EN 17075:2018

(Main)Water quality - General requirements and performance test procedures for water monitoring equipment - Measuring devices

Water quality - General requirements and performance test procedures for water monitoring equipment - Measuring devices

This European Standard specifies general requirements and performance test procedures for portable and fixed position measuring devices (MDs) that are used in an in-line or online operating position to measure physical and chemical determinands in water. It excludes at-line devices, such as chemical test kits, and off-line devices, such as laboratory analysers.

The general requirements include functional facilities that MDs need to meet users’ applications and information that need to be included in associated documents.

The test procedures specify uniform methods to be used when determining key performance characteristics of MDs. The performance tests comprise testing carried out under laboratory and field conditions.

Statistical procedures are defined for evaluation of the test data. It is recognized that for some devices certain test procedures are not applicable.

Example values for performance characteristics for a selection of MDs for monitoring waste water effluents and receiving waters are detailed in Annex A for guidance.

This European Standard requires the manufacturer of a MD to provide more technical data for verification than does EN ISO 15839:2006 [5]. Consequently, EN ISO 15839 will be of greater assistance to manufacturers wishing to characterize a new device whereas this European Standard is more focussed on user requirements for the verification of manufacturer’s claims.

Wasserbeschaffenheit - Allgemeine Anforderungen und Testverfahren zur Leistungsprüfung von Geräten zum Wassermonitoring - Messgeräte

Dieses Dokument legt allgemeine Anforderungen und Leistungsprüfungsverfahren für tragbare und fest installierte Messgeräte fest, die in einer Inline oder Online Betriebsposition verwendet werden, um physikalische und chemische Bestimmungsgrößen in Wasser zu messen. Es deckt keine chemischen Test-Kits und Laboranalysegeräte ab.

Die allgemeinen Anforderungen umfassen bestimmte Merkmale, die für den Gebrauch des Geräts, zur Information des Anwenders und für die zugehörigen Dokumente notwendig sind.

Die Prüfverfahren legen einheitliche Verfahren fest, die beim Bestimmen von wichtigen Leistungskenngrößen von MDs verwendet werden. Die Leistungsprüfungen umfassen unter Labor- und Feldbedingungen durchgeführte Prüfungen. Es ist zu beachten, dass bestimmte Prüfverfahren für einige Geräte nicht geeignet sind.

Statistische Verfahren für die Auswertung der Prüfdaten sind definiert.

Beispielwerte für Leistungskenngrößen für eine Auswahl an MDs zum Monitoring von Abläufen von Abwasser und Vorflutern sind detailliert in Anhang A als Hilfestellung angegeben.

Dieses Dokument fordert von den Herstellern eines MD die Bereitstellung von mehr technischen Daten zur Verifizierung als EN ISO 15839:2006 [7]. Deshalb ist EN ISO 15839 [7] eine bessere Hilfestellung für Hersteller, die ein neues Gerät charakterisieren möchten, während dieses Dokument den Schwerpunkt eher auf die Anwenderanforderungen für die Verifizierung der Herstellerangaben legt.

Qualité de l'eau - Exigences générales et modes opératoires d'essai de performance pour les équipements de surveillance de l'eau - Dispositifs de mesure

La présente Norme européenne spécifie les exigences générales et les modes opératoires d'essai de performance pour les dispositifs de mesure (DM) portables et fixes qui sont utilisés in situ, en ligne et en ligne avec boucle de prélèvement afin de mesurer les caractéristiques physiques et chimiques à déterminer dans l'eau. Elle exclut les dispositifs « at-line », tels que les tests chimiques en kit, et les dispositifs hors ligne, tels que les analyseurs de laboratoire.

Les exigences générales comprennent les installations fonctionnelles dont les DM ont besoin pour répondre aux besoins des utilisateurs pour leurs applications, ainsi que les informations qui doivent être incluses dans les documents associés.

Les modes opératoires d'essai spécifient les méthodes uniformes à utiliser pour déterminer les caractéristiques de performance clés des DM. Les essais de performance comprennent des essais effectués dans des conditions de laboratoire et des conditions réelles.

Des procédures statistiques sont définies pour l'évaluation des données d'essai. Il est reconnu que pour certains dispositifs, certains modes opératoires d'essai ne sont pas applicables.

Des exemples de valeurs de caractéristiques de performance pour une sélection de DM destinés à la surveillance des effluents d'eaux usées et des eaux réceptrices sont fournis à l'Annexe A à titre d’information.

La présente Norme européenne exige que le fabricant d'un DM fournisse davantage de données techniques pour la vérification que ne l'exige l'EN ISO 15839:2006 [5]. Par conséquent, l'EN ISO 15839 sera d'une plus grande utilité pour les fabricants qui souhaitent caractériser un nouveau dispositif, tandis que la présente Norme européenne est davantage axée sur les exigences de l'utilisateur relatives à la vérification des allégations du fabricant.

