EN 16436-1:2014+A3:2020

(Main + Amendment)Rubber and plastics hoses, tubing and assemblies for use with propane and butane and their mixtures in the vapour phase - Part 1: Hoses and tubings

Rubber and plastics hoses, tubing and assemblies for use with propane and butane and their mixtures in the vapour phase - Part 1: Hoses and tubings

This European Standard specifies the characteristics and performance requirements for tubing and hoses made of either rubber or plastics for use with commercial propane and commercial butane and mixtures thereof, in the vapour phase, for connection of appliances, from:

- pressurized gas container to a regulating device,

- pressurized gas container to an appliance,

- regulating device to an appliance, and

- regulating device to installation pipework,

in environments of a temperature range from -30 °C to +70 °C. Working pressures are from 0 bar to 30 bar.

Three classes are defined in Table 1 according to the maximum working pressures and minimum ambient temperatures.

This European Standard only covers the tubing or hose part of assemblies. The assemblies themselves will be covered by EN 16436-2.

This European Standard does not apply to hoses for:

- welding purposes (see EN ISO 3821, EN 1327);

- propulsion purposes;

- LPG transfer purposes (see EN 1762).

Gummi- und Kunststoff-Schläuche und -Schlauchleitungen mit und ohne Einlage zur Verwendung mit Propan, Butan und deren Gemischen in der Gasphase - Teil 1: Schläuche mit und ohne Einlage

Diese Europäische Norm legt die Merkmale von und Leistungsanforderungen an Gummi- oder Kunststoff-schläuche, mit und ohne Einlage, zum Einsatz mit handelsüblichem Propan und handelsüblichem Butan und deren Gemischen in der Gasphase fest, für die Verbindung von Geräten zwischen

einem mit Druck beaufschlagten Gasbehälter und einem Druckregelgerät,

einem mit Druck beaufschlagten Gasbehälter und einem Gerät,

einem Druckregelgerät und einem Gerät und

einem Druckregelgerät und einer Leitungsanlage

in einem Umgebungstemperaturbereich von −30 °C bis +70 °C. Die Betriebsdrücke liegen zwischen 0 bar und 30 bar.

In Tabelle 1 werden drei Klassen in Abhängigkeit vom höchsten Betriebsdruck und der niedrigsten Umgebungstemperatur festgelegt.

Diese Europäische Norm behandelt nur den Schlauchteil, mit oder ohne Einlage, von Schlauchleitungen. Die Schlauchleitungen werden in EN 16436 2 geregelt.

Diese Europäische Norm gilt nicht für Schläuche für:

Schweißanwendungen (siehe EN ISO 3821, EN 1327);

Antriebszwecke;

Flüssiggasfüll-und umfüllverfahren (siehe EN 1762).

Tuyaux, tubes et flexibles en caoutchouc et en plastique pour utilisation avec le propane, le butane et leurs mélanges en phase vapeur - Partie 1: Tuyaux et tubes

No scope available.

Gumeni in plastični priključki, cevovodi in cevi za propan, butan in njune zmesi v plinastem stanju - 1. del: Cevi in cevovodi (vključno z dopolnili do A3)

General Information

- Status

- Published

- Publication Date

- 19-May-2020

- Withdrawal Date

- 29-Nov-2020

- Technical Committee

- CEN/TC 181 - Dedicated liquified petroleum gas appliances

- Drafting Committee

- CEN/TC 181/WG 3 - Small non-domestic space heaters

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 12-Oct-2022

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 09-Feb-2026

- Refers

ISO 188:2011 - Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests - Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16436-1:2014+A3:2020 is a CEN European Standard that specifies the characteristics and performance requirements for rubber and plastics hoses and tubing used with commercial propane, commercial butane and their mixtures in the vapour phase. It covers hose/tubing used to connect appliances and pressure-regulating equipment (for example: pressurized gas container → regulator, regulator → appliance, and regulator → installation pipework) in ambient temperatures from −30 °C to +70 °C and working pressures up to 30 bar. The standard applies only to the hose or tubing part of assemblies (hose assemblies are addressed in EN 16436-2).

Key Topics and Requirements

- Scope and classification

- Defines three product classes according to maximum working pressure (examples: Class 2 up to 10 bar, Class 3 up to 30 bar) and minimum ambient temperature requirements.

