EN 12391-1:2003

(Main)Chimneys - Execution standard for metal chimneys - Part 1: Chimneys for non-roomsealed heating appliances

Chimneys - Execution standard for metal chimneys - Part 1: Chimneys for non-roomsealed heating appliances

This European Standard describes the method of specifying the design criteria and the installation method for building custom built chimneys with rigid metal liners, for relining a chimney with rigid or flexible metal liners and for system chimneys with rigid metallic liners used to convey the products of combustion from heating appliances to the outside atmosphere. It also gives information on commissioning, cleaning and maintenance of an installed chimney.

Abgasanlagen - Ausführungsbestimmungen für Metallabgasanlagen - Teil 1: Abgasanlagen für raumluftabhängige Feuerstätten

Diese Europäische Norm beschreibt das Verfahren zur Festlegung der Bemessungskriterien und das Montageverfahren für System-Abgasanlagen mit starren Metallinnenrohren, die Innenrohrerneuerung einer Abgasanlage mit starren oder flexiblen Metallinnenrohren und von System-Abgasanlagen mit starren Metallinnenrohren, welche zur Ableitung von Verbrennungsprodukten von Feuerstätten an die Außenluft verwendet werden. Sie enthält auch Angaben über die Inbetriebnahme, Reinigung und Instandhaltung einer eingebauten Abgasanlage.

Diese Norm gilt nicht für die Bemessung, den Einbau, die Inbetriebnahme, Reinigung und Instandhaltung von Abgasanlagen mit der Bezeichnung H (Abgasanlagen mit Überdruck) oder Abgasanlagen für raumluftunabhängige Feuerstätten.

Diese Norm enthält auch Festlegungen zur Begrenzung der Stütze einer Abgasanlage sowie die höchstzulässige freitragende Abgasanlagenhöhe von System- und Montage-Abgasanlagen.

Diese Europäische Norm gilt nicht für Abgasanlagen, die von Tragkonstruktionen unabhängig errichtet werden können (freistehend oder selbststützend).

Conduits de fumée - Norme de mise en oeuvre pour conduits de fumée métalliques - Partie 1: Conduits de fumée pour chaudières non étanches

La présente Norme européenne spécifie la méthode permettant de préciser les critères de conception ainsi que la méthode d'installation pour construire un conduit de fumée sur site au moyen de parois intérieure métallique rigide, pour tuber un conduit de fumée au moyen de parois intérieure métallique rigide ou flexible et pour les conduits de fumée simple paroi ou multiparois munis de parois intérieure métallique rigide utilisés pour évacuer les produits de combustion de l'appareil vers l'atmosphère extérieure. Elle donne aussi des informations sur la mise en service, le ramonage et l'entretien d'un conduit de fumée installé.

La présente norme ne traite pas de la conception, de l'installation, de la mise en service, du ramonage et de l'entretien des conduits de fumée portant la désignation H (conduit de fumée fonctionnant sous pression positive élevé) ou des conduits de fumée pour chaudières étanches (ventouses).

La présente norme prescrit également des limites pour les supports de conduit de fumée et la hauteur maximale non supportée des conduits de fumée et conduits de fumée construits sur site à l'intérieur ou contre un bâtiment, et destinés à être supportés par un mât ou une structure autre qu'un bâtiment.

Cette Norme européenne ne s'applique pas aux conduits de fumée structurellement indépendants (autoporteurs).

Dimniki – Standard za izvedbo kovinskih dimnikov – 1. del: Dimniki za ogrevalne naprave v odprtih prostorih

General Information

- Status

- Withdrawn

- Publication Date

- 16-Dec-2003

- Withdrawal Date

- 11-Sep-2007

- Technical Committee

- CEN/TC 166 - Chimneys

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 12-Sep-2007

- Completion Date

- 12-Sep-2007

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 12391-1:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chimneys - Execution standard for metal chimneys - Part 1: Chimneys for non-roomsealed heating appliances". This standard covers: This European Standard describes the method of specifying the design criteria and the installation method for building custom built chimneys with rigid metal liners, for relining a chimney with rigid or flexible metal liners and for system chimneys with rigid metallic liners used to convey the products of combustion from heating appliances to the outside atmosphere. It also gives information on commissioning, cleaning and maintenance of an installed chimney.

