EN 1264-2:2021

(Main)Water based surface embedded heating and cooling systems - Part 2: Floor heating: Methods for the determination of the thermal output using calculations and experimental tests

Water based surface embedded heating and cooling systems - Part 2: Floor heating: Methods for the determination of the thermal output using calculations and experimental tests

The EN 1264 series gives guidelines for surface embedded heating and cooling systems installed in buildings, residential and non-residential (e.g. office, public, commercial and industrial buildings) and focuses on systems installed for the purpose of thermal comfort.

The EN 1264 series gives guidelines for water based heating and cooling systems embedded into the enclosure surfaces of the room to be heated or to be cooled. It also specifies the use of other heating media instead of water, as appropriate.

The EN 1264 series specifies standardized product characteristics by calculation and testing the thermal output of heating for technical specifications and certification. For the design, construction and operation of these systems, see EN 1264-3 and EN 1264-4 for the types A, B, C, D, H, I and J. For the types E, F and G, see the EN ISO 11855 series.

The systems specified in the EN 1264 series are adjoined to the structural base of the enclosure surfaces of the building, mounted directly or with fixing supports. The EN 1264 series does not specify ceiling systems mounted in a suspended ceiling with a designed open air gap between the system and the building structure which allows the thermally induced circulation of the air. The thermal output of these systems can be determined according to the EN 14037 series and EN 14240.

EN 1264-2 specifies hot water floor heating systems. The application of EN 1264-5 requires the prior use of EN 1264-2. EN 1264-5 specifies the conversion of the thermal output of floor heating systems determined in EN 1264-2 into the thermal output of heating surfaces embedded in walls and ceilings as well as into the thermal output of cooling surfaces embedded in floors, walls and ceilings.

EN 1264-2 specifies the boundary conditions and the test methods for the determination of the thermal output of hot water floor heating systems as a function of the temperature difference between the heating medium and the room temperature.

The thermal output is tested by a calculation method and by a measurement method. The calculation method is applicable to systems corresponding to the definitions in EN 1264-1 (type A, B, C, D, H, I and J). The measurement method gives guidance for systems not corresponding to these definitions. The calculation method and the measurement method are consistent with each other and provide correlating and adequate test results.

The test results, expressed depending on further parameters, are the standard specific thermal output and the associated standard temperature difference between the heating medium and the room temperature as well as fields of characteristic curves showing the relationship between the specific thermal output and the temperature difference between the heating medium and the room.

Raumflächenintegrierte Heiz- und Kühlsysteme mit Wasserdurchströmung - Teil 2: Fußbodenheizung: Prüfverfahren für die Bestimmung der Wärmeleistung unter Benutzung von Berechnungsmethoden und experimentellen Methoden

EN 1264 gibt Leitlinien für in Wohn- und anderen Gebäuden (z. B. Bürogebäuden, öffentlichen Gebäuden sowie Gewerbe- und Industriegebäuden) installierte raumflächenintegrierte Heiz- und Kühlsysteme und legt einen Schwerpunkt auf Systeme, die für den Zweck der thermischen Behaglichkeit installiert werden.

Die Normenreihe EN 1264 gibt Leitlinien für Heiz- und Kühlsysteme mit Wasserdurchströmung, die in die Raum¬umschließungsflächen des zu heizenden oder des zu kühlenden Raumes eingebettet sind. Sie legt ggf. auch die entsprechende Verwendung anderer Heizmittel als Wasser fest.

Die Normenreihe EN 1264 legt die Identifizierung standardisierter Produktmerkmale durch Berechnung und Prüfung der Wärmeleistung der Heizung für technische Spezifikationen und die Zertifizierung fest. Für das Design, den Bau und den Betrieb dieser Anlagen siehe EN 1264 3 und EN 1264 4 für die Typen A, B, C, D, H, I und J. Für die Typen E, F und G siehe Normenreihe EN ISO 11855.

Die in der Normenreihe EN 1264 festgelegten Systeme grenzen an den tragenden Untergrund der Umschließungsflächen des Gebäudes an und werden direkt oder mit Befestigungshalterungen angebracht. Die Normenreihe EN 1264 trifft keine Festlegungen für in abgehängten Decken montierte Deckensysteme mit einem auslegungsgemäßen offenen Luftspalt zwischen dem System und der Gebäudestruktur, der eine thermisch induzierte Umwälzung der Luft erlaubt. Die Wärmeleistung dieser Systeme kann nach der Normenreihe EN 14037 und EN 14240 bestimmt werden.

EN 1264 2 legt Warmwasser-Fußbodenheizsysteme fest. Die Anwendung von EN 1264 5 erfordert die vorherige Anwendung von EN 1264 2. EN 1264 5 legt die Umrechnung der in EN 1264 2 bestimmten Wärmeleistung der Fußbodenheizsysteme in die Wärmeleistung von Heizflächen in Wänden und Decken sowie in die Kühlleistung von Kühlflächen in Fußböden, Wänden und Decken fest.

EN 1264 2 legt die Randbedingungen und die Prüfverfahren für die Bestimmung der Wärmeleistung von Warmwasser-Fußbodenheizsystemen in Abhängigkeit von der Differenz zwischen der Heizmittel- und der Raumtemperatur fest.

Die Wärmeleistung wird durch ein Berechnungsverfahren und ein Messverfahren geprüft. Das Berechnungsverfahren ist auf Systeme anwendbar, die den Definitionen nach EN 1264 1 (Typ A, B, C, D, H, I und J) entsprechen. Bei Systemen, die diesen Definitionen nicht entsprechen, gibt das Messverfahren Leitlinien. Das Berechnungsverfahren und das Messverfahren entsprechen einander und liefern korrelierende, adäquate Prüfergebnisse.

Als Prüfergebnisse werden die spezifische Norm-Wärmeleistung mit der zugehörigen Norm-Differenz zwischen der Heizmittel- und der Raumtemperatur sowie Kennlinienfelder für die Beziehung zwischen der spezifischen Wärmeleistung und der Differenz zwischen der Heizmittel- und der Raumtemperatur in Abhängigkeit von weiteren Parametern angegeben.

Systèmes de surfaces chauffantes et rafraîchissantes hydrauliques intégrées - Partie 2: Chauffage par le sol: Méthodes de démonstration pour la détermination de l'émission thermique utilisant des méthodes par le calcul et à l'aide de méthodes d'essai

La série EN 1264 fournit des lignes directrices pour les systèmes de surfaces chauffantes et rafraîchissantes intégrées dans les bâtiments résidentiels et non résidentiels (par exemple, des bureaux, des bâtiments publics, commerciaux et industriels), et se concentre sur les systèmes installés à des fins de confort thermique.

La série EN 1264 fournit des lignes directrices pour les systèmes de surfaces chauffantes et rafraîchissantes intégrées dans les parois des pièces à chauffer ou à rafraîchir. Elle spécifie également l'utilisation de fluides caloporteurs autres que l'eau, le cas échéant.

