EN 17038-1:2019

(Main)Pumps - Methods of qualification and verification of the Energy Efficiency Index for rotodynamic pump units - Part 1: General requirements and procedures for testing and calculation of Energy Efficiency Index (EEI)

Pumps - Methods of qualification and verification of the Energy Efficiency Index for rotodynamic pump units - Part 1: General requirements and procedures for testing and calculation of Energy Efficiency Index (EEI)

This document describes a methodology to evaluate energy efficiency performance of pump units based on a non-dimensional numerical value called Energy Efficiency Index (EEI).

This document covers pump units consisting of:

- one single or several rotodynamic water pump(s), including where integrated in other products, and driven by a motor system, consisting of an electrical motor, and either:

- a terminal box which only enables to operate the pump unit at constant motor stator frequency and thereby (nearly) constant rotational speed, or

- a CDM (Complete Drive Module) which enables to operate the pump unit at variable rotational speed depending on a varying demand of flow rate and/or discharge or differential pressure.

NOTE A CDM is also often called VSD (Variable Speed Drive).

Pump units as defined above are treated as extended products in respect to their energy efficiency.

Pumpen - Methoden zur Qualifikation und Verifikation des Energieeffizienzindexes für Kreiselpumpen - Teil 1: Allgemeine Anforderungen und Vorgehensweisen zur Prüfung und Berechnung des Energieeffizienzindexes (EEI)

Dieses Dokument beschreibt die Methodik, die Energie-Effizienz Leistung von Pumpenaggregaten auf der Basis einer dimensionslosen, numerischen Größe zu bewerten, die Energieeffizienzindex (EEI) genannt wird.

Dieses Dokument behandelt Pumpenaggregate, bestehend aus:

- einer einzelnen oder mehreren Kreiselpumpe(n) für Wasser, auch wenn sie in andere Produkte integriert sind, angetrieben von einem Motorsystem aus einem Elektromotor und

- entweder einem Kabelabschlusskasten, der nur den Betrieb des Pumpenaggregats bei konstanter Frequenz des Stators und daher (nahezu) konstanter Drehzahl ermöglicht,

- oder einem vollständigen Antriebsmodul (CDM, en: Complete Drive Module), das den Betrieb des Pumpenaggregats bei variabler Drehzahl entsprechend des schwankenden Bedarfsvolumenstroms und/oder der Entnahme bzw. des Differenzdrucks erlaubt.

ANMERKUNG Ein CDM wird oftmals auch drehzahlgeregelter Antrieb (VSD, en: Variable Speed Drive) genannt.

Pumpenaggregate entsprechend der obenstehenden Definition werden hinsichtlich ihrer Energieeffizienz als erweiterte Produkte behandelt.

Pompes - Méthodes de qualification et de vérification de l'indice de rendement énergétique des groupes motopompes rotodynamiques - Partie 1 : Exigences générales et procédures d'essai et de calcul de l'indice de rendement énergétique (EEI)

Le présent document décrit une méthode pour évaluer la performance énergétique des groupes motopompes qui se base sur une valeur numérique sans dimension appelée l’indice de rendement énergétique (EEI).

Le présent document s'applique aux groupes motopompes constitués des éléments suivants :

- une ou plusieurs pompe(s) à eau rotodynamique(s), intégrée(s) ou non dans d'autres produits et entraînée(e) par un système motorisé comprenant un moteur électrique ; et soit

- une boîte à bornes permettant simplement de faire fonctionner le groupe motopompe à une fréquence constante du stator de moteur et donc à une vitesse de rotation (quasi-)constante ; soit

- un CDM (module d'entraînement complet) permettant de faire fonctionner le groupe motopompe à une vitesse de rotation variable en fonction des différents besoins de débit et/ou de décharge ou de pression différentielle.

NOTE 1 Un CDM est également appelé souvent « entraînement à vitesse variable » (VSD).

Les groupes motopompes, tels qu'ils sont définis ci-dessus, sont considérés comme des produits globaux au regard de leur rendement énergétique.

Črpalke - Metode za kvalifikacijo in verifikacijo indeksa energijske učinkovitosti centrifugalnih črpalk - 1. del: Splošne zahteve in postopki za preskušanje in izračun indeksa energijske učinkovitosti (EEI)

Ta dokument zajema črpalke, sestavljene iz:

– ene ali več centrifugalnih vodnih črpalk, vključno z vgrajenimi črpalkami v ostalih proizvodih, pri čemer jih poganja motorni sistem, ki je sestavljen iz električnega motorja in

– priključne omarice, ki samo omogoča obratovanje črpalke s stalno statorsko frekvenco motorja in posledično (skoraj) stalno vrtilno hitrostjo,

– ali celovitega pogonskega modula (CDM), ki omogoča obratovanje črpalke pri spremenljivi vrtilni hitrosti glede na spreminjajoče se zahteve pretoka in/ali praznjenja ali diferenčnega tlaka.

OPOMBA 1: Motorni sistem, ki je sestavljen iz električnega motorja in celovitega pogonskega modula, se imenuje tudi pogonski sistem (PDS).

OPOMBA 2: Celovit pogonski modul se pogosto imenuje tudi pogon s spremenljivo hitrostjo (VSD).

Črpalke, kot so opredeljene zgoraj, se v zvezi z energetsko učinkovitostjo obravnavajo kot razširjeni proizvodi.

