EN 1906:2002

(Main)Building hardware - Lever handles and knob furniture - Requirements and test methods

Building hardware - Lever handles and knob furniture - Requirements and test methods

This European Standard specifies test methods and requirements for spindle and fastening elements, operating torques, permissible free play and safety, free angular movement and misalignment, durability, static strength and corrosion resistance for sprung and unsprung lever handles and knobs for doors on backplates or roses.

This standard is applicable only to lever handles and knobs that operate a latch or a lock.

It states four categories of use according to the frequency and other conditions of use.

Compliance with this European Standard ensures a margin of strength in excess of that needed for normal operation. Additional requirements are needed for special safety furniture which is suitable for use in situations where there is a high risk of falling. Since special safety furniture is not essential in every situation, this European Standard provides for additional safety requirements (see 5.13) which are only necessary when the manufacturer states that the safety furniture is claimed to conform to these requirements.

This standard states five grades of security. Grade 0 according to requirements stated in the main part of this standard. Grades 1 to 4 are stated according to requirement for security lock furniture for use on burglary resistant doors (see annex A). These additional security requirements are necessary only when the manufacturer states that the products are claimed to have a high level of security, which is not essential in every situation.

The suitability of lock or latch furniture for use on fire/smoke door assemblies is determined by fire performance tests conducted in addition to the performance tests required by this standard. Since suitability for use on fire/smoke door assemblies is not essential in every situation, the manufacturer has the option of stating whether the furniture is claimed to conform to these additional requirements or not. If so stated the additional requirements given in annex C are necessary.

Schlösser und Baubeschläge - Türdrücker und Türknäufe -Anforderungen und Prüfverfahren

Diese Europäische Norm legt Prüfverfahren und Anforderungen an Drückerstifte und Befestigungsele-

mente, Betätigungsmomente, zulässiges freies Spiel und Sicherheit, freie Winkelbewegung und Verset-

zung, Dauerfunktion, statische Festigkeit und Korrosionsbeständigkeit von Türdrückern und Türknäufen

mit und ohne Hochhaltefeder auf Türschildern oder Türrosetten fest.

Diese Norm gilt nur für Türdrücker und Türknäufe, mit denen eine Falle oder ein Schloss betätigt wird.

Diese Norm enthält entsprechend der Betätigungsfrequenz und weiteren Bedingungen vier Anwen-

dungsklassen.

Diese Europäische Norm erfüllt die grundsätzlichen Anforderungen an die Sicherheit bei der Anwendung

und die Übereinstimmung mit dieser Norm und legt einen größeren Festigkeitsbereich fest, als er für nor-

male Zwecke benötigt wird. Für spezielle Sicherheitsbeschläge, die für Einsatzzwecke geeignet sind, bei

denen eine hohe Gefährdung durch Herunterfallen besteht, sind zusätzliche Anforderungen erforderlich.

Weil spezielle Sicherheitsbeschläge nicht für jede Anwendung notwendig sind, gibt diese Europäische

Norm zusätzliche Sicherheitsanforderungen (siehe 5.13), die aber nur dann erforderlich sind, wenn vom

Hersteller angegeben wird, dass die Sicherheitsbeschläge diese Anforderungen erfüllen müssen.

Diese Norm legt fünf Sicherheitsklassen fest. Klasse 0 richtet sich nach den im Hauptteil dieser Norm

festgelegten Anforderungen. Die Klassen 1 bis 4 sind nach den Anforderungen an Sicherheitsbeschläge

für einbruchhemmende Türen festgelegt (siehe Anhang A). Diese zusätzlichen Schutzanforderungen

sind nur dann notwendig, wenn der Hersteller angibt, dass die Produkte eine hohe Einbruchsicherheit

aufweisen müssen, die nicht in jedem Fall erforderlich ist.

