ASTM A488/A488M-10

(Practice)Standard Practice for Steel Castings, Welding, Qualifications of Procedures and Personnel

Standard Practice for Steel Castings, Welding, Qualifications of Procedures and Personnel

ABSTRACT

This practice covers the qualification of procedures, welders, and operators for the fabrication and repair of steel castings by electric arc welding. The materials are categorized as carbon steel, carbon and carbon-manganese steel, low alloy steel, ferritic stainless steel, martensitic stainless steel, low carbon austenitic stainless steel, unstabilized austenitic stainless steel, austenitic stainless steel, duplex austenitic-ferritic stainless steel, precipitation-hardened austenitic stainless steel, nickel base alloy, steel castings, austenitic manganese. The orientation of the welds with respect to the horizontal and vertical planes of reference is classified into four positions, namely, flat, horizontal, vertical, and overhead. Four types of test shall be conducted in the qualification procedures such as tension test, bend test, Charpy impact test and radiographic test. Guided bend test specimens shall be prepared by cutting the test plate or pipe to form specimens of approximately rectangular cross section. Guided bend test specimens are of three types depending on which surface -side bend, face bend, or root bend is on the convex (outer) side of the bent specimen. A welding procedure must be set up as a new procedure and must be requalified when any of the changes in essential variables, inclusive, are made. Changes other than those listed may be made without requalification, provided the procedure is revised to show these changes. All welders and operators welding castings under this practice shall pass the welder qualification test. The welder or operator successfully performing the procedure qualification test is automatically qualified for performance.

SCOPE

1.1 This practice covers the qualification of procedures, welders, and operators for the fabrication and repair of steel castings by electric arc welding.

