EN 16475-7:2016

(Main)Chimneys - Accessories - Part 7: Rain caps - Requirements and test methods

Chimneys - Accessories - Part 7: Rain caps - Requirements and test methods

This European Standard specifies requirements and test methods for rain caps that are used as components, subject to flue gas, in order to prevent rain entry into the chimneys. Rain caps already tested together with system chimney products or other chimney components, e.g. terminals, are not covered by this standard. Rain caps incorporating a bird guard are also included. It also specifies the requirements for marking, manufacturers’ instruction, product information and evaluation of conformity.

Abgasanlagen - Zubehörteile - Teil 7: Regenhauben - Anforderungen und Prüfverfahren

Diese Europäische Norm legt Anforderungen und Prüfverfahren für Regenhauben fest, die als dem Abgas ausgesetzte Bauteile verwendet werden, um vor Eintritt von Regen in die Abgaszüge zu schützen.

Regenhauben, die bereits zusammen mit Produkten für System-Abgasanlagen oder mit anderen Bauteilen einer Abgasanlage geprüft worden sind, z. B. Aufsätze, fallen nicht in den Anwendungsbereich dieser Norm.

Sie legt außerdem die Anforderungen an die Kennzeichnung, Herstelleranweisungen, Produktinformationen und Bewertung und Überprüfung der Leistungsbeständigkeit fest.

ANMERKUNG Regenhauben nach dieser Norm sind sowohl für die trockene als auch für die nasse Betriebsweise geeignet.

Conduits de cheminée - Accessoires - Partie 7: Chapeaux pare-pluie - Exigences et méthodes d'essai

La présente Norme européenne spécifie les exigences et les méthodes d'essai pour les chapeaux pare-pluie utilisés comme composants, en contact avec les fumées, afin d'empêcher la pluie de pénétrer dans les conduits de fumée.

Les chapeaux pare-pluie déjà soumis à essai avec les composants de conduits système ou les autres composants du conduit de fumée, tels que les terminaux, ne sont pas couverts par la présente norme.

Les chapeaux pare-pluie comprenant un dispositif anti-volatiles sont également inclus.

Elle spécifie également les exigences pour le marquage, les instructions du fabricant, les informations sur le produit et l'évaluation de la conformité.

Dimovodne naprave - Oprema - 7. del: Dežne kape - Zahteve in preskusne metode

Ta evropski standard določa zahteve in preskusne metode za dežne kape, ki se uporabljajo kot sestavni deli, pri čemer so izpostavljene odpadnemu plinu in preprečujejo vstop padavin v dimnike. Ta standard ne zajema dežnih kap, ki so preskušene skupaj z dimovodnimi izdelki ali drugimi sestavnimi deli dimnikov, npr. terminali. Prav tako ta standard ne zajema dežnih kap z zaščito pred pticami. Določa tudi zahteve za označevanje, navodila za proizvajalca, informacije o izdelku in vrednotenje skladnosti.

General Information

- Status

- Withdrawn

- Publication Date

- 26-Jan-2016

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 166 - Chimneys

- Drafting Committee

- CEN/TC 166/WG 1 - General requirements

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 01-Jul-2020

- Completion Date

- 28-Jan-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Merged Into

EN 16475-7:2016+A1:2020 - Chimneys - Accessories - Part 7: Rain caps - Requirements and test methods - Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Amended By

EN 16475-7:2016/FprA1 - Chimneys - Accessories - Part 7: Rain caps - Requirements and test methods - Effective Date

- 13-Jun-2018

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Nonprofit organization that performs technical evaluations of building products.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

BBA (British Board of Agrément)

UK construction product certification.

Sponsored listings

Frequently Asked Questions

EN 16475-7:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chimneys - Accessories - Part 7: Rain caps - Requirements and test methods". This standard covers: This European Standard specifies requirements and test methods for rain caps that are used as components, subject to flue gas, in order to prevent rain entry into the chimneys. Rain caps already tested together with system chimney products or other chimney components, e.g. terminals, are not covered by this standard. Rain caps incorporating a bird guard are also included. It also specifies the requirements for marking, manufacturers’ instruction, product information and evaluation of conformity.