General Information

- Status

- Published

- Publication Date

- 07-May-2019

- Withdrawal Date

- 29-Nov-2019

- Technical Committee

- CEN/TC 197 - Pumps

- Drafting Committee

- CEN/TC 197/SC 3/WG 1 - Water pumps efficiency

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 22-Jul-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jul-2020

EN 17038-1:2019 - Overview

EN 17038-1:2019 (CEN) establishes the general requirements and procedures for testing and calculating the Energy Efficiency Index (EEI) of rotodynamic pump units. It defines a common, non‑dimensional indicator - the EEI = P1,avg / P1,ref - that enables comparison of energy performance across pump sizes and configurations. The standard applies to rotodynamic water pump units driven by an electric motor system, either at fixed speed (terminal box) or variable speed via a Complete Drive Module (CDM / VSD). Pump units are treated as extended products for energy-efficiency assessment.

Key topics and technical requirements

- Energy Efficiency Index (EEI): EEI is the ratio of the weighted-average electrical input (P1,avg) to a defined reference input (P1,ref). Lower EEI values indicate better energy performance.

- P1,ref (reference electrical power input): Calculated nominal input for a fictitious pump unit at the 100% nominal (BEP) point; used as the denominator in the EEI.

- P1,avg (weighted average power): Average electrical input weighted by a standardized flow‑time profile that represents typical operating time fractions at different relative flows.

- Flow‑time profiles and reference pressure control curves: Standardized, discretized profiles (pairs of Q/Q and Δt/t) are used to evaluate part‑load and variable‑speed operation.

- Semi‑analytical model: Allows EEI derivation from component nominal data when full product testing is impractical (e.g., on‑site assemblies or novel component combinations).

- Qualification and verification procedures: Clause 5 outlines methods for qualifying pump unit types (sampling, statistical approaches); Clause 6 describes verification procedures and decision rules for declared EEI values.

- Statistical and measurement guidance: Informative annexes cover confidence intervals, sample sizes, outlier tests, measurement uncertainties and the probability of verification outcomes.

Practical applications

- Benchmarking energy performance of pump units across sizes and designs.

- Supporting product declarations, tender specifications and compliance checks.

- Enabling manufacturers and assemblers to evaluate new or bespoke pump assemblies using the semi‑analytical model.

- Guiding test laboratories and certification bodies in consistent EEI verification and sampling strategies.

- Informing energy audits and lifecycle cost assessments for HVAC, water distribution, industrial pumping and building services.

Who should use this standard

- Pump manufacturers and component assemblers

- Test laboratories and conformity assessment bodies

- Energy auditors, specifiers and consulting engineers

- Regulators and procurement authorities seeking standardized EEI criteria

Related standards

EN 17038-1 is the first part of a series. Subsequent parts define specific testing procedures, detailed calculation methods, reference flow‑time profiles and pressure control curves for particular pump types and applications. Use EN 17038-1 as the general framework for EEI calculation, qualification and verification.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 17038-1:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Pumps - Methods of qualification and verification of the Energy Efficiency Index for rotodynamic pump units - Part 1: General requirements and procedures for testing and calculation of Energy Efficiency Index (EEI)". This standard covers: This document describes a methodology to evaluate energy efficiency performance of pump units based on a non-dimensional numerical value called Energy Efficiency Index (EEI). This document covers pump units consisting of: - one single or several rotodynamic water pump(s), including where integrated in other products, and driven by a motor system, consisting of an electrical motor, and either: - a terminal box which only enables to operate the pump unit at constant motor stator frequency and thereby (nearly) constant rotational speed, or - a CDM (Complete Drive Module) which enables to operate the pump unit at variable rotational speed depending on a varying demand of flow rate and/or discharge or differential pressure. NOTE A CDM is also often called VSD (Variable Speed Drive). Pump units as defined above are treated as extended products in respect to their energy efficiency.

This document describes a methodology to evaluate energy efficiency performance of pump units based on a non-dimensional numerical value called Energy Efficiency Index (EEI). This document covers pump units consisting of: - one single or several rotodynamic water pump(s), including where integrated in other products, and driven by a motor system, consisting of an electrical motor, and either: - a terminal box which only enables to operate the pump unit at constant motor stator frequency and thereby (nearly) constant rotational speed, or - a CDM (Complete Drive Module) which enables to operate the pump unit at variable rotational speed depending on a varying demand of flow rate and/or discharge or differential pressure. NOTE A CDM is also often called VSD (Variable Speed Drive). Pump units as defined above are treated as extended products in respect to their energy efficiency.

EN 17038-1:2019 is classified under the following ICS (International Classification for Standards) categories: 23.080 - Pumps; 27.015 - Energy efficiency. Energy conservation in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17038-1:2019 has the following relationships with other standards: It is inter standard links to EN 17038-2:2019, EN 17038-4:2023, EN 17038-1:2019/AC:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17038-1:2019 is associated with the following European legislation: EU Directives/Regulations: 547/2012; Standardization Mandates: M/396, M/498. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 17038-1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2019

Črpalke - Metode za kvalifikacijo in verifikacijo indeksa energijske učinkovitosti

centrifugalnih črpalk - 1. del: Splošne zahteve in postopki za preskušanje in

izračun indeksa energijske učinkovitosti (EEI)

Pumps - Methods of qualification and verification of the Energy Efficiency Index for

rotodynamic pumps units - Part 1: General requirements and procedures for testing and

calculation of energy efficiency index (EEI)

