EN 1870-7:2012

(Main)Safety of woodworking machines - Circular sawing machines - Part 7: Single blade log sawing machines with integrated feed table and manual loading and/or unloading

Safety of woodworking machines - Circular sawing machines - Part 7: Single blade log sawing machines with integrated feed table and manual loading and/or unloading

This European Standard deals with all significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to single blade circular log sawing machines with saw blade diameter ≥ 600 mm and with integrated feed table with manual loading and/or unloading, (hereinafter referred to as machines), designed to cut solid wood when they are used as intended and under the conditions foreseen by the manufacturer including reasonably foreseeable misuse.

This European Standard is not applicable to machines manufactured before the date of its publication as EN.

Sicherheit von Holzbearbeitungsmaschinen - Kreissägemaschinen - Teil 7: Einblatt- Stammkreissägemaschinen mit mechanischem Tishvorschub und Handbechickung und/oder Handentnahme

Diese Europäische Norm behandelt alle im Abschnitt 4 aufgeführten signifikanten Gefährdungen,

Gefährdungssituationen und Gefährdungsereignisse, die auf Einblatt-Stammkreissägemaschinen mit einem Sägeblattdurchmesser > oder = 600 mm und mechanischem Tischvorschub und Handbeschickung und/oder Handentnahme zutreffen (im Folgenden als "Maschinen" bezeichnet), die konstruiert sind zum Schneiden von

Massivholz, wenn sie bestimmungsgemäß und entsprechend den vom Hersteller vorgesehen Bedingungen einschließlich vernünftigerweise vorhersehbarer Fehlanwendung verwendet werden. Diese Europäische Norm gilt nicht für Maschinen, die vor dem Ausgabedatum dieser EN hergestellt wurden.

Sécurité des machines pour le travail du bois - Machines à scie circulaire - Partie 7: Scies circulaires mono-lame à grumes à avance intégrée à table et à chargement et/ou déchargement manuel

La présente Norme Européenne traite de tous les phénomènes dangereux, situations et événements dangereux significatifs, tels qu'énumérés à l'Article 4, qui sont applicables aux scies circulaires mono-lames à grumes de diamètre de lame de scie 600 mm et à avance mécanisée à table et à chargement et/ou déchargement manuel (ci-après désignées "machines") conçues pour la coupe de bois massif, lorsqu’elles sont utilisées comme prévu et dans les conditions prévues par le fabricant, incluant une mauvaise utilisation raisonnablement prévisible.

La présente Norme européenne n’est pas applicable aux machines qui ont été fabriquées avant sa date de publication comme EN.

Varnost lesnoobdelovalnih strojev - Krožne žage - 7. del: Enolistne krožne žage za razrez hlodov z vgrajeno podajalno mizo in ročnim podajanjem in/ali odvzemom

Ta evropski standard opisuje vse večje nevarnosti, nevarne razmere in dogodke iz točke 4 v zvezi z enolistnimi krožnimi žagami za razrez hlodov s premerom rezila ≥ 600 mm ter z vgrajeno podajalno mizo in ročnim podajanjem in/ali odvzemom (v nadaljevanju: »stroji«), ki so namenjeni rezanju polnega lesa ter se uporabljajo v skladu z namenom in pod pogoji, ki jih je predvidel proizvajalec, vključno z razumno predvideno nepravilno uporabo. Ta evropski standard ne velja za stroje, ki so bili izdelani, preden je bil objavljen kot standard EN.

General Information

- Status

- Withdrawn

- Publication Date

- 16-Oct-2012

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 142 - Woodworking machines - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 01-Mar-2023

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 24-Oct-2012

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 60825-1:2007 - Safety of laser products - Part 1: Equipment classification and requirements - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 1870-7:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of woodworking machines - Circular sawing machines - Part 7: Single blade log sawing machines with integrated feed table and manual loading and/or unloading". This standard covers: This European Standard deals with all significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to single blade circular log sawing machines with saw blade diameter ≥ 600 mm and with integrated feed table with manual loading and/or unloading, (hereinafter referred to as machines), designed to cut solid wood when they are used as intended and under the conditions foreseen by the manufacturer including reasonably foreseeable misuse. This European Standard is not applicable to machines manufactured before the date of its publication as EN.

This European Standard deals with all significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to single blade circular log sawing machines with saw blade diameter ≥ 600 mm and with integrated feed table with manual loading and/or unloading, (hereinafter referred to as machines), designed to cut solid wood when they are used as intended and under the conditions foreseen by the manufacturer including reasonably foreseeable misuse. This European Standard is not applicable to machines manufactured before the date of its publication as EN.