La série EN 1264 spécifie les caractéristiques normalisées des produits en calculant et en mettant à l'essai l'émission thermique du chauffage pour les spécifications techniques et la certification. Pour la conception, la construction et le fonctionnement de ces systèmes, voir l'EN 1264-3 et l'EN 1264-4 pour les types A, B, C, D, H, I et J. Pour les types E, F et G, voir la série EN ISO 11855.

Les systèmes spécifiés dans la série EN 1264 sont fixés directement ou à l'aide de supports de fixation au plancher porteur des parois du bâtiment. La série EN 1264 ne spécifie pas les systèmes de plafond montés dans un plafond suspendu, dont l'entrefer ouvert conçu entre le système et la structure du bâtiment permet la circulation de l'air induite par la chaleur. L'émission thermique de ces systèmes peut être déterminée selon la série EN 14037 et l'EN 14240.

L'EN 1264-2 spécifie les systèmes de chauffage hydrauliques par le sol. L'application de l'EN 1264-5 nécessite l'utilisation préalable de l'EN 1264-2. L'EN 1264-5 spécifie la conversion de l'émission thermique des systèmes de chauffage par le sol déterminée dans l'EN 1264-2 en émission thermique des surfaces chauffantes intégrées dans les murs et les plafonds ou en émission thermique des surfaces rafraîchissantes intégrées dans les sols, les murs et les plafonds.

L'EN 1264-2 spécifie les conditions limites et les méthodes d'essai pour la détermination de l'émission thermique des systèmes de chauffage par le sol à circulation d'eau chaude sous la forme d'une fonction de la différence de température entre le fluide caloporteur et la température ambiante.

L'émission thermique est mise à l'essai par une méthode de calcul et par une méthode de mesure. La méthode de calcul s'applique aux systèmes correspondant aux définitions données dans l'EN 1264-1 (types A, B, C, D, H, I et J). La méthode de mesure fournit des recommandations pour les systèmes ne correspondant pas à ces définitions. Ces deux méthodes sont convergentes et fournissent des résultats d'essai concordants.

Les résultats de l'essai, exprimés en fonction d'autres paramètres, constituent l'émission thermique surfacique normalisée et la différence de température normalisée associée entre le fluide caloporteur et la pièce, ainsi que les familles des courbes caractéristiques qui montrent la relation existant entre l'émission thermique surfacique et la différence de température entre le fluide caloporteur et la pièce.

Ploskovni sistemi za ogrevanje in hlajenje z vodo - 2. del: Talno ogrevanje - Metode za določevanje oddaje toplote z izračuni in preskušanjem

General Information

- Status

- Published

- Publication Date

- 18-May-2021

- Withdrawal Date

- 29-Nov-2021

- Technical Committee

- CEN/TC 130 - Space heating appliances without integral heat sources

- Drafting Committee

- CEN/TC 130/WG 9 - Floor heating - Systems and components

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 19-May-2021

- Due Date

- 15-Jul-2021

- Completion Date

- 19-May-2021

Relations

- Effective Date

- 26-May-2021

- Refers

EN 1264-3:2021 - Water based surface embedded heating and cooling systems - Part 3: Dimensioning - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 12828:2012+A1:2014 - Heating systems in buildings - Design for water-based heating systems - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 1264-4:2009 - Water based surface embedded heating and cooling systems - Part 4: Installation - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 1264-3:2009 - Water based surface embedded heating and cooling systems - Part 3: Dimensioning - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1264-2:2021 (CEN) defines methods to determine the thermal output of water‑based, surface‑embedded floor heating systems using both calculation and experimental tests. It is part of the EN 1264 series for water‑based heating and cooling systems embedded in building enclosure surfaces and focuses on thermal comfort applications in residential and non‑residential buildings. The standard establishes boundary conditions, test procedures and the form of test results (characteristic curves, standard specific thermal output and associated temperature differences).

Key Topics

- Scope and system types: Applies to hot‑water floor heating systems and supports systems defined in EN 1264‑1 (types A, B, C, D, H, I, J). Systems outside these definitions can be assessed via the measurement method.

- Two complementary methods:

- Calculation method for systems that meet EN 1264‑1 definitions.

- Measurement method for systems not covered by the calculation approach; both methods are designed to correlate.

- Thermal boundary conditions: Defines reference conditions (standard indoor temperature 20 °C) and links between average and maximum surface temperatures (examples in the standard include limits such as 29 °C and 35 °C for max surface temperatures under defined conditions).

- Characteristic outputs: Produces characteristic partial‑load curves, standard specific thermal output, standard temperature difference between heating medium and room, and limit curves (maximum permissible specific output).

- Test setup and documentation: System supplier documentation, detailed installation drawings, and a demonstration surface (approx. 2 m × 2 m) are required for testing. Clause 12 adds calculation of the system’s specific heat capacity (C‑Value).

- Material and flow requirements: Considers thermal conductivity of materials, downward heat loss, and hydraulic conditions (e.g., turbulent pipe flow criterion m/d > 4 000 kg/(h·m) is referenced).

Applications and Users

Who benefits from EN 1264‑2:2021:

- HVAC designers and engineers - for reliable thermal output data used in heat‑load calculations and dimensioning (see EN 1264‑3 for design).

- Manufacturers and product certifiers - to provide standardized ratings for product datasheets and certification.

- Testing and certification laboratories - to perform calculation and experimental tests and issue comparable performance data.

- Installers and specifiers - to verify system installation matches tested configurations (installation guidance is covered in EN 1264‑4).

- Building owners and consultants - to compare system performance and ensure compliance with tender and procurement requirements.

Practical uses include product comparison, system rating for tenders, conversion of floor heating output to wall/ceiling systems (EN 1264‑5), and ensuring predictable comfort performance.