- Materials & construction

- Tubing (single core) and hoses (lining, textile reinforcement - braided or spirally wound - and outer cover) in rubber or thermoplastic.

- Surface colour/marking options (orange; or black/white with a continuous orange line) for traceability and safety.

- Dimensions & tolerances

- Prescribes inside diameters, wall thicknesses and concentricity limits to ensure compatibility with fittings and consistent flow characteristics.

- Mechanical & chemical performance

- Tensile strength and elongation requirements (table includes minimums - e.g., Class 1 tubing shows 7.0 MPa and 250% elongation).

- Accelerated ageing, resistance to n‑pentane, ozone, UV exposure and permeability to propane.

- Pressure, integrity & durability tests

- Hydrostatic proof and burst tests, kinking/crushing resistance, low-temperature flexibility and adhesion between layers.

- Marking & cleanliness

- Identification, durability of marking and internal cleanliness (free from loose particles) are mandatory.

Applications and Users

- Who uses EN 16436-1

- Hose and tubing manufacturers for LPG applications, product designers, quality/test laboratories, certification bodies, equipment OEMs and procurement/specification engineers.

- Typical applications

- Flexible connections between LPG cylinders, pressure regulators and appliances (cookers, heaters, BBQs) where gas is in the vapour phase.

- Installation components where temperature and pressure ranges fall within the standard’s limits.

- Benefits

- Ensures safety, interchangeability and regulatory compliance for LPG hose products used in domestic and commercial appliances.

Related Standards

- EN 16436-2 (hose assemblies)

- EN ISO 1402 (hydrostatic testing)

- EN ISO 4080 (gas permeability)

- EN ISO 8033 (adhesion tests)

- ISO 188 (accelerated ageing)

- EN 1762 / EN ISO 3821 - referenced for excluded applications (LPG transfer, welding hoses)

Keywords: EN 16436-1, LPG hoses, propane and butane vapour, rubber and plastics tubing, hose classification, working pressure, hose testing, CEN standard.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 16436-1:2014+A3:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Rubber and plastics hoses, tubing and assemblies for use with propane and butane and their mixtures in the vapour phase - Part 1: Hoses and tubings". This standard covers: This European Standard specifies the characteristics and performance requirements for tubing and hoses made of either rubber or plastics for use with commercial propane and commercial butane and mixtures thereof, in the vapour phase, for connection of appliances, from: - pressurized gas container to a regulating device, - pressurized gas container to an appliance, - regulating device to an appliance, and - regulating device to installation pipework, in environments of a temperature range from -30 °C to +70 °C. Working pressures are from 0 bar to 30 bar. Three classes are defined in Table 1 according to the maximum working pressures and minimum ambient temperatures. This European Standard only covers the tubing or hose part of assemblies. The assemblies themselves will be covered by EN 16436-2. This European Standard does not apply to hoses for: - welding purposes (see EN ISO 3821, EN 1327); - propulsion purposes; - LPG transfer purposes (see EN 1762).

This European Standard specifies the characteristics and performance requirements for tubing and hoses made of either rubber or plastics for use with commercial propane and commercial butane and mixtures thereof, in the vapour phase, for connection of appliances, from: - pressurized gas container to a regulating device, - pressurized gas container to an appliance, - regulating device to an appliance, and - regulating device to installation pipework, in environments of a temperature range from -30 °C to +70 °C. Working pressures are from 0 bar to 30 bar. Three classes are defined in Table 1 according to the maximum working pressures and minimum ambient temperatures. This European Standard only covers the tubing or hose part of assemblies. The assemblies themselves will be covered by EN 16436-2. This European Standard does not apply to hoses for: - welding purposes (see EN ISO 3821, EN 1327); - propulsion purposes; - LPG transfer purposes (see EN 1762).

