EN 16602-30-11:2021

(Main)Space product assurance - Derating - EEE components

Space product assurance - Derating - EEE components

This Standard applies to all parties involved at all levels in the realization of space segment hardware and its interfaces.

The objective of this Standard is to provide customers with a guaranteed performance and reliability up to the equipment end-of-life. To this end, the following are specified:

- Load ratios or limits to reduce stress applied to components;

- Application rules and recommendations.

Raumfahrtproduktsicherung - Herabsetzen/Unterlastung von EEE-Komponenten

Assurance produit des projets spatiaux - Détarage des composants EEE

Zagotavljanje varnih proizvodov v vesoljski tehniki - Zmanjšanje števila komponent EEE

Ta standard se uporablja za vse, ki so na vseh ravneh vključeni v realizacijo vesoljske strojne opreme in njenih vmesnikov.

Cilj tega standarda je strankam zagotoviti zajamčeno zmogljivost in zanesljivost do konca življenjskega cikla opreme. V ta namen so določeni naslednji elementi:

– razmerja ali omejitve obremenitve za zmanjšanje stresa za komponente;

– pravila in priporočila glede uporabe.

General Information

- Status

- Published

- Publication Date

- 21-Dec-2021

- Withdrawal Date

- 29-Jun-2022

- Technical Committee

- CEN/CLC/TC 5 - Space

- Drafting Committee

- CEN/CLC/TC 5/WG 6 - Upstream standards

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 22-Dec-2021

- Due Date

- 30-Nov-2022

- Completion Date

- 22-Dec-2021

Relations

- Effective Date

- 29-Dec-2021

Overview

EN 16602-30-11:2021 - Space product assurance: Derating - EEE components is a European (SIST) implementation of the EN standard that specifies derating practices for electronic, electrical and electromechanical (EEE) components used in space segment hardware. Originating from ECSS-Q-ST-30-11C Rev.2 and approved by CEN/CENELEC, the standard replaces earlier editions (supersedes EN 16602-30-11:2014/2015) and is intended to guarantee component performance and reliability through end-of-life without unnecessary over-design.

Key topics and requirements

- Derating principles and objectives: Defines why derating is applied (reduce stress, extend life, improve reliability) and addresses the trade-off between conservative derating and cost/weight/size penalties.

- User responsibility: Clarifies roles for designers, procurers and quality engineers when applying derating rules.

- Applicability and component selection: Criteria to determine when and how derating applies depending on mission parameters (e.g., mission duration, mean temperature, environment).

- Derating parameters: Identifies electrical and environmental parameters to be derated (voltage, current, power, temperature, etc.) and rules for combining stresses.

- Load ratios and limits: Provides tables of load ratios or limits for many component families to reduce stress and risk of failure.

- Additional rules and recommendations: Guidance on special cases, bundles, partially loaded harnesses, and other practical design considerations.

- Extensive component tables: Derating tables cover capacitors, connectors, diodes, ICs, resistors, transistors, inductors, wires and cables, opto-electronics, RF passives, fibre-optic components, hybrids and more - organised by family-group codes.

(See the standard for full normative tables and family-group codes; specific numeric limits are provided there.)

Practical applications - who uses it

- Spacecraft system and hardware designers applying derating to meet mission reliability goals.

- Reliability and quality engineers for failure mitigation planning and verification.

- Procurement and parts engineering teams to create contract and procurement requirements for EEE components.

- Manufacturers and suppliers who need to demonstrate compliance with space product assurance expectations.

- Test engineers and integrators using derating limits to plan qualification and acceptance tests.

Use cases include part selection, specification of allowable voltage/current/power margins, harness and bundle sizing, and design trade-offs to balance reliability vs. mass/cost.

Related standards and context

- Originates from ECSS-Q-ST-30-11C Rev.2 (European Cooperation for Space Standardization).

- Implemented by CEN/CENELEC national bodies across Europe; consult national adoption for local status.

- Complementary to other space product assurance standards in the EN 16602 series (refer to the standard’s bibliography for cross-references).

Keywords: EN 16602-30-11:2021, derating, EEE components, space product assurance, spacecraft reliability, derating tables, load ratios, mission duration, component selection.

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 16602-30-11:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Space product assurance - Derating - EEE components". This standard covers: This Standard applies to all parties involved at all levels in the realization of space segment hardware and its interfaces. The objective of this Standard is to provide customers with a guaranteed performance and reliability up to the equipment end-of-life. To this end, the following are specified: - Load ratios or limits to reduce stress applied to components; - Application rules and recommendations.

This Standard applies to all parties involved at all levels in the realization of space segment hardware and its interfaces. The objective of this Standard is to provide customers with a guaranteed performance and reliability up to the equipment end-of-life. To this end, the following are specified: - Load ratios or limits to reduce stress applied to components; - Application rules and recommendations.

