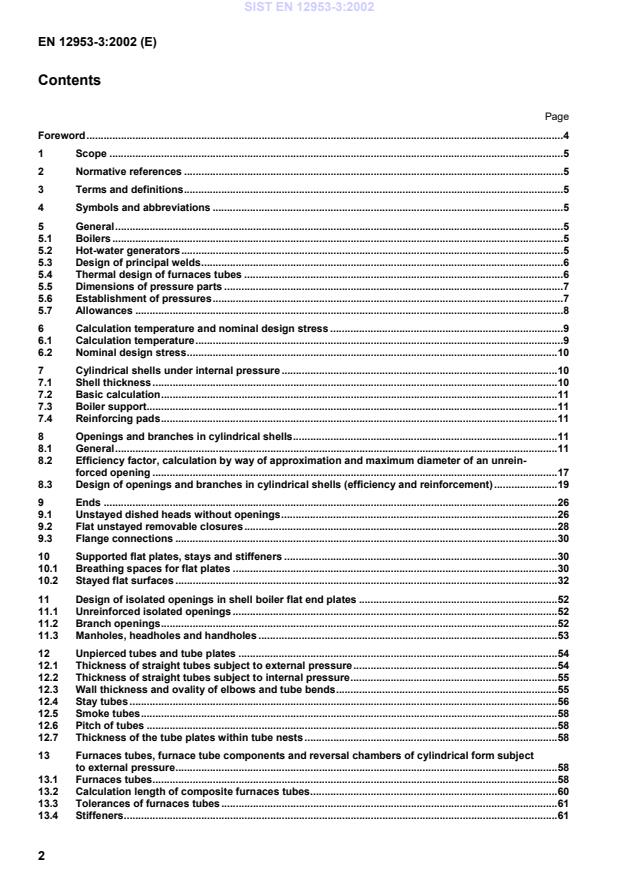

EN 12953-3:2002

(Main)Shell boilers - Part 3: Design and calculation for pressure parts

Shell boilers - Part 3: Design and calculation for pressure parts

This standard applies to shell boilers as defined in prEN 12953-1. This Part of the standard specifies rules for the design and calculation of shell boilers.

Großwasserraumkessel - Teil 3: Konstruktion und Berechnung für drucktragende Teile

Diese Norm gilt für die in prEN 12953-1 definierten Großwasserraumkessel. Dieser Teil der Norm schreibt Regeln für die Konstruktion und Berechnung von Großwasserraumkessel vor.

Chaudières à tubes de fumée - Partie 3: Conception et calcul des parties sous pression

La présente partie de l'EN 12953 s'applique aux chaudières à tubes de fumée telles que définies dans le prEN 12953-1.

La présente partie de la norme européenne spécifie les règles de conception et de calcul des chaudières à tubes de fumée.

Mnogovodni kotli - 3. del: Konstruiranje in izračun tlačno obremenjenih delov

General Information

- Status

- Withdrawn

- Publication Date

- 21-May-2002

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 269 - Shell and water tube boilers

- Drafting Committee

- CEN/TC 269/WG 1 - Water-tube boilers

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 11-May-2016

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2026

- Refers

EN 12953-2:2025 - Shell boilers - Part 2: Materials for pressure parts of boilers and accessories - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 12953-10:2003 - Shell boilers - Part 10 : Requirements for feedwater and boiler water quality - Effective Date

- 28-Jan-2026

- Refers

EN 12953-8:2001 - Shell boilers - Part 8: Requirements for safeguards against excessive pressure - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 12953-3:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Shell boilers - Part 3: Design and calculation for pressure parts". This standard covers: This standard applies to shell boilers as defined in prEN 12953-1. This Part of the standard specifies rules for the design and calculation of shell boilers.

This standard applies to shell boilers as defined in prEN 12953-1. This Part of the standard specifies rules for the design and calculation of shell boilers.