EN 16436-1:2014+A3:2020 is classified under the following ICS (International Classification for Standards) categories: 23.040.70 - Hoses and hose assemblies. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16436-1:2014+A3:2020 has the following relationships with other standards: It is inter standard links to EN 16436-1:2014+A2:2018, EN 16436-1:2014+A2:2018/prA3, ISO 37:2017, ISO 188:2011, EN ISO 8033:2017, EN ISO 7326:2016, EN ISO 4080:2024, EN ISO 176:2005, EN ISO 30013:2011, EN ISO 4671:2022, EN ISO 10619-2:2021, EN 772-19:2000, EN ISO 1402:2021, EN ISO 8330:2008, EN 16905-2:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16436-1:2014+A3:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2020

Nadomešča:

SIST EN 16436-1:2014+A2:2019

Gumeni in plastični priključki, cevovodi in cevi za propan, butan in njune zmesi v

plinastem stanju - 1. del: Cevi in cevovodi (vključno z dopolnili do A3)

Rubber and plastics hoses, tubing and assemblies for use with propane and butane and

their mixtures in the vapour phase - Part 1: Hoses and tubings

Gummi- und Kunststoff-Schläuche und -Schlauchleitungen mit und ohne Einlage zur

Verwendung mit Propan, Butan und deren Gemischen in der Gasphase - Teil 1:

Schläuche mit und ohne Einlage

Tuyaux, tubes et flexibles en caoutchouc et en plastique pour utilisation avec le propane,

le butane et leurs mélanges en phase vapeur - Partie 1: Tuyaux et tubes

Ta slovenski standard je istoveten z: EN 16436-1:2014+A3:2020

ICS:

83.140.40 Gumene cevi Hoses

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16436-1:2014+A3

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2020

EUROPÄISCHE NORM

ICS 23.040.70 Supersedes EN 16436-1:2014+A2:2018

English Version

Rubber and plastics hoses, tubing and assemblies for use

with propane and butane and their mixtures in the vapour

phase - Part 1: Hoses and tubings

Tuyaux, tubes et flexibles en caoutchouc et en plastique Gummi- und Kunststoff-Schläuche und -

pour utilisation avec le propane, le butane et leurs Schlauchleitungen mit und ohne Einlage zur

mélanges en phase vapeur - Partie 1: Tuyaux et tubes Verwendung mit Propan, Butan und deren Gemischen

in der Gasphase - Teil 1: Schläuche mit und ohne

Einlage

This European Standard was approved by CEN on 12 July 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16436-1:2014+A3:2020 E

worldwide for CEN national Members.