This European Standard describes the method of specifying the design criteria and the installation method for building custom built chimneys with rigid metal liners, for relining a chimney with rigid or flexible metal liners and for system chimneys with rigid metallic liners used to convey the products of combustion from heating appliances to the outside atmosphere. It also gives information on commissioning, cleaning and maintenance of an installed chimney.

EN 12391-1:2003 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12391-1:2003 has the following relationships with other standards: It is inter standard links to EN 15287-1:2007, EN 13384-3:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12391-1:2003 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12391-1:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2004

Dimniki – Standard za izvedbo kovinskih dimnikov – 1. del: Dimniki za ogrevalne

naprave v odprtih prostorih

Chimneys - Execution standard for metal chimneys - Part 1: Chimneys for non-

roomsealed heating appliances

Abgasanlagen - Ausführungsbestimmungen für Metallabgasanlagen - Teil 1:

Abgasanlagen für raumluftabhängige Feuerstätten

Conduits de fumée - Norme de mise en oeuvre pour conduits de fumée métalliques -

Partie 1: Conduits de fumée pour chaudieres non étanches

Ta slovenski standard je istoveten z: EN 12391-1:2003

ICS:

91.060.40 Dimniki, jaški, kanali Chimneys, shafts, ducts

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 12391-1

NORME EUROPÉENNE

EUROPÄISCHE NORM

December 2003

ICS 91.060.40

English version

Chimneys - Execution standard for metal chimneys - Part 1:

Chimneys for non-roomsealed heating appliances

Conduits de fumée - Norme de mise en oeuvre pour Abgasanlagen - Ausführungsbestimmungen für

conduits de fumée métalliques - Partie 1: Conduits de Metallabgasanlagen - Teil 1: Abgasanlagen für

fumée pour chaudières non étanches raumluftabhängige Feuerstätten

This European Standard was approved by CEN on 3 November 2003.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,

Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and United

Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2003 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12391-1:2003 E

worldwide for CEN national Members.