EN 12953-3:2002 is classified under the following ICS (International Classification for Standards) categories: 27.060.30 - Boilers and heat exchangers; 27.100 - Power stations in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12953-3:2002 has the following relationships with other standards: It is inter standard links to EN 12953-3:2016, EN 12953-4:2018, EN 12953-2:2025, EN 12953-1:2002, EN 12953-5:2002, EN 13445-3:2021, EN 12953-10:2003, EN 12953-8:2001, EN 12953-1:2012, EN 13480-3:2012, EN 12952-3:2011, EN 12953-4:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12953-3:2002 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12953-3:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Großwasserraumkessel - Teil 3: Konstruktion und Berechnung für drucktragende TeileChaudieres a tubes de fumée - Partie 3: Conception et calcul des parties sous pressionShell boilers - Part 3: Design and calculation for pressure parts27.060.30Grelniki vode in prenosniki toploteBoilers and heat exchangersICS:Ta slovenski standard je istoveten z:EN 12953-3:2002SIST EN 12953-3:2002en01-november-2002SIST EN 12953-3:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12953-3May 2002ICS 27.060.30; 27.100English versionShell boilers - Part 3: Design and calculation for pressure partsChaudières à tubes de fumée - Partie 3: Conception etcalcul des parties sous pressionGroßwasserraumkessel - Teil 3: Konstruktion undBerechnung für drucktragende TeileThis European Standard was approved by CEN on 15 May 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12953-3:2002 ESIST EN 12953-3:2002

Calculation of tube plate temperatures.70Annex B (informative)

Calculation form for "Walker"-type reverse curve sections or corrugations.87Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or otherprovisions of the Pressure Equipment Directive.89Bibliography.90SIST EN 12953-3:2002

of this European Standard is informative.The Annex B of this European Standard is normative.According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following coun-tries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Denmark, Finland,France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Swe-den, Switzerland and the United Kingdom.SIST EN 12953-3:2002

214 = 4 504 kWFurnace tube steel: P295 GHa) Minimum plain furnace tube inside diameter: 810 mmb) Minimum Fox 150

50 (Table 13.1-1) corrugated furnace tube inside diameter: 760 mm.EXAMPLE 2:Allowable heat input for a given furnace tube inside diametera) Plain furnace tube inside diameter: 1 500 mm P295 GH, oil firing:12,90 MW P295 GH, gas firing:16,77 MW P265 GH, oil firing:

8,00 MW P265 GH, gas firing:10,40 MWb) Fox 150

50 (Table 13.1-1) corrugated furnace tube inside diameter 1 000 mm P265 GH, gas firing:7,02 MW.The length of the refractory should not be larger than one third of the inside furnace tube diameter measured fromthe end of the burner.NOTEAttention is drawn to national regulations that for boilers with an inside furnace tube diameter greater than 1 400 mmor a heat input greater than 12 MW a temperature measurement consisting of at least three measurement points in the furnacecan be required.SIST EN 12953-3:2002

Coal firing (grate) P 295 GH2

Oil firing P 265 GH3

Oil firing of P 295 GH, P 355 GHaMinimum furnace tube inside diameter [mm]bHeat input [MW]NOTE 1For corrugated furnaces tubes the minimum inside diameter di can be reduced by the depth of the corrugation.NOTE 2In the case of gas firing the heat input given for oil firing can be increased by 30 %.NOTE 3Heat input is the product of the fuel flow rate and the lower calorific value. Air preheating should be taken into ac-count if the air temperature is greater than 100 °C.Figure 5.4.1 — Relation between heat input and furnace tube inside diameter5.5 Dimensions of pressure partsThe wall thickness and other dimensions of pressure parts shall be sufficient to withstand the calculation pressure atcalculation temperature and shall be determined in accordance with this Part.5.6 Establishment of pressures5.6.1 Maximum allowable pressureThe maximum allowable pressure PS is the maximum pressure for which the boiler is designed and shall bemeasured at the highest point of the shell boiler.SIST EN 12953-3:2002

2et(6.1-1)ortc = ts

25(6.1-2)whichever is the greater.c) The calculation temperature for areas of plate subject to heat transfer but not swept by flame, or for tube nestareas where the gas entry temperature is not greater than 800 °C, shall be determined in accordance with thefollowing equations:tc = ts

2eh(6.1-3)ortc = ts

50(6.1-4)whichever is the greater.The calculation temperature for flat walls in the flue gas pass with a flue gas temperature tG