EN 1870-7:2012 is classified under the following ICS (International Classification for Standards) categories: 79.120.10 - Woodworking machines. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1870-7:2012 has the following relationships with other standards: It is inter standard links to EN 1870-7:2002+A1:2009, EN 60529:1991, EN 60439-1:1999, HD 22.4 S4:2004, EN 61310-1:2008, EN 50370-1:2005, EN 60825-1:2007, EN 61800-5-2:2007, EN ISO 11202:2010, EN ISO 3744:2010, EN 12779:2004+A1:2009, EN 1088:1995+A2:2008, EN ISO 3743-2:2009, EN 1037:1995+A1:2008, EN 614-1:2006+A1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1870-7:2012 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1870-7:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

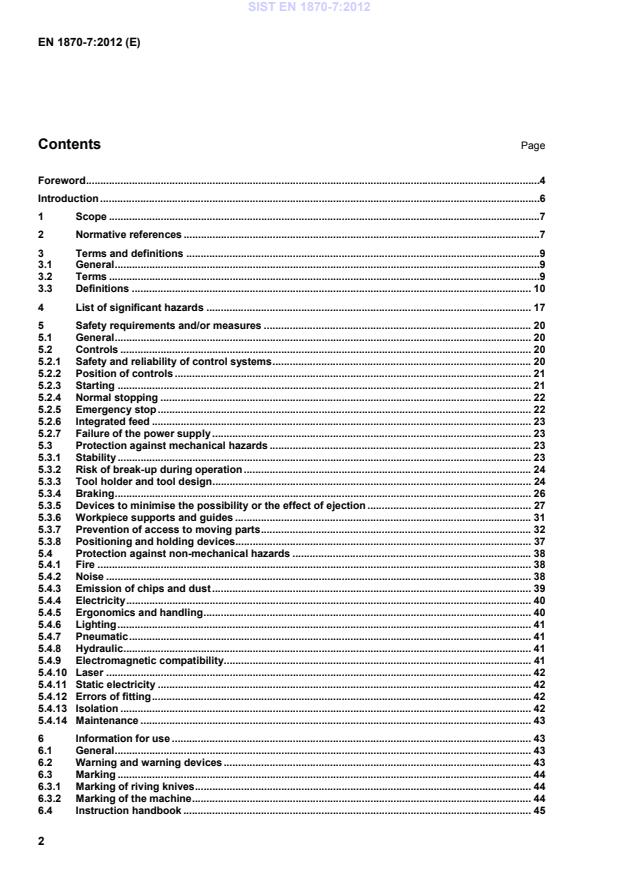

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheit von Holzbearbeitungsmaschinen - Kreissägemaschinen - Teil 7: Einblatt- Stammkreissägemaschinen mit mechanischem Tishvorschub und Handbechickung und/oder HandentnahmeSécurité des machines pour le travail du bois - Machines à scie circulaire - Partie 7: Scies circulaires mono-lame à grumes à avance intégrée à table et à chargement et/ou déchargement manuelSafety of woodworking machines - Circular sawing machines - Part 7: Single blade log sawing machines with integrated feed table and manual loading and/or unloading79.120.10Lesnoobdelovalni strojiWoodworking machines25.080.60Strojne žageSawing machinesICS:Ta slovenski standard je istoveten z:EN 1870-7:2012SIST EN 1870-7:2012en,fr,de01-december-2012SIST EN 1870-7:2012SLOVENSKI

STANDARDSIST EN 1870-7:2002+A1:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1870-7

October 2012 ICS 79.120.10 Supersedes EN 1870-7:2002+A1:2009English Version

Safety of woodworking machines - Circular sawing machines - Part 7: Single blade log sawing machines with integrated feed table and manual loading and/or unloading

Sécurité des machines pour le travail du bois - Machines à scie circulaire - Partie 7: Scies circulaires mono-lame à grumes à avance intégrée à table et à chargement et/ou déchargement manuel

Sicherheit von Holzbearbeitungsmaschinen - Kreissägemaschinen - Teil 7: Einblatt- Stammkreissägemaschinen mit mechanischem Tishvorschub und Handbechickung und/oder Handentnahme This European Standard was approved by CEN on 4 August 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1870-7:2012: ESIST EN 1870-7:2012

Saw spindle dimensional tolerances . 49Annex B (normative)