Kakovost vode - Splošne zahteve in postopki preskušanja zmogljivosti opreme za monitoring vode - Merilniki

Ta standard je 2. del skupine standardov iz dveh delov, ki določa tehnične zahteve za preskušanje zmogljivosti opreme za monitoring vode. Ta standard določa splošne zahteve in postopke preskušanja zmogljivosti za samodejne merilnike (AMD). Te naprave so lahko trajno nameščene ali prenosne in omogočajo stalne vnovične meritve kemikalij ali fizičnih parametrov v vodi v realnem času. Samodejni merilniki se obsežno uporabljajo v industrijskem procesu, vodni industriji in regulatorjih za namene nadzora skladnosti in nadzornega monitoringa ter za nadzor procesov. Ta standard podpira direktivo o industrijskih emisijah, direktivo o morski strategiji in okvirno direktivo o vodah. Preskusni parametri so zmogljivostne lastnosti, ki označujejo zmožnost samodejnega merilnika, da zagotovi zanesljive meritve. Vključujejo: sistematični pogrešek, ponovljivost in napake, ki jih povzročajo razlike v linearnosti, odstopanje, moteče komponente, kompenzacijo slanosti, izhodno impedanco, napajalno napetost, temperaturo okolice, relativno vlažnost, vpadno svetlobo, vzorčno temperaturo, vzorčni pretok in vzorčni tlak. Celotna merilna zanesljivost samodejnega merilnika se izračuna v obliki kombinirane zmogljivostne lastnosti, ki je izražena kot merilna negotovost.

General Information

- Status

- Withdrawn

- Publication Date

- 11-Dec-2018

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 230 - Water analysis

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 05-Apr-2023

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 28-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 17-Mar-2021

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 17075:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Water quality - General requirements and performance test procedures for water monitoring equipment - Measuring devices". This standard covers: This European Standard specifies general requirements and performance test procedures for portable and fixed position measuring devices (MDs) that are used in an in-line or online operating position to measure physical and chemical determinands in water. It excludes at-line devices, such as chemical test kits, and off-line devices, such as laboratory analysers. The general requirements include functional facilities that MDs need to meet users’ applications and information that need to be included in associated documents. The test procedures specify uniform methods to be used when determining key performance characteristics of MDs. The performance tests comprise testing carried out under laboratory and field conditions. Statistical procedures are defined for evaluation of the test data. It is recognized that for some devices certain test procedures are not applicable. Example values for performance characteristics for a selection of MDs for monitoring waste water effluents and receiving waters are detailed in Annex A for guidance. This European Standard requires the manufacturer of a MD to provide more technical data for verification than does EN ISO 15839:2006 [5]. Consequently, EN ISO 15839 will be of greater assistance to manufacturers wishing to characterize a new device whereas this European Standard is more focussed on user requirements for the verification of manufacturer’s claims.

This European Standard specifies general requirements and performance test procedures for portable and fixed position measuring devices (MDs) that are used in an in-line or online operating position to measure physical and chemical determinands in water. It excludes at-line devices, such as chemical test kits, and off-line devices, such as laboratory analysers. The general requirements include functional facilities that MDs need to meet users’ applications and information that need to be included in associated documents. The test procedures specify uniform methods to be used when determining key performance characteristics of MDs. The performance tests comprise testing carried out under laboratory and field conditions. Statistical procedures are defined for evaluation of the test data. It is recognized that for some devices certain test procedures are not applicable. Example values for performance characteristics for a selection of MDs for monitoring waste water effluents and receiving waters are detailed in Annex A for guidance. This European Standard requires the manufacturer of a MD to provide more technical data for verification than does EN ISO 15839:2006 [5]. Consequently, EN ISO 15839 will be of greater assistance to manufacturers wishing to characterize a new device whereas this European Standard is more focussed on user requirements for the verification of manufacturer’s claims.

EN 17075:2018 is classified under the following ICS (International Classification for Standards) categories: 13.060.45 - Examination of water in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17075:2018 has the following relationships with other standards: It is inter standard links to EN 17075:2018+A1:2023, EN ISO 5814:2012, EN 17075:2018/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17075:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2019

Kakovost vode - Splošne zahteve in postopki preskušanja zmogljivosti opreme za

monitoring vode - Merilniki

Water quality - General requirements and performance test procedures for water

monitoring equipment - Measuring devices

Wasserbeschaffenheit - Allgemeine Anforderungen und Testverfahren zur

Leistungsprüfung von Geräten zum Wassermonitoring - Messgeräte

Qualité de l'eau - Exigences générales et modes opératoires d'essai de performance

pour les équipements de surveillance de l'eau - Dispositifs de mesure

Ta slovenski standard je istoveten z: EN 17075:2018

ICS:

13.060.45 Preiskava vode na splošno Examination of water in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17075

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2018

EUROPÄISCHE NORM

ICS 13.060.45

English Version

Water quality - General requirements and performance

test procedures for water monitoring equipment -

Measuring devices

Qualité de l'eau - Exigences générales et modes Wasserbeschaffenheit - Allgemeine Anforderungen und

opératoires d'essai de performance pour les Testverfahren zur Leistungsprüfung von Geräten zum

équipements de surveillance de l'eau - Dispositifs de Wassermonitoring - Messgeräte

mesure

This European Standard was approved by CEN on 18 June 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2018 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17075:2018 E

worldwide for CEN national Members.