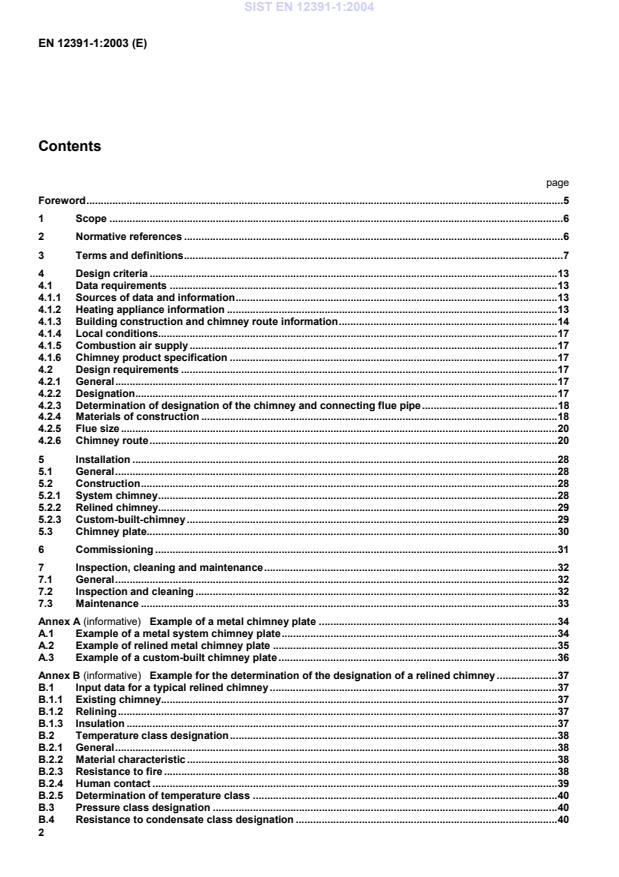

Contents

page

Foreword.5

1 Scope .6

2 Normative references .6

3 Terms and definitions.7

4 Design criteria .13

4.1 Data requirements .13

4.1.1 Sources of data and information.13

4.1.2 Heating appliance information .13

4.1.3 Building construction and chimney route information.14

4.1.4 Local conditions.17

4.1.5 Combustion air supply.17

4.1.6 Chimney product specification .17

4.2 Design requirements .17

4.2.1 General.17

4.2.2 Designation.17

4.2.3 Determination of designation of the chimney and connecting flue pipe.18

4.2.4 Materials of construction .18

4.2.5 Flue size.20

4.2.6 Chimney route.20

5 Installation .28

5.1 General.28

5.2 Construction.28

5.2.1 System chimney.28

5.2.2 Relined chimney.29

5.2.3 Custom-built-chimney.29

5.3 Chimney plate.30

6 Commissioning .31

7 Inspection, cleaning and maintenance.32

7.1 General.32

7.2 Inspection and cleaning .32

7.3 Maintenance .33

Annex A (informative) Example of a metal chimney plate .34

A.1 Example of a metal system chimney plate.34

A.2 Example of relined metal chimney plate .35

A.3 Example of a custom-built chimney plate .36

Annex B (informative) Example for the determination of the designation of a relined chimney .37

B.1 Input data for a typical relined chimney .37

B.1.1 Existing chimney.37

B.1.2 Relining.37

B.1.3 Insulation .37

B.2 Temperature class designation.38

B.2.1 General.38

B.2.2 Material characteristic .38

B.2.3 Resistance to fire .38

B.2.4 Human contact .39

B.2.5 Determination of temperature class .40

B.3 Pressure class designation .40

B.4 Resistance to condensate class designation .40

B.5 Corrosion resistance class designation.40

B.6 Soot fire resistance class and distance to combustible material designation .40

B.7 Designation of the relined chimney.40

B.8 Example of chimney plate of the relined chimney in this Example.41

Annex C (informative) Example of metal chimney product designation.42

Annex D (normative) Determination of the chimney designation for an installed system chimney.43

D.1 General.43

D.2 Temperature class .43

D.3 Pressure class.43

D.4 Resistance to condensate class .43

D.5 Corrosion resistance class.43

D.6 Soot fire resistance class and distance to combustible material.43

Annex E (normative) Determination of the chimney designation for relined of custom-built chimneys .44

E.1 General.44

E.2 Temperature class .44

E.3 Pressure class.47

E.4 Resistance to condensate class .47

E.5 Corrosion resistance class.47

E.6 Soot fire resistance class and distance to combustible material.48

Annex F (informative) Material characteristics .49

Annex G (informative) Location of the chimney outlet.54

Annex H (informative) Method for calculating the temperature of adjacent materials .56

H.1 Example for calculation the temperature of adjacent materials .57

Annex I (informative) Checking, handling and site storage of materials and components .59

I.1 General.59

I.2 Checking, handling and site storage of materials and components.59

I.2.1 Checking on delivery of materials .59

I.2.2 Checking before installation.59

I.2.3 Check of existing chimney.59

I.2.4 Site handling and storage.59

I.2.5 Coordination of work.60

Annex J (informative) Chimney commissioning test procedure.61

J.1 General.61

J.2 Flue flow test.61

J.3 Smoke test.61

J.4 Pressure test .62

Annex K (informative) Example for the determination of the designation of a custom-built chimney .63

K.1 Input data for a typical custom-built chimney .63

K.1.1 Liner .63

K.1.2 Insulation .63

K.1.3 Enclosure.63

K.2 Temperature class designation.63

K.2.1 General.63

K.2.2 Material characteristic.63

K.2.3 Resistance to fire.64

K.2.4 Human contact.65

K.2.5 Determination of temperature class .65

K.3 Pressure class designation .65

K.4 Resistance to condensate class designation .65

K.5 Corrosion resistance class designation.65

K.6 Soot fire resistance class and distance to combustible material designation .65

K.7 Designation of the custom-built chimney .66

K.8 Example of chimney plate of the custom-built chimney in this Example.66

Annex L (informative) Example of chimney designation.67

Annex M (informative) Correlation between liner material specification and corrosion load in Member

States .68

Bibliography .74

Foreword

This document (EN 12391-1:2003) has been prepared by Technical Committee CEN/TC 166 "Chimneys", the

secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an identical text or

by endorsement, at the latest by June 2004, and conflicting national standards shall be withdrawn at the latest by

June 2004.