Pumpen - Methoden zur Qualifikation und Verifikation des Energieeffizienzindexes für

Kreiselpumpen - Teil 1: Allgemeine Anforderungen und Vorgehensweisen zur Prüfung

und Berechnung des Energieeffizienzindexes (EEI)

Pompes - Méthodes de qualification et de vérification de l'indice de rendement

énergétique des groupes motopompes rotodynamiques - Partie 1 : Exigences générales

et procédures d'essai et de calcul de l'indice de rendement énergétique (EEI)

Ta slovenski standard je istoveten z: EN 17038-1:2019

ICS:

23.080 Črpalke Pumps

27.015 Energijska učinkovitost. Energy efficiency. Energy

Ohranjanje energije na conservation in general

splošno

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17038-1

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2019

EUROPÄISCHE NORM

ICS 23.080

English Version

Pumps - Methods of qualification and verification of the

Energy Efficiency Index for rotodynamic pump units - Part

1: General requirements and procedures for testing and

calculation of Energy Efficiency Index (EEI)

Pompes - Méthodes de qualification et de vérification Pumpen - Methoden zur Qualifikation und Verifikation

de l'indice de rendement énergétique des groupes des Energieeffizienzindexes für Kreiselpumpen - Teil 1:

motopompes rotodynamiques - Partie 1 : Exigences Allgemeine Anforderungen und Vorgehensweisen zur

générales et procédures d'essai et de calcul de l'indice Prüfung und Berechnung des Energieeffizienzindexes

de rendement énergétique (EEI) (EEI)

This European Standard was approved by CEN on 15 July 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17038-1:2019 E

worldwide for CEN national Members.

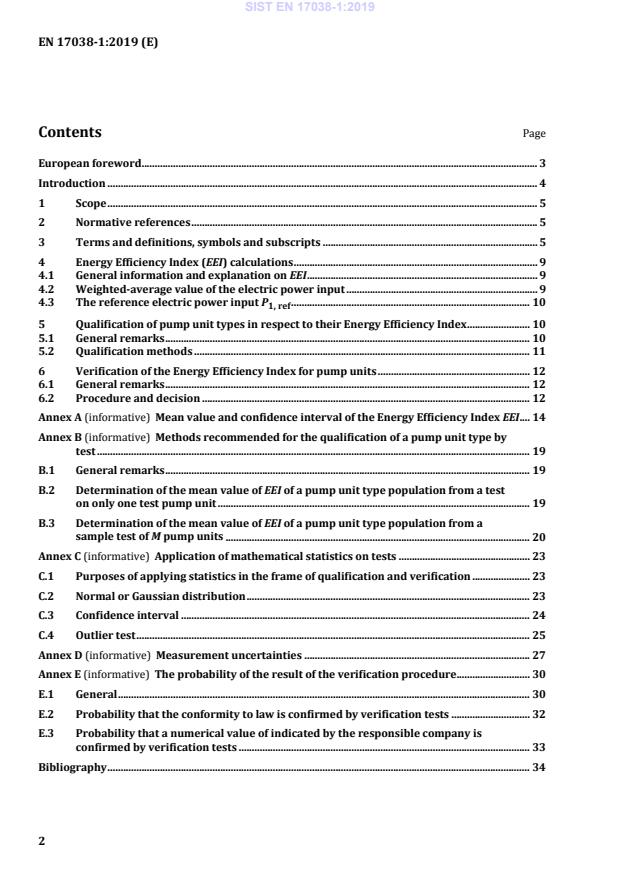

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions, symbols and subscripts . 5

4 Energy Efficiency Index (EEI) calculations . 9

4.1 General information and explanation on EEI . 9

4.2 Weighted-average value of the electric power input . 9

4.3 The reference electric power input P . 10

1, ref

5 Qualification of pump unit types in respect to their Energy Efficiency Index . 10

5.1 General remarks . 10

5.2 Qualification methods . 11

6 Verification of the Energy Efficiency Index for pump units . 12

6.1 General remarks . 12

6.2 Procedure and decision . 12

Annex A (informative) Mean value and confidence interval of the Energy Efficiency Index EEI . 14

Annex B (informative) Methods recommended for the qualification of a pump unit type by

test . 19

B.1 General remarks . 19

B.2 Determination of the mean value of EEI of a pump unit type population from a test

on only one test pump unit . 19

B.3 Determination of the mean value of EEI of a pump unit type population from a

sample test of M pump units . 20

Annex C (informative) Application of mathematical statistics on tests . 23

C.1 Purposes of applying statistics in the frame of qualification and verification . 23

C.2 Normal or Gaussian distribution . 23

C.3 Confidence interval . 24

C.4 Outlier test . 25

Annex D (informative) Measurement uncertainties . 27

Annex E (informative) The probability of the result of the verification procedure . 30

E.1 General . 30

E.2 Probability that the conformity to law is confirmed by verification tests . 32

E.3 Probability that a numerical value of indicated by the responsible company is

confirmed by verification tests . 33

Bibliography . 34

European foreword

This document (EN 17038-1:2019) has been prepared by Technical Committee CEN/TC 197 “Pumps”,

the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2019, and conflicting national standards

shall be withdrawn at the latest by November 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

Introduction

This document is the first part of a series of standards describing a methodology to evaluate energy

efficiency performance of pump units, comprising the pump, the motor with or without frequency

converter, based on a non-dimensional numerical value called Energy Efficiency Index (EEI). An EEI

allows the comparison of different pump sizes and types with one common indicator. Physical

influences such as pump size, specific speed, pump unit part-load operation, motor-efficiency

characteristic and frequency converter influence are implemented into this indicator.