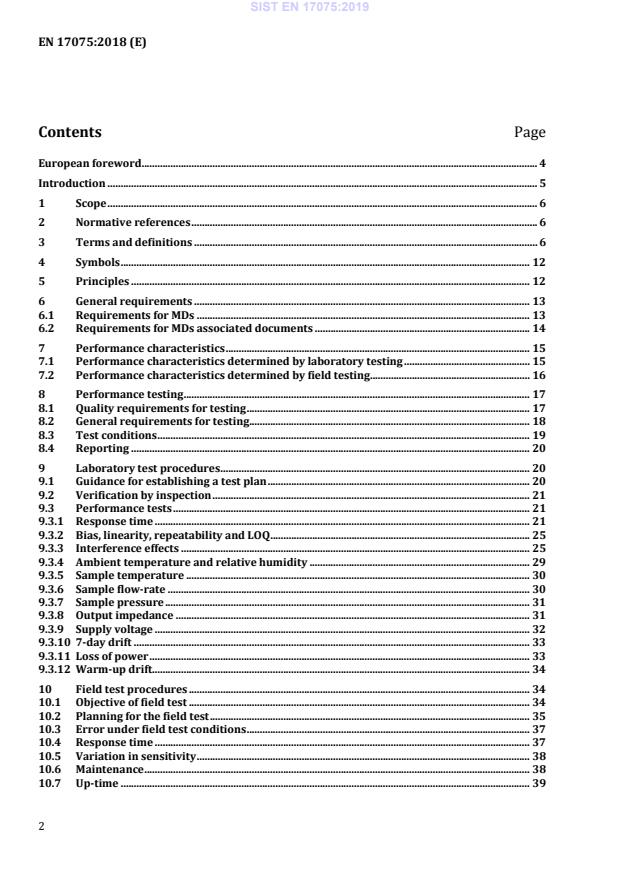

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Symbols . 12

5 Principles . 12

6 General requirements . 13

6.1 Requirements for MDs . 13

6.2 Requirements for MDs associated documents . 14

7 Performance characteristics . 15

7.1 Performance characteristics determined by laboratory testing . 15

7.2 Performance characteristics determined by field testing . 16

8 Performance testing . 17

8.1 Quality requirements for testing . 17

8.2 General requirements for testing . 18

8.3 Test conditions . 19

8.4 Reporting . 20

9 Laboratory test procedures . 20

9.1 Guidance for establishing a test plan . 20

9.2 Verification by inspection . 21

9.3 Performance tests . 21

9.3.1 Response time . 21

9.3.2 Bias, linearity, repeatability and LOQ . 25

9.3.3 Interference effects . 25

9.3.4 Ambient temperature and relative humidity . 29

9.3.5 Sample temperature . 30

9.3.6 Sample flow-rate . 30

9.3.7 Sample pressure . 31

9.3.8 Output impedance . 31

9.3.9 Supply voltage . 32

9.3.10 7-day drift . 33

9.3.11 Loss of power . 33

9.3.12 Warm-up drift. 34

10 Field test procedures . 34

10.1 Objective of field test . 34

10.2 Planning for the field test . 35

10.3 Error under field test conditions . 37

10.4 Response time . 37

10.5 Variation in sensitivity . 38

10.6 Maintenance . 38

10.7 Up-time . 39

Annex A (informative) Example values for performance characteristics for a selection of

MDs for monitoring waste water effluents and receiving waters . 41

Annex B (normative) Evaluation of performance test data . 47

Annex C (informative) Example calculations . 53

Annex D (informative) Uncertainty of the reference quantity and error calculations . 62

Annex E (informative) Example test report . 64

Bibliography . 68

European foreword

This document (EN 17075:2018) has been prepared by Technical Committee CEN/TC 230 “Water

analysis”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2019, and conflicting national standards shall be

withdrawn at the latest by May 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

Introduction

This document defines general requirements and test procedures for verifying the performance of

measuring devices (MDs) used to monitor the quality of a wide range of waters including drinking

waters, waste waters, and natural waters. It covers both portable measuring devices (PMDs) and fixed

position measuring devices (FMDs). These devices include: sensors, single and multi-parameter

instruments, discrete and batch instruments, probes and sondes. It excludes chemical test kits. For the

purposes of this document the acronym MD(s) is used except where it is necessary to be specific about

the particular type (e.g. PMDs, FMDs) or component of a MD (e.g. sensor).

This document is associated with EN 16479 [1] which covers automated sampling devices (samplers)

for water and waste water.