This European Standard is one of a series of standards as listed below.

Chimneys – Execution standard for metal chimneys – Part 1: Chimneys for non-roomsealed heating appliances.

Chimneys – Execution standard for metal chimneys – Part 2: Chimneys for roomsealed heating appliances.

The annexes A, B, C, F, G, H, I, J, K, L and M are informative, the annexes D and E are normative.

This document includes a bibliography.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Denmark, Finland,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal,

Slovakia, Spain, Sweden, Switzerland and the United Kingdom.

1 Scope

This European Standard specifies the method of specifying the design criteria and the installation method for

building custom-built chimneys with rigid metal liners, for relining a chimney with rigid or flexible metal liners and for

single wall system chimneys or multi-wall system chimneys with rigid metallic liners, used to convey the products of

combustion from heating appliances to the outside atmosphere. It also gives information on commissioning,

cleaning and maintenance of an installed chimney.

This standard does not cover the design, installation, commissioning, cleaning and maintenance of chimneys

designated H (high positive pressure chimney) and chimneys for roomsealed appliances.

This standard also specifies limitations for supporting a chimney, and the maximum unsupported chimney height

for system chimneys and custom-built chimneys within or against a building, and for supporting by a mast or other

structures than a building.

This European Standard does not apply to structurally independent (free-standing or self-supporting) chimneys.

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other publications. These

normative references are cited at the appropriate places in the text, and the publications are listed hereafter. For

dated references, subsequent amendments to or revisions of any of these publications apply to this European

Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the

publication referred to applies (including amendments).

EN 1443, Chimneys – General requirements.

EN 1806, Chimneys – Clay/ceramic flue blocks for single wall chimneys - Requirements and test methods.

EN 1856-1, Chimneys – Requirements for metal chimneys – Part 1: System chimney products.

prEN 1856-2, Chimneys – Requirements for metal chimneys – Part 2: Metal liners and connecting flue pipes.

EN 1858, Chimneys – Components – Concrete flue blocks.

EN 1859, Chimneys – Metal chimneys – Test methods.

EN 13084-1, Free-standing industrial chimneys – Part 1: General requirements.

ENV 1993-3-2, Eurocode 3: Design of steel structures – Part 3-2: Towers, masts and chimneys – Chimneys.

EN 12446, Chimneys – Components – Concrete outer wall elements.

prEN 13069, Chimneys – Clay/ceramic outer walls for system chimneys – Requirements and test methods.

EN 13384-1, Chimneys – Thermal and fluid dynamic calculation methods – Part 1: Chimneys serving one

appliance.

EN 13501-2:2003, Fire classification of construction products and building elements – Part 2: Classification using

data from fire resistance tests, excluding ventilation services.

EN 61024-1-2, Protection of structures against lightning – Part 1-2: General principles – Guide B – Design,

installation, maintenance and inspection of lightning protection systems (IEC 61024-1-2:1998).

3 Terms and definitions

For the purposes of this European Standard, the terms and definitions given in EN 1443, EN 1856-1, prEN1856-2

and EN 1859 together with the following apply.

Examples of chimney construction identifying individual component terminology and definitions are given in Figures

1, 2 and 3.

3.1

heating appliance adapter

component which connects the connecting flue pipe or the chimney to a heating appliance

3.2

chimney adapter

component which connects a chimney to a connecting flue pipe or an heating appliance

3.3

fire compartment

part of the building being isolated to provide resistance to fire

3.4

flashing

component or site fabricated materials used for weatherproofing the penetration of the roof by the chimney

3.5

storm collar

component attached and sealed to the outer wall of the chimney immediately above the flashing in order to prevent

the entry of rain into the building

3.6

fire stop

component intended to provide resistance to fire spread between rooms or compartments

3.7

fire stop spacer

component intended to locate a chimney at the correct distance from combustible material, when penetrating a wall

or a floor, which separates compartments, and to provide resistance to the spread of fire between rooms or fire

compartments

3.8

sleeve

component which provides an aperture through a wall, ceiling or floor through which the chimney passes

3.9

back ventilation

ventilation in the space between flue liner and the outer wall of the chimney or an enclosure

3.10

draught regulator

balanced hinged flap in a flue opening to allow airflow into the chimney to control draught at the boiler outlet

3.11

ventilating air flap

automatically operated flap used to introduce ventilation air for the purpose of drying the chimney

NOTE This can be a draught regulator.

