et l’isolation du calfeutrement de trémie ;

c) l’isolation du/des traversant(s), et le cas échéant, la perte d’étanchéité au feu d’un traversant.

Aucune information ne peut être déduite de l'essai en ce qui concerne l'incidence de l'intégration de ces trémies et de ces systèmes de calfeutrement sur la capacité portante de l'élément séparatif.

Cet essai n'a pas pour but de fournir des informations quantitatives sur le taux d'étanchéité aux fumées et/ou aux gaz, ou sur la transmission de gaz chauds ou la génération de fumées. Ces phénomènes ne sont à prendre en compte que dans la description du comportement général des éprouvettes durant l'essai.

Cet essai n'a pas pour but de fournir des informations sur la capacité du calfeutrement de trémie à résister aux contraintes engendrées par les mouvements ou les déplacements des traversants.

Le risque de propagation du feu vers le bas provoquée par un matériau en feu coulant à travers un tuyau vers les étages inférieurs ne peut pas être évalué par le présent essai.

Des notes explicatives de cette méthode d'essai figurent en Annexe H.

Toutes les dimensions indiquées sans tolérances sont nominales, sauf indication contraire.

Preskusi požarne odpornosti servisnih inštalacij - 3. del: Tesnitve prebojev

General Information

- Status

- Withdrawn

- Publication Date

- 24-Feb-2009

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 127 - Fire safety in buildings

- Drafting Committee

- CEN/TC 127 - Fire safety in buildings

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 22-Dec-2021

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Replaces

EN 1366-3:2004 - Fire resistance tests for service installations - Part 3: Penetration seals - Effective Date

- 22-Dec-2008

- Replaced By

EN 1366-3:2021 - Fire resistance tests for service installations - Part 3: Penetration seals - Effective Date

- 29-Dec-2021

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 1992-1-2:2023 - Eurocode 2 - Design of concrete structures - Part 1-2: Structural fire design - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 1366-3:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fire resistance tests for service installations - Part 3: Penetration seals". This standard covers: This Part of EN 1366 specifies a method of test and criteria for the evaluation (including field of application rules) of the ability of a penetration seal to maintain the fire resistance of a separating element at the position at which it has been penetrated by a service. Penetration seals used to seal gaps around chimneys, air ventilation systems, fire rated ventilation ducts, fire rated service ducts, shafts and smoke extraction ducts are excluded from this standard except for mixed penetration seals. The fire resistance of those services itself cannot be assessed with the methods described in this standard. Supporting constructions are used in this standard to represent separating elements such as walls or floors. These simulate the interaction between the test specimen and the separating element into which the sealing system is to be installed in practice. This European Standard is used in conjunction with EN 1363-1. The purpose of this test described in this standard is to assess: a) the effect of such penetrations on the integrity and insulation performance of the separating element concerned; b) the integrity and insulation performance of the penetration seal; c) the insulation performance of the penetrating service or services, and where necessary, the integrity failure of a service. No information can be implied by the test concerning the influence of the inclusion of such penetrations and sealing systems on the loadbearing capacity of the separating element. It is not the intention of this test to provide quantitative information on the rate of leakage of smoke and/or hot gases or on the transmission or generation of fumes. Such phenomena are only to be noted in describing the general behaviour of test specimens during the test. This test is not intended to supply any information on the ability of the penetration seal to withstand stress caused by movements or displacements of the penetrating services.

This Part of EN 1366 specifies a method of test and criteria for the evaluation (including field of application rules) of the ability of a penetration seal to maintain the fire resistance of a separating element at the position at which it has been penetrated by a service. Penetration seals used to seal gaps around chimneys, air ventilation systems, fire rated ventilation ducts, fire rated service ducts, shafts and smoke extraction ducts are excluded from this standard except for mixed penetration seals. The fire resistance of those services itself cannot be assessed with the methods described in this standard. Supporting constructions are used in this standard to represent separating elements such as walls or floors. These simulate the interaction between the test specimen and the separating element into which the sealing system is to be installed in practice. This European Standard is used in conjunction with EN 1363-1. The purpose of this test described in this standard is to assess: a) the effect of such penetrations on the integrity and insulation performance of the separating element concerned; b) the integrity and insulation performance of the penetration seal; c) the insulation performance of the penetrating service or services, and where necessary, the integrity failure of a service. No information can be implied by the test concerning the influence of the inclusion of such penetrations and sealing systems on the loadbearing capacity of the separating element. It is not the intention of this test to provide quantitative information on the rate of leakage of smoke and/or hot gases or on the transmission or generation of fumes. Such phenomena are only to be noted in describing the general behaviour of test specimens during the test. This test is not intended to supply any information on the ability of the penetration seal to withstand stress caused by movements or displacements of the penetrating services.