The general requirements include several features that are necessary to meet users’ applications and

information that has to be included in associated documents.

The performance tests comprise testing carried out under laboratory and field conditions They are

designed to determine, in a systematic and consistent way, the capability of MDs to make reliable

measurements. The testing focuses on key performance characteristics. Statistical procedures are

defined for evaluation of the test data.

The range of measurements over which the test procedures will be applied, the test range, is not

specified. It is for the MD manufacturer and/or the user to decide on the test range. Similarly, it is for

the MD manufacturer and/or the user to decide on the intended uses (applications) which will inform

the design of the field trial.

Water monitoring equipment is widely used for compliance monitoring purposes under national and

European regulations. This document supports the requirements of the following EU Directives:

— Industrial Emissions Directive (2010/75/EU) [2];

— Water Framework Directive (2000/60/EC) [3];

— Marine Strategy Framework Directive (2008/56/EC) [4];

— Drinking Water Directive (98/83/EC) [5];

— Technical Specifications for Chemical Analysis and Monitoring of Water Status (2009/90/EC) [6].

1 Scope

This document specifies general requirements and performance test procedures for portable and fixed

position measuring devices that are used in an in-line or online operating position to measure physical

and chemical measurands in water. It excludes chemical test kits and laboratory analysers.

The general requirements include functional facilities that MDs need to meet users’ applications and

information that needs to be included in associated documents.

The test procedures specify uniform methods to be used when determining key performance

characteristics of MDs. The performance tests comprise testing carried out under laboratory and field

conditions. It is recognized that for some devices certain test procedures are not applicable.

Statistical procedures are defined for evaluation of the test data.

Example values for performance characteristics for a selection of MDs for monitoring waste water

effluents and receiving waters are detailed in Annex A for guidance.

This document requires the manufacturer of a MD to provide more technical data for verification than

does EN ISO 15839:2006 [7]. Consequently, EN ISO 15839 [7] will be of greater assistance to

manufacturers wishing to characterize a new device whereas this document is more focussed on user

requirements for the verification of manufacturer’s claims.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 5814:2012, Water quality - Determination of dissolved oxygen - Electrochemical probe method

(ISO 5814:2012)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

measuring device

MD

device, used in an in-line or on-line operating position, which continuously (or at a given frequency)

gives an output signal proportional to the value of one or more measurands in waters which it

measures

Note 1 to entry: The device can be portable or fixed in position.

Note 2 to entry: The term “on-line measuring device” is often used for a MD used in an online position.

[SOURCE: EN ISO 15839:2006 [7], 3.26, modified]

3.2

portable measuring device

PMD

measuring device that can be moved from one measuring point to another and used in an in-line or on-

line operating position

3.3

fixed measuring device

FMD

measuring device that can be fixed in position and used in an in-line or on-line operating position

3.4

sensor

electronic device that senses a physical condition or chemical compound and delivers an electronic

signal proportional to the observed characteristic

[SOURCE: ISO/IEC 19762:2016 [8], 06.02.08]

3.5

in-line measuring device

in situ measuring device

system of automatic measurement in which at least the sensor is sited in the body of water

[SOURCE: ISO 6107-2:2006[9], 54, modified — term “analysis” replaced by term “measuring device”

and within definition “analysis” replaced by “measurement”]

3.6

on-line measuring device

system of automatic measurement in which the sample is taken from the body of water through a probe

to the measuring device by means of an appropriate conduit

Note 1 to entry: Sometimes referred to as an extractive measuring device.

[SOURCE: ISO 6107-2:2006+A1:2012 [10], 71, modified — term “analysis” replaced by term “measuring

device”, within definition “analysing equipment” replaced by “measuring device” and Note 1 to entry

added]

3.7

percentage error

error in measurement expressed as a percentage of the reference value

3.8

measurement bias

bias

estimate of a systematic measurement error

[SOURCE: ISO/IEC Guide 99:2007 [11], 2.18]

3.9

measurement repeatability

repeatability

precision under a set of repeatability conditions of measurement

[SOURCE: ISO/IEC Guide 99 [11], 2.21]

Note 1 to entry: In this standard the ability of a MD to provide closely similar indications for repeated

measurements of the same measurand under the same conditions of measurement.

3.10

limit of quantification

LOQ

stated multiple of the limit of detection, for example two or three times the limit of detection, at a

concentration of the measurand that can reasonably be determined with an acceptable level of accuracy

and precision

Note 1 to entry: Limit of quantification can be calculated using an appropriate standard or sample, and may be

obtained from the lowest calibration point on the calibration curve (excluding the blank). See ISO 6879 [12].