3.12

damper

device used to close or partially close the flue

3.13

explosion relief

device that protects the chimney against overpressure arising from deflagration or explosion in the flue

3.14

expansion component

component used to accommodate thermal movement

3.15

silencer

component installed to provide noise attenuation

3.16

access component

component installed in the chimney or in the connecting flue pipe to provide access to the flue for the purpose of

inspection or cleaning

3.17

test point

component that provides access for gas sampling and measuring

3.18

closure component

any component used to shut off an opening in the chimney, e.g. base plug, tee piece plug

3.19

common header

horizontal or inclined common connecting flue pipe to which more than one heating appliance is connected

3.20

condensate drain

component to facilitate the disposal of condensate

3.21

rigid liner

straight metal liner that cannot bend without permanent deformation

3.22

rain cap

part of the chimney that protects against the entry of rain. This may be a part of a terminal

3.23

rain seal

part of the chimney that stops the entry of rain into the insulation space

3.24

centralising spacer

component to centralise the liner

3.25

T-piece

chimney fitting which allows an appliance, connecting flue pipe or accessory to be connected to the chimney flue at

an angle

3.26

elbow

chimney fitting which provides a change of direction of the flue

3.27

infill insulation

insulation which is poured into the gap between the liner and the outer wall of the chimney

3.28

preformed insulation

insulation prefabricated to fit the insulation space

3.29

air gap insulation

closed air space between the liner and the outer wall

3.30

flexible liner

metal tube having a single or multi-skin construction that is able to bend in any direction without permanent

deformation

3.31

back ventilation air inlet

opening in the outer wall of a chimney used for the intake of room air for back ventilation

3.32

back ventilation air outlet

opening in the outer wall of a chimney or at the top of the chimney to exhaust the back ventilation air

3.33

seal

device that joins two elements in such a way as to prevent leakage

3.34

sealant

material which, applied in an unformed state to a joint, seals it by adhering to appropriate surfaces within the joint

a.) double wall insulated metal chimney in a solid block shaft

b.) internal or external insulated metal chimney without enclosure

c.) double wall insulated metal chimney in a cavity block

d.) double wall insulated metal chimney in an enclosure as a part of the building structure

e.) double wall insulated metal chimney in a specified material

Figure 1 — Terminology for a system chimney

Figure 2 — Terminology for a relined chimney

a.) double wall insulated metal chimney in a solid block shaft

b.) internal or external insulated metal chimney without enclosure

c.) double wall insulated metal chimney in a cavity block

d.) double wall insulated metal chimney in an enclosure as a part of the building structure

e.) double wall insulated metal chimney in a specified material

Figure 3 — Technology for a custom-built chimney

4 Design criteria

4.1 Data requirements

4.1.1 Sources of data and information

The data and information specified in 4.1.2 to 4.1.6 shall be obtained and documented as appropriate.

NOTE The sources may be:

- heating appliance manufacturers catalogues and literature;

- chimney manufacturers literature including installation instructions;

- architects drawings or plans and/or site surveys;

- annex A of this document;

- local building rules.

A possible source of typical or average data is EN 13384-1.

4.1.2 Heating appliance information

The following information for the heating appliance(s) shall be obtained from the documentation of the heating

appliance manufacturer or if not available the source of the data shall be documented in the design:

For selecting the chimney type (required designation):

kind/type of appliance/burner;

kind of fuel;

maximum (nominal) flue gas temperature;

maximum allowable condensate back flow rate (from the chimney).

