EN 15316-4-7:2008

(Main)Heating systems in buildings - Method for calculation of system energy requirements and system efficiencies - Part 4-7: Space heating generation systems, biomass combustion systems

Heating systems in buildings - Method for calculation of system energy requirements and system efficiencies - Part 4-7: Space heating generation systems, biomass combustion systems

Die vorliegende Europäische Norm ist Teil einer Normenreihe zu Verfahren zur Berechnung der

Energieanforderungen und Nutzungsgrade von Anlagen für die Raumheizung und Trinkwassererwärmung.

Der Anwendungsbereich dieses vorliegenden Teils dient zur Normung

⎯ der erforderlichen Eingaben,

⎯ des Berechnungsverfahrens,

⎯ der erforderlichen Ausgaben,

für die Wärmeerzeugung durch Biomassewärmeerzeuger (Kessel) mit manueller Beschickung, einschließlich

Regeleinrichtung.

Die vorliegende Europäische Norm ist sowohl für die Wärmeerzeugung für die Trinkwassererwärmung als

auch für die Raumheizung vorgesehen.

Heizungsanlagen in Gebäuden - Verfahren zur Berechnung der Energieanforderungen und Nutzungsgrade der Anlagen - Teil 4-7: Wärmeerzeugung für die Raumheizung, Biomassewärmeerzeuger

Die vorliegende Europäische Norm ist Teil einer Normenreihe zu Verfahren zur Berechnung der Energieanforderungen und Nutzungsgrade von Anlagen für die Raumheizung und Trinkwassererwärmung.

Der Anwendungsbereich dieses vorliegenden Teils dient zur Normung

der erforderlichen Eingaben,

des Berechnungsverfahrens,

der erforderlichen Ausgaben,

für die Wärmeerzeugung durch Biomassewärmeerzeuger (Kessel) mit manueller Beschickung, einschließlich Regeleinrichtung.

Die vorliegende Europäische Norm ist sowohl für die Wärmeerzeugung für die Trinkwassererwärmung als auch für die Raumheizung vorgesehen. Die Wärmeerzeugung ausschließlich für die Trinkwassererwärmung wird in EN 15316 3 3 behandelt.

Systèmes de chauffage dans les bâtiments - Méthode de calcul des besoins énergétiques et des rendements des systèmes - Partie 4-7 : Systèmes de génération de chauffage des locaux, systèmes de combustion de la biomasse

La présente Norme européenne fait partie d’une série de normes sur la méthode de calcul des besoins

énergétiques et des rendements des systèmes de chauffage des locaux et de production d’eau chaude sanitaire.

Le domaine d’application de cette partie spécifique sert à normaliser :

- les données d’entrée requises ;

- la méthode de calcul ;

- les données de sortie obtenues ;

pour les systèmes de génération pour le chauffage des locaux par des sous-systèmes de combustion de la

biomasse (chaudières) à chargement manuel, y compris la régulation.

La présente Norme européenne s’applique également à la génération de chauffage des locaux et à la production

d’eau chaude sanitaire. La génération de chaleur uniquement pour la production d’eau chaude sanitaire est traitée

dans l’EN 15316-3-3.

Ogrevalni sistemi v stavbah - Metoda za preračun energijskih zahtev in učinkovitosti sistema - 4-7. del: Proizvodnja toplote za ogrevanje prostorov, sistemi za zgorevanje biomase

General Information

- Status

- Withdrawn

- Publication Date

- 11-Nov-2008

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 228 - Heating systems in buildings

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 17-May-2017

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 15316-4-7:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Heating systems in buildings - Method for calculation of system energy requirements and system efficiencies - Part 4-7: Space heating generation systems, biomass combustion systems". This standard covers: Die vorliegende Europäische Norm ist Teil einer Normenreihe zu Verfahren zur Berechnung der Energieanforderungen und Nutzungsgrade von Anlagen für die Raumheizung und Trinkwassererwärmung. Der Anwendungsbereich dieses vorliegenden Teils dient zur Normung ⎯ der erforderlichen Eingaben, ⎯ des Berechnungsverfahrens, ⎯ der erforderlichen Ausgaben, für die Wärmeerzeugung durch Biomassewärmeerzeuger (Kessel) mit manueller Beschickung, einschließlich Regeleinrichtung. Die vorliegende Europäische Norm ist sowohl für die Wärmeerzeugung für die Trinkwassererwärmung als auch für die Raumheizung vorgesehen.