Related Standards

- EN 1264‑1: Definitions and symbols

- EN 1264‑3: Dimensioning

- EN 1264‑4: Installation

- EN 1264‑5: Conversion to wall/ceiling heating and cooling

- EN ISO 11855: For types E, F, G systems

- EN 14037 / EN 14240: Thermal output of suspended ceiling systems

Keywords: EN 1264-2:2021, floor heating, water based surface embedded heating, thermal output, calculation method, measurement method, characteristic curves, CEN.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 1264-2:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Water based surface embedded heating and cooling systems - Part 2: Floor heating: Methods for the determination of the thermal output using calculations and experimental tests". This standard covers: The EN 1264 series gives guidelines for surface embedded heating and cooling systems installed in buildings, residential and non-residential (e.g. office, public, commercial and industrial buildings) and focuses on systems installed for the purpose of thermal comfort. The EN 1264 series gives guidelines for water based heating and cooling systems embedded into the enclosure surfaces of the room to be heated or to be cooled. It also specifies the use of other heating media instead of water, as appropriate. The EN 1264 series specifies standardized product characteristics by calculation and testing the thermal output of heating for technical specifications and certification. For the design, construction and operation of these systems, see EN 1264-3 and EN 1264-4 for the types A, B, C, D, H, I and J. For the types E, F and G, see the EN ISO 11855 series. The systems specified in the EN 1264 series are adjoined to the structural base of the enclosure surfaces of the building, mounted directly or with fixing supports. The EN 1264 series does not specify ceiling systems mounted in a suspended ceiling with a designed open air gap between the system and the building structure which allows the thermally induced circulation of the air. The thermal output of these systems can be determined according to the EN 14037 series and EN 14240. EN 1264-2 specifies hot water floor heating systems. The application of EN 1264-5 requires the prior use of EN 1264-2. EN 1264-5 specifies the conversion of the thermal output of floor heating systems determined in EN 1264-2 into the thermal output of heating surfaces embedded in walls and ceilings as well as into the thermal output of cooling surfaces embedded in floors, walls and ceilings. EN 1264-2 specifies the boundary conditions and the test methods for the determination of the thermal output of hot water floor heating systems as a function of the temperature difference between the heating medium and the room temperature. The thermal output is tested by a calculation method and by a measurement method. The calculation method is applicable to systems corresponding to the definitions in EN 1264-1 (type A, B, C, D, H, I and J). The measurement method gives guidance for systems not corresponding to these definitions. The calculation method and the measurement method are consistent with each other and provide correlating and adequate test results. The test results, expressed depending on further parameters, are the standard specific thermal output and the associated standard temperature difference between the heating medium and the room temperature as well as fields of characteristic curves showing the relationship between the specific thermal output and the temperature difference between the heating medium and the room.

The EN 1264 series gives guidelines for surface embedded heating and cooling systems installed in buildings, residential and non-residential (e.g. office, public, commercial and industrial buildings) and focuses on systems installed for the purpose of thermal comfort. The EN 1264 series gives guidelines for water based heating and cooling systems embedded into the enclosure surfaces of the room to be heated or to be cooled. It also specifies the use of other heating media instead of water, as appropriate. The EN 1264 series specifies standardized product characteristics by calculation and testing the thermal output of heating for technical specifications and certification. For the design, construction and operation of these systems, see EN 1264-3 and EN 1264-4 for the types A, B, C, D, H, I and J. For the types E, F and G, see the EN ISO 11855 series. The systems specified in the EN 1264 series are adjoined to the structural base of the enclosure surfaces of the building, mounted directly or with fixing supports. The EN 1264 series does not specify ceiling systems mounted in a suspended ceiling with a designed open air gap between the system and the building structure which allows the thermally induced circulation of the air. The thermal output of these systems can be determined according to the EN 14037 series and EN 14240. EN 1264-2 specifies hot water floor heating systems. The application of EN 1264-5 requires the prior use of EN 1264-2. EN 1264-5 specifies the conversion of the thermal output of floor heating systems determined in EN 1264-2 into the thermal output of heating surfaces embedded in walls and ceilings as well as into the thermal output of cooling surfaces embedded in floors, walls and ceilings. EN 1264-2 specifies the boundary conditions and the test methods for the determination of the thermal output of hot water floor heating systems as a function of the temperature difference between the heating medium and the room temperature. The thermal output is tested by a calculation method and by a measurement method. The calculation method is applicable to systems corresponding to the definitions in EN 1264-1 (type A, B, C, D, H, I and J). The measurement method gives guidance for systems not corresponding to these definitions. The calculation method and the measurement method are consistent with each other and provide correlating and adequate test results. The test results, expressed depending on further parameters, are the standard specific thermal output and the associated standard temperature difference between the heating medium and the room temperature as well as fields of characteristic curves showing the relationship between the specific thermal output and the temperature difference between the heating medium and the room.

EN 1264-2:2021 is classified under the following ICS (International Classification for Standards) categories: 91.140.10 - Central heating systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1264-2:2021 has the following relationships with other standards: It is inter standard links to EN 1264-2:2008+A1:2012, EN 1264-3:2021, EN 15377-1:2008, EN 1264-5:2021, EN 12828:2012+A1:2014, EN 16904:2025, CEN/TR 15316-6-2:2017, EN 12828:2012, EN 1264-4:2009, EN 15316-2:2017, EN 1264-3:2009, EN ISO 11855-2:2015, EN 1264-1:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1264-2:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2021

Nadomešča:

SIST EN 1264-2:2009+A1:2013

Ploskovni sistemi za ogrevanje in hlajenje z vodo - 2. del: Talno ogrevanje -

Metode za določevanje oddaje toplote z izračuni in preskušanjem

Water based surface embedded heating and cooling systems - Part 2: Floor heating:

Methods for the determination of the thermal output using calculations and experimental

tests

Raumflächenintegrierte Heiz- und Kühlsysteme mit Wasserdurchströmung - Teil 2:

Fußbodenheizung: Prüfverfahren für die Bestimmung der Wärmeleistung unter

Benutzung von Berechnungsmethoden und experimentellen Methoden

Systèmes de surfaces chauffantes et rafraîchissantes hydrauliques intégrées - Partie 2:

Chauffage par le sol: Méthodes de démonstration pour la détermination de l'émission

thermique utilisant des méthodes par le calcul et à l'aide de méthodes d'essai

Ta slovenski standard je istoveten z: EN 1264-2:2021

ICS:

91.140.10 Sistemi centralnega Central heating systems

ogrevanja

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1264-2

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2021

EUROPÄISCHE NORM

ICS 91.140.10 Supersedes EN 1264-2:2008+A1:2012

English Version

Water based surface embedded heating and cooling

systems - Part 2: Floor heating: Methods for the

determination of the thermal output using calculations and

experimental tests

Systèmes de surfaces chauffantes et rafraîchissantes Raumflächenintegrierte Heiz- und Kühlsysteme mit

hydrauliques intégrées - Partie 2: Chauffage par le sol: Wasserdurchströmung - Teil 2: Fußbodenheizung:

Méthodes de démonstration pour la détermination de Prüfverfahren für die Bestimmung der Wärmeleistung

l'émission thermique utilisant des méthodes par le unter Benutzung von Berechnungsmethoden und

calcul et à l'aide de méthodes d'essai experimentellen Methoden

This European Standard was approved by CEN on 12 April 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1264-2:2021 E

worldwide for CEN national Members.

