EN 13361:2004

(Main)Geosynthetic barriers - Characteristics required for use in the construction of reservoirs and dams

Geosynthetic barriers - Characteristics required for use in the construction of reservoirs and dams

This document specifies the relevant characteristics of geosynthetic barriers, including polymeric geosynthetic barriers, clay geosynthetic barriers and bituminous geosynthetic barriers, to be used as fluid barriers in the construction of reservoirs and dams, and the appropriate test methods to determine these characteristics.

The intended use of these products is to control the leakage of water through the construction.

This document is not applicable to geotextiles or geotextile-related products.

This document provides for the evaluation of conformity of the product to this document.

This document defines requirements to be met by manufacturers and their authorised representatives with regard to the presentation of product properties.

This document does not cover applications where the geosynthetic barrier is to be in contact with water that has been treated for human consumption.

NOTE: Where potable water is or may be in direct contact with the product the designer should also refer to other relevant standards, requirements and/or regulations.

Geosynthetische Dichtungsbahnen - Eigenschaften, die für die Anwendung beim Bau von Rückhaltebecken und Staudämmen erforderlich sind

Dieses Dokument legt die relevanten Eigenschaften von geosynthetischen Dichtungsbahnen, einschließlich geosynthetischer Kunststoffdichtungsbahnen, geosynthetischer Tondichtungsbahnen und geosynthetischer Bitumendichtungsbahnen, die als Abdichtung beim Bau von Rückhaltebecken und Staudämmen verwendet werden, und die geeigneten Prüfverfahren zur Bestimmung dieser Eigenschaften fest.

Die bestimmungsgemäße Anwendung dieser Produkte besteht im Abdichten gegen das Durchsickern von Wasser durch das Bauwerk.

Dieses Dokument ist nicht anwendbar auf Geotextilien oder geotextilverwandte Produkte.

Dieses Dokument ermöglicht die Konformitätsbewertung des Produktes hinsichtlich dieses Dokuments.

Dieses Dokument legt die Anforderungen fest, die von Herstellern und Händlern in Bezug auf die Darstellung der Produkteigenschaften eingehalten werden müssen.

Dieses Dokument umfasst nicht die Anwendungen, bei denen die geosynthetische Dichtungsbahn in Kontakt mit Trinkwasser kommt, das für den unmittelbaren menschlichen Gebrauch behandelt wurde.

ANMERKUNG Wo Trinkwasser in direkten Kontakt mit dem Produkt kommt oder kommen kann, muss sich der Planer auf andere zutreffende Normen, Anforderungen und/oder Bestimmungen beziehen.

Géomembranes, géosynthétiques bentonitiques - Caractéristiques requises pour l'utilisation dans la construction des réservoirs et des barrages

Le présent document spécifie les caractéristiques requises pour les géomembranes polymériques ou bitumineuses, les géosynthétiques bentonitiques destinés à éviter la pénétration de fluides dans la structure des réservoirs et des barrages ; elle décrit par ailleurs les méthodes d'essai permettant de déterminer ces caractéristiques.

Ces produits ont pour objet de contrôler les fuites d'eau à travers la construction.

Le présent document ne s'applique pas aux géotextiles ou produits apparentés.

Le présent document donne les informations permettant d'évaluer la conformité du produit au présent document.

Le présent document définit les exigences auxquelles les fabricants et distributeurs doivent satisfaire pour la présentation des propriétés du produit.

Le présent document ne couvre pas les cas où la géomembrane doit se trouver en contact avec une eau traitée en vue d'une consommation domestique.

NOTE Si de l'eau potable doit ou peut se trouver en contact direct avec le produit, le concepteur est également tenu de se référer aux normes, exigences et/ou règlements applicables.