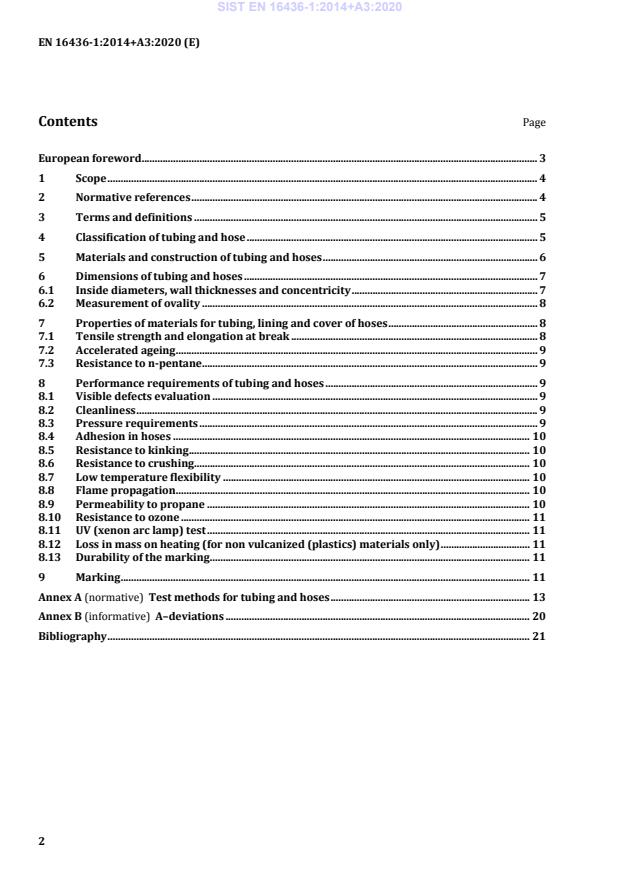

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 5

4 Classification of tubing and hose . 5

5 Materials and construction of tubing and hoses . 6

6 Dimensions of tubing and hoses . 7

6.1 Inside diameters, wall thicknesses and concentricity . 7

6.2 Measurement of ovality . 8

7 Properties of materials for tubing, lining and cover of hoses . 8

7.1 Tensile strength and elongation at break . 8

7.2 Accelerated ageing . 9

7.3 Resistance to n-pentane . 9

8 Performance requirements of tubing and hoses . 9

8.1 Visible defects evaluation . 9

8.2 Cleanliness . 9

8.3 Pressure requirements . 9

8.4 Adhesion in hoses . 10

8.5 Resistance to kinking . 10

8.6 Resistance to crushing . 10

8.7 Low temperature flexibility . 10

8.8 Flame propagation . 10

8.9 Permeability to propane . 10

8.10 Resistance to ozone . 11

8.11 UV (xenon arc lamp) test . 11

8.12 Loss in mass on heating (for non vulcanized (plastics) materials only) . 11

8.13 Durability of the marking . 11

9 Marking . 11

Annex A (normative) Test methods for tubing and hoses . 13

Annex B (informative) A–deviations . 20

Bibliography . 21

European foreword

This document (EN 16436-1:2014+A3:2020) has been prepared by Technical Committee CEN/TC 181

“Dedicated liquefied petroleum gas appliances”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2020, and conflicting national standards

shall be withdrawn at the latest by November 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1, approved by CEN on 2015-10-01, Amendment 2, approved by

CEN on 2018-05-13, and Amendment 3, approved by CEN on 2019-07-12.

This document supersedes %EN 16436-1:2014+A2:2018&.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !",

#$ and %&.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This European Standard specifies the characteristics and performance requirements for tubing and

hoses made of either rubber or plastics for use with commercial propane and commercial butane and

mixtures thereof, in the vapour phase, for connection of appliances, from:

— pressurized gas container to a regulating device,

— pressurized gas container to an appliance,

— regulating device to an appliance, and

— regulating device to installation pipework,

in environments of a temperature range from –30 °C to +70 °C. Working pressures are from 0 bar to 30

bar.

Three classes are defined in Table 1 according to the maximum working pressures and minimum

ambient temperatures.

This European Standard only covers the tubing or hose part of assemblies. The assemblies themselves

will be covered by EN 16436-2.

This European Standard does not apply to hoses for:

— welding purposes (see EN ISO 3821, EN 1327);

— propulsion purposes;

— LPG transfer purposes (see EN 1762).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 176, Plastics - Determination of loss of plasticizers - Activated carbon method (ISO 176:2005)

EN ISO 1402, Rubber and plastics hoses and hose assemblies - Hydrostatic testing (ISO 1402:2009)

EN ISO 4080, Rubber and plastics hoses and hose assemblies - Determination of permeability to gas (ISO

4080:2009)

EN ISO 4671, Rubber and plastics hoses and hose assemblies - Methods of measurement of the dimensions

of hoses and the lengths of hose assemblies (ISO 4671:2007)

EN ISO 7326, Rubber and plastics hoses - Assessment of ozone resistance under static conditions (ISO

7326:2016)

EN ISO 8033, Rubber and plastics hoses - Determination of adhesion between components (ISO

8033:2016)

EN ISO 8330:2008, Rubber and plastics hoses and hose assemblies — Vocabulary (ISO 8330:2007)

EN ISO 10619-2, Rubber and plastics hoses and tubing - Measurement of flexibility and stiffness - Part 2:

Bending tests at sub-ambient temperatures (ISO 10619-2:2017)

EN ISO 30013, Rubber and plastics hoses - Methods of exposure to laboratory light sources -

Determination of changes in colour, appearance and other physical properties (ISO 30013:2011)

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 105-A02, Textiles — Tests for colour fastness — Part A02: Grey scale for assessing change in colour

ISO 188, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 8330:2008 and the

following apply.

3.1

commercial butane

hydrocarbon product composed predominantly of butanes and/or butenes

Note 1 to entry: The remaining part can consist mainly of propane/propene and pentane/pentene isomers.

[SOURCE: ISO 9162]

3.2

commercial propane

hydrocarbon product composed predominantly of propane and/or propene

Note 1 to entry: The remaining part can consist mainly of ethane/ethene and butane/butene isomers.

