ASTM F2990-12(2018)

(Test Method)Standard Test Method for Commercial Coffee Brewers

Standard Test Method for Commercial Coffee Brewers

SIGNIFICANCE AND USE

5.1 The measured maximum energy input rate is used to confirm that the coffee brewer is operating in accordance with its nameplate rating.

5.2 If applicable and accessible, the boiler or internal tank temperature is measured to ensure that the water is maintained at a ready-to-brew temperature. This can also be used later to normalize coffee brewer energy consumption to a standard temperature.

5.3 The Preheat Test can be used to gauge the amount of time and energy required for the coffee brewer to reach a ready-to-brew state from the ambient room and incoming water temperatures.

5.4 Ready-to-Brew and Energy Save Mode energy can be used by end users to estimate the amount of energy consumed while coffee is not being brewed.

5.5 Heavy-use energy consumption can be used to estimate how much energy is consumed by the coffee brewer when brewing coffee. Along with preheat and ready-to-brew (standby) energy, this value can be used by end users to model their machine energy use.

5.6 Production capacity is a calculated measure, determined through testing, to define the performance of the coffee brewer. End users can use this value to specify a brewer that matches their production needs.

SCOPE

1.1 This test method covers the evaluation of the energy consumption, brewing, and holding performance of commercial coffee brewing machines (here after referred to as coffee brewers) used in commercial and institutional facilities. The operator can use this evaluation to select a coffee brewer and characterize its energy use and performance. This test method does not cover residential coffee brewers, “urn” coffee brewers (Type III), or espresso machines.

1.2 This test method applies to single cup (Type I) and batch (Type II) coffee brewers. The coffee brewer will be tested for the following (where applicable):

1.2.1 Maximum energy input rate,

1.2.2 Heavy use brewing energy consumption,

1.2.3 Production capacity,

1.2.4 “Ready-to-Brew” (Standby/Idle) energy rate, and

1.2.5 “Energy Save Mode” (Low power) energy rate.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2990 − 12 (Reapproved 2018) An American National Standard

Standard Test Method for

Commercial Coffee Brewers

This standard is issued under the fixed designation F2990; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the evaluation of the energy 2.1 ASTM Standards:

consumption, brewing, and holding performance of commer- F2988Specification for Commercial Coffee Brewers

cial coffee brewing machines (here after referred to as coffee

2.2 ASHRAE Standard:

brewers) used in commercial and institutional facilities. The

ASHRAE Guideline 2–1986 (RA90)Engineering Analysis

operator can use this evaluation to select a coffee brewer and

of Experimental Data

characterize its energy use and performance. This test method

doesnotcoverresidentialcoffeebrewers,“urn”coffeebrewers

3. Terminology

(Type III), or espresso machines.

3.1 Definitions:

1.2 Thistestmethodappliestosinglecup(TypeI)andbatch

3.1.1 coffee brewer, n—commercial appliances designed to

(Type II) coffee brewers. The coffee brewer will be tested for

heat water and brew coffee.

the following (where applicable):

NOTE 1—Cold water is poured into a separate chamber (manually or

1.2.1 Maximum energy input rate,

automatically),whichisthenheateduptojustbelowtheboilingpoint,and

1.2.2 Heavy use brewing energy consumption,

directedthroughthefilter.Thisprocessisalsocalled automatic drip-brew.

1.2.3 Production capacity,

3.2 Definitions of Terms Specific to This Standard:

1.2.4 “Ready-to-Brew” (Standby/Idle) energy rate, and

3.2.1 brew cycle, n—the total time required to dispense a

1.2.5 “Energy Save Mode” (Low power) energy rate.

single cup (Type I) or batch (Type II) of coffee, starting with

1.3 The values stated in inch-pound units are to be regarded

the initiation of a brew event by the user, and including the

as standard. The values given in parentheses are mathematical time needed for the machine to recover to a “ready to brew”

conversions to SI units that are provided for information only

state.

and are not considered standard.

3.2.2 brew event, n—the sequence of brewing a single cup

1.4 This standard does not purport to address all of the

(Type I) or batch (Type II) of coffee, starting with initiation by

safety concerns, if any, associated with its use. It is the

theuser,andincludingthetimefortheremainingwatertodrip

responsibility of the user of this standard to establish appro-

through the filter.

priate safety, health, and environmental practices and deter-

3.2.3 brew energy, n—energy consumed by coffee brewer

mine the applicability of regulatory limitations prior to use.

during a brew cycle.