This European Standard specifies requirements and test methods for rain caps that are used as components, subject to flue gas, in order to prevent rain entry into the chimneys. Rain caps already tested together with system chimney products or other chimney components, e.g. terminals, are not covered by this standard. Rain caps incorporating a bird guard are also included. It also specifies the requirements for marking, manufacturers’ instruction, product information and evaluation of conformity.

EN 16475-7:2016 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16475-7:2016 has the following relationships with other standards: It is inter standard links to EN 16475-7:2016+A1:2020, EN 1857:2010, EN 1858:2008+A1:2011, EN 206:2013+A2:2021, EN 1443:2019, EN 14471:2013+A1:2015, EN 14297:2004, EN 1856-2:2009, EN 16475-7:2016/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16475-7:2016 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/105. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16475-7:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Dimovodne naprave - Oprema - 7. del: Dežne kape - Zahteve in preskusne metodeAbgasanlagen - Zubehörteile - Teil 7: Regenhauben - Anforderungen und PrüfverfahrenConduits de cheminée - Accessoires - Partie 7: Chapeaux pare-pluie - Exigences et méthodes d'essaiChimneys - Accessories - Part 7: Rain caps - Requirements and test methods91.060.40Dimniki, jaški, kanaliChimneys, shafts, ductsICS:Ta slovenski standard je istoveten z:EN 16475-7:2016SIST EN 16475-7:2016en,fr,de01-marec-2016SIST EN 16475-7:2016SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16475-7

January

t r s x ICS

{ sä r x rä v r English Version

Chimneys æ Accessories æ Part

yã Rain caps æ Requirements and test methods Conduits de cheminée æ Accessoires æ Partie

yã Chapeaux pareæpluie æ Exigences et méthodes d 5essai

Abgasanlagen æ Zubehörteile æ Teil

yã Regenhauben æ Anforderungen und Prüfmethoden This European Standard was approved by CEN on

t y November

t r s wä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x v y wæ yã t r s x ESIST EN 16475-7:2016

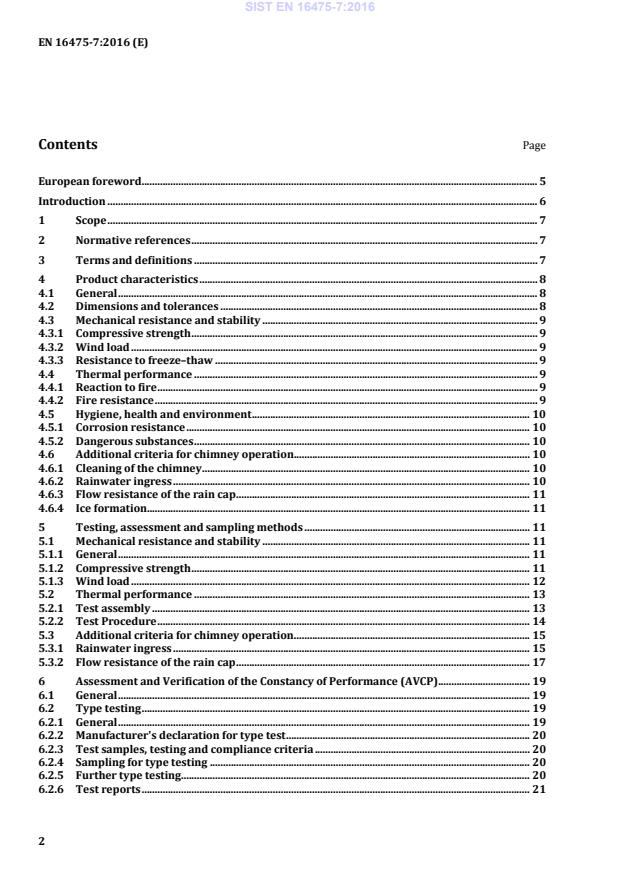

Deemed to satisfy information . 31 Annex B (informative)

Coefficients of flow resistance . 33 Annex C (normative)