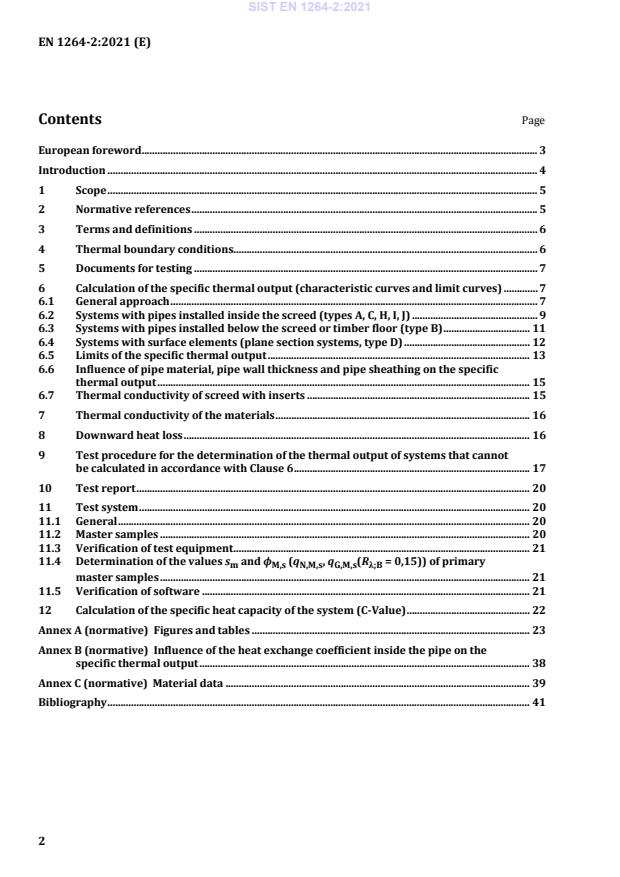

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Thermal boundary conditions . 6

5 Documents for testing . 7

6 Calculation of the specific thermal output (characteristic curves and limit curves) . 7

6.1 General approach . 7

6.2 Systems with pipes installed inside the screed (types A, C, H, I, J) . 9

6.3 Systems with pipes installed below the screed or timber floor (type B) . 11

6.4 Systems with surface elements (plane section systems, type D) . 12

6.5 Limits of the specific thermal output . 13

6.6 Influence of pipe material, pipe wall thickness and pipe sheathing on the specific

thermal output . 15

6.7 Thermal conductivity of screed with inserts . 15

7 Thermal conductivity of the materials . 16

8 Downward heat loss . 16

9 Test procedure for the determination of the thermal output of systems that cannot

be calculated in accordance with Clause 6 . 17

10 Test report . 20

11 Test system . 20

11.1 General . 20

11.2 Master samples . 20

11.3 Verification of test equipment . 21

11.4 Determination of the values s and ϕ (q , q (R = 0,15)) of primary

m M,s N,M,s G,M,s λ;B

master samples . 21

11.5 Verification of software . 21

12 Calculation of the specific heat capacity of the system (C-Value) . 22

Annex A (normative) Figures and tables . 23

Annex B (normative) Influence of the heat exchange coefficient inside the pipe on the

specific thermal output . 38

Annex C (normative) Material data . 39

Bibliography . 41

European foreword

This document (EN 1264-2:2021) has been prepared by Technical Committee CEN/TC 130 “Space

heating appliances without integral heat sources”, the secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2021 and conflicting national standards

shall be withdrawn at the latest by November 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1264-2:2008+A1:2012.

The main changes compared to the previous edition are listed below:

a) Modification of the Title;

b) Clarification of the Scope;

c) Improved wording, especially the term “prove method”;

d) Modification of Clause 9;

e) Deletion of Clause 10, Test procedure for the determination of the effective thermal resistance of

carpets and all references to this Clause;

f) Deletion of Figures A.9, A.10 and A.11;

g) Table A.13, Heat conductivities for materials was moved to the new Annex C and was modified;

h) Deletion of Annex B, Test procedure for the determination of parameters for application in the

EN 15377 series;

i) Addition of new Clause 12, Calculation of the specific heat capacity of the system (C-Value).

EN 1264, Water based surface embedded heating and cooling systems, consists of the following parts:

— Part 1: Definitions and symbols;

— Part 2: Floor heating: Methods for the determination of the thermal output using calculations and

experimental tests;

— Part 3: Dimensioning;

— Part 4: Installation;

— Part 5: Determination of the thermal output for wall and ceiling heating and for floor, wall and ceiling

cooling.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

The EN 1264 series is based on the realization that in the field of commercial trade, the thermal output

of heating and cooling systems represents the basis of rating. In order to be able to evaluate and

compare different heating and/or cooling systems, it is therefore necessary to refer to values

determined using one single, unambiguously defined method. The basis for doing so is the test methods

for the determination of the thermal output of floor heating systems specified in EN 1264-2. In analogy

to EN 442-2, Radiators and convectors — Part 2: Test methods and rating, these test methods provide

characteristic partial load curves under defined boundary conditions as well as the characteristic

output of the system represented by the standard thermal output together with the associated standard

temperature difference between the heating medium and the room temperature.

1 Scope

The EN 1264 series gives guidelines for surface embedded heating and cooling systems installed in

buildings, residential and non-residential (e.g. office, public, commercial and industrial buildings) and

focuses on systems installed for the purpose of thermal comfort.

The EN 1264 series gives guidelines for water based heating and cooling systems embedded into the

enclosure surfaces of the room to be heated or to be cooled. It also specifies the use of other heating

media instead of water, as appropriate.

The EN 1264 series specifies standardized product characteristics by calculation and testing the

thermal output of heating for technical specifications and certification. For the design, construction and

operation of these systems, see EN 1264-3 and EN 1264-4 for the types A, B, C, D, H, I and J. For the

types E, F and G, see the EN ISO 11855 series.

The systems specified in the EN 1264 series are adjoined to the structural base of the enclosure

surfaces of the building, mounted directly or with fixing supports. The EN 1264 series does not specify

ceiling systems mounted in a suspended ceiling with a designed open air gap between the system and

the building structure which allows the thermally induced circulation of the air. The thermal output of

these systems can be determined according to the EN 14037 series and EN 14240.

EN 1264-2 specifies hot water floor heating systems. The application of EN 1264-5 requires the prior

use of EN 1264-2. EN 1264-5 specifies the conversion of the thermal output of floor heating systems

determined in EN 1264-2 into the thermal output of heating surfaces embedded in walls and ceilings as

well as into the thermal output of cooling surfaces embedded in floors, walls and ceilings.

EN 1264-2 specifies the boundary conditions and the test methods for the determination of the thermal

output of hot water floor heating systems as a function of the temperature difference between the

heating medium and the room temperature.

The thermal output is tested by a calculation method and by a measurement method. The calculation

method is applicable to systems corresponding to the definitions in EN 1264-1 (type A, B, C, D, H, I

and J). The measurement method gives guidance for systems not corresponding to these definitions.

The calculation method and the measurement method are consistent with each other and provide

correlating and adequate test results.

The test results, expressed depending on further parameters, are the standard specific thermal output

and the associated standard temperature difference between the heating medium and the room

temperature as well as fields of characteristic curves showing the relationship between the specific

thermal output and the temperature difference between the heating medium and the room.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1264-1, Water based surface embedded heating and cooling systems — Part 1: Definitions and symbols

EN 1264-3:2021, Water based surface embedded heating and cooling systems — Part 3: Dimensioning

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1264-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

4 Thermal boundary conditions

A floor heating surface with a given average surface temperature exchanges the same thermal output in

any room with the same indoor room temperature (standard indoor room temperature ϑ). It is

i

therefore possible to give a basic characteristic curve of the relationship between specific thermal

output and average surface temperature that is independent of the heating system and applicable to all

floor heating surfaces (including those having peripheral areas with greater heat emissions) (see

Figure A.1 in normative Annex A).