EN 1366-3:2009 is classified under the following ICS (International Classification for Standards) categories: 13.220.50 - Fire-resistance of building materials and elements. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1366-3:2009 has the following relationships with other standards: It is inter standard links to EN 1366-3:2004, EN 1366-3:2021, EN 50525-2-21:2011, EN IEC 61386-21:2021, EN 50525-2-31:2011, EN 1566-1:2022, EN 10305-6:2016, EN 13501-2:2023, EN 1453-1:2017, EN 1992-1-2:2023, EN ISO 1452-1:2009, EN ISO 13943:2000, EN 13600:2021, EN 13501-1:2018, EN 12201-2:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1366-3:2009 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/BC/CEN/91/9. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1366-3:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Preskusi požarne odpornosti servisnih inštalacij - 3. del: Tesnitve prebojevFeuerwiderstandsprüfungen für Installationen - Teil 3: AbschottungenFire resistance tests for service installations - Part 3: Penetration seals13.220.50Požarna odpornost gradbenih materialov in elementovFire-resistance of building materials and elementsICS:Ta slovenski standard je istoveten z:EN 1366-3:2009SIST EN 1366-3:2009en,de01-julij-2009SIST EN 1366-3:2009SLOVENSKI

STANDARDSIST EN 1366-3:20041DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1366-3February 2009ICS 13.220.50Supersedes EN 1366-3:2004

English VersionFire resistance tests for service installations - Part 3: PenetrationsealsEssais de résistance au feu des installations techniques -Partie 3 : Calfeutrements de trémiesFeuerwiderstandsprüfungen für Installationen - Teil 3:AbschottungenThis European Standard was approved by CEN on 3 January 2009.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1366-3:2009: ESIST EN 1366-3:2009