This standard series covers pump units which component wise can be placed on the market and

assembled into a pump unit or are placed on the market as one single product. To cover these two cases

a semi-analytical model has been developed in order to derive the EEI based on nominal data of the

components only. This case happens for example when an assembler of the components builds the

pump unit on site and consequently a product test cannot be done by for this assembler or when a

manufacturer is quoting a pump-unit which uses a combination of components not previously built.

This particular standard gives an overview of the basic concept of EEI (Clause 4), basic concepts of flow-

time profiles and reference pressure control curves, the qualification (Clause 5) of a pump unit type

regarding an EEI and the verification of EEI values (Clause 6) given for a pump unit type either by

measurement or calculation.

Specific requirements for testing, a calculation method for an EEI, the so called semi-analytical model of

a complete pump unit, specific flow-time profiles and reference control curves are given in the

subsequent parts of this standard series.

1 Scope

This document describes a methodology to evaluate energy efficiency performance of pump units based

on a non-dimensional numerical value called Energy Efficiency Index (EEI).

This document covers pump units consisting of:

— one single or several rotodynamic water pump(s), including where integrated in other products,

and driven by a motor system, consisting of an electrical motor, and either:

— a terminal box which only enables to operate the pump unit at constant motor stator frequency

and thereby (nearly) constant rotational speed, or

— a CDM (Complete Drive Module) which enables to operate the pump unit at variable rotational

speed depending on a varying demand of flow rate and/or discharge or differential pressure.

NOTE A CDM is also often called VSD (Variable Speed Drive).

Pump units as defined above are treated as extended products in respect to their energy efficiency.

2 Normative references

There are no normative references in this document.

3 Terms and definitions, symbols and subscripts

For the purpose of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

fixed speed

constant motor stator frequency

3.2

variable speed

varying motor stator frequency

3.3

Energy Efficiency Index

EEI

ratio between P and P

1, avg 1, ref

3.4

reference electrical power input P

1, ref

calculated power input of the pump unit at the best efficiency point

3.5

average electrical power input P

1, avg

power input weighted by the load profile

3.6

pump unit

pump driven by a motor system

3.7

motor system

combination of an electric motor and either a terminal box or a CDM

3.8

pump unit type

identical pump units of the same configuration

3.9

pressure control curve

functional dependency of the demanded head H vs. the delivered flow rate Q in the form of a non-

dimensional correlation H/H = f (Q/Q )

100% 100%

3.10

reference pressure control curve

pre-defined functional dependency H/H = f (Q/Q ) for standardized measurements and

100% 100%

calculations of average power input P

1, avg

3.11

Complete Drive Module

CDM

electronic power converter connected between the electric supply and a motor as well as extensions

such as protection devices, transformers and auxiliaries

[SOURCE: EN 61800-2]

3.12

Power Drive System

PDS

combination of CDM and motor

Table 1 — List of basic letters and subscripts

Symbol Quantity Unit

C Constant dimensionless number

D Diameter m

e Measurement uncertainty, relative value dimensionless number

E Overall measurement uncertainty dimensionless number

−1

f Frequency

s , Hz

g Acceleration due to gravity

m/s

H Pump total head m

k Number of sample pumps dimensionless number

m Mass kg

M Number of pumps in a sample dimensionless number

−1 −1

n Speed of rotation

s , min

N Number of instrument readings dimensionless number

n Specific speed min−1

s

p Pressure Pa

p Probability density dimensionless number

P Power W

Q (Volume) rate of flow

m /s

s Standard deviation of a sample according to special quantity

t Tolerance factor, relative value dimensionless number

t Time s

t Student’s factor dimensionless number

T Torque Nm

u Peripheral velocity m/s

U Mean velocity m/s

U Voltage V

v Local velocity m/s

V Volume

m

x General quantity according to specified usage

y General quantity according to specified usage

z Height above reference plane m

z number of produced pumps dimensionless number

η Efficiency dimensionless number

θ Temperature °C

ν Kinematic viscosity

m /s

ρ Density

kg/m

ω Angular velocity rad/s

σ Standard deviation of normal distribution according to special quantity

Table 2 — List of letters and figures used as subscripts

Subscript Meaning

1 electrical

2 mechanical

abs absolute

allowable permitted e.g. by regulations

declared indicated by the manufacturer

verification permitted in verification process

individual specific to one pump unit

amb ambient

annual per year

BEP best efficiency point

dr drive

D datum

exp experimentally determined

G guaranteed

H pump total head

I numbering index

J numbering index

imp impeller

man manufacturing

max maximum permissible

mean arithmetic mean value

meas measured value

min, requ minimum required

N nominal

OL overload

Pd pre-defined

P power

PL part load

Q (volume) flow rate

R random

S specific, systematic

sync synchronous

tot total, overall

true true value

T torque

v vapour

x of quantity x

y % for probability of y %

4 Energy Efficiency Index (EEI) calculations

4.1 General information and explanation on EEI

The ratio of P and P is a quantitative indicator for the energy efficiency of pump units. It is

1, avg 1, ref

called Energy Efficiency Index (EEI) and is defined by Formula (1):

P

1, avg

(1)

EEI=

P

1,ref

is compared

In order to assess the efficiency of pump units, their actual electrical power input P

1, avg

with a reference value called P . It is a nominal power input of a fictitious pump unit running at

1, ref

nominal 100 % point.