EN 16602-30-11:2021 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16602-30-11:2021 has the following relationships with other standards: It is inter standard links to EN 16602-30-11:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16602-30-11:2021 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16602-30-11:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2022

Nadomešča:

SIST EN 16602-30-11:2015

Zagotavljanje varnih proizvodov v vesoljski tehniki - Zmanjšanje števila

komponent EEE

Space product assurance - Derating - EEE components

Raumfahrtproduktsicherung - Herabsetzen/Unterlastung von EEE-Komponenten

Assurance produit des projets spatiaux - Détarage des composants EEE

Ta slovenski standard je istoveten z: EN 16602-30-11:2021

ICS:

49.140 Vesoljski sistemi in operacije Space systems and

operations

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD EN 16602-30-11

NORME EUROPÉENNE

EUROPÄISCHE NORM

December 2021

ICS 49.140

Supersedes EN 16602-30-11:2014

English version

Space product assurance - Derating - EEE components

Assurance produit des projets spatiaux - Détarage des Raumfahrtproduktsicherung -

composants EEE Herabsetzen/Unterlastung von EEE-Komponenten

This European Standard was approved by CEN on 5 December 2021.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for

giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical

references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to

any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium,

Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy,

Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre:

Rue de la Science 23, B-1040 Brussels

© 2021 CEN/CENELEC All rights of exploitation in any form and by any means

Ref. No. EN 16602-30-11:2021 E

reserved worldwide for CEN national Members and for

CENELEC Members.