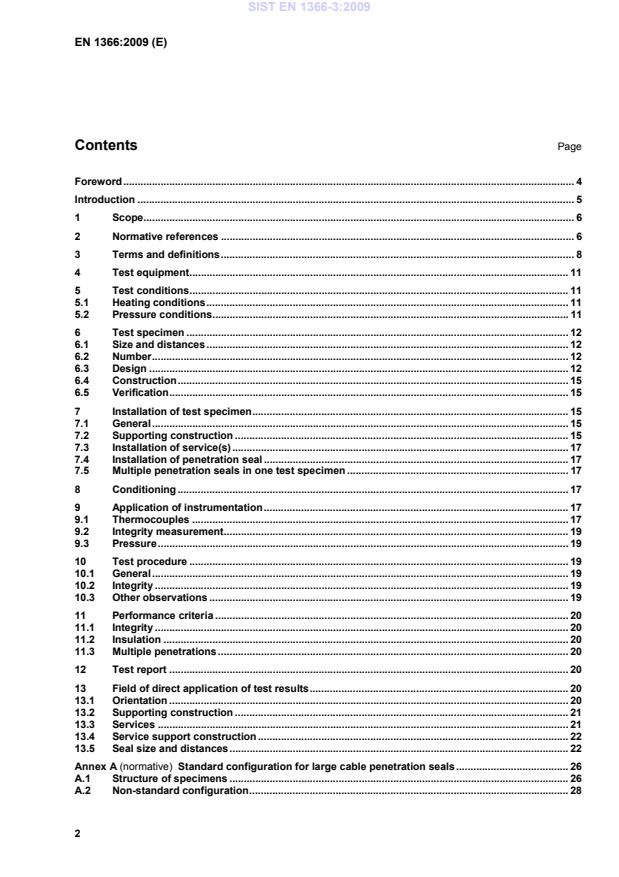

EN 1366:2009 (E) 2 Contents Page Foreword . 4 Introduction . 5 1 Scope. 6 2 Normative references . 6 3 Terms and definitions . 8 4 Test equipment . 11 5 Test conditions . 11 5.1 Heating conditions . 11 5.2 Pressure conditions . 11 6 Test specimen . 12 6.1 Size and distances . 12 6.2 Number . 12 6.3 Design . 12 6.4 Construction . 15 6.5 Verification . 15 7 Installation of test specimen . 15 7.1 General . 15 7.2 Supporting construction . 15 7.3 Installation of service(s) . 17 7.4 Installation of penetration seal . 17 7.5 Multiple penetration seals in one test specimen . 17 8 Conditioning . 17 9 Application of instrumentation . 17 9.1 Thermocouples . 17 9.2 Integrity measurement. 19 9.3 Pressure . 19 10 Test procedure . 19 10.1 General . 19 10.2 Integrity . 19 10.3 Other observations . 19 11 Performance criteria . 20 11.1 Integrity . 20 11.2 Insulation . 20 11.3 Multiple penetrations . 20 12 Test report . 20 13 Field of direct application of test results . 20 13.1 Orientation . 20 13.2 Supporting construction . 21 13.3 Services . 21 13.4 Service support construction . 22 13.5 Seal size and distances . 22 Annex A (normative)

Standard configuration for large cable penetration seals . 26 A.1 Structure of specimens . 26 A.2 Non-standard configuration . 28 SIST EN 1366-3:2009

Standard configuration for small cable penetration seals . 42 B.1 Structure of specimens . 42 B.2 Field of direct application . 43 B.3 Non-standard configuration . 44 Annex C (normative)

Standard configuration and field of direct application for modular systems and cable boxes . 49 C.1 Modular Systems . 49 C.2 Cable boxes . 51 C.3 Non-standard configuration . 52 Annex D (normative)

Specimen design and field of direct application for bus bars . 56 D.1 Structure of specimens . 56 D.2 Field of direct application . 56 D.3 Non-standard configuration . 56 Annex E (normative)

Standard configuration and field of direct application for pipe penetration seals . 58 E.1 Standard configuration for penetration seals for pipes according to

6.3.2 a) – “metal pipes“ . 58 E.2 Standard configuration for penetration seals for pipes according to

6.3.2 d) – “plastic pipes“ . 61 E.3 Trunking and conduits . 65 E.4 Standard configuration for floor penetrations ending at floor level (e.g. floor drain) . 66 Annex F (normative)

Standard configuration and field of direct application for large mixed penetration seals . 74 F.1 General . 74 F.2 Standard Mixed Module . 74 F.3 Standard configuration for combinations of type a) according to F.1.2 . 76 F.4 Standard configuration for combinations of type b), c) and d) according to F.1.2 . 76 F.5 Field of direct application . 77 Annex G (normative)

Critical pipe/cable approach . 84 G.1 General . 84 G.2 Definition of "critical" . 84 G.3 Procedure selecting critical pipes from previous test data. 84 G.4 Procedure selecting critical cables from previous test data . 85 Annex H (informative)

Explanatory notes . 87 H.1 General . 87 H.2 Notes on the scope and application of test results . 87 H.3 Notes on test conditions . 92 H.4 Notes on test construction . 92 H.5 Notes on test procedure . 102 H.6 Notes on test criteria . 102 H.7 Notes on validity of test results (field of application) . 102 H.8 Notes on test report . 103 Bibliography . 104

EN 1366:2009 (E) 4 Foreword This document (EN 1366:2009) has been prepared by Technical Committee CEN/TC 127 “”, the secretariat of which is held by BSI. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by August 2009, and conflicting national standards shall be withdrawn at the latest by August 2009. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document supersedes EN 1366-3:2004. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association. Annexes A to G are normative. Annex H is informative. EN 1366, Fire resistance tests for service installations consists of the following: Part 1: Ducts Part 2: Fire dampers Part 3: Penetration seals

Part 4: Linear joint seals Part 5: Service ducts and shafts

Part 6: Raised access floors and hollow floors

Part 7: Conveyors systems and their closures Part 8: Smoke extraction ducts Part 9: Single compartment smoke extraction ducts

Part 10: Smoke control dampers (in course of preparation) Part 11: Protective systems for essential services (in course of preparation) According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom. SIST EN 1366-3:2009