Geosintetične ovire – Zahtevane karakteristike pri gradnji rezervoarjev in nasipov

General Information

- Status

- Withdrawn

- Publication Date

- 17-Aug-2004

- Withdrawal Date

- 16-Jul-2013

- Technical Committee

- CEN/TC 189 - Geotextiles and geotextile-related products

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 17-Jul-2013

- Completion Date

- 17-Jul-2013

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Aug-2009

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 14415:2004 - Geosynthetic barriers - Test method for determining the resistance to leaching - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

CEN/TS 14416:2014 - Geosynthetic barriers - Test method for determining the resistance to roots - Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Sponsored listings

Frequently Asked Questions

EN 13361:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Geosynthetic barriers - Characteristics required for use in the construction of reservoirs and dams". This standard covers: This document specifies the relevant characteristics of geosynthetic barriers, including polymeric geosynthetic barriers, clay geosynthetic barriers and bituminous geosynthetic barriers, to be used as fluid barriers in the construction of reservoirs and dams, and the appropriate test methods to determine these characteristics. The intended use of these products is to control the leakage of water through the construction. This document is not applicable to geotextiles or geotextile-related products. This document provides for the evaluation of conformity of the product to this document. This document defines requirements to be met by manufacturers and their authorised representatives with regard to the presentation of product properties. This document does not cover applications where the geosynthetic barrier is to be in contact with water that has been treated for human consumption. NOTE: Where potable water is or may be in direct contact with the product the designer should also refer to other relevant standards, requirements and/or regulations.

This document specifies the relevant characteristics of geosynthetic barriers, including polymeric geosynthetic barriers, clay geosynthetic barriers and bituminous geosynthetic barriers, to be used as fluid barriers in the construction of reservoirs and dams, and the appropriate test methods to determine these characteristics. The intended use of these products is to control the leakage of water through the construction. This document is not applicable to geotextiles or geotextile-related products. This document provides for the evaluation of conformity of the product to this document. This document defines requirements to be met by manufacturers and their authorised representatives with regard to the presentation of product properties. This document does not cover applications where the geosynthetic barrier is to be in contact with water that has been treated for human consumption. NOTE: Where potable water is or may be in direct contact with the product the designer should also refer to other relevant standards, requirements and/or regulations.

EN 13361:2004 is classified under the following ICS (International Classification for Standards) categories: 59.080.70 - Geotextiles; 91.100.50 - Binders. Sealing materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13361:2004 has the following relationships with other standards: It is inter standard links to EN 13361:2013, ISO 527-1:1993, EN ISO 12957-1:2018, EN ISO 12957-2:2024, EN 14415:2004, EN ISO 10318:2005, EN 13493:2018, EN 14414:2004, EN 13492:2018, EN 495-5:2013, EN ISO 13438:2018, EN 12224:2000, EN 13491:2018, EN 14575:2005, CEN/TS 14416:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13361:2004 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/107. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13361:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Geosynthetic barriers - Characteristics required for use in the construction of reservoirs and damsGéomembranes, géosynthétiques bentonitiques - Caractéristiques requises pour l'utilisation dans la construction des réservoirs et des barragesGeosynthetische Dichtungsbahnen - Eigenschaften, die für die Anwendung beim Bau von Rückhaltebecken und Staudämmen erforderlich sind91.100.50Veziva. Tesnilni materialiBinders. Sealing materials59.080.70GeotekstilijeGeotextilesICS:SIST EN 13361:2004enTa slovenski standard je istoveten z:EN 13361:200401-oktober-2004SIST EN 13361:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13361August 2004ICS 91.100.50; 59.080.70English versionGeosynthetic barriers - Characteristics required for use in theconstruction of reservoirs and damsBarrières géosynthétiques - Caractéristiques requises pourl'utilisation dans la construction des réservoirs et desbarragesGeosynthetische Dichtungsbahnen - Eigenschaften, die fürdie Anwendung beim Bau von Wasserbecken undStaudämmen erforderlich sindThis European Standard was approved by CEN on 18 March 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13361:2004: E