Riving knife mounting Strength test . 50Annex C (normative)

Riving knife lateral stability test . 51Annex D (normative)

Operating conditions for noise emission measurement . 52D.1 Operating conditions . 52D.2 General data sheet . 54Annex E (normative)

Braking tests . 56E.1 Conditions for all tests . 56E.2 Tests . 56E.2.1 Run-up time . 56E.2.2 Un-braked run-down time . 56E.2.3 Braked run-down time . 56Annex F (normative)

Impact test method for guards . 58F.1 General . 58F.2 Test method . 58F.2.1 Preliminary remarks . 58F.2.2 Testing equipment . 58F.2.3 Projectile for guards . 58F.2.4 Sampling. 58F.2.5 Test procedure . 58F.3 Results . 59F.4 Assessment . 59F.5 Test report . 59F.6 Test equipment for impact test . 59Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 61Bibliography . 62 SIST EN 1870-7:2012

EN 614-1:2006+A1:2009, Safety of machinery — Ergonomic design principles — Part 1: Terminology and general principles EN 614-2:2000+A1:2008, Safety of machinery — Ergonomic design principles — Part 2: Interactions between the design of machinery and work tasks EN 847-1:2005+A1:2007, Tools for woodworking — Safety requirements — Part 1: Milling tools, circular saw blades EN 894-1:1997+A1:2008, Safety of machinery — Ergonomics requirements for the design of displays and control actuators — Part 1: General principles for human interactions with displays and control actuators EN 894-2:1997+A1:2008, Safety of machinery — Ergonomics requirements for the design of displays and control actuators — Part 2: Displays EN 894-3:2000+A1:2008, Safety of machinery — Ergonomics requirements for the design of displays and control actuators — Part 3: Control actuators EN 1005-1:2001+A1:2008, Safety of machinery — Human physical performance — Part 1: Terms and definitions EN 1005-2:2003+A1:2008, Safety of machinery — Human physical performance — Part 2: Manual handling of machinery and component parts of machinery EN 1005-3:2002+A1:2008, Safety of machinery — Human physical performance — Part 3: Recommended force limits for machinery operation EN 1005-4:2005+A1:2008, Safety of machinery — Human physical performance — Part 4: Evaluation of working postures and movements in relation to machinery EN 1037:1995+A1:2008, Safety of machinery — Prevention of unexpected start-up EN 1088:1995+A2:2008, Safety of machinery — Interlocking devices associated with guards — Principles for design and selection EN 1837:1999+A1:2009, Safety of machinery — Integral lighting of machines EN 12779:2004+A1:2009, Safety of woodworking machines — Chip and dust extraction systems with fixed installation — Safety related performances and safety requirements SIST EN 1870-7:2012

Part 1: Emission EN 50370-2:2003, Electromagnetic compatibility (EMC) — Product family standard for machine tools —

Part 2: Immunity EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:2005, modified) EN 60439-1:1999,1) Low-voltage switchgear and controlgear assemblies — Part 1: Type-tested and partially type-tested assemblies (IEC 60439-1:1999) EN 60529:1991,2) Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989) EN 60825-1:2007, Safety of laser products — Part 1: Equipment classification and requirements

(IEC 60825-1:2007) EN 61310-1:2008, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual, acoustic and tactile signals (IEC 61310-1:2007) EN 61800-5-2:2007, Adjustable speed electrical power drive systems — Part 5-2: Safety requirements — Functional (IEC 61800-5-2:2007) EN ISO 3743-1:2010, Acoustics — Determination of sound power levels and sound energy levels of noise sources using sound pressure — Engineering methods for small movable sources in reverberant fields — Part 1: Comparison method for a hard-walled test room (ISO 3743-1:2010) EN ISO 3743-2:2009, Acoustics — Determination of sound power levels of noise sources using sound pressure — Engineering methods for small, movable sources in reverberant fields — Part 2: Methods for special reverberation test rooms (ISO 3743-2:1994) EN ISO 3744:2010, Acoustics — Determination of sound power levels and sound energy levels of noise sources using sound pressure — Engineering method in an essentially free field over a reflecting plane (ISO 3744:2010) EN ISO 3745:2009,3) Acoustics — Determination of sound power levels of noise sources using sound pressure — Precision methods for anechoic and semi-anechoic rooms (ISO 3745:2003) EN ISO 3746:2010, Acoustics — Determination of sound power levels and sound energy levels of noise sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting plane (ISO 3746:2010) EN ISO 4413:2010, Hydraulic fluid power — General rules and safety requirements for systems and their components (ISO 4413:2010) EN ISO 4414:2010, Pneumatic fluid power — General rules and safety requirements for systems and their components (ISO 4414:2010) EN ISO 4871:2009, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996) EN ISO 9614-1:2009, Acoustics — Determination of sound power levels of noise sources using sound intensity — Part 1: Measurement at discrete points (ISO 9614-1:1993)