Die vorliegende Europäische Norm ist Teil einer Normenreihe zu Verfahren zur Berechnung der Energieanforderungen und Nutzungsgrade von Anlagen für die Raumheizung und Trinkwassererwärmung. Der Anwendungsbereich dieses vorliegenden Teils dient zur Normung ⎯ der erforderlichen Eingaben, ⎯ des Berechnungsverfahrens, ⎯ der erforderlichen Ausgaben, für die Wärmeerzeugung durch Biomassewärmeerzeuger (Kessel) mit manueller Beschickung, einschließlich Regeleinrichtung. Die vorliegende Europäische Norm ist sowohl für die Wärmeerzeugung für die Trinkwassererwärmung als auch für die Raumheizung vorgesehen.

EN 15316-4-7:2008 is classified under the following ICS (International Classification for Standards) categories: 91.140.10 - Central heating systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15316-4-7:2008 has the following relationships with other standards: It is inter standard links to EN 15316-4-1:2017, EN 15316-4-1:2008, EN 15316-3:2017, EN ISO 7345:1995, EN 303-5:2021+A1:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15316-4-7:2008 is associated with the following European legislation: Standardization Mandates: M/343. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15316-4-7:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Heizanlagen in Gebäuden - Verfahren zur Berechnung der Energieanforderungen und Nutzungsgrade der Anlagen - Teil 4-7: Wärmeerzeugung für die Raumheizung, BiomassewärmeerzeugerSystemes de chauffage dans les bâtiments - Méthode de calcul des besoins énergétiques et de l'efficacité des systemes - Partie 4-7 : Systeme de génération de chauffage des locaux, systemes de combustion de biomasseHeating systems in buildings - Method for calculation of system energy requirements and system efficiencies - Part 4-7: Space heating generation systems, biomass combustion systems91.140.10Sistemi centralnega ogrevanjaCentral heating systemsICS:Ta slovenski standard je istoveten z:EN 15316-4-7:2008SIST EN 15316-4-7:2009en,fr,de01-maj-2009SIST EN 15316-4-7:2009SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15316-4-7November 2008ICS 91.140.10 English VersionHeating systems in buildings - Method for calculation of systemenergy requirements and system efficiencies - Part 4-7: Spaceheating generation systems, biomass combustion systemsSystèmes de chauffage dans les bâtiments - Méthode decalcul des besoins énergétiques et des rendements dessystèmes - Partie 4-7 : Systèmes de génération dechauffage des locaux, systèmes de combustion de labiomasseHeizungsanlagen in Gebäuden - Verfahren zur Berechnungder Energieanforderungen und Nutzungsgrade der Anlagen- Teil 4-7: Wärmeerzeugung für die Raumheizung,BiomasseverbrennungssystemThis European Standard was approved by CEN on 30 September 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15316-4-7:2008: ESIST EN 15316-4-7:2009