For calculation (sizing):

kind/type of appliance/burner;

kind of fuel;

minimum and maximum flue gas mass flow (or burning rate and CO -content or heat input and CO -content or

2 2

heat output, boiler efficiency and CO -content);

minimum flue gas temperature for nominal and minimum heat output/input;

minimum draught (for N) or maximum differential pressure (for P);

CO -content;

size/shape of flue gas outlet.

For appliance/connecting flue pipe/chimney adapter design/choice:

size/shape of flue gas outlet;

position/height of flue gas outlet.

4.1.3 Building construction and chimney route information

In order to allow the chimney route to be determined the relevant details of the building or support structure shall be

obtained (see Figure 4).

If the chimney is to be supported by the building structure, the construction of the building and the materials used

shall be capable of supporting the loads imposed upon it by the chimney. The fixings shall be compatible with the

materials of construction of the building. This shall be checked before installing the chimney.

The following list of information shall be supplied where appropriate (see Figure 4):

height from ground to ceiling (structural or finished) H1;

height from intermediary floor to ceiling (structural or finished) H2;

height of ridge H3;

pitch of roof g ;

depth and thickness of joist timbers and distances between centres T1;

depth and thickness of joist timbers and distances between centres T2;

depth and thickness of roof timbers and distance centres T3;

the horizontal distance between the centre line of the chimney above roof level and the gable end of the

building L1;

the horizontal distance between the centre line of the chimney above roof level and the ridge of the roof L2;

distance through loft measured at centre line of the chimney C1;

height from the ground to the centre line of chimney inlet C2;

height from the ground to the bottom of the liner C3;

total chimney height from the ground to the chimney outlet C4;

height from the ground to the centre of each opening C5;

height from the ground to the lower bend of each offset where the centre line of the liner changes the direction

C6;

vertical distance between the lower and upper bends of each offset where the centre line of the liner changes

the direction C7;

horizontal distance between the vertical centre lines of each offset C8;

horizontal distance 1 from the centre of appliance-outlet to the centre of the chimney F1;

horizontal distance 2 from the centre of appliance-outlet to the centre of the chimney F2;

height from ground to the centre of appliance outlet F3:

materials of each floor;

materials of each ceiling;

roof finish;

existing chimney details, e.g. for relining, including:

internal dimensions throughout its length D;

designation of existing chimney;

construction materials to determine thermal performance and fire rating;

condition and nature of inner flue surface of the existing chimney;

structural details;

distance of chimney outlet position to adjacent buildings, obstructions and other building openings, e.g.

windows/ skylights etc.

Figure 4 — Example of typical building structure designed to assist exchange of information

4.1.4 Local conditions

Environmental and topographical particulars of the site shall be obtained as required in EN 13384-1.

4.1.5 Combustion air supply

Information on the size and position of apertures for combustion air supply into the room containing the appliance

shall be obtained (possible sources of data are given in 4.1.1).

4.1.6 Chimney product specification

The following information about the chimney product specification shall be obtained (see also 4.1.1):

identification and designation of the system chimney or the components for custom built chimneys or relining;

design load or maximum allowed chimney height to be supported by lengths, fittings and supports;

weights of components;

manufacturers installation instruction.

Additional information may be required for chimney sizing. Refer to EN 13384-1.

4.2 Design requirements

4.2.1 General

The design of the chimney installation shall be fully detailed and documented. The design shall enable a chimney

product manufacturer’s standard components to be used in carrying out the installation without modification.

4.2.2 Designation

The chimney products shall be chosen so that the finished chimney shall have a designation in accordance with

EN 1443 (see annex B).

The chimney and connecting flue pipe shall have designation classes appropriate to the appliance details (see

4.1.2) and the building structure details (see 4.1.3).

Each designation parameter shall be of a class at least equal to that required or shall be of a higher class

according to the following sequence:

T600 > T450 > T400 > T300 > T250 > T200 > T160 > T140 > T120 > T100 > T080;

H > P > N;

D3 > D2 > D1;

W2 > W1;

G > O;

xx (low) > xx (high).

where

T is the temperature class;

H is the high positive pressure class;

P is the positive pressure class;

N is the negative pressure class;

O is without soot fire resistance;

G is with soot fire resistance;

xx is the distance to combustibles;

and for corrosion class:

W is wet operating conditions;

D is dry operating conditions;

1 is for gas;

2 is for light oil / natural wood;

3 is for heavy oil / solid fuel.