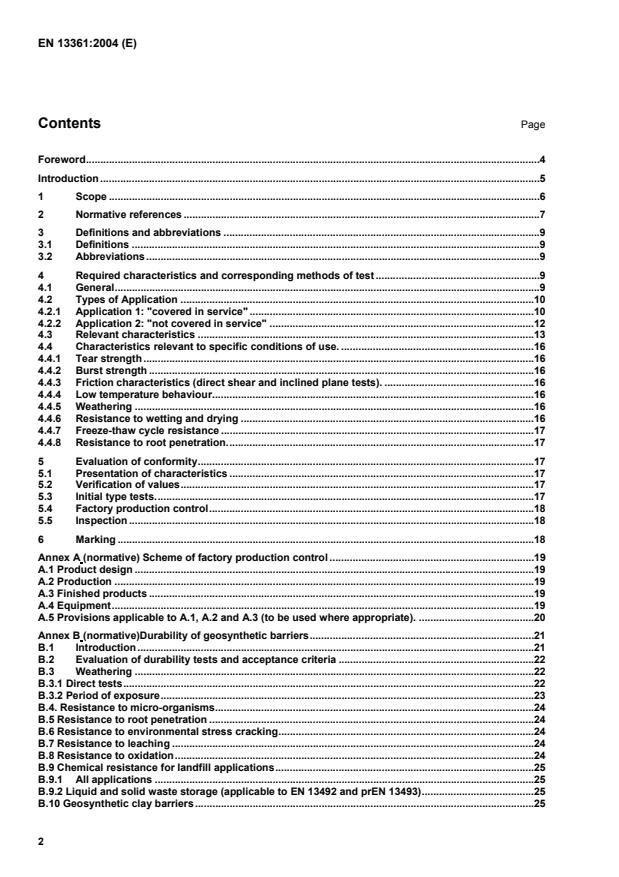

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive.26 ZA 1. Scope and relevant characteristics.26 ZA.2 System of attestation of conformity for geosynthetic barriers used in the construction of reservoirs and dams.27 ZA 3. CE marking and labelling.29 Bibliography.33

Tests for some non-mandated characteristics are still under study and will be included when the standard is revised. The term “product” used in this document refers to a geosynthetic barrier, including polymeric geosynthetic barriers, clay geosynthetic barriers and bituminous geosynthetic barriers. This document is part of a group of standards, addressing the requirements for geosynthetic barriers when used in a specific application.

Particular application cases can contain requirements about additional properties and - preferably standardised - test methods, if they are technically relevant and not conflicting with European Standards.

The design life of the product should be determined, since its function may be temporary, as a construction expediency, or permanent, for the lifetime of the structure.

1 Scope This document specifies the relevant characteristics of geosynthetic barriers, including polymeric geosynthetic barriers, clay geosynthetic barriers and bituminous geosynthetic barriers, to be used as fluid barriers in the construction of reservoirs and dams, and the appropriate test methods to determine these characteristics.

The intended use of these products is to control the leakage of water through the construction.

This document is not applicable to geotextiles or geotextile-related products. This document provides for the evaluation of conformity of the product to this document. This document defines requirements to be met by manufacturers and their authorised representatives with regard to the presentation of product properties.

This document does not cover applications where the geosynthetic barrier is to be in contact with water that has been treated for human consumption. NOTE: Where potable water is or may be in direct contact with the product the designer should also refer to other relevant standards, requirements and/or regulations.

ISO R 527-3 Plastics – Determination of tensile properties – Part 3: Test conditions for films and sheets

ASTM D 696-91 Standard test method for coefficient of linear thermal expansion of plastics between -30 °C and 30 °C. ASTM D 5397-99 Standard test method for evaluation of stress crack resistance of polyolefin geomembranes using notched constant tensile load test ASTM D 5887-95 Standard test method for measurement of index flux through saturated geosynthetic clay liner specimens using a flexible wall permeameter ASTM D 5890-95 Standard test method for swell index of clay mineral component of geosynthetic clay liners.

3.1.1 product geosynthetic barrier, including polymeric, bituminous and clay barriers 3.1.2 specification any document in which the works, functions, specific conditions and required material property values of the geosynthetic barrier of use are described 3.1.3 reservoir naturally occurring space or construction for storage, regulation and control of water 3.1.4 dam barrier constructed to hold back water to raise its level, form a reservoir or reduce or prevent flooding 3.1.5 upstream face The face of the dam that is normally in contact with the enclosed water 3.1.6 downstream face The face of a dam that is normally not in contact with the enclosed water 3.1.7 revetment construction that comprises one or more layers of material to provide protection to a slope against erosion 3.1.8 top water level maximum operating water level in any structure 3.2 Abbreviations For the purpose of this document the abbreviations given in prEN ISO 10318:2002 apply. GBR-P: polymeric geosynthetic barrier GBR-B: bituminous geosynthetic barrier GBR-C: clay geosynthetic barrier 4 Required characteristics and corresponding methods of test 4.1 General The main function of geosynthetic barriers when used in the construction of reservoirs and dams is to prevent or reduce the flow of fluid through the structure. Damage during installation has not been addressed in this document.