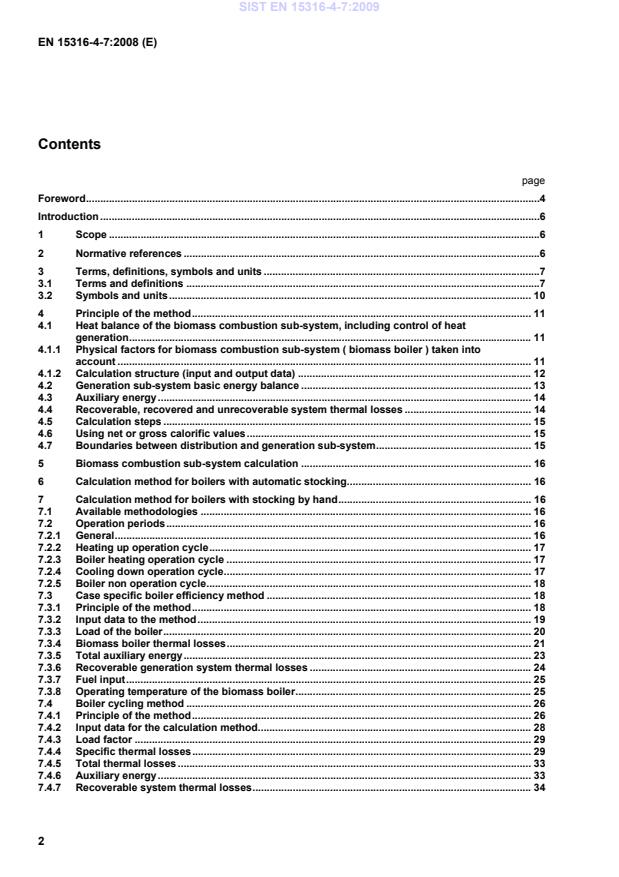

generation . 11 4.1.1 Physical factors for biomass combustion sub-system ( biomass boiler ) taken into account . 11 4.1.2 Calculation structure (input and output data) . 12 4.2 Generation sub-system basic energy balance . 13 4.3 Auxiliary energy . 14 4.4 Recoverable, recovered and unrecoverable system thermal losses . 14 4.5 Calculation steps . 15 4.6 Using net or gross calorific values . 15 4.7 Boundaries between distribution and generation sub-system . 15 5 Biomass combustion sub-system calculation . 16 6 Calculation method for boilers with automatic stocking. 16 7 Calculation method for boilers with stocking by hand . 16 7.1 Available methodologies . 16 7.2 Operation periods . 16 7.2.1 General . 16 7.2.2 Heating up operation cycle . 17 7.2.3 Boiler heating operation cycle . 17 7.2.4 Cooling down operation cycle . 17 7.2.5 Boiler non operation cycle . 18 7.3 Case specific boiler efficiency method . 18 7.3.1 Principle of the method . 18 7.3.2 Input data to the method . 19 7.3.3 Load of the boiler . 20 7.3.4 Biomass boiler thermal losses . 21 7.3.5 Total auxiliary energy . 23 7.3.6 Recoverable generation system thermal losses . 24 7.3.7 Fuel input . 25 7.3.8 Operating temperature of the biomass boiler . 25 7.4 Boiler cycling method . 26 7.4.1 Principle of the method . 26 7.4.2 Input data for the calculation method. 28 7.4.3 Load factor . 29 7.4.4 Specific thermal losses . 29 7.4.5 Total thermal losses . 33 7.4.6 Auxiliary energy . 33 7.4.7 Recoverable system thermal losses . 34 SIST EN 15316-4-7:2009

Additional formulas and default values for parametering the case specific boiler efficiency method . 35 A.1 Information on the method . 35 A.1.1 Basic assumptions and intended use . 35 A.1.2 Known approximations . 35 A.2 Boiler efficiencies and stand-by heat losses. 35 A.2.1 Default values for boiler efficiency at full load and intermediate load as a function of the boiler power output . 35 A.2.2 Stand-by heat losses . 36 A.2.3 Correction factor taking into account variation of efficiency depending on boiler average water temperature . 37 A.3 Auxiliary energy . 38 A.4 Recoverable boiler thermal losses . 38 A.4.1 Auxiliary energy . 38 A.4.2 Thermal losses (boiler envelope) . 39 A.4.3 Default data according to boiler location . 39 Annex B (informative)

Additional formulas and default values for parametering the boiler cycling method . 40 B.1 Information on the method . 40 B.1.1 Basis assumptions and intended use . 40 B.1.2 Known approximations . 40 B.2 Default specific losses . 40 B.2.1 Default data for calculation of thermal losses through the chimney with boiler on . 40 B.2.2 Default values for calculation of thermal losses through the boiler envelope . 41 B.2.3 Default values for calculation of thermal losses through the chimney with the boiler off . 42 B.3 Default values for calculation of auxiliary energy . 43 B.4 Additional default data for modulating burners . 43 Annex C (informative)

