ASTM B359/B359M-12

(Specification)Standard Specification for Copper and Copper-Alloy Seamless Condenser and Heat Exchanger Tubes With Integral Fins

Standard Specification for Copper and Copper-Alloy Seamless Condenser and Heat Exchanger Tubes With Integral Fins

ABSTRACT

This specification establishes the requirements for seamless copper and copper alloy tubing on which the external or internal surface, or both, has been modified by a coldforming process to produce an integral enhanced surface for improved heat transfer. The tubes are typically used in surface condensers, evaporators, and heat exchangers. The seamless copper and copper alloy tubing shall have the internal or external surface, or both, modified by a cold forming process to produce an integral enhanced surface for improved heat transfer. The tube, after enhancing, shall be supplied in the annealed (O61) or as-fabricated temper. The enhanced sections of tubes in the as-fabricated temper are in the cold-worked condition produced by the fabricating operation. The unenhanced sections of tubes in the asfabricated temper are in the temper of the tube prior to enhancing, annealed (O61), or light drawn (H55), and suitable for rolling-in operations. Samples of annealed-temper (O61) tubes selected for test shall be subjected to microscopical examination and shall show uniform and complete recrystallation. Grain size and mechanical properties such as tensile strength and yield strength of the alloys shall be determined. Expansion and flattening tests shall be done to the alloys for performance evaluation. Non-destructive tests such as eddy-current test, hydrostatic test, and pneumatic test shall be done as well.

SCOPE

1.1 This specification establishes the requirements for seamless copper and copper alloy tubing on which the external or internal surface, or both, has been modified by a cold-forming process to produce an integral enhanced surface for improved heat transfer.

1.2 Units—The values stated in either in-pound units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems could result in nonconformance with the specification.

1.3 The tubes are typically used in surface condensers, evaporators, and heat exchangers.

1.4 The product shall be produced of the following coppers or copper alloys, as specified in the ordering information. Copper or Copper Alloy

UNS No.

Type of Metal

C10100Oxygen-free electronic C10200Oxygen-free without residual deoxidants C10300Oxygen-free, extra low phosphorus C10800Oxygen-free, low phosphorus C12000DLP Phosphorized, low residual phosphorus

(See Note 1) C12200DHP, Phosphorized, high residual phosphorus

(See Note 1) C14200DPA Phosphorized arsenical

(See Note 1) C19200Phosphorized, 1 % iron C23000Red Brass C44300Admiralty Metal Types B, C44400C, and C44550D C60800Aluminum Bronze C68700Aluminum Brass Type B C7040095-5 Copper-Nickel C7060090-10 Copper-Nickel C7062090-10 Copper-Nickel (Modified for Welding) C7100080-20 Copper-Nickel Type A C7150070-30 Copper-Nickel C7152070-30 Copper-Nickel (Modified for Welding) C72200Copper-Nickel

Note 1—Designations listed in Classification B224.

1.5 The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 Product produced in accordance with the Supplementary Requirements section for military applications shall be produced only to the inch-pound system of this specification.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B359/B359M −12

StandardSpecification for

Copper and Copper-Alloy Seamless Condenser and Heat

1

Exchanger Tubes With Integral Fins

This standard is issued under the fixed designation B359/B359M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

C60800 Aluminum Bronze

C68700 Aluminum Brass Type B

2

1.1 This specification establishes the requirements for

C70400 95-5 Copper-Nickel

seamlesscopperandcopperalloytubingonwhichtheexternal C70600 90-10 Copper-Nickel

C70620 90-10 Copper-Nickel (Modified for Welding)

or internal surface, or both, has been modified by a cold-

C71000 80-20 Copper-Nickel Type A

forming process to produce an integral enhanced surface for

C71500 70-30 Copper-Nickel

improved heat transfer. C71520 70-30 Copper-Nickel (Modified for Welding)

C72200 Copper-Nickel

1.2 Units—The values stated in either in-pound units or SI

NOTE 1—Designations listed in Classification B224.

units are to be regarded separately as the standard. Within the

1.5 The following safety hazard caveat pertains only to the

text, the SI units are shown in brackets. The values stated in

testmethodsdescribedinthisspecification. This standard does

each system are not exact equivalents; therefore, each system

not purport to address all of the safety concerns, if any,

shall be used independently of the other. Combining values

associated with its use. It is the responsibility of the user of this

from the two systems could result in nonconformance with the

standard to establish appropriate safety and health practices

specification.

and determine the applicability of regulatory limitations prior

1.3 The tubes are typically used in surface condensers,

to use.

evaporators, and heat exchangers.