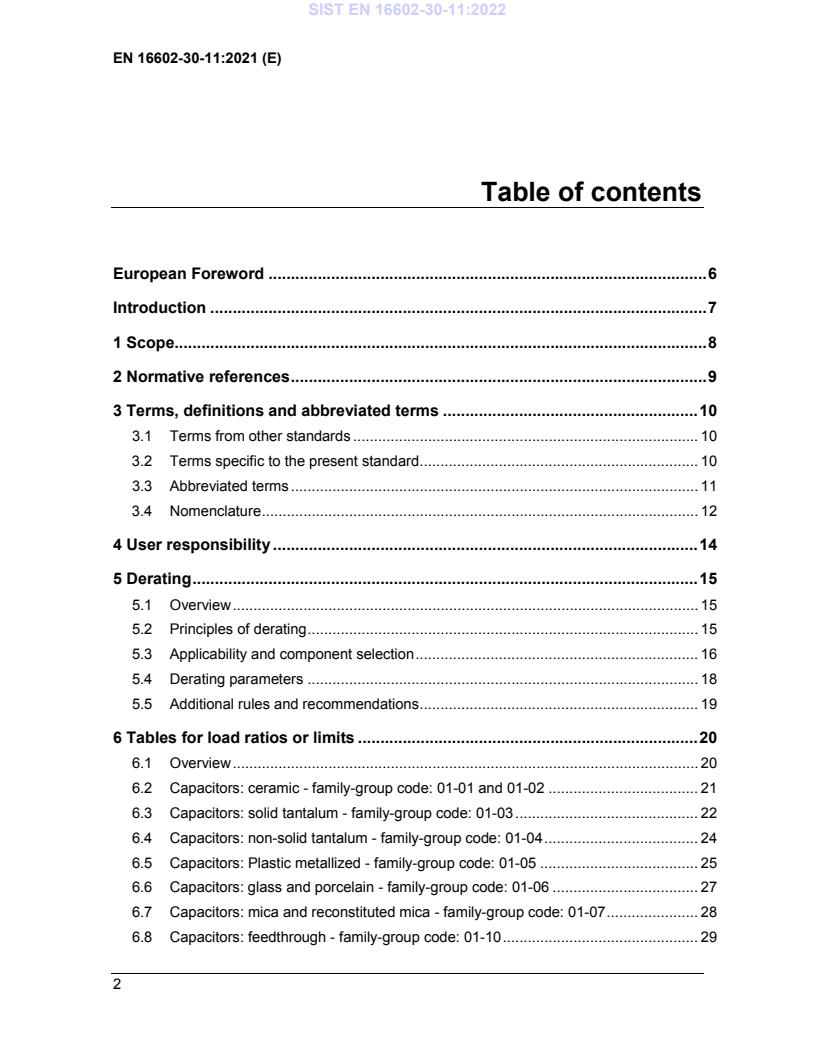

Table of contents

European Foreword . 6

Introduction . 7

1 Scope. 8

2 Normative references . 9

3 Terms, definitions and abbreviated terms . 10

3.1 Terms from other standards . 10

3.2 Terms specific to the present standard . 10

3.3 Abbreviated terms . 11

3.4 Nomenclature . 12

4 User responsibility . 14

5 Derating . 15

5.1 Overview . 15

5.2 Principles of derating . 15

5.3 Applicability and component selection . 16

5.4 Derating parameters . 18

5.5 Additional rules and recommendations . 19

6 Tables for load ratios or limits . 20

6.1 Overview . 20

6.2 Capacitors: ceramic - family-group code: 01-01 and 01-02 . 21

6.3 Capacitors: solid tantalum - family-group code: 01-03 . 22

6.4 Capacitors: non-solid tantalum - family-group code: 01-04 . 24

6.5 Capacitors: Plastic metallized - family-group code: 01-05 . 25

6.6 Capacitors: glass and porcelain - family-group code: 01-06 . 27

6.7 Capacitors: mica and reconstituted mica - family-group code: 01-07 . 28

6.8 Capacitors: feedthrough - family-group code: 01-10 . 29

6.9 Capacitors: semiconductor technology (MOS type) - family-group code: 01-

11 . 30

6.10 Capacitors: miscellaneous (variable capacitors) - family-group code: 01-99 . 31

6.11 Connectors - family-group code: 02-01, 02-02, 02-03, 02-07 and 02-09 . 32

6.12 Connectors RF - family-group code: 02-05 . 34

6.13 Piezo-electric devices: crystal resonator - family-group code: 03-01 . 35

6.14 Diodes - family-group code: 04-01, 04-02, 04-03, 04-04, 04-06, 04-08, 04-

10 and 04-14 . 36

6.15 Diodes: RF/microwave - family-group code: 04-05, 04-11 to 04-13, 04-15,

04-16 and 04-17 . 38

6.16 Feedthrough filters - family-group code: 05-01 . 39

6.17 Fuses: Cermet (metal film on ceramic) - family-group code: 06-01 . 40

6.18 Inductors and transformers - family-group code: 07-01 to 07-03 and 14-01 . 41

6.19 Integrated circuits: logic - family-group code: 08-10, 08-20, 08-21, 08-29 to

08-42, and 08-80 . 42

6.20 Integrated circuits: non-volatile memories - family-group code: 08-22, 08-23

and 08-24 . 44

6.21 Integrated circuits: linear - family-group code: 08-50 to 08-60 and 08-69 . 46

6.22 Integrated circuits: linear converters - family-group code: 08-61 and 08-62 . 48

6.23 Integrated circuits: MMICs - family-group code: 08-95 . 49

6.24 Integrated circuits: miscellaneous - family-group code: 08-99 . 51

6.25 Relays and switches - family-group code: 09-01, 09-02 and 16-01 . 52

6.26 Resistors - family-group code: 10-01 to 10-11 . 55

6.27 Thermistors - family-group code: 11-01 to 11-03 . 59

6.28 Transistors: bipolar - family-group code: 12-01 to 12-04 and 12-09 . 60

6.29 Transistors: FET - family-group code: 12-05 and 12-06 . 62

6.30 Transistors: RF: bipolar - family-group code: 12-10 and 12-13 . 64

6.31 Transistors: RF: FET - family-group code: 12-12, 12-14, 12-15(FET) and 12-

16(FET) . 67

6.32 Wires and cables - family-group code: 13-01 to 13-03 . 70

6.33 Opto-electronics - family-group code: 18-01 to 18-05 . 74

6.34 RF passive components: family-group code: 30-01, 30-07, 30-09, 30-10 and

30-99 . 75

6.35 Fibre optic components: fibre and cable: family-group-code: 27-01 . 77

6.36 Hybrids . 78

Bibliography . 89

Figures

Figure 5-1: Parameter stress versus strength relationship . 16

Tables

Table 6-1: Derating of parameters for capacitors family-group code 01-01 and 01-02 . 21

Table 6-2: Derating of parameters for capacitors family-group code 01-03 . 22

Table 6-3: Derating of parameters for capacitors family-group code . 24

Table 6-4: Derating of parameters for capacitors family-group code 01-05 . 26

Table 6-5: Derating of parameters for capacitors family-group code 01-06 . 27

Table 6-6: Derating of parameters for capacitors family-group code 01-07 . 28

Table 6-7: Derating of parameters for capacitors family-group code 01-10 . 29

Table 6-8: Derating of parameters for capacitors family-group code 01-11 . 30

Table 6-9: Derating of parameters for capacitors family-group code 01-99 . 31

Table 6-10: Derating of parameters for connectors family-group code 02-01, 02-02,

02-03, 02-07 and 02-09 . 32

Table 6-11: Derating of parameters for connectors RF family-group code 02-05 . 34

Table 6-12: Derating of parameters for piezo-electric devices family-group code 03-

01 . 35

Table 6-13: Derating of parameters for Diode (signal/switching, rectifier including