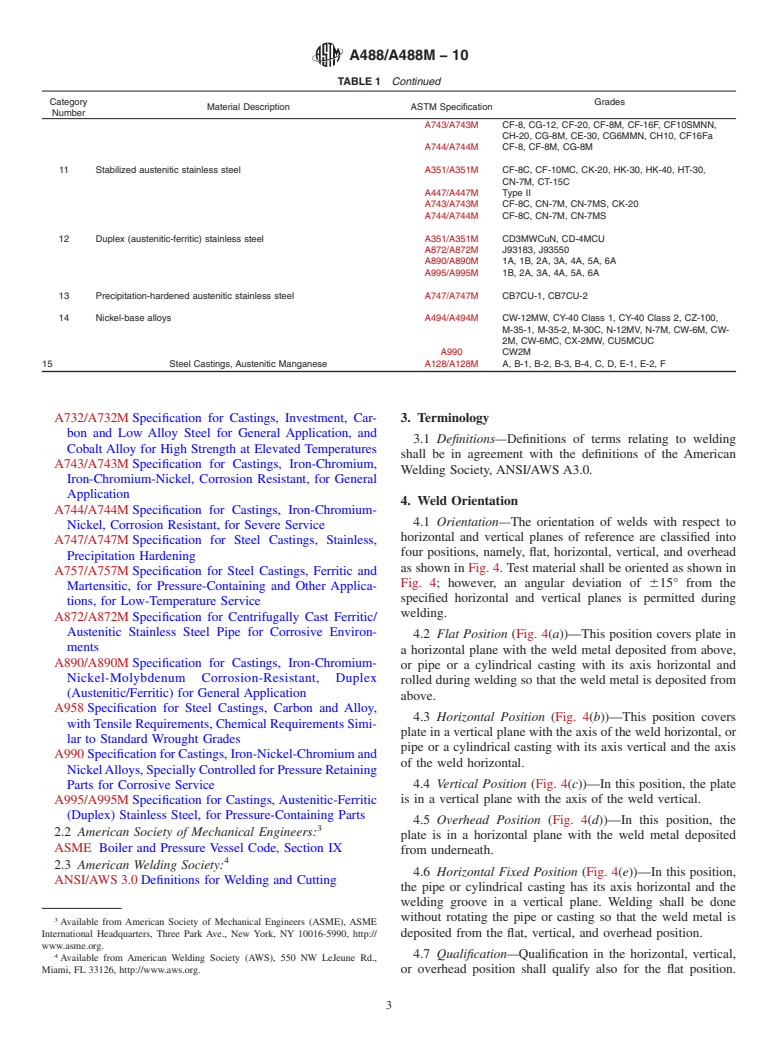

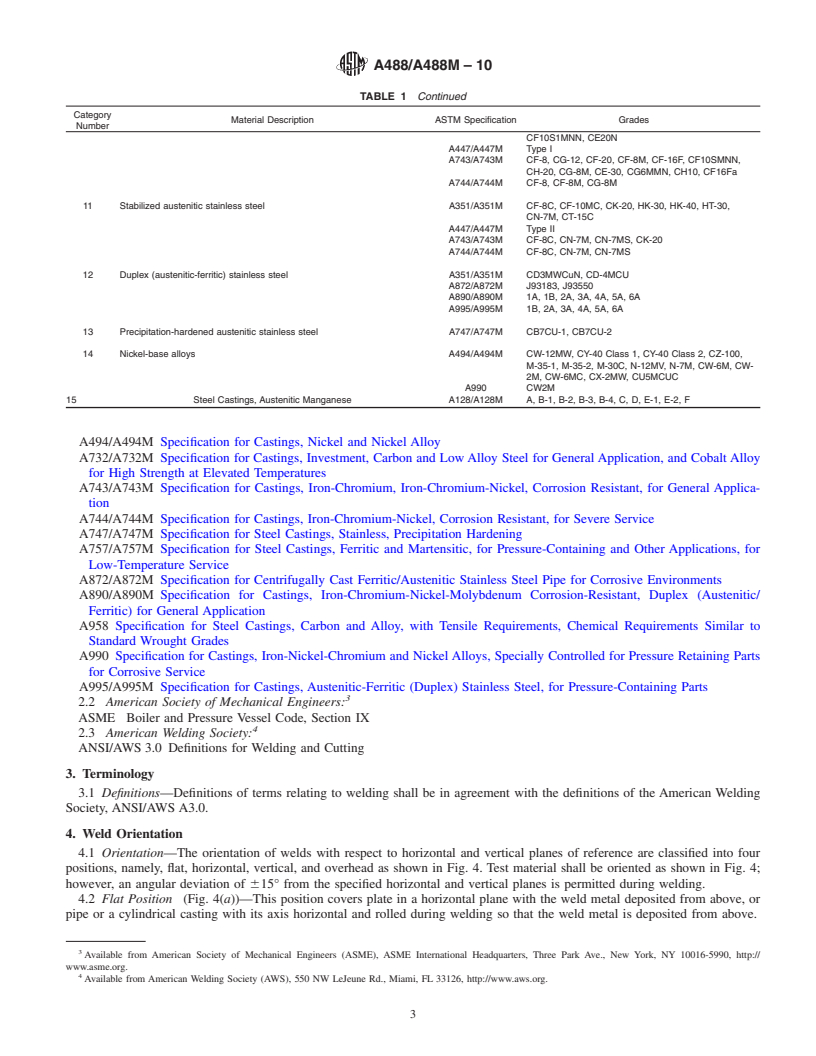

1.1.1 Qualifications of a procedure and either or both the operator or welder under Section IX of the ASME Boiler and Pressure Vessel Code shall automatically qualify the procedure and either or both the operator or welder under this practice. P-number designations in the ASME grouping of base metals for qualification may be different than the category numbers listed in Table 1. Refer to Appendix X1 for a comparison of ASTM category numbers with the corresponding ASME P-Number designations.

1.2 Each manufacturer or contractor is responsible for the welding done by his organization and shall conduct the tests required to qualify his welding procedures, welders, and operators.

1.3 Each manufacturer or contractor shall maintain a record of welding procedure qualification tests (Fig. 1), welder or operator performance qualification tests (Fig. 2), and welding procedure specification (Fig. 3), which shall be made available to the purchaser's representative on request.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4.1 SI Units—Within the text, the SI units are shown in brackets.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A488/A488M −10

StandardPractice for

Steel Castings, Welding, Qualifications of Procedures and

1

Personnel

This standard is issued under the fixed designationA488/A488M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This practice covers the qualification of procedures,

welders, and operators for the fabrication and repair of steel

2. Referenced Documents

castings by electric arc welding.

2

2.1 ASTM Standards:

1.1.1 Qualifications of a procedure and either or both the

A27/A27M Specification for Steel Castings, Carbon, for

operator or welder under Section IX of the ASME Boiler and

General Application

PressureVessel Code shall automatically qualify the procedure

A128/A128M Specification for Steel Castings, Austenitic

and either or both the operator or welder under this practice.

Manganese

P-number designations in the ASME grouping of base metals

A148/A148M Specification for Steel Castings, High

for qualification may be different than the category numbers

Strength, for Structural Purposes

listed in Table 1. Refer to Appendix X1 for a comparison of

A216/A216M SpecificationforSteelCastings,Carbon,Suit-

ASTM category numbers with the corresponding ASME

able for Fusion Welding, for High-Temperature Service

P-Number designations.

A217/A217M Specification for Steel Castings, Martensitic

1.2 Each manufacturer or contractor is responsible for the

Stainless and Alloy, for Pressure-Containing Parts, Suit-

welding done by his organization and shall conduct the tests

able for High-Temperature Service

required to qualify his welding procedures, welders, and

A351/A351M Specification for Castings, Austenitic, for

operators.