EN 1366:2009 (E) 6 1 Scope This Part of EN 1366 specifies a method of test and criteria for the evaluation (including field of application rules) of the ability of a penetration seal to maintain the fire resistance of a separating element at the position at which it has been penetrated by a service. Penetration seals used to seal gaps around chimneys, air ventilation systems, fire rated ventilation ducts, fire rated service ducts, shafts and smoke extraction ducts are excluded from this standard except for mixed penetration seals. The fire resistance of those services itself cannot be assessed with the methods described in this standard. Supporting constructions are used in this standard to represent separating elements such as walls or floors. These simulate the interaction between the test specimen and the separating element into which the sealing system is to be installed in practice. This European Standard is used in conjunction with EN 1363-1. The purpose of this test described in this standard is to assess: a) the effect of such penetrations on the integrity and insulation performance of the separating element concerned; b) the integrity and insulation performance of the penetration seal; c) the insulation performance of the penetrating service or services, and where necessary, the integrity failure of a service. No information can be implied by the test concerning the influence of the inclusion of such penetrations and sealing systems on the loadbearing capacity of the separating element. It is not the intention of this test to provide quantitative information on the rate of leakage of smoke and/or hot gases or on the transmission or generation of fumes. Such phenomena are only to be noted in describing the general behaviour of test specimens during the test. This test is not intended to supply any information on the ability of the penetration seal to withstand stress caused by movements or displacements of the penetrating services. The risk of spread of fire downwards caused by burning material, which drips through a pipe downwards to floors below, cannot be assessed with this test. Explanatory notes to this test method are given in Annex H. All dimensions given without tolerances are nominal ones unless otherwise stated. 2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 520, Gypsum plasterboards – Definitions, requirements and test methods EN 1329-1, Plastics piping systems for soil and waste discharge (low and high temperature) within the building structure – Unplasticized poly(vinyl chloride) (PVC-U) – Part 1: Specifications for pipes, fittings and the system EN 1363-1:1999, Fire resistance tests – Part 1: General requirements SIST EN 1366-3:2009

Part 3: Non-sheathed cables for fixed wiring (IEC 60227-3:1993, modified) SIST EN 1366-3:2009

EN 1366:2009 (E) 8 HD 22.4, Cables of rated voltages up to and including 450/750V and having crosslinked insulation —

Part 4: Cords and flexible cables HD 603.3, Distribution cables of rated voltage 0.6/1 kV – Part 3: PVC insulated cables – unarmoured HD 604.5, 0.6/1 kV power cables with special fire performance for use in power stations –

Part 5: Cables with copper or aluminium conductors with or without metallic covering or screen 3 Terms and definitions

For the purposes of this European Standard, the terms and definitions given in EN 1363-1:1999 and EN ISO 13943:2000 and the following apply. 3.1 blank penetration seal aperture in the separating element which is sealed or closed by the specified seal without incorporation of penetrating services 3.2 cable box housing with intumescent inlays that forms a channel which is normally fitted with a device to prevent the passage of cold smoke 3.3 combination frame two or several single frames joined together to one unit

3.4 conduit metal or plastic casing designed to accommodate cables

NOTE Normally a conduit is circular or oval in section. See also trunking. 3.5 flexible construction horizontal or vertical supporting construction consisting of studs or joists, including linings and optional insulation 3.6 modular system pre-sized frame into which are installed elastomeric insert blocks, compressed around the service 3.7 non-sheathed cable (wire) normally a single core cable with only one layer of covering 3.8 penetration aperture in a separating element for the passage of one or more services 3.9 penetration seal system used to maintain the fire resistance of a separating element at the position where services pass through or where there is provision for services to pass through a separating element SIST EN 1366-3:2009

3.17 single frame

square or rectangular frame, with predefined dimensions in different sizes, to accommodate a modular penetration seal (see Figure 1) 3.18 (single) module single block, available in different sizes, to be used inside a single frame (opening)

NOTE Adapted to seal around penetrating services in different sizes and shapes or as blanks (see Figure 1). 3.19 single opening area of the modular system within a single frame or within each single frame of a combination frame which is available for the modules (see Figure 1) SIST EN 1366-3:2009