1) EN 60439-1:1999 is impacted by EN 60439-1:1999/A1:2004. 2) EN 60529:1991 is impacted by EN 60529:1991/A1:2000. 3) EN ISO 3745:2009 is superseded by EN ISO 3745:2012. SIST EN 1870-7:2012

4) HD 22.4 S4:2004 is superseded by EN 50525-2-21:2011. SIST EN 1870-7:2012

Key

1 dropping device 2 riving knife 3 holding-down device 4 fence 5 feed table 6 feed rollers 7 controls 8 log hook Figure 1 — Terminology 3.3 Definitions 3.3.1 single blade circular log sawing machine with integrated feed table and manual loading and/or unloading machine designed for the ripping of solid wood e.g. logs, having the following characteristics: a) integrated feed table; b) saw blade diameter ≥ 600 mm; c) the saw blade is mounted on a horizontal spindle below the table; d) the saw blade spindle is in a fixed position 3.3.2 stationary machine machine designed to be located on or fixed to the floor or other parts of the structure of the premises and to be stationary during use 3.3.3 displaceable machine machine which is located on the floor, stationary during use and equipped with a device, normally wheels, which allow it to be moved between locations 3.3.4 machine actuator power mechanism used to effect motion of the machine SIST EN 1870-7:2012

3.3.9 run-up time time elapsed from the actuation of the start control device until the spindle reaches the intended speed 3.3.10 run-down time time elapsed from the actuation of the stop control device up to spindle standstill 3.3.11 dropping device device designed to remove the workpiece or off-cuts from the integrated feed table

Note 1 to entry: See Figure 2. SIST EN 1870-7:2012

Figure 2 — Example of dropping device (guards not shown) 3.3.12 log lifter equipment, integral with the machine and which lifts the log from the ground onto the integrated feed table

Note 1 to entry: See Figure 3. SIST EN 1870-7:2012

Figure 3 — Example of log lifter 3.3.13 log positioner device for horizontal (adjusting) and rotational positioning of the log/workpiece prior to sawing

Note 1 to entry: See Figure 4.

Key

1 log adjuster 2 log rotator Figure 4 — Example of log adjuster and rotator 3.3.14 log delivery device device for loading the log onto the integrated feed table

Note 1 to entry: See Figure 5. SIST EN 1870-7:2012

Figure 5 — Example of log delivery device 3.3.15 log clamp device for holding the log in position at the front end of the integrated feed table during sawing

Note 1 to entry: See Figure 6. SIST EN 1870-7:2012

Figure 6 — Example of log clamp 3.3.16 log hook device to hold the long axis of the log stable during feeding

Note 1 to entry: See Figure 7. Dimensions in millimetres

Figure 7 — Example of log hook

Key

1 riving knife 2 saw blade guide Figure 8 — Example of saw blade guide 3.3.18 holding down device adjustable device situated over the saw blade to minimise the risk of uplifted cut-offs from contacting the uppermost teeth of the saw blade

Note 1 to entry: See Figure 9.

Key

1 holding down device 2 riving knife Figure 9 — Example of holding down device over the saw blade SIST EN 1870-7:2012

PL discrete level used to specify the ability of safety-related parts of control systems to perform a safety function under foreseeable conditions [SOURCE: EN ISO 13849-1:2008, 3.1.23] 4 List of significant hazards This clause contains all significant hazards, hazardous situations and events (see EN ISO 12100:2010), identified by risk assessment as significant for the machines as defined in the scope and which require action to eliminate or reduce the risk. This document deals with these significant hazards by defining safety requirements and/or measures or by reference to relevant standards. These hazards are listed in Table 1. SIST EN 1870-7:2012