The value of P for the different pump types are defined in other parts of this standard.

1, ref

The declared EEI value is based on the actual pump curves whether these are realized with full

diameter impeller, a trimmed impeller or a power limited curve.

NOTE Contrary to the efficiency values η of the unit components, the lower the numerical value of EEI, the

better the energy efficiency of pump units.

4.2 Weighted-average value of the electric power input

The quantification of energy efficiency of pump units should be based on the weighted average of

electrical power input P .

1, avg

The weighting factor when averaging the electrical power input P is the fraction of operating time at

the respective flow rate. Generally, for any application there is a continuous function describing the

dependency of (differential) time fraction dt/t on the relative flow rate Q/Q where t is the

tot 100 % tot

total operating time and Q is defined in the specific parts of this standard.

100 %

For the assessment of the energy efficiency of pump units, common and standardized “flow-time

profiles” are needed as basis for indicating their energy efficiency. The flow-time profile is defined for

each pump type in other parts of this standard.

In order to simplify further the determination of a value which characterizes the energy efficiency of

pump units, in this document the different flow-time profiles are described by a limited number of

points, not by a continuous curve or function. These discrete points are pairs of values of Q/Q and

100 %

Δt/t . These values define the discretised flow-time profiles. They are given as reference flow-time

tot

profiles in the specific parts of this standard. (In this case, Δt is a finite fraction of operating time and

Q/Q is the average value of relative flow rate demanded within this time fraction.)

100 %

NOTE 1 The reference flow-time profiles defined in this document for variable flow operation reflect the

typical ranges and variations of demanded flow rate in these types of applications and are based on experimental

field studies, see [1], [2].

For a given reference flow-time profile, the weighted average of the electric power input P is

1, avg

calculated by Formula (2):

N

∆t

P = ⋅ P (2)

1,avg

∑ 1, i

t

tot

i=1i

where

i is the consecutive number of the points of the flow-time profile and N is the total number of the

points of the flow-time profile.

For calculating P , the electric power input P shall be known for each value Q/Q of the

1, avg 1 100 %

reference flow-time profile.

But as for the flow-time profiles, common and standardized correlations H/H = f (Q/Q ) are

100 % 100 %

needed as basis for indicating and comparing the energy efficiency of pump units placed on the market

and/or put into service as extended products. These standardized correlations H/H = f (Q/Q )

100 % 100 %

are called reference pressure control curves in this document and are defined in subsequent parts of

this standard.

For calculating P in the case of variable speed operation, the electric power input P shall be

1, avg 1

determined at the relative flow rate values Q/Q of the relevant reference load-flow profile and for

100 %

the corresponding rotational speed n.

NOTE 2 Especially at low values of Q/Q the electric power input P is considerably higher for pump units

100 % 1

operated at constant motor stator frequency than for speed controlled pump units. This holds true independently

of the actual pressure control curve.

4.3 The reference electric power input P

1, ref

For assessing the energy efficiency of pump units within the scope of this document, a non-dimensional

value is needed which directly reflects the energy efficiency of pump units. The numerical magnitude of

this value shall be independent of parameters which influence the unit component's efficiency such as,

for example, their geometrical size and nominal power. For this purpose, the actual electrical power

input P averaged according to Formula (1) is divided by an appropriate reference value P . This

1, avg 1, ref

reference value shall:

— have a physical basis;

— consider relevant influences on the electrical power input of pump units;

— be independent from the efficiency related quality of individual components of the pump unit.

The chosen definitions of P which fulfil these requirements are given in other parts of this standard.

1, ref

5 Qualification of pump unit types in respect to their Energy Efficiency Index

5.1 General remarks

The qualification of a pump unit type in respect to the Energy Efficiency Index (EEI) is the responsibility

of the company which places it on the market and/or puts it into service.

Product information on EEI of a pump unit type can either state the (legally) required EEI in the format

“EEI ≤ 0.XX” or can indicate a lower value “EEI ≤ 0.YY” if the pump unit type is qualified for that and the

manufacturer decides so. EEI values shall be rounded to two decimal places.

5.2 Qualification methods

Generally, the method which is applied to determine the EEI-value in the frame of the qualification

procedure is left to the company which is responsible.

In this document, two methods of qualification are described. Both methods result in a high probability

of a successful verification:

1) Tests on complete pump units and evaluation of the test results to determine the EEI-value.

2) Determination of the EEI-value by applying a semi-analytical model of the complete pump unit.

These methods are described in detail in specific parts of this standard for the respective types of pump

units.

1) In the case of qualification by tests on complete pump units the following procedure shall be

applied:

To qualify a pump unit type for conformity to requirements by law with respect to the EEI-value,

tests and evaluations shall be carried out by taking pump units randomly out of the pump unit

population. From the result of measurements and evaluations, the mean value EEI shall be

mean

determined (for example as described in Annex B). The pump unit type is then qualified for

conformity to law if the mean EEI-value determined as described above fulfils the condition

EEI < EEI < EEI (3)

mean declared allowable

where the value EEI is prescribed by law. EEI is without any tolerance for the

allowable mean

qualification procedure. In the verification procedure, according to Clause 6, a tolerance t = 7 %

EEI

is applied to the value of EEI which results from verification tests. This tolerance is not part of

test

the method to qualify a pump unit type by the supplier and shall not be applied on the result of the

qualification procedure.