In contrast, every floor heating system has its own maximum permissible specific thermal output, the

limit specific thermal output, q . This output is calculated for an ambient (standard) indoor room

G

temperature ϑ = 20 °C. The other condition is the maximum surface temperature ϑ = 29 °C at

i F,max

temperature drop between supply and return of the heating medium σ = 0 K. The maximum specific

thermal output for the peripheral area will be achieved at a maximum surface temperature

ϑ = 35 °C and σ = 0 K.

F,max

For the calculation and for the test procedure, the centre of the heating surface is used as the reference

point for ϑ , regardless of system type.

F, max

The average surface temperature ϑ , determining the specific thermal output (see basic characteristic

F, m

curve) is linked with the maximum surface temperature. In this context, ϑ < ϑ always applies.

F,m F, max

The achievable value ϑ depends on both the floor heating system and the operating conditions

F,m

(temperature drop σ = ϑ − ϑ , downward thermal output q and thermal resistance of the floor

V R u

covering R ).

λ,B

National regulations can limit this temperature to a lower value.

Some floor covering materials can require lower temperatures.

The calculation of the specific thermal output is based on the following conditions:

— the heat transfer at the floor surface occurs in accordance with the basic characteristic curve;

— the temperature drop of the heating medium σ = 0; the extent to which the characteristic curve

depends on the temperature drop, is covered by using the logarithmically determined temperature

difference between the heating medium and the room Δϑ (see Formula (1));

H

— turbulent pipe flow: m /d > 4 000 kg/(h ∙ m);

H i

— there is no lateral heat flow;

— the heat-conducting layer of the floor heating system is thermally decoupled by thermal insulation

from the structural base of the building. The thermal insulation need not be directly below the

system.

The aforementioned last condition does not concern the test procedure of Clause 9.

5 Documents for testing

The system supplier’s documents are taken as the basis for the determination of the thermal output.

The following documents shall be provided:

— installation drawing (section) of the floor heating system, covering two pipe spacing, including the

peripheral area and giving information on the materials used (if necessary, the test results

regarding the thermal conductivity values of the materials shall be provided);

— technical documentation of the system.

This information shall contain any details necessary for the calculation of the construction customary

on site. It shall be submitted to the installer in the same form.

With a member of the testing body present, a demonstration surface of approximately 2 m × 2 m is

constructed to represent the actual construction used on site.

6 Calculation of the specific thermal output (characteristic curves and limit

curves)

6.1 General approach

The specific thermal output q at the surface of a floor is determined by the following parameters:

— Pipe spacing T;

— Thickness s and thermal conductivity λ of the layer above the pipe;

u E

— Thermal conduction resistance R of the floor covering;

λ,B

— Pipe external diameter D = d , including the sheathing (D = d ) if necessary and the thermal

a M

conductivity of the pipe λ or the sheathing λ . In case of pipes having non-circular cross sections,

R M

the equivalent diameter of a circular pipe having the same circumference shall be used in the

calculation (the screed covering shall not be changed). Thickness and thermal conductivity of

permanently mounted diffusion barrier layers with a thickness up to 0,3 mm need not be

considered in the calculation. In this case, D = d shall be used;

a

— Heat diffusion devices having the characteristic value K in accordance with 6.3;

WL

— Contact between the pipes and the heat diffusion devices or the screed, characterized by the factor

a .

K

The calculation method is limited to the boundary conditions listed in Table 1.

Table 1 — Criteria for selection of the simplified calculation method

Type of Figure Boundary conditions Reference to

system method

A, C, H, I, J Figure A.2 T ≥ 0,050 m 6.2

s ≥ 0,01 m

u

0,008 m ≤ D ≤ 0,03 m

s /λ ≥ 0,01

u e

B Figure A.3 0,05 m ≤ T ≤ 0,45 m 6.3

0,014 m ≤ D ≤ 0,022 m

0,01 m ≤ s /λ ≤ 0,18

u e

D Figure A.4 6.4

n

The specific thermal output is proportional to (Δϑ ) , where the temperature difference between the

H

heating medium and the room temperature is:

ϑ −ϑ

V R

∆ϑ =

H

ϑ −ϑ

V i

ln

ϑϑ−

Ri

(1)

and where experimental and theoretical investigations of the exponent n have shown that:

10,,<

(2)

Within the limits of the achievable accuracy,

n = 1

is used.

The specific thermal output is calculated using Formula (3).

m

i

q B⋅ a ⋅∆ϑ

i H

∏

i

(3)

where

B

is a system-dependent coefficient, in W/(m ∙ K);

m is a power product linking the parameters of the floor construction with one another

i

a

i

∏

(see 6.2, 6.3 and 6.4).

i

A distinction shall be made between systems, where the pipes are installed inside or below the screed

or wood floors, and systems with surface elements (plane section systems). For usual constructions,

Formula (3) applies directly. For systems with additional devices for heat distribution, for air filled

hollow sections or for other components influencing the heat distribution, the thermal output is

determined experimentally in accordance with Clause 9.

6.2 Systems with pipes installed inside the screed (types A, C, H, I, J)

For these systems (see Figure A.2), the characteristic curves are calculated in accordance with

Formula (4).

mm

m

TD

u

q= Ba⋅ ⋅ a ⋅⋅a a ∆⋅ϑ

BT u D H

(4)

mm

m

TD

u

The product Ba⋅ ⋅⋅a a ⋅ a is called the equivalent heat transmission coefficient K , which leads

H

BT u D

to the abbreviated form of the expression, Formula (5):

qK= ⋅∆ϑ

H H

(5)

where

2 2

B = B = 6,7 W/(m ∙ K) for a pipe thermal conductivity λ = λ = 0,35 W/(m ∙ K) and a pipe wall

0 R R,0

thickness s = s = (d − d )/2 = 0,002 m;

R R,0 a i

a is a spacing factor in accordance with Table A.1; a = f (R );

T T λ,B

a is a covering factor in accordance with Table A.2; a = f (T, R );

u u λ,B

a is the pipe external diameter factor in accordance with Table A.3; a = f (T,

D D

R ).

λ,B

applies where 0,,050 m≤≤T 0 375 m (6)

T

m 1−

T

0,075

(7)

applies where s ≥ 0,010 m

ms=100⋅ 0,045−

( )

u

uu

applies where 0,,008 m≤≤D 0 030 m

(8)

mD250⋅− 0,020

( )

D

=

=

=

For other materials with different heat conductivities or for different pipe wall thicknesses, or for

sheathed pipes, B shall be calculated in accordance with 6.6.