EN 1366:2009 (E) 10 Table 1 — Definition of pipe insulation (3.13)

Sustained

Interrupted Continued

Case CS

Case CI Local

Case LS

Case LI NOTE Depending on the reaction to fire classification of the insulation, the insulation may be the penetration seal / be part of the penetration seal or additional sealing means (which are not shown in the figures) may be necessary. For further explanation see Annex H. Key

Building element Pipe

Thermal/acoustic/other pipe insulation Insulation acting as penetration seal or forming part of the penetration seal SIST EN 1366-3:2009

NOTE Normally trunking is square or rectangular in section. See also conduit. 3.23 waveguide

circular, elliptical or rectangular metal tube or pipe or a coaxial assembly of tubes/pipes through which electromagnetic waves are propagated in microwave and radio wave frequency communications 4 Test equipment See EN 1363-1, and if applicable EN 1363-2. 5 Test conditions 5.1 Heating conditions The heating conditions and the furnace atmosphere shall conform to those given in EN 1363-1 or, if applicable, EN 1363-2. 5.2 Pressure conditions 5.2.1 Pressure conditions including tolerances shall be as given in EN 1363-1 subject to the following: 5.2.2 A minimum pressure of 20 Pa shall be maintained at the top of the uppermost penetration seal in a vertical supporting construction. Services shall only be included in the zone where the positive pressure exceeds 10 Pa (a minimum pressure of 10 Pa shall be maintained at the lowest point of the lowest service, see Figure 2). NOTE A pressure of 10 Pa is expected to be maintained ca. 1200 mm below the plane where a pressure of 20 Pa is maintained according to the pressure gradient given in EN 1363-1. 5.2.3 In case of a blank penetration seal in a vertical supporting construction a minimum pressure of 20 Pa shall be maintained at the top of the seal. 5.2.4 For horizontal supporting constructions a nominal pressure of 20 Pa shall be maintained in the horizontal plane (100 ± 10) mm below the underside of the supporting construction. SIST EN 1366-3:2009

EN 1366:2009 (E) 12 6 Test specimen 6.1 Size and distances A penetration and the accompanying penetration seal shall be as in practice. In order to avoid boundary effects, the distance between the perimeter of the penetration seal and the internal surfaces of the furnace shall be not less than 200 mm at any point. In cases where several test specimens are included in a single test construction, the minimum distance between adjacent penetration seals shall be not less than 200 mm unless it is the intention to demonstrate that a smaller distance does not have a negative effect on fire performance. Each penetration seal shall be the subject of a separate evaluation, provided the standard test conditions are maintained throughout the test with respect to the penetration being evaluated. 6.2 Number See EN 1363-1. For horizontal separating elements only one test specimen is required with fire exposure from the underside. Where a penetration seal is intended for use both in floors and walls, the systems shall be tested both vertically and horizontally. 6.3 Design 6.3.1 General The test specimen shall be either: a) fully representative of the service and penetration seal used in practice, including any special features which are unique to that installation or b) a standard configuration which is deemed to cover a wide range of practical applications. For standard configurations or advice for designing the specimen/test setup see the following: 1) Supporting construction: 7.2.2; 2) Large cable penetration seals: Annex A; 3) Small penetration seals: Annex B; 4) Modular systems and cable boxes: Annex C; 5) Bus bars: Annex D; 6) Pipe penetration seals: Annex E; 7) Mixed penetration seals: Annex F; 8) Critical pipe/cable approach: Annex G. 6.3.2 Penetrating services For the purpose of this standard the following grouping applies: SIST EN 1366-3:2009

b) Trunking of class A1 according to EN 13501-1 with a melting or decomposition point greater than 1000°C (e.g. steel, cast iron, copper and copper alloys, nickel alloys) either insulated or non-insulated, hereafter referred to as "metal trunking". Included in this group are the above trunkings with a coating provided the overall classification is minimum A2 according to EN 13501-1.