1.5 This international standard was developed in accor-

3.2.4 warmer energy, n—the energy consumed by the plate

dance with internationally recognized principles on standard-

warmer while maintaining the delivered brew volume at

ization established in the Decision on Principles for the

serving temperature.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

NOTE 2—Warmers may not be an applicable feature of single serving

Type I machines.

Barriers to Trade (TBT) Committee.

3.2.5 ready-to-brew (standby/idle) energy, n—energy re-

quired by the coffee brewer to maintain “ready to brew”

This test method is under the jurisdiction of ASTM Committee F26 on Food

Service Equipment and is the direct responsibility of Subcommittee F26.06 on

Productivity and Energy Protocol. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2018. Published November 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2012. Last previous edition approved in 2012 as F2990–12. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2990-12R18. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2990 − 12 (2018)

conditionsincludingenergyrequiredtokeepthereservoirtank at a ready-to-brew temperature. This can also be used later to

at the brew set temperature. normalize coffee brewer energy consumption to a standard

temperature.

3.2.6 energy save mode, n—an optional low power mode

(different from the ready-to-brew state) that is designed by the

5.3 The Preheat Test can be used to gauge the amount of

manufacturer to use less energy while the coffee brewer still

time and energy required for the coffee brewer to reach a

remains “on.”

ready-to-brewstatefromtheambientroomandincomingwater

temperatures.

NOTE 3—Energy Save Modes are typically specified by the manufac-

turer and outlined in the user manual. Some examples may include an

5.4 Ready-to-Brew and Energy Save Mode energy can be

automatic reduction of tank holding temperature (for example, 140°) or

used by end users to estimate the amount of energy consumed

burner temperature after a certain period of machine un-use. The manual

while coffee is not being brewed.

turning off of accessories is not considered to be an Energy Save Mode

unless specified by the manufacturer.

5.5 Heavy-use energy consumption can be used to estimate

3.2.7 production capacity, n—calculated maximum volume

how much energy is consumed by the coffee brewer when

of coffee that can potentially be brewed in one full hour and

brewing coffee. Along with preheat and ready-to-brew

expressed in gal/h (L/h).

(standby) energy, this value can be used by end users to model

their machine energy use.

3.2.8 brew volume, n—the substantive beverage portion

delivered during a single brew event, and specified in fluid

5.6 Productioncapacityisacalculatedmeasure,determined

ounces or gallons (millilitres or litres).

throughtesting,todefinetheperformanceofthecoffeebrewer.

End users can use this value to specify a brewer that matches

3.2.9 serving temperature, n—the temperature of the bever-

age delivered from a brewing machine, measured at the their production needs.

dispensing outlet, and expressed in degrees Farenheit (degrees

Celsius). 6. Apparatus

3.2.10 holding temperature, n—the measured average inter-

6.1 Watt-Hour Meter, for measuring the electrical energy

nal temperature of a volume of dispensed beverage as main-

consumption coffee brewer, shall have a resolution of at least

tainedbytheplatewarmersandexpressedindegreesFarenheit

0.1 Wh and a maximum uncertainty no greater than 1.5 % of

(degrees Celsius).

the measured value for any demand greater than 100 W. For

any demand less than 100 W, the meter shall have a resolution

3.2.11 recovery time, n—the time required for the machine

of at least 0.1 Wh and a maximum uncertainty no greater than

to return to brew set temperature (“ready to brew state”) after

1.5 %.

a completed brew event.

6.2 Analytical Balance Scale, for measuring weights up to

4. Summary of Test Method

15 lb (6.8 kg), with a resolution of 0.001 lb (0.5 g) and an

4.1 Alltestingisconductedusingdefaultfactorysettingsfor uncertainty of 0.001 lb (0.5 g).

brewers that feature programmable settings. If not specified by

6.3 Data Acquisition System, for receiving and saving data

the manufacturer, all plate warmers and accessories featuring

for energy and temperatures with an additional capability of

adjustable input rates shall be conducted with all accessories

displaying multiple temperature updating at least every two

and brewers at 100 % input ratings.

seconds.

4.2 The coffee brewer is connected to the appropriate

6.4 Stop Watch, with a 1-s resolution.

electricalandwatermeteringdevices.Ifapplicable,theinternal

6.5 Flow Meter, for measuring total water consumption of

water tank is evacuated prior to testing. The measured maxi-

the appliance. Shall have a resolution of 0.01 gal (0.04 L) and

mum energy input is determined and checked against the rated

an uncertainty of 0.01 gal (0.04 L) at a flow rate as low as 0.2

input before continuing with testing. Total volume of water

gpm (0.8 Lpm).

used to fill the tank will also be recorded.