1.6 ProductproducedinaccordancewiththeSupplementary

1.4 The product shall be produced of the following coppers

Requirements section for military applications shall be pro-

or copper alloys, as specified in the ordering information.

duced only to the inch-pound system of this specification.

Copper or Copper Type of Metal

Alloy

2. Referenced Documents

UNS No.

3

2.1 ASTM Standards:

C10100 Oxygen-free electronic

B153Test Method for Expansion (Pin Test) of Copper and

C10200 Oxygen-free without residual deoxidants

C10300 Oxygen-free, extra low phosphorus

Copper-Alloy Pipe and Tubing

C10800 Oxygen-free, low phosphorus

B154Test Method for Mercurous Nitrate Test for Copper

C12000 DLP Phosphorized, low residual phosphorus

Alloys

(See Note 1)

C12200 DHP, Phosphorized, high residual phosphorus

B170Specification for Oxygen-Free Electrolytic Copper—

(See Note 1)

Refinery Shapes

C14200 DPA Phosphorized arsenical

(See Note 1) B224Classification of Coppers

C19200 Phosphorized, 1 % iron

B601ClassificationforTemperDesignationsforCopperand

C23000 Red Brass

Copper Alloys—Wrought and Cast

C44300 Admiralty Metal Types B,

C44400 C, and B846Terminology for Copper and Copper Alloys

C44550 D

B858TestMethodforAmmoniaVaporTestforDetermining

Susceptibility to Stress Corrosion Cracking in Copper

Alloys

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

B900Practice for Packaging of Copper and Copper Alloy

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube.

Current edition approved April 1, 2012. Published May 2012. Originally

3

approved in 1960. Last previous edition approved in 2002 as B359/B359M–02 For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(2006). DOI: 10.1520/B0359_B0359M-12. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Standards volume information, refer to the standard’s Document Summary page on

cation SB-359 in Section II of that Code. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

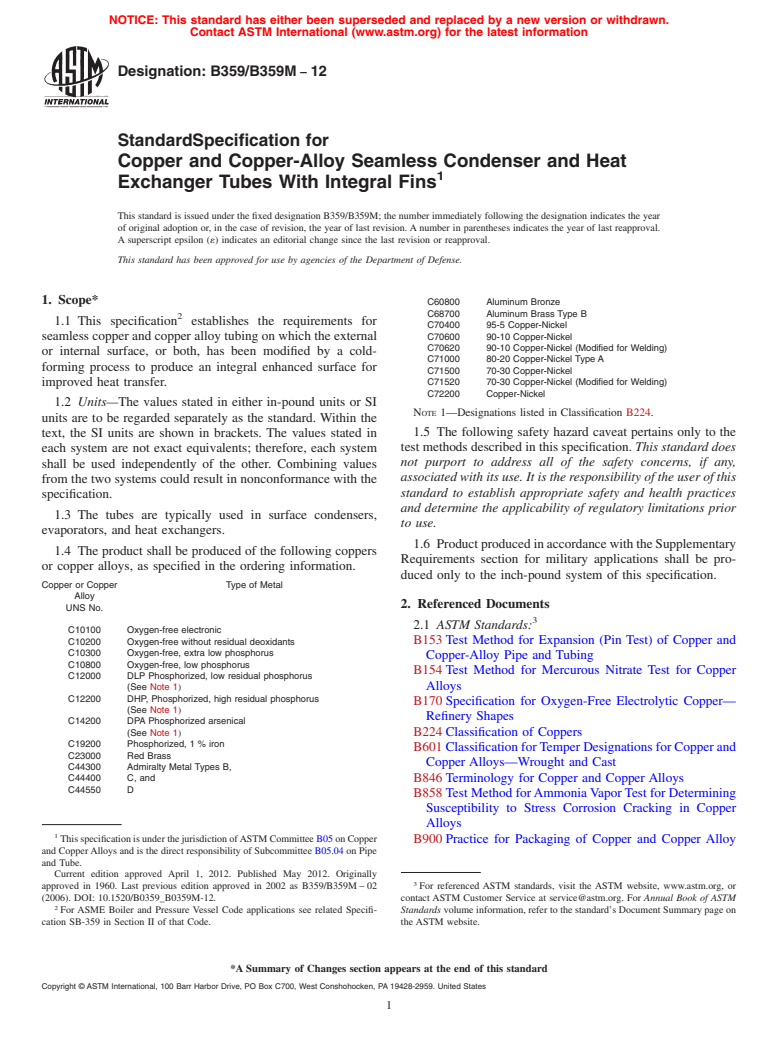

B359/B359M−12

Mill Products for U.S. Government Agencies 4. Terminology

B968/B968MTest Method for Flattening of Copper and

4.1 Forthedefinitionsoftermsrelatedtocopperandcopper

Copper-Alloy Pipe and Tube

alloys, refer to Terminology B846.