[SOURCE: ISO 6107-2:2006+A1:2012 [10], 61]

3.11

linearity

degree to which there is a straight-line relationship between the (mean) result of measurement (signal)

and the quantity (concentration) of the component to be determined

[SOURCE: EN ISO 11885:2009 [13], 3.9, modified]

3.12

drift

slow change of output, at a constant input, of a measuring system

[SOURCE: EN ISO 15796:2005 [14], 2.8]

3.13

response time (t )

time interval between the instant when a continuous measuring device is subjected to an abrupt change

in measurand value and the instant when the readings cross the limits of (and remain inside) a band

defined by the 90 % and the 110 % of the difference between the initial and final value of the abrupt

change

[SOURCE: EN ISO 15839:2006 [7], 3.3, modified]

3.14

performance characteristics

set of parameters describing the performance of a MD

[SOURCE: EN ISO 15839:2006 [7], 3.27, modified]

3.15

measurement error

error of measurement

error

measured quantity value minus a reference quantity value

Note 1 to entry: The concept of “measurement error” can be used both:

a) when there is a single reference quantity value to refer to, which occurs if a calibration is made by

means of a measurement standard with a measured quantity value having a negligible measurement

uncertainty or if conventional quantity value is given, in which case the measurement error is known;

and

b) if a measurand is supposed to be represented by a unique true quantity value or a set of true quantity

values of negligible range, in which case the measurement error is not known.

Note 2 to entry: Measurement error should not be confused with production error or mistake.

[SOURCE: ISO/IEC Guide 99:2007 [11], 2.16]

3.16

measurement uncertainty

uncertainty of measurement

uncertainty

non-negative parameter characterizing the dispersion of the quantity values being attributed to a

measurand, based on the information used

Note 1 to entry: The parameter may be, for example, a standard deviation called standard measurement

uncertainty (or a specified multiple of it), or the half-width of an interval, having a stated coverage probability.

Note 2 to entry: In general, for a given set of information, it is understood that the measurement uncertainty is

associated with a stated quantity value attributed to the measurand. A modification of this value results in a

modification of the associated uncertainty.

Note 3 to entry: Measurement uncertainty includes components arising from systematic effects, such as

components associated with corrections and the assigned quantity values of measurement standards, as well as

the definitional uncertainty. Sometimes estimated systematic effects are not corrected for but, instead, associated

measurement uncertainty components are incorporated.

Note 4 to entry: Measurement uncertainty comprises, in general, many components. Some of these may be

evaluated by Type A evaluation of measurement uncertainty from the statistical distribution of the quantity values

from series of measurements and can be characterized by standard deviations. The other components, which may

be evaluated by Type B evaluation of measurement uncertainty, can also be characterized by standard deviations,

evaluated from probability density functions based on experience or other information.

[SOURCE: ISO/IEC Guide 99:2007 [11], 2.26]

3.17

standard measurement uncertainty

standard uncertainty of measurement

standard uncertainty

measurement uncertainty expressed as a standard deviation

[SOURCE: ISO/IEC Guide 99:2007 [11], 2.30]

3.18

combined standard measurement uncertainty

combined standard uncertainty

standard measurement uncertainty that is obtained using the individual standard measurement

uncertainties associated with the input quantities in a measurement model

Note 1 to entry: In case of correlations of input quantities in a measurement model, covariances must also be

taken into account when calculating the combined standard measurement uncertainty, see also

ISO/IEC Guide 98-3:2008 [15], 2.3.4.

[SOURCE: ISO/IEC Guide 99:2007 [11], 2.31]

3.19

expanded measurement uncertainty

expanded uncertainty

product of a combined standard measurement uncertainty and a factor larger than the number one

Note 1 to entry: Expanded measurement uncertainty is termed “overall uncertainty” in paragraph 5 of

Recommendation INC-1 (1980) (see the GUM) and simply “uncertainty” in IEC documents.

Note 2 to entry: The factor depends upon the type of probability distribution of the output quantity in a

measurement model and on the selected coverage probability.

Note 3 to entry: The term “factor” in this definition refers to a coverage factor.

[SOURCE: ISO/IEC Guide 99:2007 [11], 2.35]

3.20

combined performance characteristic

combination of individual performance characteristics expressed as an expanded measurement

uncertainty (with a coverage factor of 2)

3.21

test range

measuring range over which the MD is tested

3.22

output

reading, or a digital, analogue, wired or wireless electrical signal, generated by a MD in response to a

measurand

3.23

rated operating condition

operating condition that must be fulfilled during measurement in order that a measuring instrument or

measuring system perform as designed

Note 1 to entry: Rated operating conditions generally specify intervals of values for a quantity being measured

and for any influence quantity.

[SOURCE: ISO/IEC Guide 99:2007 [11], 4.9]

3.24

interferent

physical, biological or chemical property of the sample, excluding the measurand, that affects the output

signal

[SOURCE: EN ISO 15839:2006 [7], 3.16, modified]

3.25

adjustment of a measuring system

adjustment

set of operations carried out on a measuring system so that it provides prescribed indications

corresponding to given values of a quantity to be measured

Note 1 to entry: Types of adjustment of a measuring system include zero adjustment of a measuring system,

offset adjustment, and span adjustment (sometimes called gain adjustment).