6.6 Thermocouple Probe(s), industry standard type T or

4.3 The internal water tank temperature and energy con-

type K thermocouples capable of immersion, with a range of

sumption is monitored in the, preheating mode, ready-to-brew

from 50 to 400°F (10 to 204°C) and an uncertainty of 61°F

(idle) mode, energy save mode, and accessories (plate warm-

(60.5°C).

ers) on and off.

6.7 Carafe/Decanter(s),asuitablecontainer/receptacleshall

4.4 Energy consumption and time are monitored while the

be used to hold the brewed coffee volume for batch brewers

coffee brewer is used to brew coffee sequentially to replicate a

(Type II). The volume of the container shall be rated in fluid

heavy use period.

ounces (mL) or gallons (L) depending on volumetric capacity.

5. Significance and Use

6.8 Cup(s), appropriate size to accommodate the standard

5.1 The measured maximum energy input rate is used to brew volume of the single cup (Type I) coffee brewer being

tested. The volume of the container shall be rated in fluid

confirm that the coffee brewer is operating in accordance with

its nameplate rating. ounces (mL).

5.2 If applicable and accessible, the boiler or internal tank 6.9 When specified by manufacturer, installation of a water

temperature is measured to ensure that the water is maintained treatment device is required in hard-water areas for the

F2990 − 12 (2018)

incoming water supply. A tempering or pressure regulating voltage is within 61.0 % of the operating voltage specified by

device may also be needed to supply the manufacturer- the manufacturer while the elements are energized. Record the

specified incoming water temperature and pressure to the test voltage for each test.

NOTE 4—It is the intent of the testing procedure herein to evaluate the

coffee brewer.

performance of a coffee brewer at its rated electric voltage. If an electric

unit is rated dual voltage (that is, designed to operate at either 208 or 240

7. Reagents and Materials

V with no change in components), the voltage selected by the manufac-

7.1 Water Specs—Incoming water to the coffee brewer shall turer and/or tester shall be reported. If a coffee brewer is designed to

operate at two voltages without a change in the resistance of the heating

have a maximum hardness of three grains per gallon and shall

elements, the performance of the unit (for example, preheat time) may

be within 70 6 5°F (21 6 3°C). If the tester’s water supply

differ at the two voltages.

does not meet the specification, a water softener and/or

9.3 Connect the cold water supply to a calibrated low-flow

tempering kit may be required.

water meter for automatic-fill drip brewers (does not apply to

7.2 Coffee Grounds—Genericcoffeegroundwithaspecified

pour-over brewers).

serving size of 0.125 lb 6 0.005 lb for every 64 oz (0.057 6

9.4 Install a thermocouple in the supply waterline of the

0.002 kg for every 1.89 L) of hot water shall be used for batch

coffee machine to ensure incoming water temperature main-

(TypeII)brewers.Ifthecoffeebrewerdispensessingleserving

tains an average of 70 6 5°F (21 6 3°C).

portions (Type I) using prefabricated modules, the weight of

thespentcoffeemodulewillberecordedandusedforanalysis. 9.5 Positionandsecureabeadedthermocoupletothecenter

ofeachwarmingplate(ifapplicable).Securethethermocouple

7.3 Portafilter Basket—For single cup (Type I)coffee

using High Temperature Fiberglass/Silicone Tape, 500°F/

brewers, a 58-mm “Double” espresso portafilter basket is used

260°C.

to record the temperature of the beverage as it exits the

NOTE 5—Recommending the use of 24 gauge wire and hammer the

dispensing head of the machine.

beaded end flat to facilitate better contact with the surface.