400 °C shall be:tc = ts

20(6.1-5)d) For tube plates subject to gas entry temperatures exceeding 800 °C in fired boilers using fossil fuels, includingnatural gas, the calculation temperature shall be determined in accordance with Annex A, using the true gasentry temperature tG determined from the following equation:25,051AHtG(6.1-6)For fuels where the true gas entry temperature is higher than that obtained with natural gas, and for waste-heat boilers, the calculation temperature shall be determined in accordance with Annex A.The maximum metal temperature as determined in accordance with Annex A shall not exceed 420 °C.The condition for the calculation in accordance with Annex A is good contact between smoke tubes and tubesheet. Where this cannot be ensured, the method of attachment shown in Figure 12.4-1f) may be employedwith the following limitations:1) The depth of the connecting weld between smoke tubes and tube sheet shall be greater than or equal tothe wall thickness of the smoke tube plus 2 mm;2) The length of the gap, measured from the root of the weld, shall be less than or equal to four times thewall thickness of the smoke tube. If this dimension is exceeded, a cooling groove shall be provided.SIST EN 12953-3:2002

800 °C shall be given byequation (6.1-4).e) The calculation temperature for furnaces tubes shall be determined by the following equations:1) In the case of furnaces tubes subjected to the flame and a heat input

12 MWtc = ts

4e

15(6.1-7)2) In the case of furnaces tubes subjected to flame and a heat input

12 MWfor oil firingtc = ts

3,5e

80(6.1-8)for gas firingtc = ts

3e

65(6.1-9)NOTEEquations (6.1-8) and (6.1-9) are based on a maximum heat flux of 0,3 W/mm2 for oil firing and 0,24 W/mm2 forgas firing, taking into account an allowance of 0,25 mm for the thickness of scale with a conductivity of 1,2 W/m K.Where it can be shown that the heat flux is lower, e.g. low NOx firing, the calculations can be adjusted accordingly, but thevalue of tc should be not less than that given by equation (6.1-7).3) In the case of furnace tubes without flame the calculation temperature tc shall taken as being equal to thehighest of the two values given by the following equations:tc = ts

25(6.1-10)tc = ts

2e(6.1-11)6.2 Nominal design stressUnless otherwise stated in this Part of this European Standard, the nominal design stress f shall be the lower of thevalues obtained from the following ratios:4,2;5,1min2,0mtcpRRf(6.1-12)NOTEThe term "nominal design stress", designated by the symbol f, is the stress to be used in the equations herein forthe design of pressure parts. The detailed design rules in this Part will maintain the actual maximum stresses within acceptablelimits for the type of loading considered.7 Cylindrical shells under internal pressure7.1 Shell thickness7.1.1 RequirementsThe shell thickness after deduction of allowancesers = es-c1-c2 (7.1-1)of cylindrical shell shall be at least the greatest of those required by the following:SIST EN 12953-3:2002

1 000 mm except LPB. For outside diameter 1 000 mm and LPB a minimum of 4 mm shall be required;b) the requirements of 7.2;c) the requirements of 7.2 by applying 8.2 or 8.3.3 and 8.3.4.7.1.2 Required wall thickness including allowancesThe required wall thickness including allowances shall be derived from:esa = ecs

c1

c2(7.1-2)7.2 Basic calculationThe required wall thickness without allowances ecs of a cylindrical shell shall be determined by either of the followingequationsvpfdpecsisccs2(7.2-1)if dis is given orccsosccspvpfdpe22(7.2-2)if dos is given.The equivalent value of the stress in the shell can be calculated by modifying

equations (7.2-1) or (7.2-2).7.3 Boiler supportExperience has shown that it shall not be necessary to carry out strength calculations in regard to boiler supports asfatigue is not normally encountered in this area.7.4 Reinforcing padsReinforcing pads may be used for the reinforcement of openings and branches and for the distribution of load atsupports and attachments. Such reinforcing pads shall be designed analogous to the requirements of 8.1.5.1.8 Openings and branches in cylindrical shellsNOTEThis clause specifies the design rules for openings and branches in cylindrical shells. All dimensions exclude allow-ances c1 and c2 for wall thickness.8.1 General8.1.1 Requirements for the efficiency of the main body with openings and branches8.1.1.1For cylindrical shells with openings the efficiency of the main body shall be satisfied by the following:a) by increasing the wall thickness of the main body compared with that of the cylindrical shell without openings.This wall thickness shall be available at least up to the length lrs measured from the edge of the opening (seeFigure 8.1-1; and for lrs see 8.1.2). Where there is a branch, the cylindrical length of the main body up to anyadjacent butt weld in it shall be lso

ers (see Figures 8.1-2 and 8.1-3).SIST EN 12953-3:2002

1,5 mm may be present. A wall thickness ratio of erb/ers up to and including 2 shall bepermitted for dib