It is not normally advisable to install a geosynthetic barrier on the outside face of a dam. Special consideration should be given to any geosynthetic barrier installed on the downstream face of a dam. The applications described in this document do not include such situations. 4.2.1 Application 1: "covered in service" Applications where the product is laid on the upstream face of a dam or in a reservoir and is covered in service with a revetment or other protective layers. Figures 1 and 2 show typical installations.

Key 1 Top water level 2 Upstream face 3 Revetment 4 Geosynthetic barrier 5 Dam body Figure 1 - A geosynthetic barrier on a reservoir or dam slope, covered in service

Key 1 Top water level face of dam 2 Protective layer 3 Geosynthetic barrier

4 Face of dam

5 Body of dam

6 Subsoil Figure 2 - A geosynthetic Barrier on a reservoir or dam slope, covered in service

4.2.2 Application 2: "not covered in service" As in application 1, but with the product not covered in service with a revetment or other protective layers. Figures 3 and 4 show typical installations

Key 1 Top water level

2 Crest 3 Upstream face 4 Geosynthetic barrier 5 Dam body Figure 3 - A Geosynthetic barrier on a reservoir or dam slope, exposed in service

Key 1 Top water level

2 Geosynthetic barrier

3 Face of dam

4 Body of dam Figure 4 - A geosynthetic barrier on a reservoir or dam slope steeper than 35°°°°

4.3 Relevant characteristics The characteristics and the test methods to be used, are given in Table 1. The list of characteristics in Table 1 includes those relevant to all conditions of use and subject to harmonisation (H) (see Bibliography), those relevant to all conditions of use and not subject to harmonisation (A), and those relevant to specific conditions of use and not subject to harmonisation (S).

The functions and conditions of use, corresponding with the characteristics, marked with “S” in table 1, are specified in 4.4.

The manufacturer shall provide the data based on the results of tests specified in this document and, where relevant, in accordance with 5.1. The manufacturer shall provide information on how functioning joints can be made. Where products are jointed in the factory the water permeability and if relevant the strength of the joints shall be tested and data presented.

Covered in service Not covered in service Test Methods Remarks Nr Property to be tested GBR-P GBR-B GBR-C GBR-P GBR-B

GBR-P GBR-B GBR-C

Physical Properties

1 Thickness A A A A A

EN 1849-2 EN 1849-1 EN 964-1

2 Mass per unit area A A A A A

EN 1849-2 EN 1849-1 EN 14196:2003

Hydraulic Properties

3 Water permeability (liquid tightness)

H H H H H

pr EN 14150 pr EN 14150 ASTM D 5887-95

4 Swell Index - - A - -

- - ASTM D 5890-95

Mechanical Properties

5 Tensile strength

H H H H H

ISO R 527 EN 12311-1 EN ISO 10319 For GBR-P use ISO 527, parts 1 and 3, test specimen type 5 at a speed of 100 mm/min and report the maximum strength according to the test method. 6 Elongation A A A A A

ISO R 527 EN 12311-1 EN ISO 10319 For GBR-P use ISO 527 part 1 and 3, test specimen type 5 at a speed of 100 mm/min; calculation of elongation as defined in ISO 527-1, 10.2, using grip separation measurement. 7 Static Puncture H H H H H

EN ISO 12236 EN ISO 12236 EN ISO 12236

8 Burst Strength S S S S S

prEN 14151

prEN 14151 prEN 14151 This test applies to GBR-C only if they contain a polymeric or bituminous barrier element 9 Tear strength S S - S S

ISO 34 EN 12310-1 - For GBR-P use ISO 34 method B, angle specimen (Figure 2) without nick at a speed of 50 mm/min 10 Friction Direct shear S S S - -

prEN ISO 12957-1 prEN ISO 12957-1 prEN ISO 12957-1

11 Friction Inclined

Plane S S S - -

prEN ISO 12957-2 prEN ISO 12957-2 prEN ISO 12957-2

Thermal Properties

Covered in service Not covered in service Test Methods Remarks Nr Property to be tested GBR-P GBR-B GBR-C GBR-P GBR-B

GBR-P GBR-B GBR-C

12 Low temp behaviour (flexure) S S - S S

EN 495-5 EN 1109 -

13 Thermal expansion A - - A -

ASTM D 696-91 - -

Durability and Chemical Resistance

14 Weathering H H S H H

EN 12224 EN 12224 EN 12224 GBR-C: see 4.4.5 15 Micro organisms A A A A A

EN 12225 EN 12225 EN 12225

16 Oxidation H H H H H

prEN 14575 prEN 14575 prEN ISO 13438 prEN ISO 13438 is applicable for the geotextile elements and reinforcement yarns of GBR-C barriers