Quincaillerie pour le bâtiment - Béquilles et boutons de porte - Prescriptions et méthodes d'essai

La présente Norme européenne spécifie les méthodes d'essai ainsi que les prescriptions pour les tiges carrées et les éléments de fixation, les couples opérationnels, le jeu autorisé et la sécurité, la rotation et le désaxage, l'endurance, la résistance statique et la résistance à la corrosion pour les dispositifs de porte à béquilles et boutons, avec ou sans ressort de rappel, sur plaques ou rosettes.

La présente norme s'applique uniquement aux béquilles et boutons de portes qui actionnent une serrure à pêne dormant ou une serrure bec de cane.

Elle établit quatre catégories d'utilisation selon la nature et la fréquence d'utilisation.

La conformité à cette norme assure une marge de résistance supérieure à celle requise pour une utilisation normale. Des prescriptions supplémentaires sont nécessaires pour des dispositifs de sécurité spéciaux destinés à être utilisés dans des situations où un risque majeur de chute existe. Etant donné qu'un dispositif de sécurité n'est pas nécessaire dans tous les cas, cette Norme européenne prévoit pour les prescriptions de sécurité additionnelles (voir 5.13) qu'elles soient obligatoires lorsque le fabricant stipule que le dispositif de sécurité est reconnu conforme à ces prescriptions.

Stavbno okovje - Kljuke in bunke - Zahteve in preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 12-Feb-2002

- Withdrawal Date

- 13-Apr-2010

- Technical Committee

- CEN/TC 33 - Doors, windows, shutters and building hardware

- Drafting Committee

- CEN/TC 33/WG 4 - Building hardware

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 14-Apr-2010

- Completion Date

- 14-Apr-2010

Not Harmonized89/106/EEC - Construction products

Relations

- Replaced By

EN 1906:2010 - Building hardware - Lever handles and knob furniture - Requirements and test methods - Effective Date

- 06-May-2009

- Revised

prEN 1906 - Building hardware - Lever handles and knob furniture - Requirements and test methods - Effective Date

- 18-Jan-2023

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 1906:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Building hardware - Lever handles and knob furniture - Requirements and test methods". This standard covers: This European Standard specifies test methods and requirements for spindle and fastening elements, operating torques, permissible free play and safety, free angular movement and misalignment, durability, static strength and corrosion resistance for sprung and unsprung lever handles and knobs for doors on backplates or roses. This standard is applicable only to lever handles and knobs that operate a latch or a lock. It states four categories of use according to the frequency and other conditions of use. Compliance with this European Standard ensures a margin of strength in excess of that needed for normal operation. Additional requirements are needed for special safety furniture which is suitable for use in situations where there is a high risk of falling. Since special safety furniture is not essential in every situation, this European Standard provides for additional safety requirements (see 5.13) which are only necessary when the manufacturer states that the safety furniture is claimed to conform to these requirements. This standard states five grades of security. Grade 0 according to requirements stated in the main part of this standard. Grades 1 to 4 are stated according to requirement for security lock furniture for use on burglary resistant doors (see annex A). These additional security requirements are necessary only when the manufacturer states that the products are claimed to have a high level of security, which is not essential in every situation. The suitability of lock or latch furniture for use on fire/smoke door assemblies is determined by fire performance tests conducted in addition to the performance tests required by this standard. Since suitability for use on fire/smoke door assemblies is not essential in every situation, the manufacturer has the option of stating whether the furniture is claimed to conform to these additional requirements or not. If so stated the additional requirements given in annex C are necessary.