50 mm. This shall also apply to branches with dib

50 mm insofar as the diameter ratiodib/dis

0,2. For branches with dib

50 mm and a diameter ratio dib/dis

0,2, erb/ers shall not exceed unity. Theseconditions do not apply to access and inspection openings.Expanded or set-in and seal-welded-only branches (see Figure 8.1-1) or branches attached to the main body byfillet welds with a residual root gap

1,5 mm shall not be regarded as contributing to the reinforcement.The cylindrical length of branches up to the butt weld between tube and branch shall be lbo

erb (seeFigures 8.1-2 and 8.1-3).For branches with dib/dis

0,7 reference shall be made to 8.3.3.4.In general, special emphasis shall be placed on smooth wall thickness transitions. Wall thickness transitions shallbe made with an angle

30° (see Figure 8.1-2). The reinforcement of openings by inside reinforcing plates orpads shall not be permitted.c) reinforcement by reinforcing pads analogous to increasing the wall thickness as in a) (see Figures 8.1-4 to8.1-5).8.1.1.2Where there are elliptical access and inspection openings it shall be assumed that the ratio of major tominor axis does not exceed 1,5. For elliptical or obround openings in cylindrical shells the dimension extending inthe direction of the shell axis shall be taken as the diameter for design purposes. (For oblique nozzles, see 8.3.3.3).The calculation procedure assumes that the transitions shall show a notch-free surface1). Edges shall be rounded.Openings shall be located at an adequate distance from the longitudinal and circumferential welds of the main body.The distance shall be considered adequate if the outer edge of a branch or welded-on reinforcement, on a main bodywith a thickness ers

25 mm is at a distance of 2 ers and on a main with a body thickness ers

25 mm the distance is atleast 50 mm from the weld edge.8.1.2 Effective lengths lrs for calculation of efficiencies and of compensationsFor the calculation of efficiencies by way of approximation as described in 8.2 and the calculation of isolated andadjacent branches described in 8.3, effective lengths lrs are required which shall be used for the main body.1rs;)(minsrsrsisleedl(8.1-1)for ls1 see Figures 8.1-1 to -3.and for the nozzle with

45°for external projection1;)(minbrbrbibrbleedl(8.1-2)for internal projection2;)(5,0minbrbrbibrbileedl(8.1-3)

1)Welded joints are considered to be notch-free if they are within the limits given in EN 12952-5.SIST EN 12953-3:2002

= 0°(for

see Figure 8.3-1).8.1.4 Requirements for design of branches8.1.4.1 Main body with lower design stress than the branchesIf the main body, the branch and the additional reinforcement consists of materials with different design stresses andthe material of the main body has the lowest design stress value fs, this value shall be used for all materials tocalculate the reinforcement of the branch.8.1.4.2 Branches or reinforcing pads with lower design stress than the main bodyIf the material used for the branch or the reinforcing pad has a lower design stress fb or fp respectively than the mainbody design stress fs, this design stress fb or fp shall be taken into account when using the equations provided for thiscase.8.1.4.3 Special caseThe nozzle inside diameter dib shall be used in the calculation even if the hole diameter d in the main body is less thandib.8.1.5 Requirements for design of reinforcing pads8.1.5.1 GeneralReinforcing pads shall be designed in accordance with 8.1.1.1.Where reinforcing pads are fitted (see Figures 8.1-4 and 8.1-5) they shall have close contact with the main body andshall be provided with tell-tale holes to avoid the trapping of gases, unless experience has shown that it is notnecessary.Reinforcing pads shall not be used where there is a possibility of severe corrosion or oxidation or of large temperaturegradients across the thickness of the shell. Reinforcing pads shall not be permitted on the inside of the vessel.8.1.5.2 Pressure considerationsWhen reinforcing pads are used for the reinforcement of penetrations or openings, the following conditions shall beobserved.a) the ratio dib/dis of the branch diameter to the cylinder diameter shall be not greater than 1/4 unless theadequacy of the design is demonstrated by experience or by a hydrostatic proof test.b) the sizes Li of the inner fillet welds by which reinforcing pads are attached to shell plates (see Figure 8.1-6)shall comply with the following relationship:cpieL7,0(8.1-5)SIST EN 12953-3:2002