Schottky, pin) . 36

Table 6-14: Derating of parameters for Diode (Zener, reference, transient

suppression) . 37

Table 6-15: Derating of parameters for Diodes family-group code 04-05, 04-11 to 04-

13, 04-15, 04-16 and 04-17 . 38

Table 6-16: Derating of parameters for Feedthrough filters family-group code 05-01 . 39

Table 6-17: Derating of parameters for Fuses family-group code 06-01 . 40

Table 6-18: Derating of parameters for Inductors and transformers family-group code

07-01 to 07-03 and 14-01 . 41

Table 6-19: Derating of parameters for Integrated circuits family-group code: 08-10,

08-20, 08-21, 08-29 to 08-42, and 08-80 . 42

Table 6-20: Derating of parameters for Integrated circuits family-group code: 08-22,

08-23 and 08-24 . 44

Table 6-21: Derating of parameters for Integrated circuits family-group code 08-50 to

08-60 and 08-69 . 47

Table 6-22: Derating of parameters for Integrated circuits family-group code 08-61

and 08-62 . 48

Table 6-23:Derating of parameters for non-custom MMICs . 50

Table 6-24: Derating of parameters for Relays and switches family-group code 09-

01, 09-02 and 16-01 . 53

Table 6-25: Derating of parameters for Metal film precision resistor (type RNC,

except RNC 90) . 55

Table 6-26: Derating of parameters for Metal film semi-precision resistor (type RLR) . 55

Table 6-27: Derating of parameters for Foil resistor (type RNC 90) . 56

Table 6-28: Derating of parameters Wire-wound high precision resistor (type RBR

56) . 56

Table 6-29: Derating of parameters for Wire-wound power resistor (type RWR, RER) . 57

Table 6-30: Derating of parameters for Chip resistor (RM), network resistor . 57

Table 6-31: Derating of parameters for Carbon composition resistor . 57

Table 6-32: Derating of parameters for Heaters . 58

Table 6-33: Derating of parameters for Thick Film Power . 58

Table 6-34: Derating of parameters for Thermistors family-group code 11-01 to 11-03 . 59

Table 6-35: Derating of parameters for Transistors family-group code 12-01 to 12-04

and 12-09 . 60

Table 6-36: Derating of parameters for Transistors family-group code 12-05 and 12-

06 . 62

Table 6-37: Derating of parameters for Transistors family-group code 12-10 and 12-

13 . 65

Table 6-38: Derating of parameters for Transistors family-group code 12-12, 12-14,

12-15(FET) and 12-16(FET) . 68

Table 6-39: <> . 70

Table 6-40: <> . 70

Table 6-41: Derating factor for bundles (fully loaded) . 72

Table 6-42: Additional factor for partially loaded bundles . 72

Table 6-43: Derating of parameters for Opto-electronics family-group code 18-01 to

18-05 . 74

Table 6-44: Derating of parameters for RF passive components from family-group

code 30-01, 30-07, 30-09, 30-10 and 30-99 - Low power < 5 W . 75

Table 6-45: Derating of parameters for RF passive components from family-group

code 30-01, 30-07, 30-09, 30-10 and 30-99 - Low power ≥ 5 W . 75

Table 6-46: Derating of parameters for Fibre optic components . 77

European Foreword

This document (EN 16602-30-11:2021) has been prepared by Technical

Committee CEN/CLC/TC 5 “Space”, the secretariat of which is held by DIN

(Germany).

This document (EN 16602-30-11:2021) originates from ECSS-Q-ST-30-11C

Rev.2.

This European Standard shall be given the status of a national standard,

either by publication of an identical text or by endorsement, at the latest by

June 2022, and conflicting national standards shall be withdrawn at the latest

by June 2022.

Attention is drawn to the possibility that some of the elements of this

document may be the subject of patent rights. CEN [and/or CENELEC] shall

not be held responsible for identifying any or all such patent rights.

This document supersedes EN 16602-30-11:2014.

The main changes with respect to EN 16602-30-11:2014 are listed below:

- Implementation of Change Requests,

- Addition of clause 6.26.2.9 “Thick Film Power”

- Informative Annex B “ESCC Exceptions” deleted

- Informative Annex C “Example of single wires rating currents

calculation for the wires most commonly used for space applications”

added

This document has been prepared under a standardization request given to

CEN by the European Commission and the European Free Trade

Association.

This document has been developed to cover specifically space systems and

has therefore precedence over any EN covering the same scope but with a

wider domain of applicability (e.g. : aerospace).

According to the CEN-CENELEC Internal Regulations, the national

standards organizations of the following countries are bound to implement

this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech

Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of

Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy,

Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland,

Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

Introduction

This Standard specifies derating requirements applicable to electronic,

electrical and electromechanical components.