Choice of size for type test and sampling . 34 C.1 General . 34 C.2 Fire resistance . 34 C.3 Mechanical resistance and stability . 34 C.4 Rainwater ingress . 34 C.5 Flow resistance . 34 C.6 Resistance to freeze–thaw . 34 Annex D (informative)

Example of sampling for factory production control . 35 D.1 Sampling plans . 35 D.1.1 General . 35 D.1.2 Acceptable quality level (AQL) . 35 D.1.3 The inspection level . 35 D.1.4 Normal, tightened or reduce inspection . 35 D.1.5 Single, double, multiple or sequential sampling . 35 D.1.6 Batch quantity . 35 D.2 Inspection levels and procedures . 36 D.2.1 Incoming material . 36 D.2.2 In-process inspection . 36 SIST EN 16475-7:2016

Method of measuring the hot gas temperature . 37 Annex ZA (informative)

Relationship of this European Standard with Regulation (EU) No.305/2011 . 38 ZA.1 Scope and relevant characteristics . 38 ZA.2 System of Assessment and Verification of Constancy of Performance (AVCP) . 38 ZA.3 Assignment of AVCP tasks . 38 Bibliography . 40

· 25 MPa on 150 × 300 cylinder), a relation between thickness and length of longest side of at least 20 % and fixings with tenon and mortise or similar assembly shape + mortar or jointing material. NOTE Method of fixing ww = double weld, wr = weld and rivet, rr = double rivet, b = bolt and washer, st = single self-tapping screw. Metal: The material of a metal rain cap shall be in accordance with EN 1856-2. Concrete: The material of a concrete rain cap shall be in accordance with EN 1857 or EN 1858. Plastic: The material of a plastic rain cap in contact with combustion products shall be in accordance with the chimney requirements of EN 14471 with the durability against UV (location class) LE. 4.2 Dimensions and tolerances The thickness of material of the individual components of the rain cap shall be not less than that declared by the manufacturer. SIST EN 16475-7:2016

Key 1 rain cap 2 chimney 3 sand bag Figure 1 — Example of a test assembly for compressive strength SIST EN 16475-7:2016

Key 1 terminal 2 brick stack M tilt Load (kN) Key 1 rain cap 2 chimney M upward Load in kN a) Example of test assembly for wind load (horizontal traction) b) Example of test assembly for wind load (vertical traction) Figure 2 — Example of test assembly for wind load 5.1.3.2 Procedure Measure the free area. Apply an evenly distributed test load for horizontal traction of 1,5 kN/m2 of the laterally projected surface area (see Figure 2 a)), and for vertical traction of 0,75 kN/m2 of the upward projected surface area (see Figure 2 b)). SIST EN 16475-7:2016

Key 1 rain cap 2 chimney 3 hot gas generator 4 hot gas connecting pipe D Diameter of hot gas connecting pipe Figure 3 — Example of test assembly for fire resistance 5.2.1.2 Vertical section of the chimney The length of the vertical section of chimney from the centre line of the hot gas connecting pipe to the rain cap shall be (4 ± 1).D, and have a thermal resistance

· 0,12 m2 K/W. The flue size of the vertical section shall be equal to the cross sectional area of the maximum nominal flue size for which the rain cap is suitable 5.2.1.3 Hot gas connecting pipe Construct a purpose-made insulated straight flue pipe having a diameter D equal to the cross sectional area of the maximum nominal flue size for which the rain cap is suitable, of a length of approximately seven diameters measured from the centre line of the flue gas generator to the entry to the test chimney, insulated to provide a thermal resistance value of not less than that equivalent to 50 mm SIST EN 16475-7:2016