Storage systems for biomass combustion systems . 45 C.1 General . 45 C.1.1 Accumulator storage system . 45 C.1.2 Load balancing storage system . 45 C.2 Sizing of storage systems for biomass combustion systems. 45 C.2.1 Sizing of the volume of the accumulator storage tank . 45 C.2.2 Sizing of the volume of the load balancing tank . 46 C.3 System thermal losses of storage systems. 46 C.3.1 Thermal losses . 46 C.3.2 Auxiliary energy of the circulation pump . 47 Annex D (informative)

Calculation procedure with an example for biomass boiler with stocking by hand - Case specific boiler efficiency method . 48 Annex E (informative)

Calculation procedure with an example for biomass boiler with stocking by hand (Cycling method) . 50 Bibliography . 53

Where possible, reference is made to other European or International Standards, a.o. product standards. However, use of products complying with relevant product standards is no guarantee of compliance with the system requirements. The requirements are mainly expressed as functional requirements, i.e. requirements dealing with the function of the system and not specifying shape, material, dimensions or the like.

The guidelines describe ways to meet the requirements, but other ways to fulfil the functional requirements might be used if fulfilment can be proved. Heating systems differ among the member countries due to climate, traditions and national regulations. In some cases requirements are given as classes so national or individual needs may be accommodated. In cases where the standards contradict with national regulations, the latter should be followed. EN 15316 Heating systems in buildings — Method for calculation of system energy requirements and system efficiencies consists of the following parts: Part 1: General SIST EN 15316-4-7:2009

Part 4-5: Space heating generation systems, the performance and quality of district heating and large volume systems Part 4-6: Heat generation systems, photovoltaic systems

Part 4-7: Space heating generation systems, biomass combustion systems According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

optimisation of the energy performance of a planned heat generation system, by applying the method to several possible options; assessing the effect of possible energy conservation measures on an existing heat generation system, by calculating the energy use with and without the energy conservation measures. The user needs to refer to other European Standards or to national documents for input data and detailed calculation procedures not provided by this European Standard. 1 Scope This European Standard is part of a series of standards on the method for calculation of system energy requirements and system efficiencies of space heating systems and domestic hot water systems. The scope of this specific part is to standardise the: required inputs; calculation method; resulting outputs, for space heating generation by biomass combustion sub-systems (boilers) with stocking by hand, including control. This European Standard is also intended for the case of generation for both domestic hot water production and space heating. The case of generation only for domestic hot water production is treated in EN 15316-3-3. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 303-5, Heating boilers — Part 5: Heating boilers for solid fuels, hand and automatically stocked, nominal heat output of up to 300 kW — Terminology, requirements, testing and marking EN ISO 7345:1995, Thermal insulation — Physical quantities and definitions (ISO 7345:1987) SIST EN 15316-4-7:2009

Boilers not so designed, or without the means to remove the condensate in liquid form, are called ‘non-condensing’. 3.1.18 modes of operation various modes in which the heating system can operate (set-point mode, cut-off mode, reduced mode, set-back mode, boost mode) 3.1.19 modulating boiler boiler with the capability to vary continuously (from a set minimum to a set maximum) the fuel burning rate whilst maintaining continuous burner firing 3.1.20 accumulator (storage) system part of the generation system tank which stores excess heat during operation time (resulting from the difference between the boiler output and the actual heat input to the heating system) 3.1.21 load balancing (storage) system part of the generation system tank which improves the operation conditions during operation time (resulting in reducing the starting intervals and increasing the running time of automatic fired biomass boilers

(see EN 15316-4-1) 3.1.22 biomass boiler biomass fuelled appliance designed to provide heating medium (e.g. water, fluid) for space heating 3.1.23 load factor ratio between the time with the boiler ON and the total generator operation time 3.1.24 operation cycle time period of the operation cycle of a boiler SIST EN 15316-4-7:2009

Wh/mass unit b H heat transfer coefficient c W/K k factor c - m mass kg n exponent - N number of items integer P power in general including electrical power W Q quantity of heat J or Wh a t time, period of time s or h a V volume L V' volume flow m³/s or m³/h a W auxiliary (electrical) energy, mechanical work J or Wh a . loss factor %

load factor - û prefix for difference

η efficiency factor % θ Celsius temperature °C - heat flow rate, thermal power W a If seconds (s) is used as the unit of time, the unit for energy needs to be J; If hours (h) is used as the unit of time, the unit for energy needs to be Wh. b Mass unit for fuel may be Stm³, Nm³ or kg. c Coefficients have dimensions; factors are dimensionless.