For a heating screed, a value for λ of Table C.1 shall be used. If a different value is used, its validity shall

E

be checked.

a is the floor covering factor in accordance with Formula (9):

B

s

1 u,0

+

α λ

u,0

(9)

a =

B

s

u,0

++ R

λ,B

αλ

E

where

α

= 10,8 W/(m ∙ K);

λ = 1 W/(m ∙ K);

u,0

s = 0,045 m;

u,0

R

is the thermal conduction resistance of the floor covering, in m ∙ K/W;

λ,B

λ is the thermal conductivity of the screed, in W/(m ∙ K);

E

In Formulae (6), (7) and (8)

T is the pipe spacing;

D is the external diameter of the pipe, including sheathing, where applicable;

s is the thickness of the screed covering above the pipe.

u

For a pipe spacing T > 0,375 m, the specific thermal output is approximately calculated using

0,375

qq=

0,375

T

(10)

where

q is the specific thermal output, calculated for a spacing T = 0,375 m.

0,375

*

For systems with s ≤ 0,065 m as well as 0,065 m < s ≤ s , Formula (4) applies directly. The value of

u u

u

*

s depends on the pipe spacing as follows:

u

*

For a spacing T ≤ 0,200 m, s = 0,100 m applies.

u

*

For a spacing T > 0,200 m, s = 0,5 T applies. In this relation, always the actual spacing T shall be used,

u

even if the calculation is done in accordance with Formula (10).

*

For coverings above the pipe s > s , Formula (5) shall be used. In this case, the equivalent heat

u

u

transmission coefficient shall be determined in accordance with the Formula (11):

K =

H

*

ss−

uu

+

K λ

*

E

H, ss=

uu

(11)

*

In Formula (11), K is the power product from Formula (4), calculated for a covering s above

*

u

H, ss=

uu

the pipe.

The limit curves are calculated in accordance with 6.5.

6.3 Systems with pipes installed below the screed or timber floor (type B)

For these systems (see Figure A.3), the variable thickness s of the weight bearing layer and its variable

u

thermal conductivity λ are covered by the factor a . The pipe diameter has no effect. However, the

E u

contact between the heating pipe and the heat diffusion device or any other heat distribution device is

an important parameter. In this case, the characteristic curve is calculated using Formula (12):

m

T

q Ba⋅ ⋅ a ⋅⋅a a ⋅ a ⋅∆ϑ

B T u WL K H

(12)

where

B

= B = 6,5 W/(m ∙ K) under the conditions given for Formulae (4) and (5);

a is the pipe spacing factor in accordance with Table A.8; a = f (s /λ );

T T u E

m see Formula (6);

T

a is the covering factor, which is calculated in accordance with Formula (13):

u

s

1 u,0

+

α λ

u,0

a =

u

s

u

+

α λ

E

(13)

where

α = 10,8 W/(m ∙ K);

λ = 1 W/(m ∙ K);

u,0

= 0,045 m;

s

u,0

a is the heat conduction factor (see Tables A.10 onwards); a = f (K , T, D).

WL WL WL

=

Formula (14) applies to the characteristic value K :

WL

s ⋅λλ+ bs⋅⋅

WL WL u u E

K =

WL

0,125

(14)

where

b = f (T) shall be taken from Table A.9;

u

s ∙ λ is the product of the thickness and the thermal conductivity of the heat diffusion device;

WL WL

s ∙ λ is the product of the thickness and the thermal conductivity of the screed or timber

u E

covering.

If the width L of the heat diffusion device is smaller than the pipe spacing T, the value a

WL,L = T

determined in accordance with Tables A.10 onwards, shall be corrected using Formula (15):

LL L

aa= − a − a 1−+3,,2 3 4 − 1,2

( )

WL WL,L T WL,L T WL,L 0

T T T

(15)

The heat conduction factors a and a shall be taken from Tables A.10 to A.15. For L = T, the

WL,L = T WL,L = 0

tables with K in accordance with Formula (14) apply directly, for L = 0, the tables apply with K

WL WL

determined in accordance with Formula (14) with s = 0.

WL

a is the correction factor for the contact in accordance with Table A.9; a = f (T).

K K

The correction factor for the contact a covers additional thermal transmission resistances due to cases

K

where there is only spot or line contact between the heating pipe and the heat diffusion device. These

resistances depend on the manufacturing tolerances of the pipes and heat conduction devices as well as

on the care taken in installing them, and are, therefore, subject to fluctuations in individual cases. For

this reason, Table A.16 gives a calculated average value for a .

K

is the floor covering factor:

a

B

a = (16)

B

m

T

1+⋅Ba ⋅ a ⋅ a ⋅⋅a R ⋅ f T

( )

u T WL K λ,B

with f (T) = 1 + 0,44 T

The limit curves are calculated in accordance with 6.5.

6.4 Systems with surface elements (plane section systems, type D)

For floors covered with surface elements (see Figure A.4), Formula (17) applies:

m

T

q Ba⋅ ⋅ a ⋅ a ⋅∆ϑ

BT u H

(17)

=

===

where

B = B = 6,5 W/(m ∙ K) and

m

= 1,06;

T

a

T

a is the covering factor in accordance with Formula (13);

u

a is the floor covering factor:

B

a = (18)

B

m

T

1+⋅Ba ⋅⋅a R

uT λ,B

6.5 Limits of the specific thermal output

The procedure for the determination of the limits of the specific thermal output is shown in principle

within Figure A.5.

The limit curve (see Figure A.5) gives the relationship between the specific thermal output and the

temperature difference between the heating medium and the room for cases where the maximum

permissible difference between surface temperature and indoor room temperature (9 K or 15 K

respectively) is achieved.

The limit curve is calculated using Formula (19):

n

G

∆θ

H

q ϕ⋅ B ⋅

GG

ϕ

(19)

where

B is a coefficient in accordance with Table A.4 (applicable to s /λ ≤ 0,079 2) and Table A.5

G u E

(applicable to s /λ > 0,079 2) for type A, C, H, I and J systems or in accordance with Table A.17 for

u E

type B systems; or B = 100 W/(m ∙ K) for systems with surface elements of type D;

G

n is an exponent in accordance with Table A.6 (applicable to s /λ ≤ 0,079 2) and Table A.7

G u E

(applicable to s /λ > 0,079 2) for type A, C, H, I and J systems or in accordance with Table A.18 for

u E

type B systems; or n = 0 for systems with surface elements of type D;

G

φ is a factor for the conversion to any values of the temperatures ϑ and ϑ .