7.4 CoffeeFilter(s)—Forbatch(TypeII)coffeebrewers,use

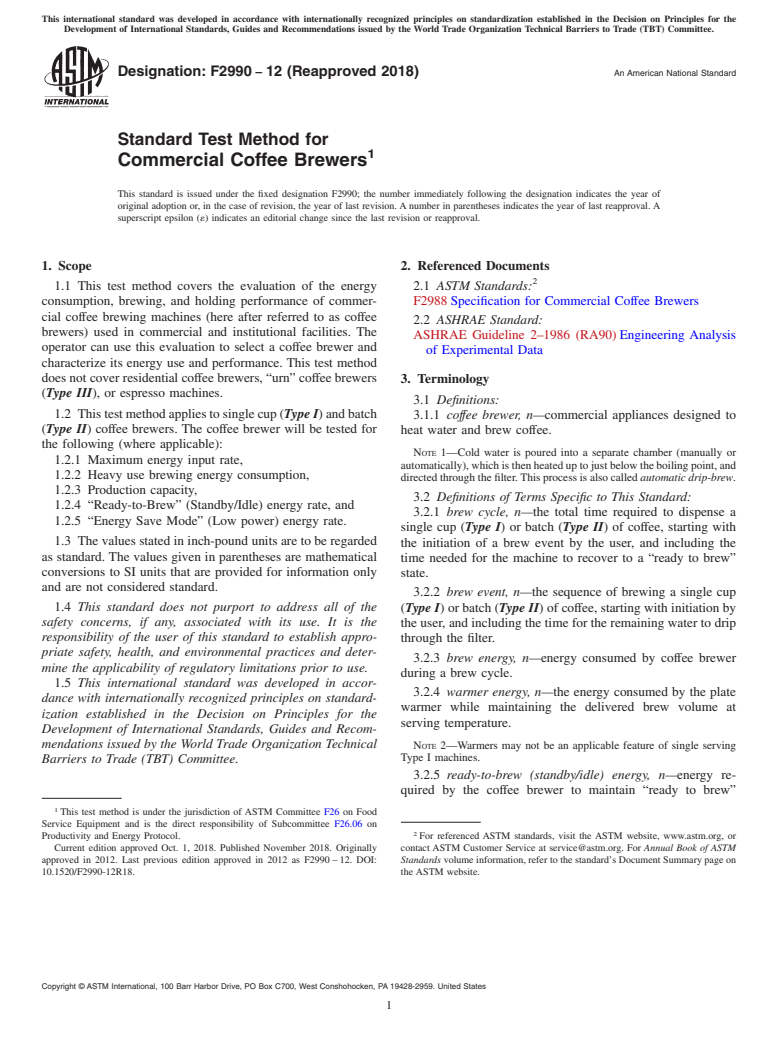

9.6 If the machine has an accessible internal tank, monitor

white paper coffee filters with a flat bottom and fit into the

the internal water tank temperature, using a beaded

manufacturer’s removable brew basket.The height of the filter

thermocouple, by placing it no closer than ⁄2 in. (1.27 cm)

paperisdependentontheamountofcoffeegroundorthebrew

from rear wall and bottom of the tank no closer than ⁄4 in.

basket dimensions so that coffee ground does not spill over the

(0.635 cm) from the heating element. See Fig. 1.

coffee filter during the brew process.

NOTE 6—Some machines may not have a heated tank.

7.5 High Temperature Fiberglass/Silicone Tape (500°F/

9.7 For single cup (Type I) brewers, install a 58 mm double

260°C)—Used to secure thermocouples, and other testing

espresso portafilter no more than a ⁄4 in. (2.54 cm) directly

apparatus to regions of extremely high heat, up to 500°F

below the dispensing head and make sure that it is level. See

(260°C), on the coffee brewing equipment to be tested. This

Fig. 2. Temperature will be measured using a thermocouple

tape should always be used on warming plates.

positioned on the inside bottom and center of the portafilter.

7.6 Aluminum Foil Tape (325°F /163°C)—High perfor-

See Fig. 3.

mancealuminumfoiltapewithaserviceoperatingtemperature

9.8 For batch (Type II) brewers, monitor the temperature in

of -20°F to 325°F (-29°C to 163°C) used to secure

the brew stream by situating a beaded thermocouple at the

thermocouples, portafilters and other testing apparatus to

bottom and in the center of the coffee filter basket. See Fig. 4.

regions of high heat, up to 325°F (163°C), on the coffee

brewing equipment to be tested. 9.9 Forsinglecup(TypeI)brewers,11individualcupslarge

enough to hold the individual brew volumes—typically 6 and

8. Sampling, Test Specimens, and Test Units

8.1 Coffee Brewer—Arepresentativeproductionmodelshall

be selected for performance testing.

9. Preparation of Apparatus

9.1 Installthecoffeebreweraccordingtothemanufacturer’s

instructionsinacontrolledtestingenvironment.Allsidesofthe

applianceshallbeaminimumof12-in.fromanysidewall,side

partition, and at least 36 in. from any other operating commer-

cial kitchen appliance. The associated heating or cooling

systemforthespaceshallbecapableofmaintaininganaverage

ambienttemperatureof75 65°F(24 63°C)withinthetesting

environment.

9.2 Connect the coffee brewer to a calibrated test energy

meter. A voltage regulator may be required during tests to

ensure that the voltage supply is within 61.0 % of the

FIG. 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.