This European Standard specifies test methods and requirements for spindle and fastening elements, operating torques, permissible free play and safety, free angular movement and misalignment, durability, static strength and corrosion resistance for sprung and unsprung lever handles and knobs for doors on backplates or roses. This standard is applicable only to lever handles and knobs that operate a latch or a lock. It states four categories of use according to the frequency and other conditions of use. Compliance with this European Standard ensures a margin of strength in excess of that needed for normal operation. Additional requirements are needed for special safety furniture which is suitable for use in situations where there is a high risk of falling. Since special safety furniture is not essential in every situation, this European Standard provides for additional safety requirements (see 5.13) which are only necessary when the manufacturer states that the safety furniture is claimed to conform to these requirements. This standard states five grades of security. Grade 0 according to requirements stated in the main part of this standard. Grades 1 to 4 are stated according to requirement for security lock furniture for use on burglary resistant doors (see annex A). These additional security requirements are necessary only when the manufacturer states that the products are claimed to have a high level of security, which is not essential in every situation. The suitability of lock or latch furniture for use on fire/smoke door assemblies is determined by fire performance tests conducted in addition to the performance tests required by this standard. Since suitability for use on fire/smoke door assemblies is not essential in every situation, the manufacturer has the option of stating whether the furniture is claimed to conform to these additional requirements or not. If so stated the additional requirements given in annex C are necessary.

EN 1906:2002 is classified under the following ICS (International Classification for Standards) categories: 91.190 - Building accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1906:2002 has the following relationships with other standards: It is inter standard links to EN 1906:2010, prEN 1906. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1906:2002 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/101. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1906:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stavbno okovje - Kljuke in

bunke -

Zahteve in preskusne metodeSchlösser und Baubeschläge - Türdrücker und Türknäufe -Anforderungenund PrüfverfahrenQuincaillerie pour le bâtiment - Béquilles et boutons de porte - Prescriptions et méthodes d'essaiBuilding hardware - Lever handles and knob furniture - Requirements and test methods91.190Stavbna opremaBuilding accessoriesICS:Ta slovenski standard je istoveten z:EN 1906:2002SIST EN 1906:2002en01-julij-2002SIST EN 1906:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1906February 2002ICS 91.190English versionBuilding hardware - Lever handles and knob furniture -Requirements and test methodsQuincaillerie pour le bâtiment - Béquilles et boutons deporte - Prescriptions et méthodes d'essaiSchlösser und Baubeschläge - Türdrücker und Türknäufe -Anforderungen und PrüfverfahrenThis European Standard was approved by CEN on 4 November 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1906:2002 E

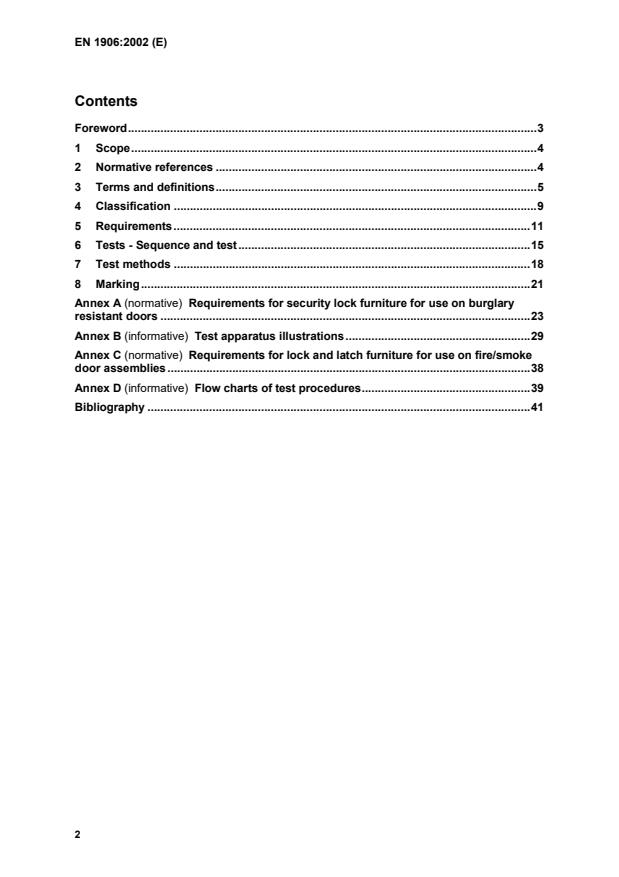

Requirements for security lock furniture for use on burglaryresistant doors.23Annex B (informative)