17 Environmental stress cracking H - S H -

ASTM D 5397-99 (appendix) - ASTM D 5397-99 (appendix) GBR-C: Only applicable to polymeric membrane element of the GBR-C 18 Leaching (water soluble) A A A A A

EN 14415

EN 14415 EN 14415

19 Wetting/drying - - S - -

- - prEN 14417

20 Freezing / thawing - - S - -

- - prEN 14418

21 Root penetration S S S S S

prCEN/TS 14416 prCEN/TS 14416 prCEN/TS 14416

Relevancy:

H : required for harmonisation;

A : relevant to all conditions of use; S : relevant to specific conditions of use;

-: not relevant

NOTE: Particular application cases may contain requirements about additional properties and - preferably standardised - test methods, if they are technically relevant and not conflicting with European Standards. The design life of the product should be determined, since its function may be temporary, as a construction expediency, or permanent, for the lifetime of the structure.

4.4.3 Friction characteristics (direct shear and inclined plane tests). Data on friction characteristics are required in all applications where differential movement may take place between the product and adjacent materials including, but not by way of limitation, geosynthetic barriers applied to slopes and certain types of anchoring arrangements.

NOTE 1: In addition to the friction characteristics information on the internal bonding strength of GBR-C in the direction of the actual stress may be relevant. A shear or peel test may be appropriate, particularly on slopes or in applications where shear stress may occur (i.e. during installation).

NOTE 2: Site specific testing should be carried out to establish the friction characteristics between all the materials used. 4.4.4 Low temperature behaviour Data on low temperature behaviour are required for applications where polymer and bituminous products may be exposed to low temperatures in storage, construction, and use

NOTE Tests which set simple pass/fail criteria at a single temperature condition may not be appropriate for this purpose.

Prehydrated GBR-C should not be stored or installed when the ambient temperature is below 0° C. 4.4.5 Weathering Data on weathering (combined effects of cycles of wetting, temperature change, and exposure to UV light) are required for applications where the GBR-C barrier will be exposed to weathering without adequate protective cover. It should be noted that in all normal situations GBR-C barriers should be covered with soil or other revetment on the same working day or prior to any circumstances which could cause a hydration of the clay component. 4.4.6

Resistance to wetting and drying Data on the resistance of GBR-C to repeated wetting and drying is required when the conditions of use will subject the product to this sequence of actions.

5 Evaluation of conformity 5.1 Presentation of characteristics The characteristics specified in Table 2, except for durability, expressed as mean values and tolerance limit(s) corresponding to the 95% confidence level, shall be given by the manufacturer, based on the statistical interpretation of his internal quality control measurements. Physical examination or preliminary testing, according to one of the test methods referenced in Table 1, may indicate that values obtained for a product lie below (or above) the sensitivity threshold established for that test method. In these particular circumstances the manufacturer may declare a value as being less (or greater) than this sensitivity threshold value. Information about durability shall be expressed in accordance with the guidelines of Annex B. 5.2 Verification of values The marking and labelling of the rolls and of the products shall be checked. The marking of the products shall be according to EN ISO 10320. NOTE: The method described in this Clause is not compulsory for an on-site control procedure. The compliance of characteristics with the values defined in 5.1 shall be based on measurements made on two representative samples (A and B), taken from two different rolls. Sampling shall be made in accordance with EN 963. The characteristics given in table 2 shall be measured in accordance with the corresponding European standards on specimens prepared from sample A.

If the test result(s) for a particular characteristic is (are) within the tolerance limit(s) given by the manufacturer, the product is accepted as complying with respect to this characteristic. If the test result(s) for a particular characteristic is (are) outside the tolerance limit(s), specimens prepared from sample B shall be tested. If the test result(s) of the sample B specimens for the same characteristic are within the given tolerance limit(s), the product is accepted as complying with respect to that characteristic. If the test result(s) is (are) outside the tolerance limit(s), the product is not accepted. 5.3 Initial type tests. Initial type tests shall be carried out by the manufacturer to define the values of the properties to be declared for the product to satisfy the requirements of this document. Initi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...