Derating is a long standing practice applied to components used on

spacecraft. Benefits of this practice are now proven, but for competitiveness

reasons, it becomes necessary to find an optimized reliability. Too high a

derating can lead to over-design, over-cost and over-sizing of components,

the direct consequence being excess volume and weight. The aim is to obtain

reliable and high performance equipment without over-sizing of the

components. For this reason and if possible, this Standard provides derating

requirements depending on mission duration and mean temperature, taking

into account demonstrated limits of component capabilities.

Scope

This Standard applies to all parties involved at all levels in the realization of

space segment hardware and its interfaces.

The objective of this Standard is to provide customers with a guaranteed

performance and reliability up to the equipment end-of-life. To this end, the

following are specified:

• Load ratios or limits to reduce stress applied to components;

• Application rules and recommendations.

This standard may be tailored for the specific characteristics and constraints

of a space project, in accordance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through

reference in this text, constitute provisions of this ECSS Standard. For dated

references, subsequent amendments to, or revisions of any of these

publications do not apply. However, parties to agreements based on this

ECSS Standard are encouraged to investigate the possibility of applying the

most recent editions of the normative documents indicated below. For

undated references the latest edition of the publication referred to applies.

EN reference Reference in text Title

EN 16601-00-01 ECSS-S-ST-00-01 ECSS system - Glossary of terms

EN 16602-60 ECSS-Q-ST-60 Space product assurance - Electrical, electronic and

electromechanical (EEE) components

EN 16602-60-13 ECSS-Q-ST-60-13 Commercial electrical, electronic and

electromechanical (EEE) components

EN 16602-60-15 ECSS-Q-ST-60-15 Radiation hardness assurance - EEE components

ESCC 2269010 Evaluation test programme for monolithic

microwave integrated circuits (MMICS)

ESCC 2265010 Evaluation Test Programme for Discrete

Microwave Semiconductors

ESCC Derating Component Derating - Deviations to ECSS-Q-ST-

deviations 30-11:

https://escies.org/webdocument/showArticle?id=82

5&groupid=6

Terms, definitions and abbreviated terms

3.1 Terms from other standards

a. For the purpose of this Standard, the terms and definitions from

ECSS-ST-00-01 apply.

1. component

2. derating

3. performance

3.2 Terms specific to the present standard

ambient temperature

temperature surrounding a component

bundle

set of two or more wires arranged in parallel ,tied or laced together.

case temperature

temperature on the component package surface

hot spot temperature

highest measured or predicted temperature within any component

junction temperature

highest measured or predicted temperature at the junction within a

semiconductor or micro-electronic device

NOTE Predicted temperature can be taken as Tcase +

thermal resistance between junction and case

times actual power (Watt) of the device.

load ratio

permissible operating level after derating has been applied; given as a

percentage of a parameter rating

operating conditions

parameter stress and environment (temperature, vibration, shock and

radiation) in which components are expected to operate

rating

maximum parameter value specified and guaranteed by the component

manufacturer and component procurement specification

NOTE Rating is considered as a limit not to be

exceeded during operation and constitutes in

most cases the reference for derating.

surge

strong rush or sweep

transient

brief change in the state of a system

3.3 Abbreviated terms

For the purpose of this Standard, the abbreviated terms from

ECSS-S-ST-00-01 and the following apply:

Abbreviation Meaning

analog to digital

A/D

application specific integrated circuit

ASIC

capacitance

C

dynamic random access memory

DRAM

electrical erasable programmable read only

EEPROM

memory

erasable programmable read only memory

EPROM

European Space Component Coordination

ESCC

equivalent series resistance

ESR

frequency

f

field effect transistor

FET

gallium arsenide

GaAs

International Organization for Standardization

ISO

Abbreviation Meaning

indium phosphide

InP

light emitting diode

LED

metal on silicon

MOS

specification of the US Department of Defense

MIL (spec)

monolithic microwave integrated circuit

MMIC

National Aeronautics and Space Administration

NASA

power

P

programmable read only memory

PROM

radiation hardened

RadHard

insulation resistance

Ri

radio-frequency

RF

single event burn-out

SEBO

single event gate rupture

SEGR

silicon, silicon germanium

Si, SiGe

safe operating area

SOA

static random access memory

SRAM

junction temperature

Tj

absolute maximum rated junction temperature

Tjmax

operating temperature

Top

collector-emitter voltage

VCE

3.4 Nomenclature

The following nomenclature applies throughout this document:

a. The word “shall” is used in this Standard to express requirements. All

the requirements are expressed with the word “shall”.

b. The word “should” is used in this Standard to express

recommendations. All the recommendations are expressed with the

word “should”.

NOTE It is expected that, during tailoring,

recommendations in this document are

either converted into requirements or

tailored out.

c. The words “may” and “need not” are used in this Standard to express

positive and negative permissions, respectively. All the positive

permissions are expressed with the word “may”. All the negative

permissions are expressed with the words “need not”.

d. The word “can” is used in this Standard to express capabilities or

possibilities, and therefore, if not accompanied by one of the previous

words, it implies descriptive text.