[SOURCE: ISO 9162]

3.3

tubing

single core of plastic or rubber with no reinforcement or cover

3.4

hose

rubber or flexible thermoplastic lining with a reinforcement made of natural or synthetic textile

material applied either spirally wound or braided, and a flexible rubber or thermoplastic outer cover

4 Classification of tubing and hose

One class of tubing and two classes of hose are specified in Table 1 depending on the maximum working

pressure and minimal ambient temperatures.

Table 1 — Classification of tubings and hoses

Maximum working pressure Minimum ambient temperature

Class

bar °C

a

1 (tubing) 0,2 -20

2 (hose) 10 -30

3 (hose) 30

NOTE Classes 1 and 2 are usually used downstream of a pressure regulating device.

5 Materials and construction of tubing and hoses

Class 1 tubing shall be made of rubber or thermoplastic material.

Class 2 and class 3 hoses shall comprise a

— rubber or thermoplastics lining;

— reinforcement of natural or synthetic fibres applied either spirally wound or braided;

— rubber or plastics cover. The outer cover may be pricked to allow any gas trapped between the

inner lining and outer cover to be released.

The surface colour of the tubing or hose shall be:

- orange (see Figure 1a); or

- black with the marking above, on, or below a continuous orange line of 5 mm minimum width (see

Figure 1b); or

- white for classes 1 and 2 with the marking above, on, or below a continuous orange line of 5 mm

minimum width (see Figure 2).

a) option 1

b) option 2

Key

orange colour

black colour

Figure 1 — Possible marking for classes 1, 2 or 3

Key

orange colour

white colour

Figure 2 — Possible marking for classes 1 or 2

6 Dimensions of tubing and hoses

6.1 Inside diameters, wall thicknesses and concentricity

When measured in accordance with EN ISO 4671 the inside diameters, tolerances and concentricity

shall conform to the values given in Table 2.

Table 2 — Dimensions of hoses or tubing

Dimensions in millimetres

Inside diameters 3,2 4,0 5,0 6,3 8,0 9,0 10,0 10,5 12,5 %14,0

Tolerance of inside ± 0,3 ± 0,4 ± 0,4 ± 0,5 ± 0,5 ± 0,5 ± 0,6 ± 0,6 ± 0,6 ± 1,0

diameter

Maximum variation in 0,3 0,4 0,4 0,4 0,5 0,5 0,5 0,5 0,5 0,6

concentricity

Wall thickness class 1 2,5 3,5 3,5 3,5 3,5 3,5 5,0 5,0 5,0 5,0

and class 2

Wall thickness class 3 3,5 4,0 4,0 5,0 5,0 5,0 5,0 5,0 6,0 6,0

Tolerance of wall ± 0,4 ± 0,4 ± 0,4 ± 0,4 ± 0,5 ± 0,5 ± 0,5 ± 0,5 ± 0,5 ± 0,5&

thickness

6.2 Measurement of ovality

When measuring on a hose cross section, the minimum diameter D and the maximum diameter D ,

min max

the ratio D /D shall not be less than 0,80.

min max

7 Properties of materials for tubing, lining and cover of hoses

7.1 Tensile strength and elongation at break

When tested in accordance with A.2, the materials used for tubing, lining and cover of hoses shall

conform to the values given in Table 3.

Table 3 — Requirements for tensile strength and elongation at break

Class Component Tensile strength Elongation at break

min. min.

MPa %

1 Tubing 7,0 250

2, 3 Lining and cover

7.2 Accelerated ageing

After ageing in accordance with ISO 188, using a normal air oven and conditions given in Table 4,

materials used for tubing, for the lining and cover of hoses shall conform to the values given in Table 4.

Table 4 — Requirements for accelerated ageing

Test duration Test temperature Minimum residual Deviation from

Class

value from origin original values

days °C

max

Tensile strength Elongation at

break

1, 14 90 ± 2 75 % ± 50 %

2, 3 28

7.3 Resistance to n-pentane

When tested in accordance with A.3, samples of the lining of hoses or tubing shall have absorption of

n-pentane (α) not exceeding 10 % and an extraction of material by n-penta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...