Test apparatus illustrations.29Annex C (normative)

Requirements for lock and latch furniture for use on fire/smokedoor assemblies.38Annex D (informative)

Flow charts of test procedures.39Bibliography.41

permits adaptation for differentthicknesses of doors, connects the lever handle or knob to the spindle and transmits imposed axialpulling forces to the opposite face of the door3.11floating spindling systemsystem in which the spindle is not attached to either of the lever handles or knobs of a lockset orlatchset but has additional fixing of the lever handles or knobs to the backplates or roses, whichallows the rotation of the follower of the lock or latch to withdraw the latchbolt and permits adaptationfor different thicknesses of doorsNOTEThis system does not transmit imposed axial pulling forces to the opposite face of the door.3.12half setsingle lever or knob attached to a plate or rose which allows operation of the lock or latch from oneside of the door only and usually supplied with a short length spindle fixed to the lever or knob3.13indicatordevice that is visible from the exterior of the door to indicate whether the door is locked or unlocked3.14internal platebackplate or rose that is fitted on the internal face of a door (see Figure 3)3.15latchplatebackplate adapted for use in conjunction with a latch and having no keyhole or cylinder aperture3.16lockplate – cylinderbackplate having a cylinder aperture for use in conjunction with a cylinder lock3.17lockplate – leverbackplate having a keyhole for use with a lever lock3.18plug protection plateplate whose function is to protect the cylinder plug and its components against violent attack3.19roseelement generally circular, but which may have equi-axed or approximately equi-axed shapes such assquare or octagonal, that otherwise has the same features as a backplate (see Figure 2)3.20security furnituredevice which provides added resistance to the lock and/or cylinder against physical attack3.21set of mortice latch furnituretwo door lever handles or knobs with two latchplates or roses and complete with a spindle andfastening elements

Baseplate2

Trim plateFigure 1a — One part backplateFigure 1b — Two part backplateFigure 1 — Illustrations of backplatesKeyKey1

Rose1

External plate4

Emergency release2

Door knob2

Internal plate5

Thumb turn3

Escutcheon3

Lever handleFigure 2 — Set of lock furnitureFigure 3 — Bathroom lockset

offshore installations (oil rigs), barracks, public toilets, etc.4.1.3 Durability (second digit)Two grades of durability are identified : grade 6 : medium frequency of use : 100 000 cycles ; grade 7 : high frequency of use : 200 000 cycles.4.1.4 Door

mass (third digit)No classification.4.1.5 Fire resistance (fourth digit)Two grades of fire resistance are identified : grade 0 : not approved for use on fire/smoke door assemblies ; grade 1 : suitable for use on fire/smoke door assemblies.4.1.6 Safety (fifth digit)Two grades of safety are identified :— grade 0 : normal use ;— grade 1 : safety applications.NOTEStandard furniture requires compliance with 5.1 to 5.12.

Safety furniture requires compliance with5.1 to 5.13.

5 %20 Nm30 Nm40 Nm60 Nm— pre-torque

0,1 N.m1 Nm1 Nm1 Nm1 Nm— permanent deformation at 50 mm

2 mm 5 mm 5 mm 5 mm 5 mmAxial strength35.4 and 7.3.3B.3— Axial strength 50% at 50 mm

1 mm300 N500 N800 N1 000 N— pre-load

1N at 50 mm

1 mm15 N15 N15 N15 N— permanent deformation at 75 mm

2 mm 2 mm 2 mm 2 mm 2 mmFree play "at-rest" and then at 60°

5 ° or maximumof design45.5 and 7.3.4B.8— force

1N at

50 mm

1 mm15 N15 N15 N15 N— total movement at 75 mm

2 mm 10 mm 10 mm 6 mm 6 mmSafety requirementsyesyesyesYesFree angular movement55.6 and 7.3.5B.9— force