Note 2 to entry: After an adjustment of a measuring system, the measuring system usually needs to be

recalibrated.

Note 3 to entry: Adjustment of a measuring system should not be confused with calibration, which is a

prerequisite for adjustment.

[SOURCE: ISO/IEC Guide 99:2007 [11], 3.11]

3.26

reference method

method to be used to obtain the measurand value of the test waters, against which the readings from

the MD under test can be compared

3.27

measurand

quantity intended to be measured

[SOURCE: ISO/IEC Guide 99:2007 [11], 2.3, modified]

3.28

reference operating condition

operating condition prescribed for evaluating the performance of a measuring instrument or measuring

system or for comparison of measurement results

[SOURCE: ISO/IEC Guide 99:2007 [11], 4.11]

3.29

flow cell

housing within which a sensor can be held and through which the test water can be directed

3.30

up-time

fraction of the total time for which usable measuring data are available from the MD

3.31

warm-up period

interval between switching on power to the measurement circuit and the instant when the MD

produces a stable value when measuring a stable measurand

4 Symbols

For the purposes of this document, the following symbols apply.

b Bias

t Response time

X Change in error due to variations in linearity

L

S Repeatability

r

X Change in error due to variations in interferents

IN

X Change in error due to incorrect salinity compensation

SC

X Change in error due to variations in incident light

LX

X Change in error due to variations in ambient temperature

T

X Change in error due to variations in relative humidity

RH

X Change in error due to variations in sample temperature

ST

X Change in error due to variations in sample flow-rate

SQ

X Change in error due to variations in sample pressure

SP

X Change in error due to variations in output impedance

O

X Change in error due to variations in supply voltage

V

X Change in error due to variations in drift

D

W Warm–up drift

D

U Combined performance characteristic

C

5 Principles

The general requirements are based on experience of users’ needs when operating a MD in online or in-

line measuring positions in a range of applications.

The performance characteristics are parameters that identify the capability of a MD to provide reliable

measurements. They are determined as measurement uncertainty and expressed as percentage error

(see 3.7) except for bias and repeatability which are expressed as relative values in percentage. For low

concentration measurements where the reading approaches zero the percentage error value becomes

inapplicable. At low concentrations the uncertainty should be expressed as an absolute value. The

tables at Annex A list example values relevant to monitoring waste water effluents and receiving

waters.

Measurement reliability includes:

— the MD's measurement bias, LOQ, linearity, drift, repeatability and response time;

— operational influences arising from variations in supply voltage, output impedance, sample

temperature, sample flow-rate and sample pressure;

— environmental influences arising from variations in ambient temperature, relative humidity,

interferents and incident light.

The overall measurement reliability of a MD is captured by bringing the individual performance

characteristics together in the form of a combined performance characteristic expressed as

measurement uncertainty.

The laboratory performance tests are designed to determine the values for the specified performance

characteristics in a systematic and consistent way. Laboratory testing is used to determine each

performance characteristic in turn in a controlled environment.

Statistical procedures are defined for evaluation of the laboratory test data to calculate the individual

performance characteristic measurement standard uncertainties, u, and the combined performance

characteristic measurement uncertainty, U . They are based on ISO/IEC Guide98-3 to the Expression of

C

Uncertainty in Measurement (GUM). The procedure for calculating the combined performance

characteristic measurement uncertainty involves converting the individual performance characteristic

uncertainties to standard uncertainties. This takes account of the probable distribution of errors. In the

GUM, standard uncertainties are combined using a root sum of squares with due account taken of the

contribution of each component through the use of sensitivity co-efficients. To determine sensitivity co-

efficients, it is necessary to know the functions by which each component contributes to overall error.

In the case of MD testing this will rarely be known. Hence for the purposes of this standard, the

sensitivity co-efficients are all taken as 1.

The combined performance characteristic, U , is expressed as an expanded uncertainty. The expanded

C

uncertainty, (U), is obtained by multiplying the standard uncertainty by a coverage factor. The coverage

factor is determined by the confidence level. This Standard uses a 95 % confidence with a coverage

factor assumed to be 2.

Field testing is carried out to demonstrate the MD's performance is maintained under representative

operational conditions. FMD field testing is carried out on an application that is representative of the

intended use of the FMD. PMD field testing involves the repeated use of the PMD on several applications

that are representative of the intended use of the PMD. A field trial can be a dedicated trial, or part of an

acceptance trial, or in the case of FMD, be carried out on a device that has already been installed and is

in operational use. The field performance tests are designed to determine the MD's measurement error,

the change in response time and variation in sensitivity between the beginning and end of the trial, the

maintenance requirements and up-time. Response time and variation in sensitivity are indicators of

how a MD performs in real conditions.

During the field test the measurement error test is carried out by comparison with a reference method.

Statistical procedures are defined for the evaluation of the measurement error test data. For each

measurement pair the difference between the reference value and the MD's reading is calculated as %

error (except for pH and temperature for which absolute values apply). The value of the measurement

error corresponding to the 90th percentile is calculated.