Tell-tale holeaOpening in shella)Key1

Tell-tale hole

is 30° to 45°b)Figure 8.1.6 — Welding of reinforcing pads8.2 Efficiency factor, calculation by way of approximation and maximum diameter of an unrein-forced opening8.2.1 GeneralExact solutions shall be given by the equations in 8.3.3 and 8.3.4. Application of the equations in 8.2.3 and 8.2.4,except equation (8.2-3), may be conservative as any reinforcement from the branch is not taken into account.SIST EN 12953-3:2002

= 0:PdPvobm(8.2-8)Where the outside diameters of adjacent openings differ from each other, the following shall apply221obobobddd(8.2-9)Instead of the calculation by approximation used in this clause, 8.3.4 may be used.8.3 Design of openings and branches in cylindrical shells (efficiency and reinforcement)8.3.1 Symbols and abbreviationsIn addition to the symbols given in EN 12953-1:2002, Table 4-1, those shown in Figures 8.3-1 to 8.3-4 shall be used.8.3.2 Requirements for application8.3.2.1 OpeningsThe rules specified in 8.3.3 to 8.3.4 shall apply to circular, elliptical and obround openings and nozzles (includingoblique nozzles) arranged singly or in groups, in cylindrical shells, provided that the following conditions are satisfied:a) Openings and nozzles non radial to the shell (Figure 8.3-2)The ratio of the major to minor axes of the opening shall not exceed 2;b) Oblique nozzles (Figure 8.3-1)The nozzle is of circular cross section and the angle between the axis of the nozzle and a line normal to theshell surface shall not exceed 45°;c) All nozzlesNo significant external forces and moments shall be applied to the nozzle. If this is not the case, EN 13445-3shall be used to calculate the resulting stresses.The nozzle inside diameter dib shall be used in the calculation even if the hole diameter d in the main body isless than dib.SIST EN 12953-3:2002

8.3-3 — Load diagram for cylindrical shell with adjacent branches,arranged with an angle

to the axis of the shellSIST EN 12953-3:2002

45°2

45°Figure 8.3-4 — Load diagram for cylindrical shell with non-radial adjacent branches,arranged on the circumference8.3.3 Design of isolated openings and branch connections8.3.3.1 GeneralThe shell thickness ers and the thickness of a branch connection erb shall be not less than that calculated for v = 1 inaccordance with 7.2.8.3.3.2 Isolated opening with a radial branch8.3.3.2.1For isolated openings fitted with a radial branch without additional reinforcement 8.3.3.4 and 8.3.3.5(with 1 = 0) shall be additionally taken into account.8.3.3.2.2If the design stress of the branch is equal to or greater than that for the main body the followingstrength condition shall apply:sfbfspcafAAApf;21min(8.3-2)SIST EN 12953-3:2002

0,7 and simultaneously erb/ers

dib/dis, the following condition shall be met forthe main body/branch transition in the cross-section vertical to the main body axis:

2)The approximate calculation in accordance with 8.2 can be used instead of this calculation, in which case the reinforcementeffect of the nozzles should not be considered.SIST EN 12953-3:2002

forthe shell generating line in accordance with Figures 8.3-3. The following strength condition shall apply:sc2fb1fb0fs2p1p20pca2222cos122fpAAAAAApf(8.3-11)Diagonal or circumferential pitches shall be calculated as a longitudinal pitch in accordance with Figure 8.3-3 with adistance P. In this case the pressure area 2 Apo shall be corrected by the factor ((1

cos2)/2) in the strengthcondition in accordance with equation (8.3-14).The efficiency 2) shall be:1222cos122p1p20p2fb1fb0fsrsismAAAAAAedv(8.3-12)8.3.4.4 Branches with equal or lower design stress than the main bodyIf the design stress of one or both branches is less than that of the main body, the following condition shall apply:s2fbs2b1fbs1b0fs2fb1fb0fs2p1p20pca222cos122fAffAffAAAAAAApf(8.3-13)SIST EN 12953-3:2002

cos2)/2) shall be replaced bythe factor 1.9 Ends9.1 Unstayed dished heads without openings9.1.1 Unstayed dished heads under internal pressureThe minimum thickness of unstayed dished he

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...