1 Mechanical hazards related to: - machine parts or workpieces:

a) shape; 6.2.2.1, 6.2.2.2, 6.3 5.3.2, 5.3.3, 5.3.5, 5.3.6, 5.3.7, 5.3.8

b) relative location; 5.3.2, 5.3.3, 5.3.5

c) mass and stability (potential energy of elements which may move under the effect of gravity) 5.2.2, 5.3.8

d) mass and velocity (kinetic energy of elements in controlled or uncontrolled motion); 5.2.3, 5.3.1, 5.3.5

e) mechanical strength. 5.3.3, 5.3.5

- accumulation of energy inside the machinery:

g) liquids and gases under pressure; 6.2.10, 6.3.5.4 5.4.7, 5.4.8 1.1 Crushing hazard

5.3.7, 5.3.8 1.2 Shearing hazard 5.3.7, 5.3.8 1.3 Cutting or severing hazard 5.3.2, 5.3.3, 5.3.4, 5.3.7 1.4 Entanglement hazard 5.3.3, 5.3.6, 5.3.7 1.5 Drawing-in or trapping hazard 5.3.7 1.6 Impact hazard 5.3.7, 5.3.8 1.9 High pressure fluid injection or ejection hazard 6.2.10 5.4.7, 5.4.8 2 Electrical hazards due to: 2.1 Contact of persons with live parts (direct contact) 6.2.9, 6.3.5.4 5.4.4, 5.4.13 2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) 6.2.9 5.4.4, 5.4.13 2.4 Electrostatic phenomena 6.2.9 5.4.11 4 Hazards generated by noise, resulting in: 4.1 Hearing loss (deafness), other physiological disorders (loss of balance, loss of awareness) 6.2.2.2, 6.3 5.4.2

5.4.2 6 Hazards gene rated by radiation 6.5 Lasers 6.3.4.5 5.4.10 7 Hazards generated by materials and substances (and their constituent elements) processed or used by the machinery 7.1 Hazards from contact with or inhalation of harmful fluids and dusts 6.2.3, 6.2.4

5.4.3 7.2 Fire hazard 6.2.4

5.4.1, 6.4 8 Hazards generated by neglecting ergonomic principles in machinery design related to: 8.1 Unhealthy postures or excessive effort 6.2.7, 6.2.8, 6.2.11.12, 6.3.5.5, 6.3.5.6 5.2.2 8.2 Hand-arm or foot-leg anatomy 6.2.8.3 5.2.2 8.4 Local lighting 6.2.8.6 6.4 8.6 Human error, human behaviour 6.2.8, 6.2.11.8, 6.2.11.10, 6.3.5.2, 6.4 6.4 8.7 Design, location or identification of manual controls 6.2.8.7, 6.2.11.8 5.2.2 8.8 Design or location of visual display units 6.2.8.8, 6.4.2 5.2.2 10 Unexpected start up, unexpected overrun/overspeed (or any similar malfunction) from: 10.1 Failure/disorder of the control system 6.2.11, 6.3.5.4

5.2.1, 5.2.7, 5.2.8 10.2 Restoration of energy supply after an interruption 6.2.11.4

5.2.7 10.3 External influences on electrical equipment 6.2.11.11 5.2.1, 5.4.4, 5.4.9 10.6 Errors made by the operator (due to mismatch of machinery with human characteristics and abilities, see 8.6) 6.2.8, 6.2.11.8, 6.2.11.10, 6.3.5.2, 6.4 5.2.1, 5.2.2, 5.4.5, 6.4 11 Impossibility of stopping the machine in the best possible conditions 6.2.11.1, 6.2.11.3, 6.3.5.2

5.2.4, 5.2.5 13 Failure of the power supply 6.2.11.1, 6.2.11.4 5.2.7 14 Failure of the control circuit 6.2.11, 6.3.5.4

5.2.1 15 Errors of fitting 6.2.7, 6.4.5 6.4 16 Break-up during operation 6.2.3 5.3.2 17 Falling or ejected objects or fluids 6.2.3, 6.2.10

5.3.2, 5.3.3, 5.3.5, 5.3.6, 5.3.7, 5.3.8 18 Loss of stability / overturning of machinery 6.3.2.6