Hot gas velocity in m/s at test temperature Temperature class T080 T100 T120 T140 T160 T200 T250 T300 T400 T450 T600 Soot-fire Test temperature in °C Pressure class D in mm 100 120 150 170 190 250 300 350 500 550 700 1000 Negative pressure 100 1,67 1,76 1,90 2,00 2,08 2,36 2,60 2,84 3,56 3,81 4,55 5,09 120 1,68 1,77 1,91 2,00 2,10 2,38 2,62 2,86 3,59 3,83 4,58 5,58 160 1,71 1,80 1,94 2,04 2,13 2,42 2,66 2,91 3,65 3,90 4,66 5,56 200 1,74 1,84 1,99 2,08 2,18 2,48 2,72 2,97 3,73 3,98 4,76 5,41 Positive pressure 100 2,35 2,47 2,65 2,77 2,90 3,26 3,56 3,85 4,73 5,01 5,86 5,09 120 2,39 2,52 2,71 2,83 2,95 3,32 3,62 3,93 4,82 5,11 5,98 5,58 160 2,51 2,64 2,84 2,97 3,10 3,48 3,80 4,12 5,06 5,36 6,27 5,56 200 2,66 2,8 3,01 3,15 3,29 3,70 4,03 4,37 5,36 5,69 6,65 5,41 High positive pressure 100 5,15 5,36 5,68 5,88 6,08 6,63 7,05 7,44 8,36 8,59 9,07 5,09 120 5,28 5,50 5,83 6,04 6,24 6,81 7,24 7,63 8,58 8,82 9,39 5,58 160 5,62 5,86 6,20 6,42 6,64 7,24 7,70 8,12 9,13 9,39 9,91 5,56 200 6,06 6,32 6,69 6,92 7,16 7,81 8,30 8,75 9,84 10,12 10,69 5,41 NOTE The table refers to a maximum diameter of 200 mm. Hot gas velocities for other sizes are possible by calculating according to EN 13384–1. 5.3 Additional criteria for chimney operation 5.3.1 Rainwater ingress 5.3.1.1 Test assembly The flue size of the test assembly shall be equal to the cross sectional area of the maximum nominal flue size for which the rain cap is suitable. The rainmaking installation is made up of parallel pipes in a horizontal plane. The tubes have small spray holes (placed vertically downwards). These spray holes are evenly distributed across the area above the wire mesh. The water from the spray holes shall be distributed through a web of fine (1,3 ± 0,1) mm wide wire mesh, after which the water will fall in the form of raindrops. A typical arrangement is shown in Figure 4. SIST EN 16475-7:2016

Key 1 rain cap 4 rainwater 2 chimney 5 mesh screen 3 pipes with spray holes 6 wind generator Figure 4 — Rainwater ingress test assembly The rain intensity is (1,6 ± 0,2) mm per minute and shall be measured. During calibration an area in front of the wind generator is found where with wind the rain intensity is (1,6 ± 0,2) mm/min. The largest area of the top of the rain cap shall not be more than 20 % of the area found by calibration. The wind generator supplies a horizontal airflow at a velocity of (12 ± 0,5) m/s at the position of the product under test. The outlet of the wind generator shall be square or circular. 5.3.1.2 Procedure Before commencing the rain ingress tests, the test assembly has to be calibrated. For calibration 5 buckets of a diameter of 150 mm, one on each corner of a rectangular area and one in the middle, will be positioned at a level corresponding to the level of the centre of the flue gas outlet. Make sure that the largest area of the top of the rain cap is less than 20 % of the area within the line circumscribing the buckets. Start the calibration test during 10 min with wind and determine if the rain intensity is (1,6 ± 0,1) mm/min by weighing the 5 buckets. Seal the outlet from the duct. With the rain cap under the rain system and in front of the wind generator in accordance to Figure 4 and in such a way that the flue outlet is in line with the centre of the wind generator outlet opening, operate the wind and rain system. Measure the amount of water entering the flue. SIST EN 16475-7:2016

1; — geometrical data of the rain cap; — test room data. — w P = 2nF21ρζ (1) where:

is the coefficient of flow resistance; PF is the measured static pressure in the measuring tube, in Pascals;

is the density of air at the test conditions; wn is the nominal velocity, in meters per second.

Dimensions in millimetres

Key 1 rain cap 2 pressure measurement point 3 fan D diameter of measurement tube a pressure measuring tube Figure 5 — Flow resistance test assembly SIST EN 16475-7:2016

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...