c) Pipes, trunking and conduits of class A1 or A2 according to EN 13501-1 with a melting or decomposition point equal to or less than 1000°C (e.g. lead, aluminium and aluminium alloys) and/or the risk of fracture (glass, fibre cement) either insulated or non-insulated. d) Pipes not classified to A1 or A2 according to EN 13501-1 (e.g. made from thermoplastic or thermosetting material) including non-homogeneous materials (e.g. glass fibre reinforced plastic pipes or layered pipes), either insulated or non-insulated, hereafter referred to as "plastic pipes". e) Trunking and conduits not classified to A1 or A2 according to EN 13501-1 (e.g. made from thermoplastic or thermosetting material) including non-homogeneous materials, either insulated or non-insulated, hereafter referred to as "plastic trunkings" and "plastic conduits". 6.3.3 Support conditions for penetrating services 6.3.3.1 General The support conditions for the service(s) shall be chosen from the following: a) without support; b) standard service support construction (see Figures A.2, A.3A, A.3B, A.4, A.5, A.6, A.8 and E.10); c) full-scale representation as in practice. A load may be applied to simulate practical conditions. In each condition the method of support (if any) shall be fully described in the test report. 6.3.3.2 Standard service support construction The standard support construction for cables shall comprise of steel H-studs, steel brackets, steel rod, steel ladders and trays as shown in Figure A.2, A.4 and A.6 for vertical test specimens, of steel angles, steel channels and steel ladders as shown in Figure A.3A, A.3B and A.5 for horizontal specimens. A single or a pair of horizontal supports (20 mm steel rod) may be used on each face. Alternative constructions for the H-studs, steel brackets, steel angels and steel channels may be used (see Figure A.8 for cable supports and Figure E.10 for pipe supports).

When installing a steel ladder, positioning of a rung within the penetration seal should be avoided. Alternative materials for cable ladders/trays, e.g. plastic, aluminium, steel with organic coatings resulting in an overall class of B to E according to EN 13501-1, shall be tested in addition to the standard ladders/trays as defined in Annex A with the cables from cable tray 1 as shown in Figure A.1. The standard support for pipes shall consist of a strut / channel system with e.g. a steel band or pipe rings either standing on or hanging from the channel (see Figure E.10) to prevent movement in the plane of the supporting construction and perpendicular to the supporting construction. SIST EN 1366-3:2009

EN 1366:2009 (E) 14 In the case of flexible floor constructions the service support construction shall be independent of the supporting construction to allow differential movement of the services relative to the supporting construction. 6.3.4 Pipe end configuration When pipes are to be tested, the pipe end configurations shall be chosen from Table 2 depending on the nature of the pipe material and the required field of application.

Table 2 — Pipe end configuration Test condition Pipe end configuration Inside the furnace Outside the furnace U/U Uncapped Uncapped C/U Capped Uncapped U/C Uncapped Capped C/C Capped Capped

Capping of pipes shall be carried out by closing the pipe end by inserting an appropriate mineral wool disc into the end of the pipe, fixed in place with an appropriate adhesive (e.g. sodium silicate adhesive). For further explanation see Annex H. In cases where vertical pipes are tested, the mineral wool shall be fixed additionally by mechanical means. For “metal pipes” the pipe may be capped by fixing a disc or cap (with a melting or decomposition point equal or greater than that of the pipe) onto the end of the pipe. For “plastic pipes”, "plastic conduits” and “plastic trunkings” the pipe may be capped using a plastic cap.

Where a flue gas recovery system is intended to be used the following rules shall be obeyed: 1) Maximum 4 pipes of a comparable diameter, i.e. mean value ± 20% (for further explanation see H.4.2.3), at the same horizontal level shall be connected to one recovery pipe made from a metallic folded spiral-seam tube of 100 mm diameter. Appropriate bushings shall be used to connect the pipes to the recovery pipe; 2) The length of the recovery pipe outside the furnace shall be 1,5 ± 0,1 m (for further explanation see H.4.2.3). For relation between the use of a flue gas recovery system and the pipe end configuration see Annex E. 6.3.5 Cable end configuration The heated ends of cables shall be left uncapped. Cables projecting from the unheated face of the supporting construction shall be capped using an appropriate method, e.g. acrylic sealants, to prevent hot gases escaping. 6.3.6 Blank penetration seal If a blank penetration seal is to be evaluated, this shall be incorporated into the supporting construction. To gain the maximum field of application the largest envisaged penetration seal shall be tested. SIST EN 1366-3:2009