F,max i

11,

ϑϑ−

F,max i

ϕϑ with ∆ 9K

o

∆ϑ

o

(20)

The limit temperature difference between the heating medium and the room Δϑ is calculated using

H,G

Formula (21) from the intersection of the characteristic curve with the limit curve (see Figure A.5):

1−n

G

B

G

∆=ϑϕ⋅

HG,

m

i

Ba⋅

i

∏

i

(21)

==

=

For type A, C, H, I and J systems, the above mentioned Formulae (19) and (21) apply directly to pipe

spacing T ≤ 0,375 m. In case of spacing T > 0,375 m, for these systems the conversion shall be made

using Formula (22) and (23):

0,375

qq ⋅ f

G G;,0 375 G

T

(22)

∆=ϑϑ∆ ⋅ f

H,G H,G;,0 375 G

(23)

where

q is the limit specific thermal output, calculated for a spacing T = 0,375 m;

G;0,375

ϑ is the limit temperature difference between the heating medium and the room, calculated

H,G;0,375

for a spacing T = 0,375 m.

The factor f shall be determined as follows, depending on the ratio s /T:

G u

For s /T ≤ 0,173, f = 1 applies.

u G

/T > 0,173, Formula (24) applies:

For s

u

s

u

−⋅20−0,173

0,375 T

q −−qq ⋅ ⋅ e

G,max G,max G;,0 375

T

f =

G

0,375

q ⋅

G;,0 375

T

(24)

where

q is the maximum permissible specific thermal output in accordance with Table A.19, calculated

G, max

for an isothermal surface temperature distribution using the basic characteristic curve (Figure A.1),

with (ϑ − ϑ ) = (ϑ − ϑ ).

F,m i F,max i

For type B systems, Formulae (19) and (21) apply directly, when the pipe spacing T and the width of the

heat diffusion device L are the same. For L < T, the specific thermal output q , calculated in

G,L = T

accordance with Formula (19), shall be corrected using Formula (25):

a

WL

q ⋅ q

G GL, =T

a

WL,L=T

(25)

where

a is the heat conduction factor in accordance with Table A.10 to Table A.15;

WL, L = T

a is the heat conduction factor, calculated in accordance with Formula (15).

WL

The limit temperature difference between the heating medium and the room Δϑ remains unchanged

H,G

as with L = T.

For Δϑ − Δϑ = 9 K, φ = 1 and R = 0, the limit specific thermal output q is designated as standard

F,max i λ,B G

specific thermal output q , and the associated limit temperature difference between the heating

N

medium and the room Δϑ is designated as standard temperature difference between the heating

H,G

medium and the room Δϑ (see Figure A.5). These values serve as characteristic values in the system

N

comparison.

=

=

The maximum possible specific thermal output q for an isothermal surface temperature

G,max

distribution is represented by the ordinate value for ϑ = ϑ on the basic characteristic curve (see

F,m F,max

Figure A.1).

Table A.19 gives values for q , depending on the maximum floor surface temperature ϑ and the

G,max F,max

standard indoor room temperature ϑ .

i

If (due to calculation and interpolation inaccuracies as well as linearization) higher values for q than

G

q are calculated using Formulae (19), (22), (25), q has to be used.

G,max G,max

6.6 Influence of pipe material, pipe wall thickness and pipe sheathing on the specific

thermal output

The factors B are specified in Formulae (4) and (12) for a pipe thermal

conductivity λ = 0,35 W/(m ∙ K), a wall thickness s = 0,002 m. For other materials (see Annex C)

R,0 R,0

with a thermal conductivity of the pipe material λ or other wall thicknesses s , the factor B shall be

R R

calculated using:

dd

1 1 1,1 m 1 1

aa

i

+ ⋅ aT⋅⋅ ln − ln

i

∏

B B π 2λλds−−22 ds2

0 R a R R0, a R0,

i

(26)

If the pipe has an additional sheathing with an external diameter d , an internal diameter d and a

M a

thermal conductivity of the sheathing λ , Formula (27) applies:

M

ddd

1 1 1,1 m 1 1 1

M a M

i

+ ⋅ aT⋅⋅ ln + ln − ln

i

∏

BB π 2λλd 2 d − 22s λ d − 2s

0 M a R a R R0,,M R0

i

(27)

Any oxygen diffusion barrier layers with thicknesses ≤ 0,3 mm need not be considered. In this case,

Formula (26) shall be used.

In cases with air gaps within the sheathing, Formula (27) only applies if a valid average value λ

M

including the air gaps is available.

In rare cases of application with laminar tube flow, the formulas in the normative Annex B may be

applied.

6.7 Thermal conductivity of screed with inserts

Where system plates for type A systems are used, the heat conduction in the screed is changed by

inserts (such as attachment studs or similar components). If their volume fraction in the screed

'

amounts to 15 % ≥ ψ ≥ 5 %, an effective thermal conductivity λ of the component is to be expected.

E

'

λ= 1−ψ⋅λ+⋅ψλ

( )

E EW

(28)

where

λ is the thermal conductivity of the screed;

E

λ is the thermal conductivity of the attachment studs;

W

ψ is the volume fraction of the attachment studs in the screed.

=

=

7 Thermal conductivity of the materials

For carrying out the calculation, the heat conductivities specified in Annex C are used. If the materials

listed in Annex C are used, the values of Table C.1 shall be taken. For other materials, the heat

conductivities shall be taken from effectual European Standards if available or shall be verified by a

certificate prepared by an approved testing body.

8 Downward heat loss

The downward specific heat loss of floor heating systems towards rooms under the system is calculated

in accordance with Formula (29) (see EN 1264-3:2021, Figure A.3):

q ⋅ Rq⋅+ϑϑ−

( )

u O iU

R

U

(29)

where

q downward specific heat loss;

U

q specific thermal output of the floor heating system;

R downwards partial thermal transmission resistance of the floor structure;

U

R upwards partial thermal transmission resistance of the floor structure;

O

ϑ standard indoor room temperature of the floor heated room;

i

ϑ indoor room temperature of a room under the floor heated room.

U

With respect to EN 1264-3:2021, Figure A.3, the following applies:

s

U

RR=++ (30)

OBλ,

αλ

U

where

1/α = 0,092 6 m ·K/W

RR=++R R + R (31)

U λ,,ins λ ceiling λ,plaster α,ceiling

where

R = 0,17 m ·K/W

α,ceiling

In the special case of ϑ = ϑ the simple formula

i U

R

O

qq⋅

U

R

U

(32)

applies.

=

=

9 Test procedure for the determination of the thermal output of systems that

cannot be calculated in accordance with Clause 6

For constructions which do not correspond to the basic construction of the types A, B, C or D, or in case

of dimensions or material data outside the scope of the calculation method, the specific thermal output

shall be determined by testing (experimentally) as follows.