NOTE In ECSS “may” and “can” have completely

different meanings: “may” is normative

(permission), and “can” is descriptive.

e. The present and past tenses are used in this Standard to express

statements of fact, and therefore they imply descriptive text.

User responsibility

a. The user of this Standard shall verify that the ordered assurance level

of procured components is compatible with the intended application.

Derating

5.1 Overview

The term derating refers to the intentional reduction of electrical, thermal

and mechanical stresses on components to levels below their specified rating.

Derating is a means of extending component life, increasing reliability and

enhancing the end-of-life performance of equipment.

Derating participates in the protection of components from unexpected

application anomalies and board design variations.

The load ratios or limits given in clause 6 were derived from information

available at the time of writing this Standard and do not preclude further

derating for specific applications.

This Standard also defines how to handle transients.

5.2 Principles of derating

The component parameter strength defines the limits and the performance

component technology in the particular application and varies from

manufacturer to manufacturer, from type to type, and from lot to lot and can

be represented by a statistical distribution. Likewise, component stress can be

represented by a statistical distribution. Figure 5-1 illustrates the strength of a

component and the stress applied at a given time, where each characteristic is

represented by a probability density function.

A component operates in a reliable way if its parameter strength exceeds the

parameter stress. The designer should ensure that the stress applied does not

exceed the component parameter strength. This is represented by the

intersection (shaded area) in Figure 5-1. The larger the shaded area, the

higher the possibility of failure becomes.

There are two ways, which may be used simultaneously, in which the shaded

area can be decreased:

• Decrease the stress applied (which moves the stress distribution to the

left).

• Increase the component parameter strength (by selecting over-sized

components) thereby moving the strength distribution to the right.

The goal is to minimize the stress-to-strength ratio of the component.

Derating moves the parameter stress distribution to the left while the

selection processes applied to the components for space applications

contribute to moving the parameter strength distribution to the right. The

selection processes also reduce the uncertainty associated with the

component parameter strength.

Derating reduces the probability of failure, improves the end-of-life

performance of components and provides additional design margins.

Another effect of derating is to provide a safety margin for design. It allows

integrating parameter distribution from one component to another, and from

one procurement to another.

probability

strength

density

stress distribution

distribution

region of stress and strength

interference where failures

can occur

parameter

Figure 5-1: Parameter stress versus strength relationship

5.3 Applicability and component selection

5.3.1 Overview

This Standard applies to all components, selected for space applications, that

are used for a significant duration. The meaning of “significant duration” is a

period that contributes to the component life, for instance, one month is

considered to be a significant duration. These requirements apply to

screened components procured in accordance with approved space

specifications.

This Standard only applies to approved components for which quality was

proven after rigorous testing in accordance with ECSS-Q-ST-60.

Derating applies on normal operational conditions, where “normal” is

opposed to “fault” and “Operational” indicates all functional modes of the

unit.

5.3.2 Requirements

a. Derating shall be applied in consideration of temperature limits

recommended by the manufacturer.

b. The derating requirements of this Standard shall not be used as a

justification to upgrade the quality level of components.

c. The derating requirements shall be taken into account at the beginning

of the design cycle of an equipment for any consequential design

trade-off to be made.

NOTE It is important to pay specific attention to

breadboards and engineering models where

parameter derating was not considered.

d. For families and groups of components excluded from this Standard

due to the lack of experimental data and failure history, the user shall

consult a component design and reliability specialist to apply the

requirements of this Standard.

e. Components may be excluded from this Standard if they are used for

short durations of less than one month provided the device ratings are

not exceeded, and it is ensured that the applied stress level does not

exceed the component maximum rating.

NOTE For example, components used in solar

generator deployment systems, redundancy

commutation and launchers (except in some

specific cases, noted family by family).

f. The derating requirements are not applicable to test conditions for

which the maximum ratings shall not be exceeded.

NOTE For example, circuit or equipment level

qualification and EMC.

g. Derating requirements are not applicable to fault conditions, for which

the maximum rating shall not be exceeded, with the exception defined

in 5.3.2h.

h. Where components are required to operate in protection mode or in

fail-safe mode in order to prevent failure propagation, the components

concerned shall meet the derating requirements and application rules

when performing the protection or fail-safe function under the worst

failure case.

NOTE 1 Short circuit is an example of failure mode

that can potentially propagate.

NOTE 2 Example of a condition needing protection or

fail-safe function under the worst failure

case: highest stress applied to the

components that can last throughout the

mission.

i. Derating analysis shall be performed at the equipment maximum hot

acceptance temperature, unless otherwise specified.