7.2.2.1.2 Flexible wall constructions The standard supporting construction shall be in accordance with the provisions given in EN 1363-1, subject to the following:

1) The size of the supporting construction shall be minimum 3 m in height and minimum 1,20 m in width. The flexible wall shall contain minimum 1 vertical joint between the boards; SIST EN 1366-3:2009

EN 1366:2009 (E) 16 2) The wall shall be restrained only on the top and bottom edge; 3) The number and thickness of the gypsum board(s) shall be as given in Table 3; 4) A construction including insulation shall be used. The insulation material shall be mineral wool with a classification of A1 or A2 according to EN 13501-1. The density of the insulation shall be 45 ± 15 kg/m3 for a desired fire resistance up to and including 60 min and 100 ± 15 kg/m3 for a fire resistance of more than 60 min. The thickness shall be such that the remaining gap between the board and the insulation is maximum 15 mm; 5) Demonstration of performance of a penetration seal that does not require an aperture framing may be shown by using an insulated flexible wall construction where the insulation is removed to a depth of 100 mm around the seal provided a minimum of 100 mm of insulation is left along the studs; 6) Steel studs of varying widths may be used to fit the flexible wall constructions defined in Table 3; 7) Provisions shall be made to ensure that the H-studs shown in Figure A.6 do not restrain movement of the flexible wall construction during the fire resistance test. A distance of 100 mm is considered to be appropriate. The fixing on the lower end shall be slotted to allow elongation and to avoid distortion; 8) Where the test sponsor’s penetration seal system requires the cavity of the supporting wall around the penetration to be capped, this should be accomplished in accordance with the test sponsor’s specification. The test result obtained is then only valid when used in conjunction with this capping detail. Table 3 — Standard flexible wall constructions

Nominal minimum overall thicknessa

mm Thickness of gypsum board EN 520 Type F

mm Number of layers each side Indicative fire resistance

min 69 - 75 12,5 1 30 94 - 100 12,5 2 60 94 - 100 12,5 2 90 122 - 130 15 2 120 a The values given consider the different stud widths available within the European construction market.

7.2.2.2 Floor constructions 7.2.2.2.1 Rigid floor construction The standard supporting constructions for rigid floor separating elements shall be made of aerated concrete slabs, lightweight concrete or high density concrete and a thickness appropriate to the required fire resistance classification according to the tables given in EN 1992-1-2 for lightweight concrete and high density concrete and EN 1996-1-2 for autoclaved aerated concrete.

7.2.2.2.2 Flexible floors In the case of flexible floors, e.g. steel joisted floors, the minimum size of the supporting construction shall be at least 4 m in span and 2 m in width. In the case of timber joist floors the minimum size of the supporting construction shall be at least 3 m in span and 2 m in width.

Any coating, wrapping or other protection to the services (for instance the insulation of case LS and LI according to 3.13) shall be considered part of the penetration seal.

In the case of metallic services and metallic service supports that penetrate the seal the length of the unprotected part of the service/service support on the unexposed face shall not be greater than 500 mm.

In the case of plastic pipes the length of pipe on the unexposed side may be extended to allow for collection of the effluent gases. 7.4 Installation of penetration seal The penetration seal shall be installed in accordance with the manufacturer's instructions. 7.5 Multiple penetration seals in one test specimen When more than one penetration seal is incorporated into a single supporting construction in accordance with the requirements of Clause 6, care shall be taken to ensure that there is no interaction between different penetration seals. 8 Conditioning

The test construction shall be conditioned in accordance with EN 1363-1. 9 Application of instrumentation 9.1 Thermocouples 9.1.1 Furnace thermocouples (plate thermometers) Plate thermometers shall be provided in accordance with EN 1363-1. There shall be at least one for every 1,5 m² of the exposed surface area of the test construction, subject to a minimum of 4. In vertical supporting constructions, the plate thermometers shall be orientated so that side ‘A’ faces towards the back wall of the furnace. In horizontal supporting constructions, the plate thermometers shall be orientated so that side 'A' faces the floor of the furnace. No part of the plate thermometer shall be closer than 100 mm to any part of the seal, a penetrating service or any part of the furnace at the start of the test. 9.1.2 Unexposed face thermocouples 9.1.2.1 General Unexposed surface tem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...