1N at 50 mm

1 mm15 N15 N15 N15 N— misalignment measured at 75 mm

2 mm 10 mm 10 mm 5 mm 5 mmTorque of return mechanism— unsprung lever handles 0,6 Nm 0,6 Nm 1,5 Nm 1,5 Nm— unsprung knobs 0,6 Nm 0,6 Nm 0,6 Nm 0,6 Nm— spring-loaded lever handles/knobs 1,5 Nm 1,5 Nm 2,4 Nm 2,4 Nm65.7 and 7.3.6—— spring-assisted lever handles :

a)

to operate lever handle 1,5 Nm 1,5 Nm 2,4 Nm 2,4 Nm

b)

to return lever handle 0,6 Nm 0,6 Nm 1,5 Nm 1,5 NmAngle of rotation— except spring-assisted lever 40° 40° 40° 40°Limit deviations "at-rest" for spring-loaded"

leverhandles/knobs 4° 2° 1° 1°Endurance test— number of cycles 10%100 000100 000200 000200 00075.8 and 7.3.7B.6— force L 50 %60 N60 N100 N100 N— force P 50 %60 N60 N100 N100 N— limit deviations "at-rest" after test (except for spring 4 ° 2 ° 1 ° 1 °

assisted levers)85.9 and 7.3.8B.3Axial strength (repetition of test 3)Same values as for test 395.10 and7.3.9B.8Free play (repetition of test 4)Same values as for test 4 except for specialsafety requirements105.11 and7.3.10B.9Free angular movement (repetition of test 5)Same values as for test 5115.12 and 7.3.11—Torque of return mechanism

(repetition of test 6)Same values as for test 6125.13 and 7.3.12B.3Axial strength 50% at

50 mm

1 mm optional test1 500 N1 500 N2 500 N2 500 Napplicable to special safety furniture only.135.14 and 7.4—Corrosion resistanceTo comply with requirements of EN 1670:1998

shall not exceed 10 mm for category of use grades 1and 2, and 6 mm for category of use grades 3 and 4, for lock or latch furniture.This requirement only applies to lever handles and knobs that will not be driven during the endurance test.5.5.2 Safety requirementsWhen the lock or latch furniture is fitted to the test block there shall be no sharp edges that can cause injury.This requirement shall typically be satisfied by edges that are broken by a chamfer of 0,5 mm maximum x 45° or bya radius of 0,5 mm minimum.In the area of rotation of the lever handle or knob, the head of any visible fastening element shall be level with orbelow the surface of the backplate or rose after fitting, except that raised head screws may stand proud of thefurniture plate by the domed height of the screw head.Any fastening element that secures the lever handle or knob to the spindle shall not project above the surface bymore than 1 mm after fitting.The design of lock or latch furniture shall ensure that after fitting it is not possible for the fingers of a user to betrapped between lever handle or knob and backplate or rose over the full range of rotation of the lever handle orknob.5.6 Free angular movement or misalignmentWhen the furniture is tested in accordance with 7.3.5, the free angular movement or misalignment shall not exceed10 mm for category of use grades 1 and 2, and 5 mm for category of use grades 3 and 4.

This requirement appliesto all furniture with either a fixed or floating spindle.

within ±2° for category of usegrade 2, and within ±1° for category of use grades 3 and 4. This requirement does not apply to spring assistedlever furniture.5.9 Repeat test of axial strength of lock or latch furniture and methods of fixingAfter completion of 7.3.7, the lock or latch furniture shall be repeat tested in accordance with 7.3.8 and shall meetthe requirement of 5.4.5.10 Repeat test of free play measurementAfter completion of 7.3.8, the free play measured on the lever handle or knob not driven during the endurance testshall be repeat tested in accordance with 7.3.9 and shall meet the requirement of 5.5.1.5.11 Repeat test of measurement of free angular movement or misalignmentAfter completion of 7.3.9, the lock or latch furniture shall be repeat tested in accordance with 7.3.10 and shall meetthe requirements of 5.6.