2) In the case of qualification by applying the semi-analytical models as described in other parts of

Standard, the EEI-value resulting from the calculations (considering uncertainties of input values

and model errors), taken as the mean value EEI :

mean

— is used to qualify the pump unit type for conformity to law per Formula (3);

— and can be indicated as numerical value with two digits after the decimal point on the

nameplates and/or in the technical documentation.

6 Verification of the Energy Efficiency Index for pump units

6.1 General remarks

The Indicated Energy Efficiency Index can be checked and confirmed by an independent institution, e.g.

in the frame of market surveillance. This is called verification procedure in this document.

A verification procedure either needs checking the technical documentation and (re-)calculation

according to the methodology called semi analytical models, if specified in the respective parts of this

standard, or the verification procedure can be done by measuring the test pump units. These tests need

only a very limited number of test pump units and tests, but nevertheless enable with sufficient

certainty the confirmation (or rejection) of the conformity with respect to EEI or validity of the

allowable

indicated value of EEI. The procedure is based on simple pass-or-fail tests. Some explanations regarding

the probability of the results of a verification procedure are given in Annex E.

6.2 Procedure and decision

In the case of a verification procedure based on measurement the verification procedure consists of

several steps:

1) An individual pump unit is drawn at random out of the pump unit population, tested and evaluated

according to other parts of this standard and assessed with respect to the corresponding Energy

Efficiency Index (EEI) as described below.

2) If the individual pump unit has passed according to the criterion described below, the conformity

and/or the validity of the indicated numerical EEI-value of the investigated pump unit type is

confirmed.

3) If the first individual pump unit does not fulfil the criterion described below, three other individual

pump units are drawn at random, tested and evaluated according to other parts of this standard.

4) The values of EEI determined for each of the three additionally tested pump units are arithmetically

averaged by the means of Formula (4)

()EEI ⋅ ()EEI (4)

∑

avg,3 i

i=1

where (EEI) is the EEI-value determined individually for each of the three additional test pump

i

units.

5) The (EEI) of pump units is assessed with respect to the criterion described below.

avg,3

6) If the (EEI) of pump units also fails according to the criterion described below, the qualification

avg,3

of the investigated pump unit type with respect to the Energy Efficiency Index (EEI) is rejected.

7) If the (EEI) of pump units passes according to the criterion described below, the pump unit

avg,3

type passes although the first pump unit has failed.

The tests and evaluations on each of the pump units drawn at random and independently from each

other out of the pump unit type population for which the Energy Efficiency Index (EEI) shall be verified

shall be carried out according to other parts of this standard.

=

For the decision on passing or failing the verification in respect to EEI, a total tolerance of

t = 7 %

EEI

is applied to the nominal value of EEI. The nominal value for a pump unit type is:

— the maximum allowable value EEI required by law for assessing the conformity to law,

allowable

— the numerical EEI-value indicated on the nameplates and/or in the technical documentation of the

pump unit type for assessing the indicated value.

This tolerance considers the effects of manufacturing performance tolerances within a pump unit type

population (see Annex B) and the measurement uncertainties (see Annex D) of the verification test(s).

By application of the total tolerance on the nominal value, i.e. by multiplying it with the factor

1+ t

= 1.07,

EEI

the particular threshold value results serves for assessment.

Decision criterion:

The first tested pump unit or the (EEI) of the pump units passes with respect to assessing the

avg,3

Energy Efficiency Index (EEI) if the EEI-value resulting from the test(s) and evaluations is not

avg,3

higher than the corresponding particular threshold value.

The first tested pump or the (EEI) of the pump units fails with respect to assessing the Energy

avg,3

Efficiency Index (EEI) if the EEI-value resulting from the test(s) and evaluations is higher than the

corresponding particular threshold value.

Annex A

(informative)

Mean value and confidence interval of the Energy Efficiency Index EEI

In respect to the energy efficiency, the whole pump unit type is characterized by the mean value

EEI of its population.

mean

Within one pump unit type, there is an inevitable scatter of performance data and characteristics of the

components (pump, motor, frequency converter (if available) and auxiliaries (if available)). This applies

also to the hydraulic and electrical performance quantities which relevant for the Energy Efficiency

Index (EEI). This scatter of performance data and characteristics results from small differences of

relevant geometrical dimensions (such as internal flow cross sections, impeller blade angles, gap

clearances in the case of the pumps), material properties (such as the electrical properties of copper

windings in the case of the electric motors) and other influencing quantities of the components of pump

units. These differences are within the range of tolerance which are inherent in every manufacturing

process and which cannot be reduced below some economically acceptable limits.

The bandwidth of the manufacturing tolerances leads to a corresponding bandwidth of hydraulic or

electric performance characteristics of all components (pump, motor, …) of the individual pump units

within a pump unit type. The bandwidth of hydraulic or electric performance characteristics which is

caused by manufacturing tolerances is called manufacturing performance tolerance. As pump units are

composed of various components the tolerances of the components lead to the resulting manufacturing

performance tolerance of the complete unit. As long as the tolerances of the components are

statistically independent of each other, the tolerances of the various components can be assumed to be

added to each other according to probability laws (see Annex C).