A test sample consisting of at least three heating pipes, with the pipe spacing to be tested, in accordance

with the system design of the floor heating to be investigated is positioned in the testing equipment

according to Figure A.6. The size of the test sample shall be approximate 1 m × 1 m in agreement with

the test laboratory. It shall cover preferably three-pipe spacing. In Figure A.6 the cooling plates simulate

the room above the floor heating system (see Figure A.6, key 1), i.e. the temperature of the heated room

ϑ , and the room below (see Figure A.6, key 4). For the cooling plates the construction according to

i

Figure A.7 is recommended consisting of panel radiators with flat tubes in which disconnecting points

realize the appropriate cooling water flow. The cooling plate shall be at least of size 1 m x 1 m. The

upper plate shall exert a weight force of (450 ± 50) N during measurements. The thermal transfer

resistance 1/α at the floor surface is simulated by the heat transfer layer (see Figure A.6, key 2).The two

lateral heating pipes serve as a protection field to enable the optimum undisturbed temperature field

around the central pipe. The thermal transfer resistance 1/α at the floor surface, given by the basic

characteristic curve, is replaced by the thermal conduction resistance s/λ of the heat transfer layer of

equal magnitude (mean value):

1 s K

0, 092 6 m ⋅

αλ W

(33)

The tolerance on the value s/λ is ± 0,01 m ∙ K/W.

The temperature drop of the sample ϑ − ϑ (see Figure A.8) shall not exceed 0,5 K. The temperature

V R

rise of the water flow in the cooling plates ϑ − ϑ (see Figure A.7) shall not exceed 0,3 K.

C,out C,in

ϑ is the heat water supply temperature of the sample;

V

ϑ

is the heat water return temperature of the sample;

R

ϑ is the outlet cooling water temperature of the cooling plates;

C,out

ϑ is the inlet cooling water temperature of the cooling plates.

C,in

Temperatures shall be measured with a permissible uncertainty of ± 0,1 K.

The temperature field of the floor surface is measured in order to determine the values ϑ and ϑ .

F,m F,max

The measurement shall be carried out in the undisturbed area around the central pipe or central pipes

and, at least, over the width of one pipe spacing. If possible, it is recommended using two pipe spacing.

The configuration of the measuring points using two pipe spacing should be done in principle as shown

in Figure A.8. For an example, with the measuring values ϑ (see Figure A.8) the calculation procedure

F,j

is as follows:

8 17

ϑϑ++ϑ +ϑ

F,,1 F 9 F,10 F,18

ϑ ϑ+ ϑ+ / 16

F,m F,,i F i

∑ ∑

2 11

(34)

ϑϑ+

F,,5 F 14

ϑ =

F,max

(35)

=

==

where

are the local floor surface temperatures (measuring points);

ϑ

F,i

is the average floor surface temperature;

ϑ

F,m

is the maximum floor surface temperature.

ϑ

F,max

In the case of not feasible values of the measured temperature field caused by inhomogeneity of the

screed, another part of the surface shall be taken.

Because of the fact that the temperature drop of the sample ϑ − ϑ is very little and the fact that the

V R

temperature measurements shall be carried out in the undisturbed area around the central pipe no

variation is necessary depending on the laying system (spirally or meandering).

The explanations above refer to the most usual case that the floor heating system is characterized by

the repetition of the pipe spacing. The test sample in Figure A.6 which is symmetrical with respect to

the central pipe is based on this fact. If another dimension characterizes the system the procedure has

to be adjusted.

At first the test is realized for R = 0.

λ,B

The average floor surface temperature ϑ is determining the specific thermal output, and the

F,m

maximum floor surface temperature ϑ is limiting the thermal output. The measurement is carried

F,max

out when steady-state conditions are reached and a temperature of both cooling plates of

ϑ = 20 °C ± 0,5 K is maintained. Under these conditions the average temperature of the heating medium

i

ϑ is set to achieve a maximum floor surface temperature of ϑ = 29 °C (i.e. ϑ − ϑ = 9 K), and in

H F,max F,max I

this case the difference between the average temperature of the heating medium and the temperature

of the cooling plates ϑ − ϑ = Δϑ = Δϑ (standard value) applies.

H i H N

If it is not possible to set the temperature difference (ϑ − ϑ ) exactly to 9 K, a value slightly below

F,max i

and a value slightly above 9 K shall be set and the results used to formulate a mean value.

− ϑ ) = 9 K is maintained and the average temperature difference of the floor surface

Given that (ϑ

F,max i

and the room (ϑ − ϑ) is determined, this temperature difference is used within the basic

F,m i

characteristic curve (Figure A.1) and gives the standard specific thermal output:

11,

q=8, 92⋅−ϑϑ

( )

N F,m i

N

(36)

The standard specific thermal output q , together with the above determined corresponding standard

N

temperature difference Δϑ , gives the formula for the characteristic curve for R = 0:

N λ,B

qK= ⋅∆ϑ

N H,N N

with the following gradient of the characteristic curve (the equivalent heat transmission coefficient):

q

N

K =

H,N

∆ϑ

N

(37)

' '

K

If for a given thermal resistance of the covering R the gradient of the characteristic curve applies

H

λ,B

'

(determination of K see Formula (39)), for any thermal resistance of the floor covering R > 0, the

λ,B

H

associated gradient of the characteristic curve K (R ) can be determined in accordance with

H λ,B

Formula (38):

K

H,N

K KR

(38)

( )

H H λ,B

RK

λ,,B H N

11+ −

''

RK

λ,BH

Using Formula (38), the gradients of the characteristic curves K (R ) can be calculated for thermal

H λ,B

2 2 2

resistances R = 0,05 m ∙ K/W, 0,10 m ∙ K/W and 0,15 m ∙ K/W.

λ,B

'

K

In order to establish the gradient of the characteristic curve to be used in Formula (38), another

H

measurement like the one described above for R = 0, has to be carried out, but with a thermal

λ,B

'

2 2

resistance of the floor covering R = 0,15 m ∙ K/W ± 0,01 m ∙ K/W. By doing this measurement, the

λ,B

'

'

q

limit specific thermal output and the limit temperature difference ∆ϑ are determined, which give

G

HG,

'

the needed value K :

H

'

q

' '' G

K KR (39)

( )

H H λ,B

'

∆ϑ

HG,

In accordance with Formula (40), the limit temperature differences Δϑ for the thermal conduction

H,G

resistances R > 0 are given by the interfaces of the characteristic curves and the limit curve resulting

λ,B

from the measurement data and the gradient K of the characteristic curve calculated from

H

Formula (38):

'' '

qq⋅∆ϑϑ−∆

G N N HG,

'

∆=ϑϕ⋅ (40)

HG,

''

K ⋅ ∆ϑ −∆ϑ −+qq

( )

H N HG, N G

For systems having several spacing, the maximum and the minimum spacing as well as sufficient

intermediate spacing to achieve a spacing ratio not exceeding 1 : 2, shall be tested in accordance with

the method described. Values for spacing not tested this way, shall be determined by interpolation

using suitable polynomials. The results shall be presented in a test report as specified in Clause 10.

==

==

10 Test report

For a given construction the results shall be documented for each scheduled pipe spacing T and each

scheduled thickness s above the pipe. The testing body presents the results in a test report. The results

U

are documented in a field of characteristic curves with linear coordinates, using Formula (41):

(41)

qf∆ϑ , R

( )

HBλ,

The characteristic curves are drawn for values of the t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...