5.3.3 Requirements ESCC exceptions

a. For a particular type or manufacturer, when a specific derating rule is

defined in the appendix of the approved ESCC detail specification

issued by the ESCC Executive, it shall take precedence over the generic

requirement of this standard.

NOTE There are many misunderstandings about

ratings vs derating. Specifications normally

only contain ratings. The exceptions are

listed in 5.3.3b.

b. Users shall check for application the actual status of the ESCC

Derating exceptions on the following ESCC web site page: ESCC

Derating deviations

c. Users shall clearly identify in the Parts Stress Analysis document the

list of the ESCC Derating exceptions taken into consideration in their

analysis.

5.4 Derating parameters

5.4.1 Overview

Derating requirements are provided in clause 6 for each component family.

For each category, the parameters to be derated are identified. The main

parameters to be derated are:

• junction or case temperature;

• power (rating, dissipation);

• voltage;

• current.

The parameters to be derated depend on component type.

A stress balancing concept offers flexibility between one stress versus

another (voltage and temperature). In some cases, e.g. resistors, derating has

a direct impact on component performance.

5.4.2 Requirements for transient and surge

conditions

a. For transient or surge conditions, if ratings are provided, the same

derating figures as for steady-state equivalent parameters shall be

used.

b. For transient or surge conditions, if ratings are not provided, then it

shall be assured that the transient or surge values are below the

steady-state specified maximum ratings.

c. For all periodic signals or transient conditions which are repeated or

made incessant, the steady-state derating figures shall apply.

d. <>

e. As an exception in case clause 5.4.2c is not compatible for specific

repeated and incessant transient use conditions, for the parts types and

parameters listed, load ratio shall not exceed the steady state derated

values +10 % or 80 % of the steady state rated values, which ever is

lower:

1. Connectors: voltage, current

2. Ceramic Capacitors: voltage

3. Resistors: current

4. Diodes: current

5. Transistors_ bipolar , MOSFETs, power FETs: current.

5.5 Additional rules and recommendations

5.5.1 Overview

In addition to strict derating requirements, some application rules and

recommendations are given in this Standard to achieve the suitable

reliability. This additional application rules and recommendations are listed

separately in the clauses titled “Additional requirements not related to

derating”. This disposition is valid until other adequate ECSS documents can

host these additional clauses.

5.5.2 Additional requirements not related to

derating

a. Where radiation sensitive components are identified, the specific

requirements within ECSS-Q-ST-60-15 shall be applied.

Tables for load ratios or limits

6.1 Overview

This clause provides the load ratios or limits.

They are also available on the World Wide Web at the following address:

https://escies.org

Abbreviations used in the tables are explained in clause 3.

Annex A contains a complete listing of the family and group codes for parts

that are referred to in this Standard.

Annex B contains ESCC exceptions at date of publication of this standard.

6.2 Capacitors: ceramic - family-group code: 01-01 and

01-02

6.2.1 General

a. The capacitor stress sum value of steady-state voltage, AC voltage

shall not exceed the load ratios specified hereunder. For transients

refer to clause 5.4.

b. <>

c. <>

d. Internal heating due to ESR can increase ageing and should be taken

into account by applying a margin in temperature.

e. Where ESR is not known at the frequency of a ripple current, an

extrapolation of the ESR value and resonance, from manufacturer’s or

test data, should be made where possible.

6.2.2 Derating

a. Parameters of capacitors from family-group code 01-01 and 01-02 shall

be derated as per Table 6-1.

Table 6-1: Derating of parameters for capacitors family-group code 01-01 and 01-

6.2.3 Additional requirements not related to

derating

a. The dV/dt rating capability of the capacitors shall be respected.

6.3 Capacitors: solid tantalum - family-group code: 01-

6.3.1 General

a. The capacitor stress sum value of steady-state voltage and AC voltage

shall not exceed the load ratio specified hereunder, for transients refer

to clause 5.4.

b. <>

c. Surge current shall be derated to 75 % of the Isurge max. Isurge max is

defined as Vrated/(ESR+Rs). Vrated is the maximum rated voltage,

ESR is the maximum specified value and Rs is the value of series

resistance specified in the circuit for surge current testing as defined in

the applicable procurement specification.

d. Reverse voltage shall not exceed 75 % of the manufacturer’s specified

maximum value for the reverse voltage.

e. Ripple power shall never exceed 50 % of the manufacturer’s specified

maximum value.

f. Internal heating due to ESR can increase ageing and should be taken

into account by applying a margin in temperature.

g. Where ESR is not known at the frequency of a ripple current, an

extrapolation of the ESR value and resonance, from manufacturer’s or

test data, should be made where possible.

6.3.2 Derating

a. Parameters of capacitors from family-group code 01-03 shall be

derated as per Table 6-2.