The entire pump unit type is characterized by its mean performance data and curves. These mean

values are defined by Formula (A.1):

z

xx⋅ (A.1)

mean ∑ i

z

i=1

where

x is the respective performance quantity (for example Q, H, η , η , P ) and z is the total number of

PU M 1

pump units of the same pump unit type produced and placed on the market and/or put into

service.

Figure A.1 — In case z is large (usually z ≥ 30), and assuming a normal (Gaussian) distribution (see C.2)

the resulting performance quantities are characterized by their mean value x which is identical to

mean

the value defined by Formula (A.1) and the standard deviation (Formula (A.2) which is associated with

the bandwidth scatter.

=

Key

f(x) relative frequency of x

x performance quantity

x mean value of x

mean

s standard deviation of x

x

P 95 % probability interval of x

95 %

Figure A.1 — Normal distribution of a quantity x within a pump unit type

For normal distributions, the probability is 95 % that any individual true value x of the respective

i

performance quantity x is confined to a confidence interval of ± 1,96·s around the mean value x

x mean

where

z

s= ⋅ xx− (A.2)

( )

x i mean

∑

z− 1

i=1

is the standard deviation of the scatter of the performance quantity x within the same pump unit type

(see Annex C).

The manufacturing performance tolerance t of a quantity x can be defined as ± 1,96 s .

man, x x

Furthermore, the true value x of any pump within the same pump unit type population has a

i

probability of:

— 50 % to be equal to or higher than x ;

mean

— 97,5 % to be equal to or higher than x – 1,96 s ;

mean x

— 97,5 % to be equal to or lower than x + 1,96 s .

mean x

For example, a pump unit drawn at random out of a pump unit type population can have any value of

electric power input P at a given hydraulic load point Q/Q , H/H within the scatter bandwidth

1 100 % 100 %

and, as one of two possible extreme cases, either the minimum value or the maximum value of electric

power input P at the boundaries of the bandwidth.

The true mean value of a quantity x as well as the corresponding manufacturing performance tolerance

t could only be determined exactly by Formulae (A.1) and (A.2) if the values x of all z individual

man,x i

pump units out of the pump unit type population were known from tests. Because, in most cases, the

total number z of a pump unit type population is very large, it is normally not possible for economic

reasons to test each individual pump unit.

Therefore, only estimates of the mean values of the pump unit type can be determined:

— either based on tests on a sample of a number M (typically being very small compared to z) of test

pump units drawn at random out of the production (see Annex B),

— or by the application of semi-analytical models (see Part 2 and Part 3 of this standard).

It needs to be emphasized that – based on tests on a sample – the true mean values of performance

quantities x can only be determined to be confined with a certain probability (usually 95 %) within

mean

a range called confidence interval (see Annex B and Annex C).

As to all performance quantities x, these facts apply also to the EEI-value which results from tests on

only one or on a (small) sample of pump units (see Annex B).

If the estimate of EEI of a pump unit type and the corresponding confidence interval is determined

mean

by tests and evaluations on sample pump units, additionally to the manufacturing performance

tolerances the effect of measurement uncertainties shall be considered. While the manufacturing

performance tolerances are only dependent on the quality of manufacturing, the width of the

confidence interval of EEI is additionally dependent on the accuracy of the measuring methods and

mean

devices, i.e. on the actual overall measurement uncertainties (see Annex D).

If the estimate of EEI of a pump unit type and the corresponding confidence interval is determined

mean

by the application of semi-analytical models, additionally to the manufacturing performance tolerances

the effect of model errors shall be considered instead of measurement uncertainties. Information on

model errors is given together with the description of the method in in the respective parts of this

standard.

From reasons explained above, the true value of EEI of a pump unit type cannot be determined

mean, true

exactly, but can only be determined as being limited to a confidence interval. The magnitude of the

confidence interval can be quantified by a total tolerance t . This total tolerance can either be pre-

tot, EEI

defined (as, for example, for the application of the method described B.2) or can be determined directly

from measurements on a sample of several pump units of the same pump unit type population (when

applying, for example, the method described in B.3).

In Figure A.2 and Figure A.3, the effect of the confidence interval width of the value EEI of a pump

mean

unit type value EEI on the comparison with the corresponding threshold value used for verification

mean

according to Clause 6 is demonstrated qualitatively. In both cases, the estimate of EEI – resulting

mean

from either test on a sample of pump units or from application of the semi-analytical models – as well as

the allowable value EEI and the corresponding threshold value EEI are assumed to be

allowable verification

the same. The probability that the same pump unit type will succeed in the verification procedure in

case of a larger confidence interval (shown in Figure A.2) is quite lower than in the case of a smaller

confidence interval (shown in Figure A.3).

Key

EEI nominal value of allowable EEI, for example required by law

nominal

EEI particular value of EEI for the verification process

verification

t tolerance of EEI allowed within the verification procedure, see Clause 6

EEI,verification

estimate value of EEI from tests or from semi-analytical model

A

mean

B 95 % confidence interval EEI

mean

C maximum possible value of true EEI (with 97,5 % probability)

mean

Figure A.2 — Effect of the magnitude of the confidence interval of EEI , case 1

mean

Key

EEI nominal value of allowable EEI, for example required by law

nominal

EEI particular value of EEI for the verification process

verification

t tolerance of EEI allowed within the verification procedure, see Clause 6

EEI,verification

A estimate value of EEI from tests or from semi-analytical model

mean

B 95 % confidence interval EEI

mean

C maximum possible value of true EEI (with 97,5 % probability)

mean

Figure A.3 — Effect of the magnitude of the confidence interval of EEI , case 2

mean

Generally, the width of the confidence interval is the smaller:

— the smaller the performance scatter within the pump unit type population is (what requires good

manufacturing quality, small manufacturing tolerances).