6 General requirements

6.1 Requirements for MDs

Unless otherwise stated a MD shall have the following:

a) a unique designation that unambiguously identifies it (e.g. model, serial number);

b) for a FMD a means of protection against inadvertent or unauthorized access to the control

functions;

c) an output signal and/or display;

d) the units of measurement should be appropriate to the measurand being measured and should not

require reference to a calibration chart or table or visual comparison;

e) a means of indicating and/or communicating its operating status, for example, stand-by,

maintenance mode or malfunction;

f) for a FMD, a means of communicating fault conditions to an external system;

g) for a MD operating from an external power supply, a method of indicating loss of power supply (e.g.

a relay that fails open);

h) a method of indicating when the power supply voltage is below its normal operating limit (applies

only to a MD operating from a battery);

i) a means of retaining all pre-set data, including calibration and alarm set points and adjustments, for

a minimum period of 30 days for FMDs and for 1 h for PMDs after disconnection of the power

supply;

j) for a PMD, a means of calibration in the field, or where this is impractical, functionality checks that

can be carried out in the field to verify correct operation;

k) for a PMD, a self-contained power supply that consists of primary cells, rechargeable cells or any

other power source that is capable of providing the necessary power under all operating

conditions. An external power source can be used for recharging and / or operating the PMD, for

example in a laboratory;

l) a means of supporting the sensor unit (e.g. a chain) for MDs that utilize a remote sensor (intended

to be lowered into a watercourse, chamber or tank etc.).

6.2 Requirements for MDs associated documents

Unless otherwise stated a MD shall have associated documents which include the following information:

a) a statement of the intended use (application) of the MD;

b) operating instructions which cover the full functionality and measurement principle of the MD;

c) a statement of the Limit of Quantification, where relevant to the measurement principle, the

method by which it has been determined and the related measurement range for the MD;

NOTE 1 The expected method for the determination of LOQ is the one specified in this European standard

at 9.3.2, however, it may not be applicable to all MDs (e.g. pH).

d) a statement about the storage life of scheduled consumable spares and reagents;

e) identification of any special conditions (including advice from the supplier) necessary for the

storage of consumable spares and reagents;

f) a statement of installation conditions; including any requirements for sample pre-conditioning (e.g.

filtration);

g) a statement of the rated operating conditions for the power supply and / or battery;

h) a statement of the rated operating conditions for the signal load impedance on any analogue

output;

i) a statement of the rated operating conditions for sample flow-rate, temperature and pressure, as

appropriate;

j) a statement of the rated operating conditions for ambient temperature and relative humidity;

NOTE 2 Guidance on the ambient temperature and relative humidity, by usage group, which MDs are likely

to be subject to is given in EN 60746-1:2003 [16].

NOTE 3 The influence of ambient temperature and relative humidity on the performance of a MD is tested

(see 9.3.4) over the rated environmental operating conditions.

k) a statement of known chemical, biological and physical interferents to the measurement method

and the maximum amounts at which the interferences remain acceptable for intended applications;

NOTE 4 Knowledge of interferents should be available from understanding of the operating principle,

testing and practical applications of MDs.

l) for a MD, recommendations for maintenance to ensure reliable operation can be made;

NOTE 5 Automated routines for cleaning, maintenance, adjustment or recalibration can be used to

maintain performance between manual interventions. It is the responsibility of the user to ensure that a

suitable regime is adopted for a site-specific application.

m) a statement of the ingress protection (IP) rating.

NOTE 6 Guidance on ingress protection is given in EN 60529 [17].

7 Performance characteristics

7.1 Performance characteristics determined by laboratory testing

The relevant characteristics are expressed as bias (b), change in error (X), or expanded uncertainty (U)

as shown in Table 1. Annex B describes in detail how the values are calculated for each characteristic.

Annex C provides example calculations.

Table 1 — Summary of performance characteristics determined by laboratory tests

Characteristic Expression of characteristic Test

The mean response times, t , for an increasing and decreasing

Response time 9.3.1

step change.

Bias The bias, b, measured at each test point 9.3.2

,

The maximum deviation, X from a straight line fitted to the

L

Linearity 9.3.2

measured values across the test range

The standard deviation, S at each test point of the measurement

r

Repeatability 9.3.2

values

The maximum change in error, X , calculated in accordance with

9.3.3.

IN

Substance interference

B.7.1 in Annex B.

Salinity compensation

The change in error, X , calculated in accordance with B.7.1 in

9.3.3.

SC

for dissolved oxygen

Annex B.

MDs

The change in error, X , calculated in accordance with B.7.1 in

9.3.3.

LX

Incident light

Annex B.

Characteristic Expression of characteristic Test

The change in error, X , calculated in accordance with B.7.3 in

T

Ambient temperature 9.3.4

Annex B.