spindle and fastening elements (see 5.2), a half set of lock or latch furniture shall be fitted to atest block as defined in 6.2.1.1 and shall meet the requirements for test 7.3.2.A set of lock or latch furniture, including the half set already submitted to 7.3.2, shall be fitted to a test block asdefined in 6.2.1.2. The half set already tested shall be submitted to tests 7.3.3 to 7.3.12, as appropriate to the typeof furniture, in the sequence specified in Table 1.Corrosion resistance specified in 5.14 and 7.4, shall be carried out on samples that have not been subjected to anyof the preceding tests, in order to verify compliance with the requirements of EN 1670:1998.6.2 Test apparatus6.2.1 Fixing to a test block (see Figures B.1 and B.2)6.2.1.1 After checking that the

spindle and fastening elements meet the requirements of 5.2, a half-set of lockor latch furniture shall be mounted on a test block of laminated wood (bonding type 1F 20, quality 11/11, 19laminates, see DIN 68705) as shown in Figure B.1.The dimensions of the test block shall be 300 mm ± 5 mm

150 mm ± 5 mm

20 mm ± 1 mm finished thickness.Fastening elements supplied or specified by the manufacturer shall be used.NOTEIf fastening elements are unsuitable for the 20 mm block thickness, any other suitable means can be used.The spindle shall be engaged with the lever handle or knob to the minimum recommended by the manufacturer orotherwise to the minimum permitted by the design. It shall pass through a clearance hole in the test block toengage in a fixed reaction plate for a distance of 8 mm 01 mm.

30° ± 3°. When the knob is in the "at-rest" position or at 55° ± 5°, thetorque shall not vary by more than 0,03 Nm from the torque at the 30° position. A counterbalanced bar or othersuitable device may be attached to the knob or levers, if less than 85 mm, to apply the rotary movement and triggerthe return movement.The initial point of contact of the driving peg with the lever handle or counterbalanced bar shall be 50 mm ± 1 mmfrom the axis of rotation of the furniture.A rigid steel stop of 10 mm diameter attached to the frame of the test apparatus and positioned 80 mm ± 1 mmfrom the axis of rotation of the furniture shall be provided to arrest unsprung levers or knobs at the "at-rest" position± 1°.The "at-rest" position is when the spindle hole in the lever or knob is square to the horizontal/vertical. This positionmay be set by reference to the "cord" hole in the pulley

(see Figure B.4).6.2.3.3 Application of test loadsA force ‘P’ shall be applied to one of the lever handles or knobs by a cord which passes over a pulley whose axis is500 mm ± 10 mm from the face of the test block, the cord carrying a suitable load. The position of the pulley shallbe such that when the lever handle or knob is in its "at-rest" position, the cord is perpendicular ± 2° to the plane ofthe test block (see Figure B.6).For lever handles, the force shall be applied

without shock and in a controlled manner, at a point 50 mm ± 1 mmfrom the axis of rotation of the spindle.For knobs, the force shall be applied without shock and in a controlled manner coaxially with the axis of rotation ± 1mm.A downward force L shall be applied to the pulley as indicated in Figure B.6.A suitable bottom pulley is shown in Figure B.7.Means of repeating the required test cycle for the specified numbers of operations, as required in 7.3.7, shall beprovided.