In the case of sample tests the width of the confidence interval is:

— the smaller the measurement uncertainties of the tests on the sample pump units are (this requires

high accuracy of measuring equipment and small random errors, Annex D),

— the larger the number M of tested sample pump units is, see Annex B.

In case the semi-analytical models are applied, the confidence interval is smaller:

— the smaller the model errors of the applied models are (what depends on the type of the models,

see specific parts of this standard).

Two possibilities to determine – based on tests as described in the subsequent parts of this standard on

sample pump units - the confidence interval of the mean EEI-value for a pump unit type are described in

detail in Annex B.

Annex B

(informative)

Methods recommended for the qualification of a pump unit type by test

B.1 General remarks

To determine the mean value EEI of a pump unit type population by sample tests, two possibilities

mean

exist and are recommended to be applied in the frame of the qualification procedure:

1) Only one test on a single test pump unit drawn at random out of the pump unit type population is

carried out and its EEI-value is determined by measurements and evaluations as described in Part 2

and Part 3 of this standard. An estimate EEI of the mean value is calculated by making use of a

exp

manufacturing tolerance factor t which is based on the experience of the manufacturer(s) of

man,EEI

the complete pump unit or of its separate components concerning maximum manufacturing

tolerances to be expected for the respective pump unit type. But it is generally not known where

the experimentally determined value EEI of the sample pump unit is lying within the scattering

test

bandwidth caused by manufacturing tolerances. Also, the actual magnitude of the scattering

bandwidth is unknown. But the true mean value EEI can be expected to be confined to the

mean,true

interval of ± t ∙ EEI around the experimentally determined values EEI . To reach a high

man,EEI test test

probability that the true mean value fulfils the verification criterion specified in 5.2, the extreme

case should be considered that the individual EEI-value of the tested sample pump unit is at the low

end of the scattering bandwidth of individual values of EEI. If the value of ± t is chosen

man,EEI

correctly to reflect the actual scattering bandwidth caused by manufacturing performance

tolerances, the true mean value EEI will not be higher than (1 + t )·EEI with a

mean,true man,EEI test

probability of 97,5 %.

2) Tests are carried out on a sample consisting of M test pump units drawn at random out of the pump

unit type population. On the results of these tests, small (or exact) sampling theory is applied.

Based on the results for the M tested pumps, the arithmetically averaged values, the standard

deviation and the actual confidence interval of the value EEI are calculated.

mean

While the second method needs more experimental effort, it will normally lead to a smaller confidence

interval if good manufacturing quality is attained by quality management measures applied by the

manufacturer(s). This is because the magnitude of a fixed manufacturing tolerance factor used for the

first method should be set to cover even cases of poorer manufacturing quality. Therefore, the higher

effort when applying the second method is – in most cases – justified by smaller margins (in comparison

to the fixed tolerance in the first method) by which the experimentally determined estimate of the mean

value EEI should be below the corresponding threshold value which is relevant for the

mean,test

verification procedure described in Clause 6.

B.2 Determination of the mean value of EEI of a pump unit type population from a

test on only one test pump unit

The test on a single pump unit shall be performed and evaluated as described in the subsequent parts of

this standard.

Thereby, the value EEI is determined for the test pump unit.

test

Based on this value, the total tolerance interval shall be determined in order for the true mean value

EEI of the whole pump unit type population to be included with a high probability. For the

mean,true

determination of the width of this interval, the total tolerance factor t shall be applied.

tot,EEI

EEI ⋅−1 t ≤ EEI ≤ EEI ⋅+1 t (B.1)

( ) ( )

test tot,,test mean true test tot,EEI

The scatter of relevant performance quantities within the pump unit type population and the

measurement uncertainties of the test of the selected pump unit can be assumed to be normally

(Gaussian) distributed and statistically independent of each other. Therefore, the total tolerance factor

for the true mean value EEI of the pump unit type population can be calculated by the means of

mean,true

Formula (B.2):

t et+ (B.2)

tot,EEI tot,,EEI man EEI

In Formula (B.2), t is the total (relative) tolerance resulting from manufacturing tolerances

man,EEI

within the pump unit type population and e the total measurement uncertainties. The value of

tot

t shall be set on the basis of the manufacturer(s) experience, for example on the basis of data

man,EEI

available from quality management. The tolerance interval of ± t shall be sufficiently large to

man,EEI

enclose about 95 % of the true EEI-values of individual pump units of the pump type population they

belong to.

Normally, each of the main components of a pump unit (pump(s), motor(s), CDM(s) (if available),

auxiliaries) will have its own manufacturing tolerance. As long as the scattering behaviour of

performance quantities of the components caused by manufacturing shows normal (or Gaussian)

distributions and are statistically independent from each other, the resulting total manufacturing

tolerance of EEI can be calculated by the means of Formula (B.3):

2 2 2 2 2 2

t F ⋅ t + Ft⋅ + F ⋅ t + (B.3)

man,EEI PU→→EEI man,,PU M EEI man M CDM→EEI man,CDM

In Formula (B.3) F are sensitivity factors which quantify the effect of the manufacturing

comp→EEI

performa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...