4.2.3 Determination of designation of the chimney and connecting flue pipe

4.2.3.1 System chimney

The designation of the system chimney product shall be according to EN 1856-1 (see annex C in this document).

The installed chimney shall be assigned a chimney designation according to EN 1443 (see annex D in this

document).

4.2.3.2 Relined and custom-built chimney

The designation of a relined or custom-built chimney shall be determined according to the calculations of annex E.

4.2.3.3 Connecting flue pipe

The designation of the connecting flue pipe shall be in accordance either with prEN 1856-2. Chimney components

complying with EN 1856-1 can also be used.

4.2.3.4 Supplementary components or materials

Supplementary components or materials shall have performance characteristics appropriate to the designation of

the chimney components, which affect them e.g. insulation operating temperatures.

4.2.4 Materials of construction

4.2.4.1 General

Supplementary materials not supplied with the chimney products should be fit for purpose, e.g. in terms of

corrosion, temperature, strength, e.g. fixings, screws or additional supports.

4.2.4.2 System chimneys

System chimneys shall be in accordance with EN 1856-1.

4.2.4.3 Relined chimneys

4.2.4.3.1 Flue Liners

Flue liners for relining shall be made from rigid or flexible metal chimney liners in accordance with the requirements

of prEN 1856-2.

NOTE System chimney products in accordance with the requirements of EN 1856-1 may also be used as liners.

4.2.4.3.2 Insulation

Insulation between the new liner and the outer wall shall be either rigid (e.g. Table F.1) or be loose material or be

an air gap.

Insulation materials including loose infill insulation shall be approved to be fit for the purpose.

NOTE 1 Care should be taken when using loose infill to prevent the risk of flue blockage arising from the escape of the

insulation.

NOTE 2 Loose infill with binders should not prevent free movement of the liner.

NOTE 3 To determine the effect of a closed air gap see Table F.5 for thermal resistance values.

NOTE 4 To determine the effect of an open air gap an external heat transfer coefficient of 8 W/m2K should be used in the

calculation for heat transfer (see EN 13384-1). Any additional insulation outside of the airgap is excluded in the calculation.

4.2.4.3.3 Outer wall

The existing chimney is the outer wall of the relined chimney. The existing chimney shall be checked that it is fit for

its intended use.

4.2.4.3.4 Seals and sealants

Only those seals and sealants specified by the chimney product manufacturers shall be used.

4.2.4.4 Custom-built-chimneys

4.2.4.4.1 Liners

Liners for custom-built chimneys shall be made from rigid metal chimney liners complying with the requirements of

prEN 1856-2.

NOTE System chimney products complying with the requirements of EN 1856-1 may also be used as liners.

4.2.4.4.2 Insulation

Insulation between the new liner and the outer wall shall be either rigid (e.g. Table F.1) or loose fill material or be

an air gap.

Insulation materials including loose infill insulation shall be fit for purpose.

NOTE 1 Care should be taken when using loose infill without binders to prevent the risk of flue blockage arising from the

escape of the insulation.

NOTE 2 Loose infill with binders should not prevent free movement of the liner.

NOTE 3 To determine the effect of a closed air gap see Table C.5 for thermal resistance values.

NOTE 4 To determine the effect of an open air gap an external heat transfer coefficient of 8 W/m K should be used in the

calculation for heat transfer (see EN 13384-1). Any additional insulation outside of the airgap is excluded in the calculation.

4.2.4.4.3 Outer wall

Outer wall components of custom-built chimneys shall comply with EN 12446, EN 1806, EN 1858, prEN 13069 or

as specified in annex F, Table F.4.

4.2.4.4.4 Seals and sealants

Only those seals and sealants specified by the chimney product manufacturers shall be used.

4.2.4.5 Connecting flue pipe and adapters

The material of the connecting flue pipe and adapters shall comply with prEN 1856-2. Chimney components

complying with EN 1856-1 can also be used. Flexible liners complying with prEN 1856-2 can also be used where

permitted and in accordance with national regulations.