Table 6-2: Derating of parameters for capacitors family-group code 01-03

6.3.3 Additional requirements not related to

derating

a. 100 % surge current screening shall be applied for all surface mounted

capacitors types.

b. The dV/dt rating capability of the capacitors shall be respected.

c. For control of ESR drift especially in the case of polymer tantalum

capacitors, a higher derating may be applied than specified.

NOTE For example 50 % to 85 °C maximum and no

use at higher temperature than 85 °C.

6.4 Capacitors: non-solid tantalum - family-group code:

01-04

6.4.1 General

a. Reverse voltage shall not exceed 75 % of the manufacturer’s specified

maximum value for the reverse voltage.

b. Manufacturer’s ratings for ripple power or current shall never be

exceeded.

c. Internal heating due to ESR can increase ageing and should be taken

into account by applying a margin in temperature.

d. Where ESR is not known at the frequency of a ripple current, an

extrapolation of the ESR value and resonance, from manufacturer’s or

test data, should be made where possible.

6.4.2 Derating

a. Parameters of capacitors from family-group code 01-04 shall be

derated as per Table 6-3.

Table 6-3: Derating of parameters for capacitors family-group code

6.4.3 Additional requirements not related to

derating

a. <>

6.5 Capacitors: Plastic metallized - family-group code:

01-05

6.5.1 General

a. <>

b. <>

c. Internal heating due to ESR can increase ageing and should be taken

into account by applying a margin in temperature.

d. Where ESR is not known at the frequency of a ripple current, an

extrapolation of the ESR value and resonance, from manufacturer’s or

test data, should be made where possible.

6.5.2 Derating

a. Parameters of capacitors from family-group code 01-05 shall be

derated as per Table 6-4.

Table 6-4: Derating of parameters for capacitors family-group code 01-05

6.5.3 Additional requirements not related to

derating

a. Self healing requirements (if applicable): clearing recommendations

from manufacturers shall be followed.

b. The dV/dt rating capability of the capacitors shall be respected.

6.6 Capacitors: glass and porcelain - family-group

code: 01-06

6.6.1 General

a. Internal heating due to ESR can increase ageing and should be taken

into account by applying a margin in temperature.

b. Where ESR is not known at the frequency of a ripple current, an

extrapolation of the ESR value and resonance, from manufacturer’s or

test data, should be made where possible.

6.6.2 Derating

a. Parameters of capacitors from family-group code 01-06 shall be

derated as per Table 6-5.

Table 6-5: Derating of parameters for capacitors family-group code 01-06

6.6.3 Additional requirements not related to

derating

No additional requirement.

6.7 Capacitors: mica and reconstituted mica - family-

group code: 01-07

6.7.1 General

a. Internal heating due to ESR can increase ageing and should be taken

into account by applying a margin in temperature.

b. Where ESR is not known at the frequency of a ripple current, an

extrapolation of the ESR value and resonance, from manufacturer’s or

test data, should be made where possible.

6.7.2 Derating

a. Parameters of capacitors from family-group code 01-07 shall be

derated as per Table 6-6.

Table 6-6: Derating of parameters for capacitors family-group code 01-07

6.7.3 Additional requirements not related to

derating

No additional requirement.

6.8 Capacitors: feedthrough - family-group code: 01-10

6.8.1 General

a. Internal heating due to ESR can increase ageing and should be taken

into account by applying a margin in temperature.

b. Where ESR is not known at the frequency of a ripple current, an

extrapolation of the ESR value and resonance, from manufacturer’s or

test data, should be made where possible.

6.8.2 Derating

a. Parameters of capacitors from family-group code 01-10 shall be

derated as per Table 6-7.

Table 6-7: Derating of parameters for capacitors family-group code 01-10

6.8.3 Additional requirements not related to

derating

No additional requirement.

6.9 Capacitors: semiconductor technology (MOS type) -

family-group code: 01-11

6.9.1 General

a. Internal heating due to ESR can increase ageing and should be taken

into account by applying a margin in temperature.

b. Where ESR is not known at the frequency of a ripple current, an

extrapolation of the ESR value and resonance, from manufacturer’s or

test data, should be made where possible.

6.9.2 Derating

a. Parameters of capacitors from family-group code 01-11 shall be

derated as per Table 6-8.

Table 6-8: Derating of parameters for capacitors family-group code 01-11

6.9.3 Additional requirements not related to

derating

No additional requirement.

6.10 Capacitors: miscellaneous (variable capacitors) -

family-group code: 01-99

6.10.1 General

a. Internal heating due to ESR can increase ageing and should be taken

into account by applying a margin in temperature.

b. Where ESR is not known at the frequency of a ripple current, an

extrapolation of the ESR value and resonance, from manufacturer’s or

test data, should be made where possible.

6.10.2 Derating

a. Parameters of capacitor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...