Pressure-Containing Parts

1.3 Each manufacturer or contractor shall maintain a record

A352/A352M Specification for Steel Castings, Ferritic and

of welding procedure qualification tests (Fig. 1), welder or

Martensitic, for Pressure-Containing Parts, Suitable for

operator performance qualification tests (Fig. 2), and welding

Low-Temperature Service

procedure specification (Fig. 3), which shall be made available

A356/A356M Specification for Steel Castings, Carbon, Low

to the purchaser’s representative on request.

Alloy, and Stainless Steel, Heavy-Walled for Steam Tur-

bines

1.4 The values stated in either SI units or inch-pound units

A370 Test Methods and Definitions for Mechanical Testing

are to be regarded separately as standard. The values stated in

of Steel Products

each system may not be exact equivalents; therefore, each

A389/A389M Specification for Steel Castings, Alloy, Spe-

system shall be used independently of the other. Combining

cially Heat-Treated, for Pressure-Containing Parts, Suit-

values from the two systems may result in non-conformance

able for High-Temperature Service

with the standard.

A447/A447M Specification for Steel Castings, Chromium-

1.4.1 SI Units—Within the text, the SI units are shown in

Nickel-Iron Alloy (25-12 Class), for High-Temperature

brackets.

Service

1.5 This standard does not purport to address all of the

A487/A487M Specification for Steel Castings Suitable for

safety concerns, if any, associated with its use. It is the

Pressure Service

responsibility of the user of this standard to establish appro-

A494/A494M Specification for Castings, Nickel and Nickel

Alloy

1

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

2

A01.18 on Castings. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2010. Published April 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1963. Last previous edition approved in 2009 as A488/A488M – 09. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0488_A0488M-10. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A488/A488M−10

TABLE 1 Categories of Base Materials

Category Grades

Material Description ASTM Specification

Number

1 Carbon steel (carbon less than 0.35 %, tensile strength less than or A27/A27M all grades

equal to 70 ksi [480 MPa]).

A216/A216M WCA, WCB

A352/A352M LCB, LCA

A356/A356M

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A488/A488M–09 Designation: A488/A488M – 10

Standard Practice for

Steel Castings, Welding, Qualifications of Procedures and

1

Personnel

This standard is issued under the fixed designationA488/A488M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This practice covers the qualification of procedures, welders, and operators for the fabrication and repair of steel castings

by electric arc welding.

1.1.1 Qualifications of a procedure and either or both the operator or welder under Section IX of theASME Boiler and Pressure

Vessel Code shall automatically qualify the procedure and either or both the operator or welder under this practice. P-number

designations in theASME grouping of base metals for qualification may be different than the category numbers listed in Table 1.

Refer to Appendix X1 for a comparison of ASTM category numbers with the corresponding ASME P-Number designations.

1.2 Each manufacturer or contractor is responsible for the welding done by his organization and shall conduct the tests required

to qualify his welding procedures, welders, and operators.

1.3 Each manufacturer or contractor shall maintain a record of welding procedure qualification tests (Fig. 1), welder or operator

performance qualification tests (Fig. 2), and welding procedure specification (Fig. 3), which shall be made available to the

purchaser’s representative on request.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4.1 SI Units—Within the text, the SI units are shown in brackets.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A27/A27M Specification for Steel Castings, Carbon, for General Application

A128/A128M Specification for Steel Castings, Austenitic Manganese

A148/A148M Specification for Steel Castings, High Strength, for Structural Purposes

A216/A216M Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service

A217/A217M Specification for Steel Castings, Martensitic Stainless and Alloy, for Pressure-Containing Parts, Suitable for

High-Temperature Service

A351/A351M Specification for Castings, Austenitic, for Pressure-Containing Parts

A352/A352M Specification for Steel Castings, Ferritic and Martensitic, for Pressure-Containing Parts, Suitable for Low-

Temperature Service

A356/A356M Specification for Steel Castings, Carbon, Low Alloy, and Stainless Steel, Heavy-Walled for Steam Turbines

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A389/A389M Specification for Steel Castings, Alloy, Specially Heat-Treated, for Pressure-Containing Parts, Suitable for

High-Temperature Service

A447/A447M Specification for Steel Castings, Chromium-Nickel-Iron Alloy (25-12 Class), for High-Temperature Service

A487/A487M Specification for Steel Castings Suitable for Pressure Service

1

This practice is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.18

on Castings.

Current edition approved Nov.April 1, 2009.2010. Published December 2009.April 2010. Originally approved in 1963. Last previous edition approved in 20072009 as

A488/A488M – 079. DOI: 10.1520/A0488_A0488M-109.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A488/A488M – 10

TA

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.