on aux auxiliary

gnr generator op operation avg average grs gross out output from subsystem

brm boiler room H heating P0 at zero load

cham chamber hup heating up Pint at intermediate load ch chimney i, j, k indices Pn at nominal load ci calculation step in input to subsystem Px at x load cmb combustion ins insulation rbl recoverable cod cooling down int intermediate ref reference cor corrected / correction lob load balancing rvd recovered ctr control ls losses s gross (calorific value) dis distribution

m mean sby in stand-by operation em emission max maximum ta tank fa factor mass massic test test conditions fib fire bed min minimum

W heating system water fg flue gas net

net w water ge generator envelope

off off z indices The indices specifying symbols for sub-system energy balance quantities are in the following order: the first index represents the use (H = space heating, W = domestic hot water etc.); the second index represents the sub-system (gen = generation, dis = distribution etc.); the third index represents the balance item (ls= losses, in = input, aux = auxiliary etc.). Other indices may follow for more details (rvd = recovered, rbl = recoverable etc.). 4 Principle of the method 4.1 Heat balance of the biomass combustion sub-system, including control of heat

generation 4.1.1 Physical factors for biomass combustion sub-system ( biomass boiler ) taken into account The calculation method of the boiler takes into account heat losses and/or recovery due to the following physical factors: heat losses to the chimney (or flue gas exhaust) during total time of boiler operation (running and stand-by); heat losses through the boiler envelope during total time of boiler operation (running and stand-by); auxiliary energy. SIST EN 15316-4-7:2009

Key SUB generation sub-system balance boundary HF heating fluid balance boundary (see Equation (1)) QH,gen,out generation sub-system heat output (input to distribution subsystem(s)) EH,gen,in generation sub-system fuel input (energyware) WH,gen,aux generation sub-system total auxiliary energy QH,gen,aux,rvd generation sub-system recovered auxiliary energy QH,gen,ls generation sub-system total thermal losses QH,gen,ls,rbl generation sub-system thermal losses recoverable for space heating

QH,gen,rbl,th generation sub-system thermal loss (thermal part) recoverable for space heating QH,gen,rbl,aux generation sub-system recoverable auxiliary energy QH,gen,nrbl,th generation sub-system thermal loss (thermal part) non recoverable QH,gen,nrbl,aux generation sub-system non recoverable auxiliary energy

NOTE Figures shown are sample percentages. Figure 1 — General generation sub-system inputs, outputs and energy balance 4.2 Generation sub-system basic energy balance The basic energy balance of the generation sub-system is given by:

lsH,gen,rvdaux,H,gen,H,gen,outinH,gen,QQQE+−= (1) where EH,gen,in

heat requirement of the generation sub-system (fuel input); QH,gen,out

heat supplied to the distribution sub-systems (space heating); SIST EN 15316-4-7:2009

∑∑+=jjin,dis,W,iiin,dis,H,outgen,HW,QQQ (2) 4.3 Auxiliary energy Auxiliary energy is the energy, other than fuel, required for operation of the burner, the primary pump and any equipment whose operation is related to operation of the heat generation sub-system. Auxiliary energy is accounted for in the generation part as long as no transport energy from the auxiliary equipment is transferred to the distribution sub-system (example: zero–pressure distribution array). Such auxiliary equipment can be (but need not be) an integral part of the boiler. Auxiliary energy, normally in the form of electrical energy, may partially be recovered as heat for space heating or for the generation sub-system. Examples of recoverable auxiliary energy: electrical energy transmitted as heat to the water of the primary circuit; part of the electrical energy for the boiler fan. Example of non-recoverable auxiliary energy: electrical energy for electric panel auxiliary circuits, if the boiler is installed outside the heated space. 4.4 Recoverable, recovered and unrecoverable system thermal losses Not all of the calculated system thermal losses are necessarily lost. Some of the losses are recoverable and part of the recoverable system thermal losses are actually recovered. Example of recoverable system thermal losses: thermal losses through the envelope of a boiler installed within the heated space. Examples of non-recoverable system thermal losses: thermal losses through the envelope of a boiler installed outside the heated space; thermal losses (flue gas losses) through the chimney. Recovery of system thermal losses to the heated space can be accounted for: either as a reduction of total system thermal losses within the specific part (simplified method); SIST EN 15316-4-7:2009