4.2.4.6 Additional materials

All fixings e.g. screws, nuts, bolts, plugs, washers shall be such that the assembly is non-combustible and they

shall have a corrosion resistance at least equal to that of the external surface of the chimney.

4.2.5 Flue size

The flue for the chimney and the connecting flue pipe shall be sized in accordance with thermal and fluid dynamic

calculation methods.

NOTE 1 EN 13384-1 describes a calculation method for chimneys serving one appliance.

NOTE 2 EN 13384-2 describes a calculation method for chimneys serving more than one appliances.

4.2.6 Chimney route

4.2.6.1 General

The chimney route should be the shortest, most direct route between the heating appliance outlet and the chimney

terminal and should be straight and vertical wherever possible, with the termination being as near to the highest

part of the building (e.g. ridge) as practicable to ensure adequate draft and dispersion of flue gas.

The chimney route selected should enable the chimney manufacturers standard components to be used in carrying

out the installation.

4.2.6.2 Connecting flue pipe

A connecting flue pipe designated suitable for wet operating conditions, shall be inclined to allow condensate to be

drained.

NOTE 1 It is recommended that it should be inclined at least 3° to the horizontal.

The connecting flue pipe shall not pass through a ceiling or into another fire compartment.

Where it is necessary for a connecting flue pipe to pass through a wall within a fire compartment or through a wall

to the outside atmosphere, a sleeve shall be used to allow free movement and assure minimum distance to

combustible materials.

NOTE 2 It is recommended that the connecting flue pipe should be as short as possible and the angle of entry into the

chimney should not exceed 45°.

NOTE 3 For natural draught installations with a draught diverter a vertical run of flue directly above the draught diverter

sufficient to prevent spillage from the appliance should be provided unless otherwise stated in the appliance manufacturers

installation instructions.

The appliance manufacturer’s installation instructions shall be followed for any specific requirements.

4.2.6.3 Resistance to fire

A chimney installation shall achieve the resistance to fire (external to external) required for the specific parts of the

building through which it passes. The required resistance to fire shall be classified in terms of EI (Integrity and

insulation) according to EN 13501-2:2003, 7.5.10.4. This may be achieved by one of the following:

a chimney itself with the required resistance to fire;

a chimney built into a shaft with the necessary resistance to fire (e.g. non-combustible enclosure);

a chimney and its enclosure which together fulfil the necessary resistance to fire.

4.2.6.4 Distance to combustible material

4.2.6.4.1 System chimneys

The minimum distance to combustible materials for a system chimney shall be declared by the manufacturer in

accordance with EN 1856-1.

A system chimney which passes through a combustible wall shall be sleeved and/or shielded to maintain the

appropriate distance to combustible material or in the case of cavity wall construction to contain any infill. Any

sleeve or shield opening to the outside shall be weatherproofed.

4.2.6.4.2 Relined and custom-built chimneys

The minimum distance to combustible materials for a relined chimney and a custom-built chimney shall be

determined in accordance with the calculation of E.2.

NOTE Formula E.1 covers the case of non-ventilated spaces between the chimney and combustible material and gives the

maximum allowed flue gas temperature for a given distance.

Formula E.3 covers the cases of ventilated spaces between the chimney and combustible material and gives the maximum

allowed flue gas temperature for a gap of 4 cm.

A custom-built chimney which passes through a combustible wall shall be sleeved and/or shielded to maintain the

appropriate distance to combustible material or in the case of cavity wall construction to contain any infill. Any

sleeve or shield opening to the outside shall be weatherproofed.

4.2.6.4.3 Connecting flue pipe

NOTE 1 Connecting flue pipes are considered normally to be single wall uninsulated ventilated.

Connecting flue pipes in temperature classes T100 to T160 shall be at a minimum distance of 40 mm from

combustible materials, when installed in natural ventilated conditions or at a distance as calculated in formula E.1

of E.2.

NOTE 2 Connecting flue pipes in temperature class T080 do not require a minimum distance to combustible materials.

However, direct contact is not recommended.

Naturally ventilated connecting flue pipes with a temperatu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...