D4727/D4727MSpecification for Corrugated and Solid Fi-

4.2 Definitions of Terms Specific to This Standard:

berboard Sheet Stock (Container Grade) and Cut Shapes

4.2.1 tube condenser, n—see tube, heat exchanger in Ter-

E3Guide for Preparation of Metallographic Specimens

minolog

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B359/B359M–02 (Reapproved 2006) Designation: B359/B359M – 12

Standard Specification for

Copper and Copper-Alloy Seamless Condenser and Heat

1

Exchanger Tubes With Integral Fins

This standard is issued under the fixed designation B359/B359M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

2

1.1 This specification establishes the requirements for seamless copper and copper alloy tubing on which the external or

internal surface, or both, has been modified by a cold-forming process to produce an integral enhanced surface for improved heat

transfer.

1.2 Units—The values stated in either in-pound units or SI units are to be regarded separately as the standard. Within the text,

theSIunitsareshowninbrackets.Thevaluesstatedineachsystemarenotexactequivalents;therefore,eachsystemshallbeused

independently of the other. Combining values from the two systems could result in nonconformance with the specification.

1.3 The tubes are typically used in surface condensers, evaporators, and heat exchangers.

1.4 The product shall be produced of the following coppers or copper alloys, as specified in the ordering information.

Copper or Copper Alloy Type of Metal

UNS No.

C10100 Oxygen-free electronic

C10200 Oxygen-free without residual deoxidants

C10300 Oxygen-free, extra low phosphorus

C10800 Oxygen-free, low phosphorus

C12000 DLP Phosphorized, low residual phosphorus

(See Note 1)

C12200 DHP, Phosphorized, high residual phosphorus

(See Note 1)

C14200 DPA Phosphorized arsenical

(See Note 1)

C19200 Phosphorized, 1 % iron

C23000 Red Brass

C44300 Admiralty Metal Types B,

C44400 C, and

C44550 D

C60800 Aluminum Bronze

C68700 Aluminum Brass Type B

C70400 95-5 Copper-Nickel

C70600 90-10 Copper-Nickel

C70620 90-10 Copper-Nickel (Modified for Welding)

C71000 80-20 Copper-Nickel Type A

C71500 70-30 Copper-Nickel

C71520 70-30 Copper-Nickel (Modified for Welding)

C72200 Copper-Nickel

NOTE 1—Designations listed in Classification B224.

1.5 The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 Product produced in accordance with the Supplementary Requirements section for military applications shall be produced

only to the inch-pound system of this specification.

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Oct.April 1, 2006.2012. Published October 2006.May 2012. Originally approved in 1960. Last previous edition approved in 2002 as

B359/B359M–02 (2006). DOI: 10.1520/B0359_B0359M-02R06. 10.1520/B0359_B0359M-12.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-359 in Section II of that Code.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B359/B359M – 12

2. Referenced Documents

3

2.1 ASTM Standards:

B153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

B154 Test Method for Mercurous Nitrate Test for Copper Alloys

B170 Specification for Oxygen-Free Electrolytic CopperRefinery Shapes

B224 Classification of Coppers

B601 Classification for Temper Designations for Copper and Copper AlloysWrought and Cast

B846 Terminology for Copper and Copper Alloys

B858 Test Method for Ammonia Vapor Test for Determining Susceptibility to Stress Corrosion Cracking in Copper Alloys

B900 Practice for Packaging of Copper and Copper Alloy Mill Products for U.S. Government Agencies

B968/B968M Test Method for Flattening of Copper and Copper-Alloy Pipe and Tube

D4727/D4727M Specification for Corrugated and Solid Fiberboard Sheet Stock (Container Grade) and Cut Shapes

E3 Guide for Preparation of Metallographic Specimens

E88/E8M Test Methods for Tension Testing of Metallic Materials

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.