the procedures for each of these tests are shown in annex D.It is important to check requirements before performance tests are commenced.7.2 Acceptance conditions7.2.1If each test set complies with the appropriate requirements of clause 5, the whole stock from which thesamples were taken shall be deemed to comply with this European Standard.7.2.2If any one set fails to comply with all the appropriate requirements of clause 5, a second test sample ofthree sets shall be taken at random from the same stock, and shall be tested in accordance with clauses 6 and 7.7.2.3If more than one set of lock or latch furniture fails to comply with the appropriate requirements of clause 5,the stock shall be deemed not to comply with this European Standard and no further testing shall be allowed.7.3 Performance tests7.3.1 Check of spindle and fastening elements (Test 1)Before fitting the set of lock or latch furniture to a test block it shall be verified that the spindle and fasteningelements supplied comply with requirements of 5.2 and 6.1.7.3.2 Rotational strength

(Test 2)The requirements of 5.3 shall be satisfied.The sample half set of lock or latch furniture shall be mounted on the test block specified in 6.2.1.1 and shown inFigure B.1.A dial gauge shall be mounted in contact with the lever handle or knob bar, at a point 50 mm ± 2 mm from the axisof rotation of the spindle. A pre-torque of 1 Nm ± 0,1 Nm shall be applied without shock in a plane parallel to theblock surface ± 2° and the reading of the dial gauge shall be recorded.A torque in accordance with Table 1 shall be applied without shock, in a plane parallel to the block surface ± 2°.The torque shall be maintained for 60 s 010s and then removed without shock.After removal of the torque except for the pre-torque, the reading of the dial gauge shall be recorded.

set of

lock or latch furniture shall be mounted on the test block as required by 6.2.1.2 and shown inFigure B.3The sample shall be subjected to a pre-load of 15 N ± 1 N, followed by a test force applied without shock in adirection away from the test block surface and perpendicular to it ± 2°. The forces shall be applied at a distance of50 mm ± 1 mm from the axis of rotation.Apply the pre-load, measure and record the distance from the face of the test block to the underside of the leverhandle or knob bar, at a reference point 75 mm ± 2 mm from the axis of rotation.Apply the test force in accordance with Table 1 and maintain the test force for 60 s 010s and then slowly reduce itback to the pre-load value of 15 N ± 1 N. Re-measure and record the distance from the face of the test block to thereference point on the lever handle or knob bar.7.3.4 Free play and safety (Test 4)The requirements of 5.5.1 and 5.5.2 shall be satisfied.With the lever handle or knob in its "at-rest" position, apply a force of 15 N ±1 N to the lever handle or knob bar at apoint 50 mm ± 1 mm from the axis of rotation, alternately towards and away from the test block, in a directionperpendicular to the face of the test block ± 5°, as shown in Figure B.8.Measure and record the maximum total movement between the extreme positions of a reference point 75 mm ± 2mm from the axis of rotation, while the forces are applied.Repeat and record the measurements with the lever handle or knob rotated to a position 60° ± 5° from the "at-rest"position as shown in Figure B.8, or at the maximum angle of rotation permitted by the design.7.3.5 Free angular movement or misalignment (Test 5)The requirements of 5.6 shall be satisfied.With one lever handle or knob held against rotation, the other lever handle or knob shall be rotated by applying aforce of 15 ± 1 N at a point 50 mm ± 1 mm from the axis of rotation in a parallel plane ± 2° to the face of the testblock as indicated in Figure B.9.The displacement of the lever handle or knob bar at a point 75 mm ± 2 mm from the axis of rotation shall bemeasured and recorded, for comparison with the position of the corresponding point on the fixed lever handle orbar.7.3.6 Torque of return mechanism (Test 6)7.3.6.1 Unsprung lever handles and spring-assisted lever handlesThe requirements of 5.7.2 shall be satisfied.Verify that the lever handle rotates through the required minimum operating angle of 60° for unsprung leverhandles or 40° for spring-assisted lever handles.A torque shall be applied to return the lever handle to its "at-rest" position, at 5° and 10° intervals, up to 60° or 40°as appropriate.

Measure and record the value of the torqueFor spring assisted lever handles only, a torque shall be applied to rotate the lever handle to a minimum of 40°from its "at-rest" position.

Measure and record the value of the torque.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...