The change in error, X ,, calculated in accordance with B.7.2 in

RH

Relative humidity 9.3.4

Annex B

The change in error, X , calculated in accordance with B.7.3 in

ST

Sample temperature 9.3.5

Annex B.

The change in error, X , calculated in accordance with B.7.3 in

SQ

Sample flow-rate 9.3.6

Annex B.

The change in error, X , calculated in accordance with B.7.3 in

SP

Sample pressure 9.3.7

Annex B.

The maximum change in error, X , calculated in accordance with

O

Output impedance 9.3.8

B.7.1 in Annex B.

The maximum change in error, X , calculated in accordance with

V

Supply voltage 9.3.9

B.7.1 in Annex B.

The maximum change in error, X , observed during the drift test

7-day drift (FMD only) 9.3.10

D

An expanded uncertainty, U , (2 × combined uncertainty) obtained

Combined

C

performance -

by combining individual performance characteristics in accordance

characteristic

with the statistical procedures detailed at B.8 in Annex B.

Loss of power (FMD Changes in values of pre-set data, calibration data or alarm set

9.3.11

only) points following loss of power

Warm up drift (PMD

The time, W , necessary for stabilizing the output signal reported

9.3.12

D

only)

A MD shall be tested using reference methods, devices or materials to determine all of the performance

characteristics listed in Table 1 that are appropriate to the particular MD. The values for the

performance characteristics should be expressed as a percentage of reading, except for MDs that

measure pH which should be in pH units, and MDs that measure temperature which should be in °C.

As the value of the measurand becomes small it is increasingly difficult to determine the bias of a

measurement, expressed as a percentage of reading, in any meaningful way. This is caused by

limitations on the resolution or accuracy of reference methods.

7.2 Performance characteristics determined by field testing

Table 2 provides a summary of the performance characteristics determined by the field tests specified

in Clause 10.

Table 2 — Summary of performance characteristics determined by field tests

Performance

Expression of performance characteristics Test

characteristic

FMDs — Between 1 and 3 months of recorded data

demonstrating continuous operation.

Period of test 10.2

PMDs — At least 120 measurements taken over a period

between 1 and 3 months.

A minimum of 24 measurements with a simultaneous

Error (X) 10.3

reference measurement.

Change in response time Measured at the beginning and end of the trial. 10.4

Variation in sensitivity Measured at the beginning and end of the trial. 10.5

Maintenance Reported as detailed in 10.6. 10.6

FMDs — As calculated in 10.7.

Up-time (V) 10.7

PMDs — Not applicable.

8 Performance testing

8.1 Quality requirements for testing

MD testing shall be carried out in accordance with good quality management system practices. If test

results are to be widely acceptable then testing should be carried out in accordance with

EN ISO/IEC 17025 [18] or other equivalent standards.

The reference method used to test the MD shall be an appropriate European, international or national

method.

When selecting a reference method consideration should be given to the physical and chemical

speciation of the measurand to be measured as various species might be measured by different

methods. The following considerations should be taken into account:

— dissolved matter is defined by reference methods as everything that passes through a 0,45 µm

membrane filter;

— physical speciation of substances can occur leading to partitioning between solids, colloids,

surfaces and dissolved phases, and chemical speciation between free ions, complexes with

inorganic and organic ligands, different oxidation states etc. IUPAC recommendations provide more

information [19];

— some measurands are empirical (e.g. turbidity, COD) which means that the measurement is

dependent on the analytical method. The analytical methods to be used for reference purposes shall

be reported.

Reference solutions shall be prepared in accordance with good laboratory practice. The preparation of

air saturated water (100 % DO) reference solutions should take into account published guidance

[20][21][22].

Consideration shall be given to the likely stability of reference solutions during the course of the

performance tests. Instability could be caused by the nature of the measurand (e.g. DO), the duration of

the test (e.g. see 9.3.4), variations in sample temperature (e.g. see 9.3.5), and variations in sample

pressure (see 9.3.7). The concentration of the measurand in the reference solution should be checked

by a method independent of the MD under test at the start of each test procedure and where the above

considerations apply further independent measurements should be made, for example, prior to each

test run.

The use of simulated inputs or secondary standards should be recorded and justified in the test report.

The uncertainty of the reference method shall be included in the calculation of the results for all tests

except where the uncertainty of the reference method is no more than 1/5 of the value of the

performance characteristic being determined. Further information is given at Annex D

Fewer measurements than required by an individual test can be made if this can be justified, (e.g. where

a pattern of low variability is supported by statistical analysis). If this approach is adopted it should be

recorded and justified in the test report.

8.2 General requirements for testing

All required reagents for the operation of the MD shall be prepared and stored according to the MD

manufacturer’s specifications. If possible, reagents from the same manufacturing batch should be used

throughout the testing period. If this is not possible, then the output of the MD immediately before and

after changeover of reagents should be noted so as to isolate possible reagent effects.

Laboratory test procedures shall be carried out in accordance with the following generic procedure.

Before each test the MD shall be set up, calibrated and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...