iisnetin,H,gen,latHHHEQ−⋅= (3)

latnetin,gen,H,grsin,gen,H,QEE+=

(4)

latnetls,gen,H,grsls,gen,H,QQQ+= (5)

latnetnrbl,th,ls,gen,H,grsnrbl,th,ls,gen,H,QQQ+= (6)

NOTE The latent heat of condensation Qlat

varies extremely depending on the type of biomass fuel, place of origin, quality of storing etc. Therefore reference values should be given in a national annex. 4.7 Boundaries between distribution and generation sub-system Boundaries between generation sub-system and distribution sub-system should be defined according to the principles described in 4.8 of EN 15316-4-1:2005. SIST EN 15316-4-7:2009

-

boiler heating up

tgnr,hup

-

boiler heating operation

tgnr,op

-

boiler cooling down

tgnr,cod

boiler in non operation tgnr,off consisting of 2 sub-periods:

-

boiler in fire bed operation tgnr,fib

-

boiler in non operation

tgnr,non The total operation period tgnr,tot of the boiler is given by:

tgnr,tot

=

tgnr,on +

tgnr,off

(7) NOTE Boiler in fire bed operation is only relevant for boilers with fan assistance. 7.2.2 Heating up operation cycle The operation period for the heating up operation cycle tgnr,hup is influenced by: quality of the biomass fuel applied; quantity of the biomass fuel applied (according to the required quantity of the loaded biomass fuel). 7.2.3 Boiler heating operation cycle The operation period for the heating operation cycle tgnr,op is influenced by: quality of the biomass fuel applied; quantity of the biomass fuel applied (according to the required quantity of the loaded biomass fuel); intermediate load of the boiler. The running time of the boiler in heating operation cycle, tgnr,op,d is calculated by: davgoutgnrHdindisHdopgnrQt,,,,,,,,,Φ= (h) (8) where tgnr,op,,d running time in heating operation cycle within a 24 h operation period in h; QH,dis,in,d heat to be supplied to the distribution system within a 24 h operation period in kWh; H,gnr,out,avg,d average heat output from the biomass boiler within a 24 h operation period in kW. 7.2.4 Cooling down operation cycle The operation period for the cooling down operation cycle tgnr,cod is influenced by: time when the operation cycle starts again; mass of the relevant parts of the boiler; SIST EN 15316-4-7:2009

boiler in fire bed operation cycle - operation period tgnr,fib NOTE 1 In this case, the boiler temperature is the same as the regular boiler operating temperature. boiler in non operation cycle - operation period tgnr,non NOTE 2 In this case, the boiler temperature is the same as the ambience temperature (no heat loss). 7.3 Case specific boiler efficiency method 7.3.1 Principle of the method This method is related to the test values according to relevant European Standards. If no values are available, default values are given in Annex A or in a national annex. a) data are collected for three basic load factors or power outputs: gnr,Pn efficiency at 100 % load; gnr,Pint efficiency at intermediate load; gnr,ls,P0 heat losses at 0 % load. b) efficiencies and heat losses data are corrected according to actual boiler operating conditions (temperature); c) thermal losses at 100 % load, gnr,ls,Pn, and at intermediate load, gnr,ls,Pint, are calculated according to the temperature corrected efficiencies; d) calculation of thermal losses corresponding to the actual power output is made by linear or polynomial interpolation between thermal losses determined for the three basic power outputs; NOTE For the case specific boiler efficiency method, thermal losses and the load factor gnr are referred to boiler output. e) auxiliary energy is calculated taking into account the actual power output of the boiler; f) recoverable boiler envelope thermal losses are calculated according to a tabulated fraction of stand-by heat losses and boiler location; g) rec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...