5.3.1

EN ISO 12100:2010 for hazards relevant but not significant, which are not dealt with by this document (e.g. sharp edges of the machine frame). For guidance in connection with risk reduction by design, see EN ISO 12100:2010, 6.2, and for safeguarding measures, see EN ISO 12100:2010, 6.3. 5.2 Controls 5.2.1 Safety and reliability of control systems 5.2.1.1 General For the purpose of this document, safety related part of a control system means the system from the initial device, e.g. actuator or position detector or sensor up to and including the power control element of the final machine actuator, e.g. motor or brake. Safety related parts of the control system of this machine comprise parts concerning the following functions and they shall fulfil at least the requirements of the PL given below in accordance with the requirements of EN ISO 13849-1:2008: starting: PL=c (see 5.2.3); normal stopping: PL=c (see 5.2.4); emergency stopping: PL=c (see 5.2.5); interlocking: PL=c (see 5.2.3, 5.2.5, 5.3.7.1, 5.3.7.2, 5.3.7.4, 5.3.7.5); the braking system: PL=b or PL=c (see 5.2.4, 5.2.5, 5.3.4); limited movement control device: PL=c (see 5.3.7.3); hold to run control: PL=c (see 5.2.6); power operated movement of the fence: PL=c (see 5.2.3). Verification: By checking the relevant drawings and/or circuit diagrams and inspection of the machine. NOTE For components characteristics the information from the component supplier can be useful. 5.2.1.2 Use of protective devices Protective devices shall be in accordance with the specific standards. For the devices listed below the following requirements apply: a) magnetic/proximity switches shall be in accordance with the requirements of 6.3 of EN 1088:1995+A2:2008 and the related control system shall conform to at least PL=c in accordance with the requirements of EN ISO 13849-1:2008; b) time delay shall be at least PL=c in accordance with the requirements of EN ISO 13849-1:2008. Verification: By checking the relevant drawings and/or circuit diagrams, inspection of the machine and relevant functional testing of the machine. SIST EN 1870-7:2012

Key

1 area Y 2 area X R = 850 mm for both hands Figure 10 — Position of controls 5.2.3 Starting The requirements of EN 60204-1:2006, 9.2.5.2 apply and in addition: For the purpose of this document "safeguards are in place and functional" is achieved by the interlocking arrangements described in 5.3.7 and "operation" means rotation of the saw spindle and/or any powered movement of any workpiece holding device and/or any machine element and/or any feed mechanism. The exceptions described in 9.2.5.2 of EN 60204-1:2006 are not relevant. SIST EN 1870-7:2012

a) cut power to all machine actuators and actuate the brake; b) cut power to brake after braking sequence is complete. The stopping sequence shall be satisfied at the level of the control systems. If a time delay device is used, time delay shall conform to 5.2.1.2 b) and be at least the maximum run-down time and either time delay shall be fixed or the time delay adjustment shall be sealed. The safety related part of the control systems (see also 5.2.1) for normal stopping shall be at least PL=c in accordance with the requirements of EN ISO 13849-1:2008. Verification: By checking relevant drawings and/or circuit diagrams, inspection and relevant functional testing of the machine. 5.2.5 Emergency stop The requirements of EN ISO 13850:2008 shall apply and in addition: The machine shall be fitted with emergency stop control devices, which when actuated shall stop all machine actuators. The emergency stop control device shall be at any time of self latching type. On electric driven machines the emergency stop control system shall conform to 9.2.5.4 and 10.7 of EN 60204-1:2006. For emergency stop of PDS(SR) see 4.2.2.2 "safe torque off (STO)” and 4.2.2.3 “safe stop 1 (SS1)” of EN 61800-5-2:2007. On Power Take Off (PTO) driven machines it shall not be possible to operate the machine unless the emergency stop is functional e.g. by mechanical or electrical interlocking between the power source and movements of the machine. Where a spring operated mechanical brake is provided this stop control shall be of category 0 in accordance with 9.2.2 of EN 60204-1:2006. SIST EN 1870-7:2012

Involuntary actuation of the hold-to-run control device by e.g. protruding branches or logs not placed carefully on the machine shall be avoided e.g. by means of positioning of the hold-to-run control device or a cover. This is to prevent overhanging branches or a log which is not properly loaded from striking and holding the control device in the feed position, which would create hazards to the operator and others. The control of the log delivery device, log adjuster and rotator, log lifter and log clamp and any additional devices associated with handling of the workpiece or parts of it, shall be hand operated hold-to-run control devices. The safety related part of the control systems (see also 5.2.1) for hold-to-run control shall be at least PL=c in accordance with the requirements of EN ISO 13849-1:2008. Verification: By checking the relevant drawings and/or circuit diagrams, inspection and relevant functional testing of the machine. 5.2.7 Failure of the power supply On electrically driven machines an automatic restart in the case of supply interruption after the restoration of the supply voltage shall be prevented in accordance with paragraphs 1 and 3 in 7.5 of EN 60204-1:2006. Where the machine is fitted with pneumatic and/or hydraulic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...